- DL manuals

- Panasonic

- Air Conditioner

- CS-MTZ16TKE

- Service Manual

Panasonic CS-MTZ16TKE Service Manual

© Panasonic Corporation 2017

Order No: PAPAMY1702032CE

Indoor Unit

Outdoor Unit

CS-TZ20TKEW

CS-TZ25TKEW

CS-TZ35TKEW

CS-TZ42TKEW

CS-MTZ16TKE

CU-TZ20TKE

CU-TZ25TKE

CU-TZ35TKE

CU-TZ42TKE

Destination

Europe

Turkey

Please file and use this manual together with the service manual for Model No. CU-2E12SBE, CU-2E15SBE, CU-2E18SBE,

CU-3E18PBE, CU-3E23SBE, CU-4E23PBE, CU-4E27PBE, CU-5E34PBE, CU-2RE15SBE, CU-2RE18SBE, CU-3RE18SBE,

Order No. PAPAMY1601016CE, PAPAMY1601015CE, PAPAMY1301048CE, PAPAMY1303046CE.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the products dealt with in this service information by anyone else could result in serious injury or death.

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by in the Schematic

Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced

with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of

manufacturer.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

CAUTION

R32 REFRIGERANT

– This Air Conditioner contains and operates with refrigerant R32.

THIS PRODUCT MUST ONLY BE INSTALLED OR SERVICED BY QUALIFIED PERSONNEL.

Refer to Commonwealth, State, Territory and local legislation, regulations, codes, installation & operation manuals, before the

installation, maintenance and/or service of this product.

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Summary of CS-MTZ16TKE

Page 1

© panasonic corporation 2017 order no: papamy1702032ce indoor unit outdoor unit cs-tz20tkew cs-tz25tkew cs-tz35tkew cs-tz42tkew cs-mtz16tke cu-tz20tke cu-tz25tke cu-tz35tke cu-tz42tke destination europe turkey please file and use this manual together with the service manual for model no. Cu-2e12sbe,...

Page 2: Table of Contents

2 table of contents page page 1. Safety precautions ............................................. 3 2. Precaution for using r32 refrigerant .............. 5 3. Specifications ..................................................... 9 4. Features ............................................................

Page 3: 1. Safety Precautions

3 1. Safety precautions read the following “safety precautions” carefully before installation. Electrical work must be installed by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model to be installed. The caution items stated here must be follow...

Page 4

4 warning 17. Use the attached accessories parts and specified parts for installation. Otherwise, it will cause the set to fall, water leakage, fire or electrical shock. 18. Install at a strong and firm location which is able to withstand weight of the set. If the strength is not enough or installat...

Page 5

5 2. Precaution for using r32 refrigerant the basic installation work procedures are the same as conventional refrigerant (r410a, r22) models. However, pay careful attention to the following points: warning 1. Since the working pressure is higher than that of refrigerant r22 models, some of the pipi...

Page 6

6 caution 2-5. No ignition sources no person carrying out work in relation to a refrigeration system which involves exposing any pipe work that contains or has contained flammable refrigerant shall use any sources of ignition in such a manner that it may lead to the risk of fire or explosion. He/she...

Page 7

7 caution 7. Leak detection methods electronic leak detectors shall be used to detect flammable refrigerants, but the sensitivity may not be adequate, or may need re- calibration. (detection equipment shall be calibrated in a refrigerant-free area.) ensure that the detector is not a potential source...

Page 8

8 caution 11. Labelling equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant. The label shall be dated and signed. Ensure that there are labels on the equipment stating the equipment contains flammable refrigerant. 12. Recovery when removing refrigerant fro...

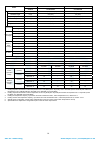

Page 9: 3. Specifications

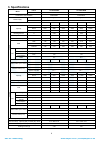

9 3. Specifications model indoor cs-tz20tkew cs-tz25tkew outdoor cu-tz20tke cu-tz25tke performance test condition eurovent eurovent power supply phase, hz single, 50 single, 50 v 230 230 min. Mid. Max. Min. Mid. Max. Cooling capacity kw 0.75 2.00 2.40 0.85 2.50 3.00 btu/h 2560 6820 8180 2900 8530 10...

Page 10

10 model indoor cs-tz20tkew cs-tz25tkew outdoor cu-tz20tke cu-tz25tke compressor type hermetic motor (rotary) hermetic motor (rotary) motor type brushless (6 poles) brushless (6 poles) output power w 500 500 indoor fan type cross-flow fan cross-flow fan material asg20k1 asg20k1 motor type dc / trans...

Page 11

11 model indoor cs-tz20tkew cs-tz25tkew outdoor cu-tz20tke cu-tz25tke piping pipe diameter (liquid / gas) mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8) standard length m (ft) 5.0 (16.4) 5.0 (16.4) length range (min – max) m (ft) 3 (9.8) ~ 15 (49.2) 3 (9.8) ~ 15 (49.2) i/d & o/d height di...

Page 12

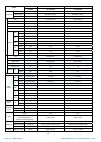

12 model indoor cs-tz35tkew cs-tz42tkew outdoor cu-tz35tke cu-tz42tke performance test condition eurovent eurovent power supply phase, hz single, 50 single, 50 v 230 230 min. Mid. Max. Min. Mid. Max. Cooling capacity kw 0.85 3.50 3.90 0.85 4.20 4.60 btu/h 2900 11900 13300 2900 14300 15700 kcal/h 730...

Page 13

13 model indoor cs-tz35tkew cs-tz42tkew outdoor cu-tz35tke cu-tz42tke compressor type hermetic motor (rotary) hermetic motor (rotary) motor type brushless (6 poles) brushless (6 poles) output power w 700 700 indoor fan type cross-flow fan cross-flow fan material asg20k1 asg20k1 motor type dc / trans...

Page 14

14 model indoor cs-tz35tkew cs-tz42tkew outdoor cu-tz35tke cu-tz42tke piping pipe diameter (liquid / gas) mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 12.70 (1/2) standard length m (ft) 5.0 (16.4) 5.0 (16.4) length range (min – max) m (ft) 3 (9.8) ~ 15 (49.2) 3 (9.8) ~ 15 (49.2) i/d & o/d height d...

Page 15

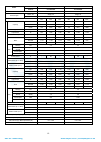

15 model indoor cs-mtz16tke outdoor cu-3re18sbe performance test condition eurovent power supply phase, hz single, 50 v 230 min. Mid. Max. Cooling capacity kw 1.30 1.60 2.30 btu/h 4440 5460 7860 running current a – 2.30 – input power w 250 470 710 annual consumption kwh – 235 – eer w/w 5.20 3.40 3.2...

Page 16

16 model indoor cs-mtz16tke outdoor cu-3re18sbe dimension height (i/d) mm (inch) 290 (11-7/16) width (i/d) mm (inch) 799 (31-15/32) depth (i/d) mm (inch) 197 (7-25/32) weight net (i/d) kg (lb) 8 (18) pipe diameter (liquid / gas) mm (inch) 6.35 (1/4) / 9.52 (3/8) drain hose inner diameter mm 16.7 len...

Page 17

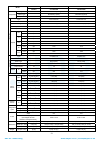

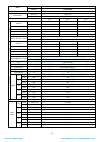

17 multi split combination possibility: o a single outdoor unit enables air conditioning of up to two separate rooms for cu-2re15sbe, cu-2re18sbe. O a single outdoor unit enables air conditioning of up to three separate rooms for cu-3re18sbe. Connectable indoor unit outdoor unit cu-2re15sbe* cu-2re1...

Page 18

18 multi split combination possibility: o a single outdoor unit enables air conditioning of up to two separate rooms for cu-2e12sbe, cu-2e15sbe, cu-2e18sbe. O a single outdoor unit enables air conditioning of up to three separate rooms for cu-3e23sbe. Connectable indoor unit cu-2e12sbe* cu-2e15sbe* ...

Page 19

19 multi split combination possibility: o a single outdoor unit enables air conditioning of up to three separate rooms for cu-3e18pbe. O a single outdoor unit enables air conditioning of up to four separate rooms for cu-4e23pbe, cu-4e27pbe. O a single outdoor unit enables air conditioning of up to f...

Page 20: 4. Features

20 4. Features inverter technology o wider output power range o energy saving o quick cooling o quick heating o more precise temperature control environment protection o non-ozone depletion substances refrigerant (r32) long installation piping o long piping up to 15 meters (3/4 ~ 1.75hp) and 20 mete...

Page 21: 5.1 Indoor

21 5. Location of controls and components 5.1 indoor unit aluminium fin auto off/on button • use when remote control is misplaced or malfunction occurs. Air filters front panel remote control receiver vertical airflow direction louver • do not adjust by hand. Horizontal airflow direction louver • ma...

Page 22: 6. Dimensions

22 6. Dimensions 6.1 indoor unit 16.4 264.6 unit: mm b a c pipe hole center pipe hole center 128mm to pipe hole center 128mm to pipe hole center 496.6 128 184 222 128 right piping hole left piping hole installation plate indoor unit external dimensions line 420 380 45 95 relative position between th...

Page 23: 6.2 Outdoor

23 6.2 outdoor unit 6.2.1 cu-tz20tke cu-tz25tke cu-tz35tke (18) 69.5 61.6 542 289 39 570.3 22 (104.7) 67.6 780 85.5 155.2 34.3 60.5 104.9 space necessary for installation anchor bolt pitch 320 x 570 unit: mm 2-way valve at liquid side (high pressure) 3-way valve at gas side (low pressure) 1000 mm 10...

Page 24

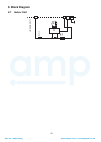

24 7. Refrigeration cycle diagram indoor outdoor intake air temp. Sensor air temp. Sensor pipe temp. Sensor 1 pipe temp. Sensor 2 tank sensor pipe temp. Sensor liquid side 2-way valve 3-way valve gas side cooling heat exchanger (evaporator) heating compressor 4-ways valve condenser muffler muffler s...

Page 29: 9.1 Indoor

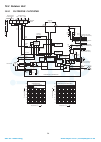

29 9. Wiring connection diagram 9.1 indoor unit grounding terminal y/g g evaporator fan motor bl bl w w b r r y 7 4 1 4 5 1 6 5 5 1 1 1 5 1 1 1 5 to outdoor unit terminal board noise filter circuit communication circuit ac306 (blk) ac303 (wht) ac304 (red) g301 (grn) cn-fm (wht) fuse301 t3.15a l250v ...

Page 30: 9.2 Outdoor

30 9.2 outdoor unit 9.2.1 cu-tz20tke cu-tz25tke ms 3 ~ u v w p n q1 m reactor w u v ms 3 ~ t° t° t° to indoor unit single phase power supply (wht) (wht) (wht) (blk) (red) (red) l n (blk) 1 2 3 grn grn blk blk ylw/grn wht wht red ac-wht ac-blk (blk) data (red) grounding terminal fuse101 (20a 250v) fg...

Page 31

31 9.2.2 cu-tz35tke ms 3 ~ u v w p n q1 m reactor w u v ms 3 ~ t° t° t° to indoor unit single phase power supply (wht) (wht) (wht) (blk) (red) (red) l n (blk) 1 2 3 grn grn blk blk ylw/grn wht wht red ac-wht ac-blk (blk) data (red) grounding terminal fuse101 (20a 250v) fg 1 (grn) fg 2 (grn) cn-mtr1 ...

Page 32

32 9.2.3 cu-tz42tke ms 3 ~ u v w p n q1 m reactor w u v ms 3 ~ t° t° t° to indoor unit single phase power supply (wht) (wht) (wht) (blk) (red) (red) l n (blk) 1 2 3 grn grn blk blk ylw/grn wht wht red ac-wht ac-blk (blk) data (red) grounding terminal fuse101 (20a 250v) fg 1 (grn) fg 2 (grn) cn-mtr1 ...

Page 33: 10.1 Indoor Unit

33 10. Electronic circuit diagram 10.1 indoor unit 70 60 50 40 30 20 -10 0 10 20 30 40 50 10 0 re s is ta n c e (k Ω ) sensor (thermistor) characteristics pipe temp. Sensor intake air temp. Sensor temperature (°c) grounding terminal y/g g evaporator fan motor bl bl w w b r r y 7 4 1 4 5 1 6 5 5 1 1 ...

Page 34: 10.2 Outdoor Unit

34 10.2 outdoor unit 10.2.1 cu-tz20tke cu-tz25tke sensor (thermistor) characteristics 70 60 50 40 30 20 10 0 -10 0 10 temperature ( o c) resistance (kΩ) 20 30 40 50 1 2 1 2 outdoor air sensor outdoor heat exchanger sensor compressor temp. Sensor (thermistor) characteristics 70 60 50 40 30 20 10 0 20...

Page 35

35 10.2.2 cu-tz35tke sensor (thermistor) characteristics 70 60 50 40 30 20 10 0 -10 0 10 temperature ( o c) resistance (kΩ) 20 30 40 50 outdoor air sensor outdoor heat exchanger sensor compressor temp. Sensor (thermistor) characteristics 70 60 50 40 30 20 10 0 20 40 60 temperature ( o c) resistance ...

Page 36

36 10.2.3 cu-tz42tke sensor (thermistor) characteristics 70 60 50 40 30 20 10 0 -10 0 10 temperature ( o c) resistance (kΩ) 20 30 40 50 outdoor air sensor outdoor heat exchanger sensor compressor temp. Sensor (thermistor) characteristics 70 60 50 40 30 20 10 0 20 40 60 temperature ( o c) resistance ...

Page 42: 12. Installation

42 12. Installation instruction 12.1 select the best location 12.1.1 indoor unit do not install the unit in excessive oil fume area such as kitchen, workshop and etc. There should not be any heat source or steam near the unit. There should not be any obstacles blocking the air circulation. A place w...

Page 43: 12.2 Indoor Unit

43 12.2 indoor unit 12.2.1 how to fix installation plate the mounting wall shall be strong and solid enough to prevent it from vibration. 3 4 b a c ceiling wall wall installation plate 1 2 screw more than 1 more than 1 measuring tape indoor unit 184 mm 128 mm 222 mm 128 mm more than 2 pipe hole cent...

Page 44

44 12.2.2 to drill a hole in the wall and install a sleeve of piping 1 insert the piping sleeve to the hole. 2 fix the bushing to the sleeve. 3 cut the sleeve until it extrudes about 15 mm from the wall. Caution when the wall is hollow, please be sure to use the sleeve for tube assembly to prevent d...

Page 45

45 12.2.3 indoor unit installation ● do not turn over the unit without it’s shock absorber during pull out the piping. It may cause intake grille damage. ● use shock absorber during pull out the piping to protect the intake grille from damage. Piping intake grille shock absorber piping pull out the ...

Page 46

46 • how to pull the piping and drain hose out, in case of the embedded piping. • in case of left piping how to insert the connection cable and drain hose. Rear view for left piping installation adjust the piping slightly downwards. Drain hose connection cable exchange the drain hose and the cap (fo...

Page 47

47 5 secure the connection cable onto the control board with the holder. O ensure the colour of wires of outdoor unit and the terminal nos. Are the same to the indoor’s respectively. O earth wire shall be yellow/green (y/g) in colour and longer than other ac wires for safety reason. Connection cable...

Page 48: 12.3 Outdoor Unit

48 12.3 outdoor unit 12.3.1 install the outdoor unit after selecting the best location, start installation to indoor/outdoor unit installation diagram. 1 fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2 when installing at roof, please consider strong wind and e...

Page 49

49 12.3.2.3 connecting the piping to outdoor multi decide piping length and then cut by using pipe cutter. Remove burrs from cut edge. Make flare after inserting the flare nut (locate at valve) onto the copper pipe. Align center of piping to valve and then tighten with torque wrench to the specified...

Page 50

50 air purging method is prohibited for r32 system 12.3.3 evacuation of the equipment when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. Do not purge the air with refrigerants but use a vacuum pump to vacuum the installation. ...

Page 51

51 12.3.4 connect the cable to the outdoor unit 1 remove the control board cover from the unit by loosening the screw. 2 cable connection to the power supply through isolating devices (disconnecting means). O connect approved type polychloroprene sheathed power supply cord 3 x 1.5 mm 2 (3/4 ~ 1.75hp...

Page 52

52 12.3.5 piping insulation 1 please carry out insulation at pipe connection portion as mentioned in indoor/outdoor unit installation diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2 if drain hose or connecting piping is in the room (where dew may form),...

Page 53

53 12.3.9 evaluation of the performance operate the unit at cooling/heating operation mode for fifteen minutes or more. Measure the temperature of the intake and discharge air. Ensure the difference between the intake temperature and the discharge is more than 8°c during cooling operation or more th...

Page 54

54 13. Installation and servicing air conditioner using r32 13.1 about r32 refrigerant for air conditioning refrigerants such as r410a, the refrigerants were collected back in order to prevent their air dissipation, to curbe the global warming impact, in case they were released into the atmosphere. ...

Page 55

55 2. Characteristic of pressure as shown in table 2, r32 does not have much difference in vapor pressure at the same refrigerant temperature comparing to r410a, but comparing to r22, it is higher at 1.6 times more. Thus, the same as in case of r410a, it is necessary to do installation and service u...

Page 56

56 13.3 refrigerant piping installation • tools used in services 13.3.1 required tools r32 refrigerant air conditioners use the common parts as r410a air conditioners for two-way valves and three-way valves (diameters of service ports); thus, they maintain commonality in the maintenance of the compr...

Page 57

57 3. Torque wrenches (diameters 1/2, 5/8) in order to strengthen the compressive strength, the diameters of wrenches change depending on the flare nut sizes. Torque wrenches differences in torque wrenches r32 (common r410a) r22 1/2 (diameter × torque) 26 mm × 55 n•m (550 k g f•m) 24 mm × 55 n•m (55...

Page 58

58 7. Hfc refrigerant_electric gas leakage tester r32 refrigerant is often used for other mixed refrigerant (r410a, r404a, r407c etc.). Therefore, the usage of existing hfc detectors is possible, but in order to detect more accurately, we recommend to use detectors specially set and adjusted for r32...

Page 59

59 11. Tools used for refrigerant piping installations and services tools for r410a common with r32 possibility of usage for r22 1. Pipe cutters, reamers or scrapers ○ ○ 2. Flare tools (clutch type) ○ ○ 3. Torque wrench (1/4, 3/8) ○ ○ 4. Torque wrench (1/2, 5/8) ○ × 5. Manifold gauges ・ charging hos...

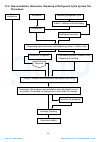

Page 60: Procedures

60 13.4 new installation, relocation, repairing of refrigerant cycle system the procedures operation testing new installation relocation repairing refrigerant cycle pump down refrigerant recovery prevention of impurity leakage checking insertion of refrigerant • dismantling indoor / outdoor units • ...

Page 61

61 13.5 piping installation of r32 13.5.1 pipe materials used and flaring copper pipes are used for refrigerant piping. Pipes which comply with jis regulations need to be used. Room air conditioners which use r410a and r32 have higher pressure; thus, using pipes which comply with the regulations is ...

Page 62

62 13.6 installation, relocation, and service 13.6.1 air purge and gas leak test for new installation (using new refrigerant pipes) using vacuum pump (from the point of view of global environment protection, do not release cfcs into the atmosphere during installation work) 1. Connect the charging ho...

Page 63

63 13.6.2 process of refrigerant recovery 1. Connect the center charging hose of manifold gauge to the in-let side of recovery device. 2. Connect the valves of the discharge side of recovery device and liquid side of refrigerant cylinder with red hose (charging hose). 3. Connect the yellow float swi...

Page 64

64 13.6.3 relocation 1. Removing the air conditioning unit a) recovery of outdoor unit refrigerant by pumping down press “forced cooling button” (as a general rule, since 1998 the name of cooling testing button is changed, and this name is unified within the air conditioning industry), and then you ...

Page 65

65 13.6.6 re-insertion of refrigerant in service when re-insertion is needed, follow the procedures to ensure the insertion of new refrigerant at correct amount. 1. Attach charging hose (blue) to the service port of the outdoor unit. 2. Attach charging hose (red) to the vacuum pump. Fully open the 2...

Page 66

66 13.7 repairing of refrigerant cycle / brazing point 13.7.1 preparation for repairing of refrigerant cycle / brazing brazing which is a technique needed for repairing refrigerant cycle requires advanced technique and experience, and this brazing procedure can only be performed by the workers who c...

Page 67

67 2. Cylinder without adjustment valve 2 nd side gauge pressure is adjusted by the adjuster. Check the both side valves of the torch and open the cylinder valve to check the remaining refrigerant in the cylinder. Caution: do not attach oil component on the connection port of the adjuster. Especiall...

Page 68

68 13.7.5 types of flame types of flame change based on the proportion of propane and oxygen. [neutral flame] perform brazing with this flame (this is a flame when oxygen and propane are mixed at proper proportion, and has lesser effect on the brazed metals) white core flame 10 ~ 15 mm outer flame (...

Page 69

69 13.7.7 selection of brazing material use ba g brazing material (silver solder) to increase the welding performance. Category jis standard number composition of ingredients (%) temperature (°c) tensile strength (reference) characteristics and applications a g cu zu cd ni p solidus liquidus brazing...

Page 70

70 13.7.10 checking of brazing (insert) points 1. No impurity on the brazing point if dirt or oil is attached on the brazing point, the brazing filler metal does not reach to junction, and it may cause poor welding. 2. Adequate gap space in the brazing point the advantage of capillary current situat...

Page 71

71 (reference) melting temperature of copper • • • • • • • approx. 1083°c maximum temperature obtained in propane and oxygen • • • • • • • approx. 1083°c the important point is to heat the bonding part uniformly within a short period of time until reaching to the brazing temperature in the following...

Page 72: Warming

72 13.8 analysis method for no error code, no cooling / no warming 13.8.1 preparation for appropriate diagnosis in order to obtain appropriate operation characteristics, minimum 15 minutes or more operation time [testing operation (rated operation)] is required. 1. Method of rated operation (rated o...

Page 73

73 1. Measuring temperature 1) indoor unit suction temperature, release temperature, temperature difference, → measure by thermometer 2) 2-way valve pipe temperature in cooling mode is low temperature (benchmark : 5 ~ 10°c), in heating mode is medium temperature (benchmark : 25 ~ 35°c). 3) 3-way val...

Page 74: 14. Operation

74 14. Operation control 14.1 basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer maintai...

Page 75

75 14.1.5 automatic operation this mode can be set using remote control and the operation is decided by remote control setting temperature, remote control operation mode and indoor intake air temperature. During operation mode judgment, indoor fan motor (with speed of lo-) is running for 30 seconds ...

Page 76

76 [heating] according to indoor pipe temperature, automatic heating fan speed is determined as follows. Rpm increased rpm maintain rpm red u ced off indoor pipe temp. 35 o c 39 o c 16 o c 19 o c b. Feedback control immediately after the fan motor started, feedback control is performed once every se...

Page 77: 14.4 Airflow Direction

77 14.4 airflow direction there are two types of airflow, vertical airflow (directed by horizontal vane) and horizontal airflow (directed by vertical vanes). Control of airflow direction can be automatic (angles of direction is determined by operation mode, heat exchanger temperature and intake air ...

Page 78: 14.5 Timer Control

78 side view (outer vane) stopper closed position step 1 step 2 step 3 step 4 step 5 reference point figure 2 135º * the horizontal vane angle tolerance is within +/- 5 degree. 14.4.2 horizontal airflow the horizontal airflow direction louver can be adjusted manually by hand. 14.5 timer control ther...

Page 79: 14.6 Sleep Mode Operation

79 14.6 sleep mode operation sleep to maximise comfort while sleeping (cancel) this operation provides you with a comfortable environment while sleeping. It will automatically adjust the sleep pattern temperature during the activation period. The indoor unit indicator will dim when this operation is...

Page 80

80 14.10 quiet operation (heating) a. Purpose to provide quiet heating operation compare to normal operation. B. Control condition a. Quiet operation start condition o when “powerful/quiet” button at remote control is pressed. B. Quiet operation stop condition 1 when one of the following conditions ...

Page 81: 15.1 Cooling

81 15. Operation control (for multi split connection) during multi split connection, indoor unit’s operation controls are same with single split connection unless specified in this chapter. 15.1 cooling operation 15.1.1 thermostat control capability supply to indoor unit is off (expansion valve clos...

Page 82: 15.4 Automatic

82 15.4 automatic operation this mode can be set using remote control and the operation is decided by remote control setting temperature, remote control operation mode, indoor intake and outdoor air temperature. During operation mode judgment, indoor fan motor (with speed of -lo) and outdoor fan mot...

Page 83: 16. Protection

83 16. Protection control 16.1 protection control for all operations 16.1.1 restart control (time delay safety control) the compressor will not turn on within 3 minutes from the moment operation stops, although the unit is turned on again by pressing off/on button at remote control within this perio...

Page 84

84 compressor = off compressor frequency reduce compressor frequency maintain free comp. Temperature 103°c 99°c 96°c 88°c 87°c 86°c 16.1.5 low pressure prevention control (gas leakage detection) control start conditions o for 5 minutes, the compressor continuously operates and outdoor total current ...

Page 85: 16.2

85 16.2 protection control for cooling & soft dry operation 16.2.1 outdoor air temperature control the compressor operating frequency is regulated in accordance to the outdoor air temperature as shown in the diagram below. This control will begin 1 minute after the compressor starts. Compressor freq...

Page 86

86 16.2.5 dew prevention control 1 to prevent dew formation at indoor unit discharge area. This control will be activated if: o outdoor air temperature and indoor pipe temperature judgment by microcontroller is fulfilled. O when cooling or dry mode is operated more than 20 minutes or more. This cont...

Page 87

87 16.3.4 low temperature compressor oil return control in heating operation, if the outdoor temperature falls below -10°c when compressor starts, the compressor frequency will be regulated up to 600 seconds. 16.3.5 cold draught prevention control when indoor pipe temperature is low, cold draught op...

Page 88: 17. Servicing

88 17. Servicing mode 17.1 auto off/on button 1 auto operation mode the auto operation will be activated immediately once the auto off/on button is pressed. This operation can be used to operate air conditioner with limited function if remote control is misplaced or malfunction. 2 test run operation...

Page 89: 17.2 Heat Only Operation

89 4 remote control receiving sound off/on mode the remote control receiving sound off/on mode will be activated if the auto off/on button is pressed continuously for more than 16 seconds (4 “beep” sounds will occur at 16th seconds to identify the remote control receiving sound off/on mode is in sta...

Page 90: 17.3 Remote Control Button

90 17.2.2 operation mode during heating only operation the table below shows the operation mode comparison when heating only operation mode activated and deactivated. Operation mode heating only operation mode activated heating only operation mode deactivated auto after 30s sampling, regardless of t...

Page 91

91 17.3.2 reset (rc) to clear and restore the remote control setting to factory default. O press once to clear the memory. 17.3.3 reset (ac) to restore the unit’s setting to factory default. O press once to restore the unit’s setting. 17.3.4 timer ▲ to change indoor unit indicator’s led intensity. O...

Page 92

92 4 to enter zone 2 area: (press continuously for t ≥ 5 secs) once t ≥ 5secs enter zone2 [range (50~99)] enter zone1 normal display mode 5 function & options list: note: the functions described in the table may not be applicable to the model and may subject to change without further notice. Functio...

Page 93: 18. Troubleshooting

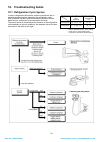

93 18. Troubleshooting guide 18.1 refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a f...

Page 94

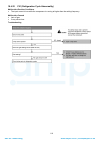

94 18.1.1 relationship between the condition of the air conditioner and pressure and electric current condition of the air conditioner cooling mode heating mode low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refr...

Page 95

95 18.2 breakdown self diagnosis function 18.2.1 self diagnosis function (three digits alphanumeric code) once abnormality has occurred during operation, the unit will stop its operation, and timer led blinks. Although timer led goes off when power supply is turned off, if the unit is operated under...

Page 96: 18.3 Error Codes Table

96 18.3 error codes table diagnosis display abnormality / protection control abnormality judgment protection operation problem check location h00 no memory of failure — normal operation — — h11 indoor/outdoor abnormal communication after operation for 1 minute indoor fan only operation can start by ...

Page 97

97 diagnosis display abnormality / protection control abnormality judgment protection operation problem check location h41 abnormal wiring or piping connection — — wrong wiring and connecting pipe, expansion valve abnormality check indoor/outdoor connection wire and connection pipe expansion valve a...

Page 98: 18.4 Self-Diagnosis

98 18.4 self-diagnosis method 18.4.1 h11 (indoor/outdoor abnormal communication) malfunction decision conditions during startup and operation of cooling and heating, the data received from outdoor unit in indoor unit signal transmission is checked whether it is normal. Malfunction caused faulty indo...

Page 99

99 18.4.2 h12 (indoor/outdoor capacity rank mismatched) malfunction decision conditions during startup, error code appears when different types of indoor and outdoor units are interconnected. Malfunction caused wrong models interconnected. Wrong indoor unit or outdoor unit pcbs mounted. Indoor unit ...

Page 100

100 18.4.3 h14 (indoor intake air temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the indoor intake air temperature sensor are used to determine sensor errors. Malfunction caused faulty connector connec...

Page 101

101 18.4.4 h15 (compressor temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor compressor temperature sensor are used to determine sensor errors. Malfunction caused faulty connector connection. ...

Page 102

102 18.4.5 h16 (outdoor current transformer) malfunction decision conditions an input current, detected by current transformer ct, is below threshold value when the compressor is operating at certain frequency value for 3 minutes. Malfunction caused lack of gas broken ct (current transformer) broken...

Page 103

103 18.4.6 h19 (indoor fan motor – dc motor mechanism locked) malfunction decision conditions the rotation speed detected by the hall ic during fan motor operation is used to determine abnormal fan motor (feedback of rotation > 2550 rpm or malfunction caused operation stops due to short circuit insi...

Page 104

104 18.4.7 h23 (indoor pipe temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the indoor heat exchanger temperature sensor are used to determine sensor errors. Malfunction caused faulty connector connecti...

Page 105

105 18.4.8 h27 (outdoor air temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor air temperature sensor are used to determine sensor errors. Malfunction caused faulty connector connection. Faulty...

Page 106

106 18.4.9 h28 (outdoor pipe temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor pipe temperature sensor are used to determine sensor errors. Malfunction caused faulty connector connection. Faul...

Page 107

107 18.4.10 h30 (compressor discharge temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor discharge pipe temperature sensor are used to determine sensor errors. Malfunction caused faulty connect...

Page 108

108 18.4.11 h32 (outdoor heat exchanger temperature sensor 2 abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor heat exchanger temperature sensor are used to determine sensor errors. Malfunction caused faulty con...

Page 109

109 18.4.12 h33 (unspecified voltage between indoor and outdoor) malfunction decision conditions the supply power is detected for its requirement by the indoor/outdoor transmission. Malfunction caused wrong models interconnected. Wrong indoor unit and outdoor unit pcbs used. Indoor unit or outdoor u...

Page 110

110 18.4.13 h34 (outdoor heat sink temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor heat sink temperature sensor are used to determine sensor errors. Malfunction caused faulty connector conne...

Page 111

111 18.4.14 h36 (outdoor gas pipe sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor gas pipe temperature sensor are used to determine sensor errors. Malfunction caused faulty connector connection. Faulty ...

Page 112

112 18.4.15 h37 (outdoor liquid pipe temperature sensor abnormality) malfunction decision conditions during startup and operation of cooling and heating, the temperatures detected by the outdoor liquid pipe temperature sensor are used to determine sensor errors. Malfunction caused faulty connector c...

Page 113

113 18.4.16 h97 (outdoor fan motor – dc motor mechanism locked) malfunction decision conditions the rotation speed detected by the hall ic during fan motor operation is used to determine abnormal fan motor. Malfunction caused operation stops due to short circuit inside the fan motor winding. Operati...

Page 114

114 18.4.17 h98 (error code stored in memory and no alarm is triggered / no timer led flashing) malfunction decision conditions indoor high pressure is detected when indoor heat exchanger is detecting very high temperature when the unit is operating in heating operation. Phenomena: unit is stopping ...

Page 115

115 18.4.18 h99 (indoor freeze prevention protection: cooling or soft dry) error code will not display (no timer led blinking) but store in eeprom malfunction decision conditions freeze prevention control takes place (when indoor pipe temperature is lower than 2°c) malfunction caused air short circu...

Page 116

116 18.4.19 f11 (4-way valve switching failure) malfunction decision conditions when indoor heat exchanger is cold during heating (except deice) or when indoor heat exchanger is hot during cooling and compressor operating, the 4-way valve is detected as malfunction. Malfunction caused indoor heat ex...

Page 117

117 18.4.20 f17 (indoor standby units freezing abnormality) malfunction decision conditions when the different between indoor intake air temperature and indoor pipe temperature is above 10°c or indoor pipe temperature is below -1.0°c. Remark: when the indoor standby unit is freezing, the outdoor uni...

Page 118

118 18.4.21 f90 (power factor correction protection) malfunction decision conditions to maintain dc voltage level supply to power transistor. To detect high dc voltage level after rectification. Malfunction caused during startup and operation of cooling and heating, when power factor correction (pfc...

Page 120

120 18.4.23 f93 (compressor rotation failure) malfunction decision conditions a compressor rotation failure is detected by checking the compressor running condition through the position detection circuit. Malfunction caused compressor terminal disconnect faulty outdoor pcb faulty compressor troubles...

Page 121

121 18.4.24 f95 (outdoor high pressure protection: cooling or soft dry) malfunction decision conditions during operation of cooling or soft dry, when outdoor unit heat exchanger high temperature data is detected by the outdoor unit heat exchanger thermistor. Malfunction caused outdoor heat exchanger...

Page 122

122 18.4.25 f96 (ipm overheating) malfunction decision conditions during operating of cooling and heating, when ipm temperature data (100°c) is detected by the ipm temperature sensor. Multi models only o compressor overheating: during operation of cooling and heating, when the compressor ol is activ...

Page 123

123 18.4.26 f97 (compressor overheating) malfunction decision conditions during operation of cooling and heating, when compressor tank temperature data (112°c) is detected by the compressor tank temperature sensor. Malfunction caused faulty compressor tank temperature sensor 2/3 way valve closed ref...

Page 124

124 18.4.27 f98 (input over current detection) malfunction decision conditions during operation of cooling and heating, when an input over-current (x value in total running current control) is detected by checking the input current value being detected by current transformer (ct) with the compressor...

Page 125

125 18.4.28 f99 (dc peak detection) malfunction decision conditions during startup and operation of cooling and heating, when inverter dc peak data is received by the outdoor internal dc peak sensing circuitry. Malfunction caused dc current peak due to compressor failure. Dc current peak due to defe...

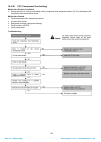

Page 126: Removal Procedures

126 19. Disassembly and assembly instructions warning high voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. 19.1 indoor electronic ...

Page 127

127 ac303 cn-stm3 cn-stm1 cn-th cn-fm 8 pull out the main electronic controller halfway. 9 detach connectors as labeled from the electronic controller. Then pull out main controller gently. 5 detach the earth wire screw, lead wires ac306 (black) and ac304 (red) from the terminal board. 7 remove scre...

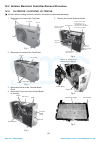

Page 130

130 19.2 outdoor electronic controller removal procedure 19.2.1 cu-tz20tke cu-tz25tke cu-tz35tke caution! When handling electronic controller, be careful of electrostatic discharge. 1 remove the 5 screws of the top panel. Top panel scre w s scre w scre w s fig. 1 2 remove the 6 screws of the front p...

Page 131

131 19.2.2 cu-tz42tke caution! When handling electronic controller, be careful of electrostatic discharge. 1 remove the 5 screws of the top panel. Fig. 1 2 remove the 8 screws of the front panel. Fig. 2 3 remove the screw of the terminal board cover. 4 remove the top cover of the control board by 4 ...

Page 132: 20. Technical

132 20. Technical data technical data provided are based on the air conditioner running under free frequency. 20.1 cool mode performance data unit setting: standard piping length, hi fan, cool mode at 16°c voltage: 230v 20.1.1 cs-tz20tkew/cu-tz20tke indoor (°c) outdoor db (°c) db wb -10 -7 0 5 16 25...

Page 133

133 20.1.4 cs-tz42tkew/cu-tz42tke indoor (°c) outdoor db (°c) db wb -10 -7 0 5 16 25 35 tc shc ip tc shc ip tc shc ip tc shc ip tc shc ip tc shc ip tc shc ip 27 19 4445 3100 924 4466 3119 919 4484 3074 924 4356 3092 1076 4904 3338 735 4572 3263 975 4200 3010 1260 22 4903 2494 935 4825 2492 1016 4848...

Page 134

134 20.2 heat mode performance data unit setting: standard piping length, hi fan, heat mode at 30°c voltage: 230v 20.2.1 cs-tz20tkew/cu-tz20tke indoor (°c) outdoor wb (°c) db -15 -7 2 7 12 tc ip tc ip tc ip tc ip tc ip 24 1653 767 1948 865 2535 899 2521 671 2684 668 20 1656 726 2140 860 2610 920 270...

Page 135: 21. Service

135 21. Service data service data provided are based on the air conditioner running under rated frequency during forced cooling / forced heating mode. 21.1 cool mode outdoor air temperature characteristic condition - indoor room temperature: 27°c dry bulb/19°c wet bulb - unit setting: standard pipin...

Page 136

136 21.1.2 cs-tz25tkew cu-tz25tke indoor discharge air temperature (°c) outdoor air temperature (°c) low pressure (mpa) outdoor air temperature (°c) current (a) outdoor air temperature (°c) 1.00 1.50 2.00 2.50 3.00 3.50 4.00 12 16 20 24 28 32 36 40 44 48 0.80 0.85 0.90 0.95 1.00 1.05 1.10 1.15 1.20 ...

Page 137

137 21.1.3 cs-tz35tkew cu-tz35tke indoor discharge air temperature (°c) outdoor air temperature (°c) low pressure (mpa) outdoor air temperature (°c) current (a) outdoor air temperature (°c) 2.00 2.40 2.80 3.20 3.60 4.00 4.40 4.80 5.20 12 16 20 24 28 32 36 40 44 48 0.60 0.70 0.80 0.90 1.00 1.10 1.20 ...

Page 138

138 21.1.4 cs-tz42tkew/cu-tz42tke indoor discharge air temperature (°c) outdoor air temperature (°c) low pressure (mpa) outdoor air temperature (°c) current (a) outdoor air temperature (°c) 1.50 2.50 3.50 4.50 5.50 6.50 7.50 12 16 20 24 28 32 36 40 44 48 0.60 0.70 0.80 0.90 1.00 1.10 12 16 20 24 28 ...

Page 139

139 21.2 heat mode outdoor air temperature characteristic condition - indoor room temperature: 20°c dry bulb/ -°c wet bulb - unit setting: standard piping length, forced heating at 30°c, hi fan - compressor frequency: rated for heating operation - piping length: 5m - voltage: 230v 21.2.1 cs-tz20tkew...

Page 140

140 21.2.2 cs-tz25tkew cu-tz25tke indoor discharge air temperature (°c) outdoor air temperature (°c) high pressure (mpa) outdoor air temperature (°c) current (a) outdoor air temperature (°c) 1.50 2.00 2.50 3.00 3.50 4.00 4.50 -20 -15 -10 -5 0 5 10 15 1.00 1.50 2.00 2.50 3.00 3.50 -20 -15 -10 -5 0 5 ...

Page 141

141 21.2.3 cs-tz35tkew cu-tz35tke indoor discharge air temperature (°c) outdoor air temperature (°c) high pressure (mpa) outdoor air temperature (°c) current (a) outdoor air temperature (°c) 2.70 2.90 3.10 3.30 3.50 3.70 3.90 4.10 4.30 4.50 4.70 4.90 5.10 -20 -15 -10 -5 0 5 10 15 1.20 1.40 1.60 1.80...

Page 142

142 21.2.4 cs-tz42tkew cu-tz42tke indoor discharge air temperature (°c) outdoor air temperature (°c) high pressure (mpa) outdoor air temperature (°c) current (a) outdoor air temperature (°c) 4.00 4.50 5.00 5.50 6.00 6.50 7.00 -20 -15 -10 -5 0 5 10 15 1.80 2.00 2.20 2.40 2.60 2.80 3.00 3.20 3.40 3.60...

Page 143

143 21.3 piping length correction factor the characteristic of the unit has to be corrected in accordance with the piping length. 21.3.1 cs-tz20tkew cu-tz20tke cs-tz25tkew cu-tz25tke cs-tz35tkew cu-tz35tke cs-tz42tkew cu-tz42tke cooling capacity correction factor heating capacity correction factor p...

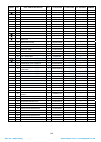

Page 144: 22.1 Indoor Unit

144 22. Exploded view and replacement parts list 22.1 indoor unit 37 a a a a 1 6 7 2 3 5 4 31 17 14 21 19 20 8 16 15 28 12 20 35 34 24 24a 27 30 23a 23 18 32 33 29 26 11 10 22 cwh5 5025j cwh5 5051j o/i 39 o/i 38 i/i 40 i/i 41 i/i 42 i/i 43 i/i 46 i/i 45 i/i 44 i/i 47 i/i 48 i/i 49 36 note the above ...

Page 145

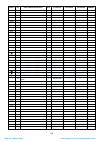

145 safety ref. No. Part name & description qty. Cs-tz20tkew cs-tz25tkew cs-tz35tkew remark 1 chassis complete 1 acxd50c00440 ← ← 2 fan motor 1 l6cbyyyl0195 ← ← o 3 cross-flow fan complete 1 cwh02c1159 ← ← 4 screw - cross-flow fan 1 cwh551146 ← ← 5 bearing assy 1 cwh64k1010 ← ← 6 evaporator 1 acxb30...

Page 146

146 safety ref. No. Part name & description qty. Cs-tz20tkew cs-tz25tkew cs-tz35tkew remark 48 installation instruction 1 acxf60-05750 ← ← 49 installation instruction 1 acxf60-05760 ← ← (note) all parts are supplied from papamy, malaysia (vendor code: 00029488). “o” marked parts are recommended to b...

Page 147

147 safety ref. No. Part name & description qty. Cs-tz42tkew cs-mtz16tke remark 1 chassis complete 1 acxd50c00440 ← 2 fan motor 1 l6cbyyyl0195 ← o 3 cross-flow fan complete 1 cwh02c1159 ← 4 screw - cross-flow fan 1 cwh551146 ← 5 bearing assy 1 cwh64k1010 ← 6 evaporator 1 acxb30c02740 acxb30c02730 7 ...

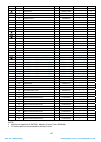

Page 148: 22.2 Outdoor Unit

148 22.2 outdoor unit 22.2.1 cu-tz20tke cu-tz25tke cu-tz35tke 34 15 17 11 10 9 23 21 20 38 39 19 26 28 25 32 30 12 22 6 5 3 8 7 2 31 4 1 41 27 33 16 14 24 29 36 45 46 13 43 44 42 i/i 56 i/i 52 i/i 53 i/i 54 i/i 55 i/i 57 i/i 58 i/i 59 i/i 60 i/i 61 note the above exploded view is for the purpose of ...

Page 149

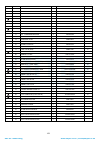

149 safety ref. No. Part name & description qty. Cu-tz20tke cu-tz25tke cu-tz35tke remark 1 chassis complete 1 acxd52k00150 ← cwd52k1399 2 sound proof material (top) 1 cwg302737 ← cwg302314 3 fan motor bracket 1 cwd541157 ← ← 4 screw - fan motor bracket 2 cwh551217 ← ← 5 fan motor 1 l6cayyyl0064 ← l6...

Page 150

150 safety ref. No. Part name & description qty. Cu-tz20tke cu-tz25tke cu-tz35tke remark 57 installation instruction 1 acxf60-06380 ← ← 58 installation instruction 1 acxf60-06390 ← ← 59 installation instruction 1 acxf60-06400 ← ← 60 installation instruction 1 acxf60-06410 ← ← 61 installation instruc...

Page 151

151 22.2.2 cu-tz42tke 32 26 27 33 28 34 38 19 39 21 20 9 31 11 10 15 1 16 17 4 23 46 22 2 3 8 7 5 30 12 24 29 41 43 42 13 6 25 45 14 i/i 53 i/i 49 i/i 50 i/i 51 i/i 52 i/i 54 i/i 55 i/i 56 i/i 57 i/i 58 44 note the above exploded view is for the purpose of parts disassembly and replacement. The non-...

Page 152

152 safety ref. No. Part name & description qty. Cu-tz42tke remark 1 chassis complete 1 cwd52k1277 2 sound proof material 1 cwg302719 3 fan motor bracket 1 cwd541167 4 screw - fan motor bracket 2 cwh551217 5 fan motor 1 ars6411ac o 6 screw - fan motor mount 4 cwh55252j 7 propeller fan assy 1 cwh03k1...

Page 153

153 safety ref. No. Part name & description qty. Cu-tz42tke remark 53 installation instruction 1 acxf60-06370 54 installation instruction 1 acxf60-06380 55 installation instruction 1 acxf60-06390 56 installation instruction 1 acxf60-06400 57 installation instruction 1 acxf60-06410 58 installation in...