- DL manuals

- Panasonic

- Air Conditioner

- CS-ME10CKPG

- Service Manual

Panasonic CS-ME10CKPG Service Manual

1 Features

3

2 About Lead Free Solder (PbF)

3

2.1.

DISTINCTION OF PbF P.C. BOARD

3

2.2.

CAUTION

3

3 Functions

4

3.1.

REMOTE CONTROL

4

3.2.

INDOOR UNIT

5

3.3.

OUTDOOR UNIT

7

4 Product Specifications

8

4.1.

PRODUCT SPECIFICATIONS

8

4.2.

APPROXIMATE COOLING AND HEATING CAPACITIES

10

5 Dimensions

12

© 2002 Matsushita Electric Industrial Co., Ltd. All

rights

reserved.

Unauthorized

copying

and

distribution is a violation of law.

CS-ME7CKPG

CS-ME10CKPG

CS-ME12CKPG

CS-ME14CKPG

CS-ME18CKPG

CU-2E15CBPG

CU-2E18CBPG

CU-3E23CBPG

CU-4E27CBPG

5.1.

INDOOR UNIT (CS-

ME7CKPG/ME10CKPG/ME12CKPG/ME14CKPG/ME18CK

PG)

12

5.2.

OUTDOOR UNIT (CU-2E15CBPG/2E18CBPG)

13

5.3.

OUTDOOR UNIT (CU-3E23CBPG)

14

5.4.

OUTDOOR UNIT (CU-4E27CBPG)

15

6 Refrigeration Cycle Diagram

16

6.1.

OUTDOOR UNIT (CU-2E15CBPG/2E18CBPG)

16

6.2.

OUTDOOR UNIT (CU-3E23CBPG/CU-4E27CBPG)

17

7 Block Diagram

18

7.1.

INDOOR UNIT

18

7.2.

OUTDOOR UNIT (CU-2E15CBPG/2E18CBPG)

19

Room Air Conditioner

CONTENTS

Page

Page

Order No: RAC0209005C2

Summary of CS-ME10CKPG

Page 1

1 features 3 2 about lead free solder (pbf) 3 2.1. Distinction of pbf p.C. Board 3 2.2. Caution 3 3 functions 4 3.1. Remote control 4 3.2. Indoor unit 5 3.3. Outdoor unit 7 4 product specifications 8 4.1. Product specifications 8 4.2. Approximate cooling and heating capacities 10 5 dimensions 12 © 2...

Page 2

8 wiring diagram 20 8.1. Indoor unit 20 8.2. Outdoor unit (cu-2e15cbpg/2e18cbpg) 21 8.3. Outdoor unit (cu-3e23cbpg/cu-4e27cbpg) 22 9 operation details (functions & protection) 23 9.1. Indoor unit operation 23 9.2. Outdoor unit operation (cu- 2e15cbpg/2e18cbpg) 41 9.3. Outdoor unit operation (cu-3e23...

Page 3: 1 Features

1 features · product − − − − a single outdoor unit enables air conditioning of up to four separate rooms − − − − inverter controlled for high energy efficiency and optimal comfort − − − − e - scroll compressor - guarding against global warning − − − − new refrigerant r410a is used for protecting ozo...

Page 4: 3 Functions

3 functions 3.1. Remote control 4 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

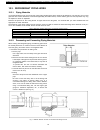

Page 5

3.2. Indoor unit 5 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 6

6 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 7

3.3. Outdoor unit 7 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 8: 4 Product Specifications

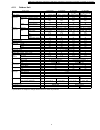

4 product specifications 4.1. Product specifications 4.1.1. Indoor unit model name cs-me7ckpg cs-me10ckpg cs-me12ckpg cs-me14ckpg cs-me18ckpg type wall mounted wall mounted wall mounted wall mounted wall mounted power source single phase, 230v, 50hz (power supply from outdoor unit) air volume (hi) l...

Page 9

4.1.2. Outdoor unit model name cu-2e15cbpg cu-2e18cbpg cu-3e23cbpg cu-4e27cbpg indoor-units combination 2.2 kw + 2.2 kw 3.2 kw + 3.2 kw 2.8 kw + 3.2 kw + 4.0 kw 3.2 kw + 3.2 kw + 3.2 kw + 4.0 kw power source single phase , 230 v, 50 hz (power supply from outdoor unit) cooling operation capacity kw 4...

Page 10

4.2. Approximate cooling and heating capacities 10 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 11

11 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 12: 5 Dimensions

5 dimensions 5.1. Indoor unit (cs- me7ckpg/me10ckpg/me12ckpg/me14ckpg/me18ckpg) 12 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 13

5.2. Outdoor unit (cu-2e15cbpg/2e18cbpg) 13 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 14

5.3. Outdoor unit (cu-3e23cbpg) 14 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 15

5.4. Outdoor unit (cu-4e27cbpg) 15 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

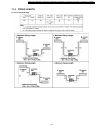

Page 16

6 refrigeration cycle diagram 6.1. Outdoor unit (cu-2e15cbpg/2e18cbpg) 16 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 17

6.2. Outdoor unit (cu-3e23cbpg/cu-4e27cbpg) 17 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

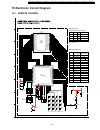

Page 18: 7 Block Diagram

7 block diagram 7.1. Indoor unit 18 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 19

7.2. Outdoor unit (cu-2e15cbpg/2e18cbpg) 19 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

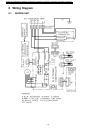

Page 20: 8 Wiring Diagram

8 wiring diagram 8.1. Indoor unit 20 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 21

8.2. Outdoor unit (cu-2e15cbpg/2e18cbpg) 21 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 22

8.3. Outdoor unit (cu-3e23cbpg/cu-4e27cbpg) 22 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 23

9 operation details (functions & protection) 9.1. Indoor unit operation 9.1.1. Simultaneous operation control 1. Operation modes which can be selected using the remote control unit: automatic, cooling, dry, heating, fan operation mode. 2. Types of operations modes which can be performed simultaneous...

Page 24

9.1.2. Room temperature control (compressor control) the room temperature is adjusted by changing the compressor´s operation frequency in response to the difference between setting temperature of remote control unit and the room temperature (intake air temperature sensor). 9.1.2.1. Cooling operation...

Page 25

9.1.3. Airflow direction control the vertical airflow direction louver is controlled as shown in the table below in response to the operation of the remote control air swing button and the operating conditions. · when the air conditioner is operated using the remote control, the vertical airflow dir...

Page 26

9.1.4. Indoor fan control · depending on the airflow selector button setting of the remote control unit and the operating conditions, the operations for indoor fan control are as shown in the table below. · airflow control may be at variance from the airflow which has been set. 26 cs-me7ckpg / cs-me...

Page 27

27 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 28

9.1.4.1. Cooling operation 1. Automatic fan speed this air conditioner comes with a odour removing function. When operation starts or the thermostat is set on, the fan stops for 40 seconds. This is done in order to clean off the odour components which have accumulated on the heat exchanger using the...

Page 29

9.1.4.2. Dry mode operation 1. Basic fan speed in the cooling zone, the fan speed for cooling operations is used. When it reaches into the dry mode zone, operation is performed at the slo fan speed. 2. Automatic fan speed during the thermostat off period, a stop of 90 seconds and sslo operation for ...

Page 30

9.1.5. Automatic operation · the operation mode (cooling, dry or heating) is selected automatically. · the operation mode is first selected when operation starts and re-selected after each 3-hours period. The temperature, fan speed and airflow direction are set using the remote control. 9.1.5.1. Sel...

Page 31

· when the operation mode is changed over, the value for t1, t2 and t3 are shifted as follows: cooling/soft dry → heating: -2 °c heating → cooling/soft dry: +2 °c · when the indoor intake air temperature is lower than 16 °c, heating operation is immediately started. · when the outdoor air temperatur...

Page 32

2. Sleep mode operation during heating operation 9.1.7. Timer operation delay on/off timer · in accordance with the air-conditioning load, the preparatory operation is performed so that the setting temperature will be reached at the set time. The preparatory operation period is fixed as shown in the...

Page 33

9.1.8. Filter cleaning indicator · the blinking filter lamp warns the user that the air filter is dirty. When the air conditioner has operated for a total of 360 hours or so, this lamp blinks during cooling and heating operation and stop. · the blinking filter lamp is turned off by pressing the filt...

Page 34

9.1.9.2. Odour clear mode operation (off-season) · by conducting heating operations simultaneously in all the rooms for a short period of time, the odour components are removed, the insides of the indoor units are dried out, and the growth of mold is minimized. Odour clear control has two operation ...

Page 35

(2) odour clear mode operation (with timer setting) · the power lamp lights up if the air conditioner is operated before the odour clear operation, and it goes off if air conditioner has been stop. · operation is switched to odour removing control 50 minutes after the odour clear operation started. ...

Page 36

9.1.10. Auto restart control · if there is a power failure, operation will automatically be restarted when the power is resumed. It will start with the previous operation mode and airflow direction. (time delay safety control is valid) 1. Control start conditions the 24-hour timer must not be set. T...

Page 37

9.1.11. Other indoor unit operation functions · auto button proceed with operation when the air conditioner is stopped. (when the auto button is pressed during operation, the air conditioner is stopped.) 1. Emergency operation press the auto button and release it within 5 seconds to perform emergenc...

Page 38

Setting the air conditioner unit to “b” 1. Press the “auto” button for about 11 to 15 seconds. When you hear three short beeps “pep, pep, pep”, release the button. Note: you will hear one beep “pep” in about 5 seconds, and then two beeps “pep, pep” in about 8 seconds. 2. Press again the “auto” butto...

Page 39

9.1.12. Self diagnosis display the diagnostic displays that appear when trouble has occurred can be checked using the remote control unit. When trouble occurs, operation is stopped automatically, and the timer lamp blinks. The diagnosis time has been reduced by warning the user by means of the blink...

Page 40

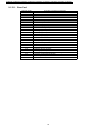

9.1.12.1. Error cord diagnostic display abnormality or protection control works h 11 indoor/outdoor abnormal communication h 12 indoor unit capacity unmatched h 14 intake air temp.Sensor h 16 outdoor current transformer h 19 indoor fan motor mechanism lock h 23 indoor heat exchanger temp.Sensor h 27...

Page 41

9.2. Outdoor unit operation (cu-2e15cbpg/2e18cbpg) 9.2.1. Compressor operation frequent 9.2.1.1. Cooling, dry and heating operations · the compressor operation frequency is determined by room temperature, capacity rank algebra and model code algebra. 1. When operation is started after the air condit...

Page 42

9.2.3. Protection control 9.2.3.1. Time delay safety control · the compressor does not restart for 3 minutes after stop of compressor. 9.2.3.2. Total running current control 1. When the air conditioner has been operated at the capacity designated by the indoor unit and the total running current exce...

Page 43

9.2.3.5. Over load protection control (cooling . Dry mode) · cooling over load protection control 1. When the temperature of the outdoor unit heat exchanger exceeds 52 °c during a cooling or dehumidifying operation, the compressor frequency is restricted, and when it exceeds 62 °c, the compressor is...

Page 44

9.2.3.7. 4-way valve failure protection control (cooling/heating switching errors) · during a cooling operation 1. If the temperature of the indoor unit heat exchanger exceeds 45 °c 4 minutes after the compressor started, the compressor is stop. (it restarts 3 minutes later → time delay safety contr...

Page 45

9.2.4. Abnormal wiring or piping connection checking control 1. Objective to check for abnormal wiring or piping connections during a cooling operation after the air conditioner has been installed. 2. Detection subjects heat exchanger temperature of indoor unit which is not operating, and outdoor un...

Page 46

9.3. Outdoor unit operation (cu-3e23cbpg/cu-4e27cbpg) 9.3.1. Room temperature control 9.3.1.1. Cooling, dry and heating operations concerning cu-3e23cbpg and cu-4e27cbpg compressor frequency control 1. Immediately after the compressor has started up during an ongoing operation, the initial frequency...

Page 47

9.3.3. Forced cooling operation control · forced cooling operations can be performed by the outdoor unit. 1. Set the operation mode setting switch (sw2) to cool. 2. The forced cooling operation is performed when the forced operation switch (sw1) is pressed. * the forced cooling operation stops when ...

Page 48

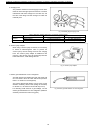

The useful wiring error check function automatically corrects wiring errors using a microcomputer. In cases where wires are embedded or the locations of connecting wires are not known for other reasons, for instance, pressing the wiring error check switch inside the right side panel of the outdoor u...

Page 49: (General Information)

10 installation and servicing air conditioner using r410a (general information) 10.1. Outline 10.1.1. About r410a refrigerant 1. Converting air conditioners to r410a since it was declared in1974 that chlorofluorocarbons (cfc), hydro chlorofluorocarbons (hcfc) and other substances pose a destructive ...

Page 50

D. R410a refrigerating machine oil conventionally, mineral oil or a synthetic oil such as alkylbenzene has been used for r22 refrigerating machine oil. Because of the poor compatibility between r410a and conventional oils like mineral oil, however, there is a tendency for the refrigerating machine o...

Page 51

10.2.2. R410a tools 1. Cooper tube gauge for clearance adjustment (used when flaring with the conventional flaring tool (clutch type)) · this gauge makes it easy to set the clearance for the copper tube to 1.0-1.5 mm from the clamp bar of the flaring tool. 2. Flaring tool (clutch type) · in the r410...

Page 52

5. Charging hose · the pressure resistance of the charging hose has been raised to match the higher pressure of r410a. The hose material has also been changed to suit hfc use, and the size of the fitting has been changed to match the manifold ports. 6. Vacuum pump adaptor · when using a vacuum pump ...

Page 53

8. Electronic scale for refrigerant charging · because of the high pressure and fast vaporizing speed of r410a, the refrigerant cannot be held in a liquid phase inside the charging cylinder when charging is done using the charging cylinder method, causing bubbles to form in the measurement scale gla...

Page 54

10.3. Refrigerant piping work when working with refrigerant piping, the following points must be carefully observed: no moisture od dust must be allowed to enter the piping, and there must be no refrigerant leaks. 1. Procedure and precautions for flaring work a. Cut the pipe use a pipe cutter, and c...

Page 55

2. Procedure and precautions for flare connection table 11 r410a flaring dimensions nominal diameter outside diameter (mm) wall thickness (mm) a (mm) r410a flaring tool, clutch type conventional flaring tool clutch type wing-nut type 1/4 6.35 0.8 0 - 0.5 1.0 - 1.5 1.5 - 2.0 3/8 9.52 0.8 0 - 0.5 1.0 ...

Page 56

Precautions · be sure to read the instructions for the vacuum pump, vacuum pump adaptor and manifold gauge prior to use, and follow the instructions carefully. · make sure that the vacuum pump is filled with oil up to the designated line on the oil gauge. · the gas pressure back flow prevention valv...

Page 57

10.4.2. Transferring (using new refrigerant piping) 1. Removing the unit a. Collecting the refrigerant into the outdoor unit by pumping down the refrigerant can be collected into the outdoor unit (pumping down) by pressing the test run button, even when the temperature of the room is low. · check to...

Page 58

5. Set the refrigerant cylinder onto the electronic scale, then correct the hose the cylinder and to the connection port for the electronic scale. (1)(2) precaution: be sure to set up the cylinder for liquid charging. If you use a cylinder equipped with a siphon tube, you can charge the liquid witho...

Page 59

10.4.6. Brazing as brazing requires sophisticated techniques and experiences, it must be performed by a qualified person. In order to prevent the oxide film from occurring in the pipe interior during brazing, it is effective to proceed with brazing while letting dry nitrogen gas (n2) flow. 1. Attach...

Page 60

11.1.2. The shapes of the 3-way valve caps of the outdoor unit have been changed. · accompanying the changes in the shapes of the 3-way valve caps, the tightening method has also been changed. · firmly tighten the 3-way valve caps by hand, and then tighten them up by another 30 degrees or so (one-tw...

Page 61

11.2. Outdoor unit (cu-3e23cbpg) 11.2.1. Check points 61 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 62

11.3. Outdoor unit (cu-4e27cbpg) 11.3.1. Check points 11.3.2. The pipe diameter for the 4.0 kw or above models has been reduced. · 1/4” and 3/8” pipes are used for models with a rated cooling capacity of up to 5.0 kw. · applicable connecting tube kit: cz-3f type. 62 cs-me7ckpg / cs-me10ckpg / cs-me1...

Page 63

11.4. Piping length (in case of cu-2e15cbpg) 63 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 64

12 installation instruction 12.1. Indoor unit required tools for installation works safety precautions warning this indication shows the possibility of causing death or serious injury. Caution this indication shows the possibility of causing injury or damage to properties only. The items to be follo...

Page 65

1 2 6 3 4 5 7 8 indoor unit installation diagram no. No. Accessories part accessories part qty. Qty. Attached accessories. Applicable piping kit cz-3f5, 7aen 1 6 1 1 1 1 2 2 installation plate installation plate fixing screw remote control battery air purifying filter remote control holder remote co...

Page 66

200 mm 120 mm 210 mm 150 mm more than 440 mm more than 425 mm wall wall measuring tape installation plate screw ˇ bushing for tube ass'y 15 mm outdoor indoor wall sleeve for tube ass'y ø70 through hole putty or caulking compound approx. 5 - 7 mm 2 3 caution 1. Insert the piping sleeve to the hole. 2...

Page 67

78 cm cable : centre of the piping hole (left rear side of piping) 4 pull out the piping and drain hose 1. For the right rear piping pull out the indoor piping install the indoor unit secure the indoor unit insert the connecting cable 2. For the right and right bottom piping pull out the indoor pipi...

Page 68

1 2 3 terminals on the indoor unit 1 2 3 color of wires terminals on the outdoor unit 1 2 3 5 connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved...

Page 69

Open the below operations will be performed by pressing the “auto” switch. 1. Auto operation mode 1. The auto operation will be activated immediately once the auto switch is pressed. 2. Test run operation (for pump down/servicing purpose) the test run operation will be activated if the auto switch i...

Page 70

12.2. Outdoor unit (cu-2e15cbpg/2e18cbpg) indoor/outdoor unit installation diagram piping direction attention not to bend up drain hose right right bottom right rear left rear left bottom left (front side) • this illustration is for explanation purposes only. The indoor unit will actually face a dif...

Page 71

Connect the piping 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut onto the cop...

Page 72

Control board control board cover power supply cord indoor unit a indoor unit b 5 6 connect the cable to the outdoor unit pipe insulation when installing an air conditioner, be sure to evacuate the air insidethe indoor unit and pipes in the following procedure. 4 evacuation of the equipment (for eur...

Page 73

12.3. Outdoor unit (cu-3e23cbpg/cu-4e27cbpg) accessories supplied with the outdoor unit: cu-3e23cbpg cu-4e27cbpg accessories supplied with the outdoor unit: cannot be installed hanging from ceiling or stacked. Note outdoor unit 1) choose a place solid enough to bear the weight and vibration of the u...

Page 74

Do not connect the embedded branch piping and the outdoor unit when only carrying out piping work without connecting the indoor unit in order to add another indoor unit later. Make sure no dirt or moisture gets into either side of the embedded branch piping. See “6 refrigerant piping work” for detai...

Page 75

Outdoor unit installation guidelines where a wall or other obstacle is in the path of outdoor unit’s intake or exhaust airflow, follow the installation guidelines below. For any of the below installation patterns, the wall height on the exhaust side should be 1200 mm or less. Selecting a location fo...

Page 76

Outdoor unit 1 installing outdoor unit when installing the outdoor unit, refer to “precautions for selecting the location” and the “indoor/outdoor unit installation drawings.” if drain work is necessary, follow the procedures below. 2 drain work (cu-3e23cbpg) use drain plug for drainage. If the drai...

Page 77

Purging air and checking gas leakage if using additional refrigerant, perform air purging from the refrigerant pipes and indoor unit using a vacuum pump, then charge additional refrigerant. Use a hexagonal wrench (4 mm) to operate the shut-off valve rod. All refrigerant pipe joints should be tighten...

Page 78

Wiring do not turn on the safety breaker until all work is completed. (1) strip the insulation from the wire (20 mm). (2) connect the connection wires between the indoor and outdoor units so that the terminal numbers match. Tighten the terminal screws securely. We recommend a flathead screwdriver be...

Page 79

Before starting the test run, measure the voltage at the primary side of the safety breaker. Check that it is 230v. Check that all liquid and gas shut-off valves are fully open. Check that piping and wiring all match. The wiring error check can be conveniently used for underground wiring and other w...

Page 80: 13 Servicing Information

13 servicing information 13.1. Troubleshooting 13.1.1. Rated frequency operation during troubleshooting and servicing, rated compressor operating frequency must be obtained in order to check the specification and technical data. Below are the methods used to obtain rated compressor operating frequen...

Page 81

81 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 82

13.2. Self diagnosis display 13.2.1. Indoor unit [table of diagnosis methods] symbol diagnosis diagnosis method h11 indoor/outdoor abnormal communication this trouble display appears when indoor/outdoor unit communication fails to be established after 30 or more seconds. 1. Measure the voltages of t...

Page 83

Symbol diagnosis diagnosis method h30 outdoor discharge pipe temp. Sensor cu-2e: this trouble display appears when a temperature of under approximately -16 °c or above approximately 200 °c has been detected by the outlet temperature sensor for 2 to 5 seconds. Cu-3e/4e: disconnected discharge sensor ...

Page 84

Symbol diagnosis diagnosis method h99 indoor operating unit freezing the restriction on the compressor frequency is started when the indoor unit heat exchanger temperature is between 8 °c and 12 °c. Operation stops if a temperature below 0 °c continues for 6 minutes. Three minutes later, operation i...

Page 85

Symbol diagnosis diagnosis method f93 compressor abnormal revolution cu-2e: when the rotation of the compressor is not synchronized with the control signal, the f93 diagnostic display is stored in the memory, and operation stops. 3 minutes later, operation is restarted. This trouble display appears ...

Page 86

Symbol diagnosis diagnosis method f99 dc peak detection cu-2e: if the current level exceeds 22.5a after startup, the compressor stops, and it is restarted 3 minutes later. When this occurs on 7 consecutive occasions, operation stops, and the trouble display appears. Cu-3e/4e: when "output current tr...

Page 87

13.2.2. Outdoor unit (cu-3e23cbpg/4e27cbpg) 87 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 88

13.3. Disassembly of parts 13.3.1. Indoor unit 1. Remove the control box cover (steel plate). 2. Remove the display p.C. Board (plastic). 3. Disconnect the connectors, rearrange the lead wires, and remove the discharge grille. 4. Remove the ground screw. 5. Disconnect the connectors of the fan motor...

Page 89

6. Remove the control board complete. 7. Remove the screw at the particular plate (heat exchanger clamp) on the left of the unit. 8. Remove the screw that fix the heat exchanger to the base pan. 89 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e...

Page 90

9. Remove the four screws that fix the fan motor cover (white), and release the hooks. 10. Hold down the hook of the heat exchanger using a screwdriver or other tool and remove the heat exchanger (while lifting 1, 2). Now remove the fan motor cover. 90 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me1...

Page 91

11. Remove the screw that fix the fan, and then remove the fan motor. 12. Remove the cross-flow fan, and then remove the flucrum. 91 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 92

13.3.2. Outdoor unit (cu-2e15cbpg/2e18cbpg) 13.3.2.1. Removing the cabinet top plate and cabinet front plate 1. Remove the cabinet top plate (by removing the 4 screws). 2. Remove the 5 screws fixing the cabinet front plate, release the 6 hooks, and pull the cabinet front plate toward front side. 13....

Page 93

13.3.2.3. Removing the control p.C. Board 6. Remove the control board cover. 7. Remove the 6 screws at the positions on the control p.C. Board indicated by the arrows. 8. Disconnect the connectors and pipe sensor connected to the compressor and reactor. 9. Remove the control p.C. Board. * when pulli...

Page 94

13.3.3. Outdoor unit (cu-3e23cbpg/cu-4e27cbpg) 13.3.3.1. Removing the cabinet top plate and cabinet front plate ■ ■ ■ ■ cu-3e23cbpg 1. Remove the cabinet top plate (remove the 4 screws). 2. Remove the 3 screws (1 on the right and 2 at the bottom) securing the cabinet front plate, release the 2 hooks...

Page 95

13.3.3.2. Remove the control board cover (right side plate for cu-4e27cbpg) ■ ■ ■ ■ cu-3e23cbpg 3. Remove the control board cover (remove 2 screw). ■ ■ ■ ■ cu-4e27cbpg 3. Remove the 5 screws and release the 2 hooks of the right side plate, and remove the side plate. 95 cs-me7ckpg / cs-me10ckpg / cs-...

Page 96

13.3.3.3. Removing the control p.C. Board 4. Remove the drip proof cover. 5. Disconnect the connectors (lead wires of the compressor, sensor, and others). 6. Remove the screw at the right side of the control box, and pull out the entire control box. 7. Release the control p.C. Board tab to remove th...

Page 97: 14 Technical Data

14 technical data 14.1. Operation characteristics 97 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 98

98 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 99

99 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 100

100 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 101

101 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 102

102 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cbpg / cu-4e27cbpg.

Page 103

15 electronic circuit diagram 15.1. Remote control a b c d e f g h 1 2 3 4 5 6 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 seg6 seg5 seg4 seg3 seg2 seg1 com3 com...

Page 104

15.2. Indoor unit a b c d e f g h 1 2 3 4 5 6 7 8 9 10 11 12 5v 5v 5v pipe temp sensor (20k ,b=3950) display cwa742894 c33 250v 2200p fuse 250v 3.15a d1 era15-06v5 r1 6.8k 2w r67 6.2k 2w 5v zd1 rd36eb1 zd2 rd36eb1 r10 1.21k znr1 erzveav511 r7 510k 1/4w r8 510k 1/4w d2 era15-06v5 d3 1ss355 r9 3.9k r5...

Page 105

Function 24 hours off/on timer cooling fc max hot start forced completion hot start forced completion after deice auto mode judgment sampling time sleep mode timer shift thermo off timer 7 min. 0 time test mode 1 hour 1 min. 30 min. 3 sec. Indoor 3 min. 18 sec. 180 min. 30 sec. 60 min. 120 min. 180 ...

Page 106

15.3. Outdoor unit (cu-2e15cbpg/2e18cbpg) a b c d e f g h 1 2 3 4 5 6 7 8 9 10 11 12 2-room outdoor 1/3 5v 5v 10 11 12 13 14 15 brown ry-pwr terminal ac-blk fuse 20.0a fuse 5.0a xba2c50tr0 black ac-wht white power terminal to indoor unit a coil coil 2t 3t coil 2t to indoor unit b room-a terminal roo...

Page 107

A b c d e f g h 13 14 15 16 17 18 19 20 21 22 23 24 2-room outdoor 2/3 r106 232k 1/4w reactor gry2 gray gry1 gray 1 2 3 4 ljp101 a67c4053 ljp102 jp13 jp12 jp1 1 jp10 a67c4053 ljp104 a67c4056 ljp105 a67c4054 ljp107 a67c4055 ljp103 a67c4056 2 1 3 4 r411 10k r410 100 3 4 8 2 1 r409 1.8k c406 0.82 c407 ...

Page 108

Pin no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 port no. Description p16 t06 rxd txd si so sck reset vdd x2 x1 vss ic(vpp) p90 p91 p92 p93 p94 p95 p40 p41 p42 p43 p44 p45 p46 p47 p50 p51 p52 p53 p54 vss p55 p56 p57 p60 p61 p62 p6...

Page 109

15.4. Outdoor unit (cu-3e23cbpg/cu-4e27cbpg) a b c d e f g h 1 2 3 4 5 6 7 8 9 10 11 12 3, 4-room outdoor 1/2 r49 33k ac230v 50hz l n jp101 fu1 ac250v 30a l101 50 h sa1 hs hr he 8 6 2 4 3 1 e (grn/ylw) ecn1 (grn) (red) ac1 (blk) ac2 s15 0is15a pc814a/x1 jp5 jp1 r44 91k 2w r43 1k 1 2 4 3 0is15b pc814...

Page 110

A b c d e f g h 13 14 15 16 17 18 19 20 21 22 23 24 3, 4-room outdoor 2/2 v5 470nr-14d-204 4 1 3 2 3 fu2 ac250v 3.15a r5 82 10w 2 3 4 mrm20b mrm10b mrm11b 3 4 mrb8 jp4 l2 60 h l3 60 h c9 ac250v 3.3 c10 ac250v 3.3 ct1 etq19z60am 5 4 tpct2 tpct1 3 1 d14 d16 d13 d15 d13 - 16 1ss133 c20 25v 47 r7 560 r8...

Page 111

16 exploded view & replacement parts list 16.1. Cs-me7ckpg/me10ckpg/me12ckpg/me14ckpg/me18ckpg 16.1.1. Exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 111 cs-me7ckpg / cs-me10ckpg / cs...

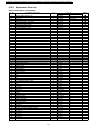

Page 112

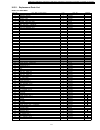

16.1.2. Replacement parts list ref. No. Part name & description q’ty part no. Remarks cs-me7ckpg cs-me10ckpg cs-me12ckpg cs-me14ckpg cs-me18ckpg 1 terminal board complete 1 cwa28k1045 ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ● ● ● ● 2 sensor complete (pipe) 1 cwa50c2101 ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ← ● ● ● ...

Page 113

16.2. Cu-2e15cbpg/2e18cbpg 16.2.1. Exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 113 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / ...

Page 114

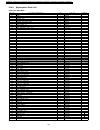

16.2.2. Replacement parts list ref. No. Part name & description q’ty part no. Remarks cu-2e15cbpg cu-2e18cbpg 1 terminal board complete (3p) 1 cwa28k1045 ← ← ← ← ● ● ● ● 2 terminal board complete (4p) 2 cwa28k1046 ← ← ← ← ● ● ● ● 3 valve coil 1 cwa43c2112 cwa43c2086 ● ● ● ● 4 expansion valve coil 2 ...

Page 115

Ref. No. Part name & description q’ty part no. Remarks cu-2e15cbpg cu-2e18cbpg 67 flare nut (1/4) 2 cwt25086 ← ← ← ← 68 flare nut (3/8) 2 cwt25087 ← ← ← ← 69 multi bend tube-1 1 cwt332957 ← ← ← ← 70 multi bend tube-2 1 cwt332958 ← ← ← ← 71 multi bend tube-3 1 cwt333298 ← ← ← ← 72 tube assy-8 1 cwt02...

Page 116

16.3. Cu-3e23cbpg 16.3.1. Exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 116 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cb...

Page 117

16.3.2. Replacement parts list ref. No. Part name & description q’ty part no. Remarks 1 swing compressor 1 cw1266081 ● ● ● ● 2 vibration isolator 3 cw1289899 3 nut with washer 3 cwh56062 4 terminal cover 1 cw1262647 5 rubber bush, lead wire 1 cwh51260 6 retainer, over-load relay 1 cw380620 7 sound i...

Page 118

Ref. No. Part name & description q’ty part no. Remarks 85 motorized exp. V coil, ass’y 1 cw1313350 ● ● ● ● 87 coil, motorized exp. Valve 1 cw1305234 88 coil, motorized exp. Valve 1 cw1305241 89 coil, motorized exp. Valve 1 cw1305210 90 thermistor ass’y (liquid line) 1 cw1309438 ● ● ● ● 91 thermistor...

Page 119

16.4. Cu-4e27cbpg 16.4.1. Exploded view note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 119 cs-me7ckpg / cs-me10ckpg / cs-me12ckpg / cs-me14ckpg / cs-me18ckpg / cu-2e15cbpg / cu-2e18cbpg / cu-3e23cb...

Page 120

16.4.2. Replacement parts list ref. No. Part name & description q’ty part no. Remarks 1 swing compressor 1 cw1266081 ● ● ● ● 2 spring 3 cw390208 3 nut with washer 3 cwh56062 4 terminal cover 1 cw1262647 5 guard bush, power cord 1 cw354120 6 retainer, over-load relay 1 cw380620 7 spring holder (1) 3 ...

Page 121

Ref. No. Part name & description q’ty part no. Remarks 76 power transistor module 1 cw1289921 ● ● ● ● 77 thermistor ass’y 1 cw1296633 ● ● ● ● 81 coil, solenoid valve ass’y 1 cw1364310 ● ● ● ● 82 coil, solenoid valve 1 cw1296378 ● ● ● ● 83 coil, four way valve 1 cw1176304 85 reactor 1 cw1305955 86 wi...