- DL manuals

- Panasonic

- Air Conditioner

- CS-MVG103KE

- Service Manual

Panasonic CS-MVG103KE Service Manual

Summary of CS-MVG103KE

Page 1

© 1999 matsushita electric industrial co., ltd. All rights reserved. Unauthorized copying and distribution is a violation of law. Cs-mvg103ke cu-mvg153ke room air conditioners order number rac9911058c2.

Page 2: Contents

1 features 2 2 functions 3 2.1. Remote control 3 2.2. Indoor unit 4 2.3. Outdoor unit 6 3 product specifications 7 4 dimensions 9 4.1. Cs-mvg103ke (indoor unit) 9 4.2. Cu-mvg153ke (outdoor unit) 10 5 refrigeration cycle diagram 11 6 block diagram 12 7 wiring diagram 13 7.1. Cs-mvg103ke ( indoor unit...

Page 3: 2 Functions

2 functions 2.1. Remote control 3 cs-mvg103ke / cu-mvg153ke.

Page 4: 2.2. Indoor Unit

2.2. Indoor unit 4 cs-mvg103ke / cu-mvg153ke.

Page 5

5 cs-mvg103ke / cu-mvg153ke.

Page 6: 2.3. Outdoor Unit

2.3. Outdoor unit 6 cs-mvg103ke / cu-mvg153ke.

Page 7: 3 Product Specifications

3 product specifications unit cs-mvg103ke cu-mvg153ke cooling capacity kw btu/h (1 unit) (2 units) 2.8(0.7 3.5) 2.25(0.45 2.3) 9,500(2,400 11,900) 7,650(1,500 7,850) heating capacity kw btu/h (1 unit) (2 units) 4.0(0.7 4.3) 2.6(0.45 3.05) x 2 13,600(2,400 14,700) 8,850(1,500 10,400) x 2 moisture rem...

Page 8

Unit cs-mvg103ke cu-mvg153ke refrigerant control device - expansion valve refrigeration oil (c.C) - rb88a(290) refrigerant(r410a) g(oz) - 1250(44.1) thermostat electronic control - protection device electronic control air filter material style p.P honeycomb - capacity control expansion valve fan mot...

Page 9: 4 Dimensions

4 dimensions 4.1. Cs-mvg103ke (indoor unit) 9 cs-mvg103ke / cu-mvg153ke.

Page 10

4.2. Cu-mvg153ke (outdoor unit) 10 cs-mvg103ke / cu-mvg153ke.

Page 11

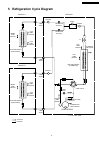

5 refrigeration cycle diagram 4-way valve 2-way valve pipe temp. Sensor pipe temp. Sensor sensor temp. Intake pipe temp. Sensor pipe temp. Sensor indoor a outdoor cooling heating heat exchanger (evaporator) heat exchanger (condenser) 2-way valve valve 3-way 2-way valve valve 3-way c1 strainer c ; ca...

Page 12: 6 Block Diagram

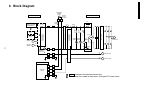

6 block diagram compressor + + noise fill ter diode + - electr onic cont r oller electr onic cont r oller fm r y -ho t r y -2cv ry -l 4-way valve 2-way valve fan motor ry-ac ry-pwr ptc reactor noise fill ter 5c exp.Valve(a) 5c exp.Valve(b) 1 1 2 2 3 1 2 3 5c 3c terninal thermal fuse 102 fm 9c fan mo...

Page 13: 7 Wiring Diagram

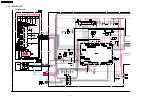

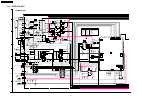

7 wiring diagram 7.1. Cs-mvg103ke ( indoor unit ) t erm i nal compl et e 6 5 1 1 16 cn - p w r 1 ( b ) 7 9 8 te r m i n a l cn - t h 1 (w ) 4 3 2 1 6 5 f use t 3 . 1 5 a l 2 5 0 v zn r cn - m t r 1 ( g ) rb y 1 2 3 5 3 1 4 se n so r (a ir te m p. ) se n s o r 1 ( p ip e t em p. 1 ) mo t o r di spl a...

Page 14

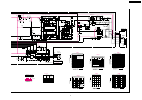

7.2. Cu-mvg153ke ( outdoor unit ) 2 5 1 4 3 1 1 1 0 8 9 7 p: pink v: violet 6 cn - w ( yel l ow ) cn - v ( bl ue) cn- pw m ( w hit e) exp. Val ve exp. Exp. Val ve val ve bl ry- l noise f i lt er bl ry- 2 cv 1 bl diode + 420v 750 f + - 1 7 5 v 4 5 f r react or b + 420v 750 f - r 1 1 3 l p ry- pwr c n...

Page 15

8 operation details (functions) 8.1. Simultaneous operation control 15 cs-mvg103ke / cu-mvg153ke.

Page 16: 8.2. Temperature Shift

8.2. Temperature shift once the operation starts, the remote control setting temperature will be shifted internally based on the setting fan speed and outdoor air temperature. In addition, if sleep mode or powerful mode are set, the temperature shift will be carried out. Setting of internal setting ...

Page 17

8.3. Compressor operating frequency operation compressor operation frequency according to comp. Operation frequency command number(indoor unit) 8.3.1. Cooling & soft dry (unit : hz) comp.Operation frequency command number of indoor unit a 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 comp. Operation frequen...

Page 18: 8.4. Cooling Operation

8.4. Cooling operation 8.4.1. Room temperature control 1. When the remote control setting temperature is less than 24°c. Refer to8.3.2. Compressor operation frequency 2. When the remote control setting temperature is 24°c and above. Refer to8.3.1. Compressor operation frequency · thermostat off temp...

Page 19

8.4.2. Deodorizing control · this control is available during automatic fan speed for cooling and soft dry operation. It is not available during anti-freezing control. · when the thermostat on operation, the deodorizing status starts from 1 → 2 → 3. · when the thermostat off operation, the deodorizi...

Page 20: 8.5. Soft Dry Operation

8.5. Soft dry operation 8.5.1. Room temperature control at the start of operation, cooling operation is running until the intake air temperature is 0.5°c higher than internal setting temperature, then the operation will shift to soft dry with indoor fan speed slo. Refer to8.3.1. Compressor operation...

Page 21: 8.6. Heating Operation

8.6. Heating operation 8.6.1. Room temperature control · during heating operation, the room temperature control depends on intake air temperature and internal setting temperature. Basically it can be divided into 2 periods as shown below: 1. When indoor fan speed is medium or above. Refer to8.3.2. C...

Page 22

· thermostat off temperature = thermostat on temperature. · the operation frequency changes every 30 seconds. · when the difference of the intake air temperature and internal setting temperature is -1.5°c or more, compressor will operate at fh continuously for 3 minutes and then change over to fh ma...

Page 23

2. Hot start · at the start of heating operation, the indoor fan stops and comp. Operation frequency command number at fh max. This is to heat up the indoor heat exchanger in order to avoid cold air discharged. · hot start ends when a. Indoor heat exchanger temperature reaches over 15°c or b. 4 minu...

Page 24

Deice operation time chart · compressor frequency is set at 40hz when the deice operation starting signal is generated. · 120 seconds later deice operation starting signal is generated, indoor fan, outdoor fan, 4-way valve are turned off and compressor operates at 61hz for 30 seconds. (deice operati...

Page 25: 8.7. Fan Operation

8.7. Fan operation this operation is to enable the fan operation without compressor running. Timer operation is valid for fan operation. 8.8. Automatic operation when the automatic mode is selected, the operation mode is decided in accordance to remote control setting temperature, intake air tempera...

Page 26

Setting temp °c t1 t2 t3 note: base temperature for t1 is 29 °c base temperature for t2 is 27 °c base temperature for t3 is 21 °c 18 and below +10 +8 -5 19 - 22 +8 +7 -7 23 - 26 +7 +6 -7 27 and above +6 +5 -8 · when the operation mode is changed over, the value for t1, t2 and t3 are shifted as follo...

Page 27

8.9. Indoor fan speed control fan speed no. Voltage supply to fan motor dc(v) cooling soft dry remarks heating remarks manual auto manual auto 0 off off off off off · hot start control 2 13.0 slo · deodorizing control · sleep mode · slo:hot start control 3 13.7 lo- · auto operation mode judgement · ...

Page 28

1. Cooling automatic fan speed the automatic fan speed for cooling operation is shown as below: a. When automatic fan speed is selected b. When automatic fan speed and powerful mode are selected note: the fan speed will change every 10 seconds and it will be repeated from a to h every 80 seconds. 2....

Page 29: 8.10. Outdoor Fan Control

8.10. Outdoor fan control · outdoor fan motor is controlled with 1 speeds. Fan is in operation when the compressor starts operation and stops 30 seconds after compressor stops operation. 8.11. Airflow direction · blade angle setting (upper limit reference) operation blade angle 1 2 3 4 5 heating air...

Page 30

1. Airflow direction manual by pressing the remote control airflow direction setting switch, the blade will move to the indicated angle (1, 2, 3, 4, 5) as shown in the table. When the remote control off/on switch is pressed, the blade will move to the close position. 2. Airflow direction auto by set...

Page 31: 8.12. Quiet Operation

8.12. Quiet operation the purpose of this control is to reduce indoor operating noise. Indoor fan speed is set to lo- when the following conditions occur. · indoor fan speed is set at low · indoor heat exchanger temperature rises to 17°c or above · compressor operates for 5 minutes or above · comp. ...

Page 32

8.14. Sleep mode operation 1. Cooling operation/soft dry operation · when the sleep button is pressed, the remote control setting temperature will increase 0.5°c after 1 hour or when the remote control setting temperature is reached. After another hour, 0.5°c will be increased again. · during sleep ...

Page 33

8.15. Delay on timer control · when the delay on timer is set by using remote control, the unit will start to operate slightly earlier before the set time, so that the room will nearly reach the set temperature by the on timer set time. · 60 minutes before the set time, the indoor fan operates at sl...

Page 34

8.17. Power monitor display power monitor led lights on when the compressor is in operation. The number of the led lights on is in accordance to the comp. Operation frequency command number. Display a a, b a, b, c a, b, c, d a, b, c, d, e cooling & soft dry indication comp. Operation frequency comma...

Page 35

9 operation details (protection) 9.1. Protection control for all operations 1. Time delay safety control · the compressor is not restarted for 3 minutes after stop of compressor. 2. 30 second forced operation · once the compressor is on, it will not turn off for 30 seconds. However, it is turned off...

Page 36

4. Power transistor overheating prevention control · when the power transistor temperature rises to 110°c, the olp goes into operation and compressor stops immediately. The compressor is restarted when the power transistor temperature decreases to 95°c after 3 minutes (time delay safety control). 5....

Page 37

6. Low pressure control (gas leakage detection) · when the following conditions as shown in the below table occur, the compressor stops and restarts after 3 minutes. If this phenomenon is continuously occurring twice within 20 minutes, the air conditioner will stop operation and the timer led blinks...

Page 38

11. Outdoor air temperature control · the compressor operating frequency is regulated in accordance to the outdoor air temperature. 12. 2 way valve control ( protection of compressor ) · when the 2 way valve is on at a. 15 seconds later after the compressor started operation. ( on time of 2 way valv...

Page 39

9.2. Protection control for cooling & soft dry 1. Anti-freezing control · when the temperature of the indoor heat exchanger becomes low, the compressor operating frequency is reduced and stopped when the temperature falls to lower than 2°c continuously for 6 minutes. This is to prevent freezing of i...

Page 40

9.3. Protection control for heating operation 1. Intake air temperature control · when the intake air temperature is 10°c or above and remote control setting fan speed is less than medium, the compressor operates at 92hz. 2. High pressure control · the compressor operating frequency is regulated in ...

Page 41: 10.1. Outline

10 installation and servicing air conditioner using r410a 10.1. Outline 10.1.1. About r410a refrigerant 1. Converting air conditioners to r410a since it was declared in 1974 that chlorofluorocarbons (cfc), hydro chlorofluorocarbons (hcfc) and other substances pose a destructive danger to the ozone l...

Page 42

Conventional refrigerating machine oils. Also, these synthetic oils will degrade if mixed with mineral oil or alkylbenzene, causing clogging in capillary tubes or compressor malfunction. Do not mix them under any circumstances. 10.1.2. Safety measures when installing/servicing refrigerant piping cau...

Page 43

10.2.2. R410a tools 1. Copper tube gauge for clearance adjustment (used when flaring with the conventional flaring tool (clutch type)) · this gauge makes it easy to set the clearance for the copper tube to 1.0-1.5 mm from the clamp bar of the flaring tool. Fig. 1 copper tube gauge for clearance adju...

Page 44

5. Charging hose · the pressure resistance of the charging hose has been raised to match the higher pressure of r410a. The hose material has also been changed to suit hfc use, and the size of the fitting has been changed to match the manifold ports. Fig. 4 manifold gauge charging hose table 8 differ...

Page 45

9. Refrigerant cylinders · the r410a cylinders are labeled with the refrigerant name, and the coating color of the cylinder protector is pink, which is the color stipulated by ari of the u.S. · cylinders equipped with a siphon tube are available to allow the cylinder to stand upright for liquid refr...

Page 46

10.3. Refrigerant piping work 10.3.1. Piping materials it is recommended that you use copper and copper alloy jointless pipes with a maximum oil adherence of 40 mg/10 m. Do not use pipes that are crushed, deformed, or discolored (especially the inside surface). If these inferior pipes are used, impu...

Page 47

Table 12 r22 flaring dimensions nominal diameter outside diameter (mm) wall thickness (mm) a(mm) r410a flaring tool, clutch type conventional flaring tool clutch type wing-nut type 1/4 6.35 0.8 0 - 0.5 0.5 - 1.0 1.0 - 1.5 3/8 9.52 0.8 0 - 0.5 0.5 - 1.0 1.0 - 1.5 1/2 12.70 0.8 0 - 0.5 0.5 - 1.0 1.5 -...

Page 48

Precautions · be sure to read the instructions for the vacuum pump, vacuum pump adaptor and manifold gauge prior to use, and follow the instructions carefully. · make sure that the vacuum pump is filled with oil up to the designated line on the oil gauge. · the gas pressure back flow prevention valv...

Page 49

· press the test run button on the indoor unit, and allow preliminary operation for 5-6 minutes. (test run mode) · after stopping the operation, let the unit sit for about 3 minutes, then close the 2-way valve by turning the valve stem in the clockwise direction. · press the test run button on the i...

Page 50

7. Open the valve of the refrigerant cylinder, then open the charging valve slightly and close it. Next, press the check valve of the manifold gauge and purge the air. (2)(4) (watch the liquid refrigerant closely at this point.) 8. After adjusting the electronic scale to zero, open the charging valv...

Page 51

6. After taking the steps above, keep the nitrogen gas flowing until the piping cools down to a certain extent (i.E. Temperature at which pipes are touchable with finger). 7. Completely remove the flux after brazing. Fig. 14 prevention of oxidation during brazing * cautions during brazing 1. General...

Page 52

11 installation information 11.1. Attached accessories 11.2. Select the best location 11.2.1. Indoor unit · there should not be any heat source or steam near the unit. · there should not be any obstacles blocking the air circulation. · a place where air circulation in the room is good. · a place whe...

Page 53

11.2.3. Piping length 53 cs-mvg103ke / cu-mvg153ke.

Page 54

11.3. Indoor/outdoor unit installation diagram 54 cs-mvg103ke / cu-mvg153ke.

Page 55: 11.5. Note

11.4. Connection pipes for air conditioner units with r410a · it is necessary to use seamless copper pipes which are made of either copper or copper alloy and it is desirable that the amount of residual oil is less than 40mg / 10m. Do not use copper pipes having a collapsed, deformed or discolored p...

Page 56: 12 Servicing Information

12 servicing information 12.1. Troubleshooting 12.1.1. Rated frequency operation during troubleshooting and servicing, rated compressor operating frequency must be obtained in order to check the specification and technical data. Below are the methods used to obtain rated compressor operating specifi...

Page 57

Relationship between the condition of the air conditioner and pressure and electric current condition of the air conditioner cooling mode heating mode low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refrigerant (g...

Page 58

12.2. Self diagnosis display the diagnostic display can be seen on the receiver of the front grille. · when an abnormality occurs, the unit automatically stops, and the timer led blinks to indicate a malfunction. At the same time, the type of abnormality will be indicated on the receiver as shown in...

Page 59

Diagnosis display abnormality/protection control abnormality judgement temporary operation primary location to verify h23 indoor heat exchanger temperature sensor 1 abnormality ● (cooling only) · heat exchanger temperature sensor (defective or disconnected) h24 indoor heat exchanger temperature sens...

Page 60: 12.3. Remote Control

12.3. Remote control 12.3.1. Remote control reset when the batteries are inserted for the first time, or the batteries are replaced, all the indications will blink and the remote control might not work. If this happens, remove the back cover of the remote control and you will find a resetting termin...

Page 61

12.4. Disassembly of parts 12.4.1. Indoor control board removal procedure 1. Remove the front grille fig1 fig2 2. Remove the indoor control board. Fig3 fig4 61 cs-mvg103ke / cu-mvg153ke.

Page 62

12.4.2. Removal of electronic controller procedure fig5 fig6 fig7 fig8 fig9 fig10 62 cs-mvg103ke / cu-mvg153ke.

Page 63

12.4.3. Indoor fan motor removal procedure fig11 fig12 fig13 fig14 fig15 63 cs-mvg103ke / cu-mvg153ke.

Page 64

12.4.4. Cross flow fan removal procedure 1. Remove discharge grille fig16 2. Remove cross flow fan fig17 fig18 fig19 64 cs-mvg103ke / cu-mvg153ke.

Page 65

12.4.5. Removal procedure of the control board 1. Remove the cabinet top plate. (four screws) (fig.20) fig. 20 2. Remove the front grille. (three screws, six tabs) (fig.21) fig. 21 3. Remove the control board cover (top). (four tabs) (fig.22) fig. 22 65 cs-mvg103ke / cu-mvg153ke.

Page 66

4. Remove the control board cover (front). (three tabs) (fig.23) fig. 23 5. Remove all connectors which are connected to the control board and remove the main control board from the power supply board. (three screws, four tabs) (fig.24) fig. 24 6. Remove the noise filter. (six tabs) (fig.25) fig. 25...

Page 67

7. Remove the transistor. (two screws) (fig.26) fig. 26 8. Remove the diode. (one screws) (fig.27) fig. 27 12.4.6. Removal procedure of the propeller fan and the motor 1. Remove the cabinet top plate and the front grille. (fig.20) 2. Remove the propeller fan by rotating the nut at the center of the ...

Page 68

4. Remove all connectors which are connected to the motor from the main control board. 5.Remove the motor by releasing four screws. (fig.29) fig. 29 68 cs-mvg103ke / cu-mvg153ke.

Page 69: 13 Technical Data

13 technical data 13.1. Operation characteristics 69 cs-mvg103ke / cu-mvg153ke.

Page 70

70 cs-mvg103ke / cu-mvg153ke.

Page 71: 14.2. Timer Table

Before the circuit diagram, read the following carefully. Voltage measurement voltage has been measured with a digital tester when the indoor fan is set at high fan speed under the following conditions without setting the timer. Use them for servicing. Voltage indication is in red at cooling and all...

Page 72: 14.3. Indoor Unit

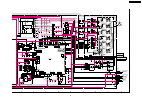

14.3. Indoor unit 16 15 14 13 12 11 10 7 6 5 4 3 2 1 8 9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 r42 150k x1 ...

Page 73

1 2 3 4 5 r70 200k c5 2200p 1 2 3 4 r73 1/4w 1k r66 330 Ω r64 7.5k c4 1000p thermal fuse 1 2 3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 4 5 3 2 1 6 7 8 9 10 11 12 13 14 15 16 to outdoor unit thermal fuse cn-pwr1 (jl16) fuse1 t3.15a l250v 102 c(3a) znr1 znr2 d6 r76 2ws 15k d3 r68 68o Ω r74 1/2w 20k r75...

Page 74: 14.4. Outdoor Unit

14.4. Outdoor unit 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 25 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 cn-hot cn-2cv cn-fm cn-rooma cn-roomb cn-eva cn-ev...

Page 75

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 r51 10k c26 1000p da143xk reception da143xk reception da143xk transmi...

Page 76: 14.5. Remote Controller

14.5. Remote controller wireless remote control cwa 755c2020 1 seg 6 64 seg 7 63 seg 8 62 seg 9 61 seg 10 60 seg 11 59 seg 12 58 seg 13 57 seg 14 56 seg 15 55 seg 16 54 seg 17 53 seg 18 52 seg 19 51 seg 20 50 seg 21 49 seg 22 seg 7 seg 8 seg 9 seg 10 seg 11 seg 12 seg 13 seg 14 seg 15 seg 16 seg 17 ...

Page 77: 15 Printed Circuit Board

15 printed circuit board 15.1. Indoor unit cs-mvg103ke main pcb ( front side ) display pcb ( front side ) ( back side ) 77 cs-mvg103ke / cu-mvg153ke.

Page 78

Cs-mvg103ke main pcb ( back side ) receiver pcb 78 cs-mvg103ke / cu-mvg153ke.

Page 79

15.2. Outdoor unit / main pcb cu-mvg153ke main pcb ( front side ) cs- mvg1 03ke / c u -mvg1 53ke 79.

Page 80

Cu-mvg153ke main pcb ( back side ) cs- mvg1 03ke / c u -mvg1 53ke 80

Page 81

15.3. Outdoor unit / transistor module cu-mvg153ke transistor module pcb ( front side ) ( back side ) 81 cs-mvg103ke / cu-mvg153ke.

Page 82: 16.1. Cs-Mvg103Ke

16 exploded view & replacement parts list 16.1. Cs-mvg103ke 16.1.1. Exploded view 82 cs-mvg103ke / cu-mvg153ke.

Page 83

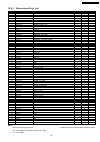

16.1.2. Replacement parts list no. Cs-mvg103ke description & name q’ty remarks 1 cwa28c2004 terminal board complete 1 m ● ● ● ● 2 cwa50c2023 sensor complete 1 m ● ● ● ● 3 cwa67c2106 lead wire complete 1 m 4 cwa67c2310 lead wire complete 1 m 5 cwa741553 pc board with component 1 m ● ● ● ● 6 cwa742020...

Page 84: 16.2. Cu-Mvg153Ke

16.2. Cu-mvg153ke 16.2.1. Exploded view 84 cs-mvg103ke / cu-mvg153ke.

Page 85

(note) · spare parts are supplied from ; "m" is from macc, malaysia (vender code : 086). "j" is from japan. · " " marked parts are recommended to be kept in stock. 16.2.2. Replacement parts list no. Cu-mvg153ke part name & description q’ty remarks 1 cwa28c2006 terminal board complete 1 j 2 cwa28k217...

Page 86: 17 Electronic Parts List

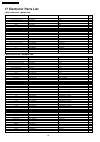

17 electronic parts list ( model:cwa742020 ) indoor pcb symbol part no. Description & name rema rks bz1 a48040 buzzer m d1,d2,d4,d5,d7,d8 a541ss355t diode m d3,d6,d9 a54dif60 diode m db1 a54d3sba60f1 diode bridge m fuse xba2c31tr0 fuse m ic1 a5278366f105 intergrated circuit m ic2 a52br9020f intergra...

Page 87

Symbol part no. Description & name rema rks ry-l a00207m relay m ry-pwr a00139 relay m ry-hot,ry-2cv a00207m relay m znr200,znr201 erzveav271 znr m x1 a45ccc6mh02t resonator m x2 a45ccc4mh02t resonator m (note) · spare parts are supplied from ; "m" is from macc, malaysia (vender code : 086). "j" is ...