- DL manuals

- Panasonic

- Air Conditioner

- CS-PA12DKD

- Service Manual

Panasonic CS-PA12DKD Service Manual

CS/CU-PC12DKD

CS/CU-PA12DKD

Air Conditioner

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-techical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

1 Features

2

2 Functions

3

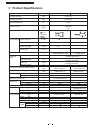

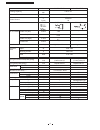

3 Product Specifications

6

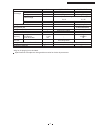

4 Dimensions

10

5 Refrigeration Cycle Diagram

12

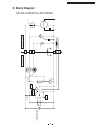

6 Block Diagram

13

7 Wiring Diagram

15

8 Operation Details

17

9 Installation Insruction

31

10 2-way,3-way Valve

11

Disassembly of The Parts

12 Troubleshooting Guide

13 Technical Data

14 Exploded View

15 Replacement Parts List

16 Exploded View

17 Replacement Parts List

18 Electronic Circuit Diagram

CONTENTS

Page

Page

Order No. GMAC0504039C3

Guangzhou Matsushita Air Conditioner Co., Ltd.

(GMAC) All rights reserved. Unauthorized copying

and distribution is violation of law.

C

R

41

48

51

53

55

56

57

58

59

------------------------------------------------------

--------------------------------------------------------

------------------------------------------

-----------------------------------------------------

-----------------------------------

--------------------------------------------------

-------------------------------------------------

-----------------------------------------------

---------------------------------------------------

-----------------------------------------------------

--------------------------------------

----------------------------------------

--------------------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------

R

OFF

MODE

TEMP

OFF/ON

ON

CANCEL

SET

STD

TIMER

FAN

SPEED

AIR

SWING

Summary of CS-PA12DKD

Page 1

Cs/cu-pc12dkd cs/cu-pa12dkd air conditioner warning this service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not contain warnings or cautions to advise non-techical individuals of potential dangers in attempting to servic...

Page 2: 1 Features

2 1 features high efficiency air quality indicator comfort environment air filter with function to reduce dust and smoke auto restart control automatically restart after power failure 12-hour timer setting cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd.

Page 3: Functions

Operation start/stop operation mode selection automatic operation heating mode operation (for pa12dkd) cooling mode operation soft dry mode operation air circulation mode operation (for pc12dkd) mode indoor fan speed selection low speed medium speed high speed automatic speed airflow direction contr...

Page 4

Indoor unit demonstration mode when the remote control cannot be used or for repairing and testing ,please use this button. Power switch on/off signal receiving sound control keep pressing this button for 10seconds to turn on or turn off the signal receiving sound. Operation indication lamps power (...

Page 5

Outdoor unit 5 panasonic anti-reverse protection to protect the compressor from reverse rotation when power off suddenly. Overload protector the 2-step overload protector is to protect the compressor when 1)temperature of compressor reaches 2)high temperature or current enters into the compressor 14...

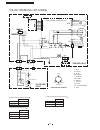

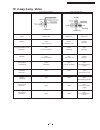

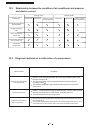

Page 6: 3 Product Specifications

6 3 product specifications cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd cooling capacity heating capacity moisture removal power source airflow method air circulation indoor air (low) indoor air (medium) indoor air (high) outdoor air noise level electrical data piping connection port(flare pipi...

Page 7

7 specifications are subject to change without notice for further improvement. * 60g for air purging is not included. Cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd heat exchanger description tube material fin type fpi refrigerant control device refrigeration oil refrigerant (r-22) thermostat pro...

Page 8

8 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd cooling capacity moisture removal power source airflow method air circulation indoor air (low) indoor air (medium) indoor air (high) outdoor air noise level electrical data piping connection port(flare piping) piping size(flare piping) drain hose p...

Page 9

Specifications are subject to change without notice for further improvement. * 60g for air purging is not included. 9 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd heat exchanger description tube material fin type fpi refrigerant control device refrigeration oil refrigerant (r-22) thermostat pro...

Page 10: 4 Dimensions

4 dimensions indoor unit 10 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd b a 254 (631) (382) (118) (131) 95 61 165 49 (420) (50) front view installation plate hook gas side liquid side drain port 790 air intake 280 49 61 5 side view 183 air outlet left piping hole right piping hole (100) off mo...

Page 11

Outdoor unit unit : mm 11 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd more than 10cm more than 100 cm 780 48 570 34.5 289 540 18 320 352 16 291 274 inverter more than 10cm.

Page 12

Cs/cu-pa12dkd 5 refrigeration cycle diagram intake air sensor intake air sensor piping sensor piping sensor piping sensor piping sensor cs/cu-pc12dkd air quality sensor 12 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd intake air sensor piping sensor 4-way valve piping sensor air quality sensor c...

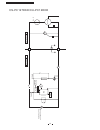

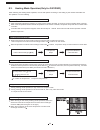

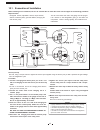

Page 13: 6 Block Diagram

Cs-pa12dkd/cu-pa12dkd 6 block diagram fm fm 2 cr201 3 4 1 r y -hot ssr202 ssr201 fuse r y -pwr outdoor unit receiver remote control fm 4-v alve compressor sensor indicator piping sensor o.L.P . Indoor unit 13 power suppl y ac220v -230v 50hz cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd.

Page 14

Fm ssr201 sc fuse r y -pwr fm compressor cs-pc127dkd/cu-pc12dkd receiver remote control sensor indicator 14 power suppl y ac220v -230v 50hz cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd o.L.P ..

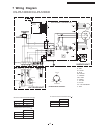

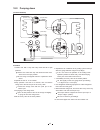

Page 15: 7 Wiring Diagram

Cs-pa12dkd/cu-pa12dkd 7 wiring diagram 15 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd compressor terminal br bl w r b b y/g indoor unit terminal board fuse 102 250v 3a y w b b b y y r y/g capacitor capacitor r compressor fan motor sensor(piping temp .) y/g fuse electronic controller 1 3 5 b r ...

Page 16

Cs-pc12dkd/cu-pc12dkd 16 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd wireless remote control indicator complete w w w w w w w w w w w electronic controller br r o y p b r y w br bl sensor(piping temp.) auto switch b y/g w ac(wht) thermal fuse 102 (250v 3a) y/g ventilation signal transmitter(pu...

Page 17: 8 Operation Details

17 8 operation details 8.1 . Cooling mode operation when selecting the cooling mode operation, the unit will operate according to the setting by the remote controller or the control panel on the indoor unit and the operation is as the following. Time delay safety control 3 min.----if the compressor ...

Page 18

18 intake air temperature evaporater temperature 10 2 start stop 1.5 basic time comp. Indoor fan outdoor fan operation indicator 1 1 3 7 operation status time delay safety control compressor test control auto restart control anti-freezing control time d - g g - h h - o q - t : : : : operate stop a b...

Page 19

19 automatic fan speed during soft dry operation, use remote controller to select auto fan speed mode. Indoor fan speed is at “lo-” 70 t2 40 t1 slo lo- off on off 10 6 70 t2 40 t1 10 slo slo lo- on off off off indoor fan compressor time graph for soft dry operation a b c d e f g h i j k l m n o p q ...

Page 20

8.3. Heating mode operation(only for pa12dkd) when selecting the heating mode operation, the unit will operate according to the setting by the remote controller and the operation is as the following. Time delay safety control over load protection control when temperature of indoor heat exchanger ris...

Page 21

A b c d e f g h i j k l m n o p q r 2 42 34 32 30 off on 1' 58'' 30 30' 150' indoor heat exchanget temp. Intake temp. Basic time compressor indoor fan outdoor fan operation indicator 4-way valve automatic fan speed during heating operation, use remote controller to select auto fan speed mode. Indoor...

Page 22

22 deice control deice operation is to protect the outdoor unit from freezing. Normal deice operation deicing starts 30 minutes after heating mode operation or 60 minutes after the latest deicing operation. If temperature of outdoor piping, tested by trs, falls to -3 (trs off) or below for continuou...

Page 23

Time graph for overload deicing a b c d e f g h i j k l m n o p q 49 max 12’ overload control a-i i-l overload deicing(timer) l-m: warm booting control m-r overload control out door fan stop for 60' accumulatively 20’’ 20’’ 51 outdoor heat exchanger outdoor heat exchanger 10’’ 20’’ basic time compre...

Page 24

8.4 automatic mode operation standard for determining operation mode cooling mode soft dry mode heating mode cooling mode soft dry mode heating mode intake air temperature setting temperature (standard) 23 20 25 22 21 one hour after the above determination, the unit will operate according to the tab...

Page 25

8.6 air quality sensor control 20minutes max1 max2 max3 max0 max1 max2 maximum of rs maxr1 of previous measuring period updating of maxr max1 max0 max0 max1 max0 max1 max2 max1 max1 max2 max1 max2 max3 max2 max2 max3 max2 max3 20minutes 20minutes the following conditions should be fulfilled the init...

Page 26

26 air quality control detecting of air quality(when the air conditioner is on standby.) rs/maxr will be calculated automatically every 2 seconds and the air quality level will be determined in accordance with the value below, signal of air quality sensor air quality level a i r q u a l i t y gettin...

Page 27

27 added operation of air quality sensor when the air quality getting worse if the air pollution level changes from 0 to 2, the color of the air quality indicator changes as below, green orange (2 sec.) red when the air quality getting better (added operation ) if the air pollution level changes fro...

Page 28

28 8.7demo mode ( outdoor unit not needed) activate the demo mode: in demo mode, the air conditioner can be operated(if the outdoor unit is connected to the indoor unit); whenever you turned off the air conditioner, it will restart automatically into demo mode opertion. Keep the auto button on the i...

Page 29

Auto heat cool dry off auto std fan speed air swing auto 8.9 about cursor key which points to “off” on remote control auto heat cool dry off auto std press "off/on" button fan speed air swing auto 1. 2. When the on/off button on the remote control is pressed, the cursor key which points to “off” wil...

Page 30

30 8.12. Airflow direction control cooling soft dry operating mode determining operation mode manual auto manua auto 1 2 3 4 5 12 17 26 32 36 o o o o o 12 ~36 o o 9 o 9 21 29 44 55 o o o o o heating 9 ~55 o o airflow direction auto-control the left and right airflow direction louver can be adjusted ...

Page 31

9 installation instructions required tools for installation works 1. Philips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter 2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench 18 n.M (1.8 kgf.M) 42 n.M (4.2 kgf.M) 55 n.M (5.5 kgf.M) 3. Electric drill, hole core drill (ø70...

Page 32

1. The equipment must be earthed. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in ins...

Page 33

Select the best location indoor unit there should not be any heat source or steam near the unit. There should not be any obstacles blocking the air circulation. A place where air circulation in the room is good. ıa place where drainage can be easily done. ıa place where noise prevention is taken int...

Page 34

9.2.1. Select the best location (refer to “select the best location” section) 9.2.2. How to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The centre of installation plate should be at more than 450 mm at right and left of the wall. The distance...

Page 35

Cs-pc12dkd/ cu-pc12dkd / cs-pa12dkd / cu-pa12dkd 35.

Page 36

9.2.5. Connect the cable to the indoor unit 1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 5 (pa12dkd) x 1.5 mm 2 flexible cord, type designation 245 ie...

Page 37

How to take out front grille please follow the steps below to take out front grille if necessary such as when servicing. 1. Set the vertical airflow direction louver to the horizontal position. 2. Slide down the two caps on the front grille as shown in the illustration at right, and then remove the ...

Page 38

Cutting and flaring the piping 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut ...

Page 39

(1) * * connect the manifold gauge to the service port of 3-way valve. Measure the pressure. (2) * * keep it for 5-10 minutes. Ensure that the pressure indicated on the gauge is the same as that of measured during the first time. 9.3.5. (b) air purging of the piping and indoor unit the remaining air...

Page 40

Disposal of outdoor unit drain water ıı ı if a drain elbow is used, the unit should be placed on a stand which is taller than 3 cm. ı if the unit is used in an area where temperature falls below 0°c for 2 or 3 days in succession, it is recommended not to use a drain elbow, for the drain water freeze...

Page 41: 10 2-Way,3-Way Valve

10 2-way,3-way valve 2-way valve (liquid side) works shaft position shaft position service port shipping close closed closed (with cap) air purging(installation and re- installation) open closed open (counter-clockwise) (clockwise) (push-pin) operation open open closed (counter-clockwise) (with cap)...

Page 42

10.1. Evacuation of installation when installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure. Required tools: hexagonal wrench, adjustable wrench, torque wrench, wrench to hold the joints, gas leak detector, charging set and vacuum pump...

Page 43

(indoor unit) (liquid side) (outdoor unit) open 2-way valve (gas side) closed 3-way valve closed closed low high 10.2. Pumping down (for re-installation) procedure 1.Confirm that both 2-way and 3-way valves are set to open positions. Remove the valve stem cap and confirm that the valve stems are in ...

Page 44

10.3.Re-air purging (re-installation) (indoor unit) (liquid side) (outdoor unit) 2-way valve (gas side) open 3-way valve open low high open closed vacuum pump be sure to connect the end of the charging hose with the push pin to the service port. 2. 3. 4. 1.Connect a charging hose with a push pin to ...

Page 45

10.4. Balance refrigerant of the 2-way,3-way walves (gas leakage) (indoor unit) (liquid side) (outdoor unit) 2-way valve (gas side) open 3-way valve open low high open closed vacuum pump procedure 1. 2. Leave the valve on the charge set closed. Connect the charge hose with the push-pin to the servic...

Page 46

10.5. Evacuation (installation) (no refrigerant in the refrigeration cycle) (indoor unit) (liquid side) (outdoor unit) 2-way valve (gas side) open 3-way valve open low high open closed vacuum pump procedure 1. 2. Confirm that the gauge needle has moved toward -76cmhg (-0.1mpa) [vacuum of 4 mmhg or l...

Page 47

10.6. Gas charging (after evacuation) (indoor unit) (liquid side) (outdoor unit) 2-way valve (gas side) open 3-way valve open low high open closed charging cylinder procedure 1.Connect the charge hose to the charging cylinder. 2.Purge the air from the charge hose. 3 open the valve (low side) on the ...

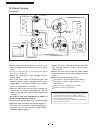

Page 48: Disassembly Of The Parts

48 11 disassembly of the parts 1. Open the intake grille and pull it to the horizontal position. (fig. 1) 2. Pull up the intake grille until it falls off.(fig. 2) removal procedure for intake grille 1.Remove the two caps at the discharge port (right and left) (fig. 3) 2.Release the two screws under ...

Page 49

49 2 remove the cover of control board and holder removal procedure for electronic controller 4. Release the lead wire cn-fm, cn-vf, cn-stm, cn-disp and earth wire(yellow/green). Take out the sensor from the socket. Pull out the whole electronic controller. Removal procedure for the discharge grille...

Page 50

Removal procedure for cross flow fan remote control reset if the display is chaotic or can not be adjusted, remove the back lid of the remote control and you will find the resetting terminals and shorten the two terminals using a screw driver to reset. Resetting terminals fig 16 50 1. (fig. 12) rele...

Page 51: 12 Troubleshooting Guide

51 in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of compressor or fan. The normal outlet air temperature and pressure of the refri...

Page 52

52 condition of the air conditioner insufficient refrigerant (gas leakage) clogged capillary tube short circuit in the indoor unit heat radiation deficiency of the outdoor unit insufficient compression cooling mode low pressure high pressure electric current during operation 12.2. Relationship betwe...

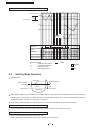

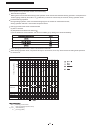

Page 53: 13 Technical Data

53 thermostat characteristics soft dry mode cooling on cooling off set temperature = soft dry off soft dry on 1.5 in difference 1.0 in difference temperature setting intake air temperature cooling mode compressor on compressor off= set temperature 1.5 in difference temperature setting intake air tem...

Page 54

Cooling characteristics 54 cs/cu-pa12dkd 30 32 34 36 38 40 42 44 220v 17 16 15 14 13 0.70 0.65 0.60 0.55 0.50 3.7 3.5 3.3 3.1 5.2 5.0 4.8 4.6 i: current (a) q: cooling capacity (kw) lp: gas side piping pressure (mpa) o:outlet air temp( ) outdoor temp( ) [condition] room temp: 27/19 cooling operation...

Page 55: 14 Exploded View

Cs-pa12dkd 14 exploded view 35 1 3 4 37 2 27 34 17 5 25 10 32 33 29 26 31 33 32 30 11 13 9 12 28 22 19 15 8 23 14 20 21 24 16 off mode temp off/on on cancel set std timer fan speed air swing 36 55 16 cs-pc12dkd cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd.

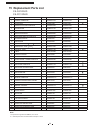

Page 56: 15 Replacement Parts List

15 replacement parts list 56 note: 1.All parts are supplied from gmac, p.R. China. 2."*" marked parts are recommended to be kept in stock. Cs-pa12dkd cs-pc12dkd cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd no. Description&name q'ty cs-pa12dkd cs-pc12dkd re 1 chassis complete 1 cwd50c1423 cwd50c...

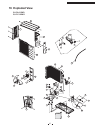

Page 57: 16 Exploded View

16 exploded view cu-pa12dkd 57 36 33 35 34 37 4 5 3 2 6 7 28 26 24 27 25 38 23 11 29 22 21 20 32 14 8 10 9 1 13 15 17 12 19 31 30 16 18 cu-pc12dkd cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd.

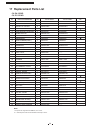

Page 58: 17 Replacement Parts List

17 replacement parts list cu-pa12dkd cu-pc12dkd 58 note: 1.All parts are supplied from gmac, p.R. China. 2."*" marked parts are recommended to be kept in stock. No. Description&name q'ty cu-pa12dkd cu-pc12dkd re 1 base ass'y 1 cwd50k2124a cwd50k2122a 2 holder-fan motor 1 cwd541020 cwd541020 3 screw-...

Page 59

B c d e f 1 2 3 4 7 ry-pwr k6biaga00076 znr2 erzv10d511 c16 0.1 250v ac ecq 3 5 ac(wht) 12 13 14 15 16 17 2 3 cr1 ry-hot ac 220v/230vv, 50hz 1 2 1 2 2 20 21 22 23 1 1 0.047 c13 l5 3 4 5 znr1 ct fm(blu) r43 d15 c28 out-th1 out-th2 25 r9 1k r8 c27 27 yellow red blue tf cn-fm vh5-3 (wht) 28 15.8k 1% c-...

Page 60

5 6 7 8 9 10 piping temp sensor (20k 3950) 10 8 t01 50 4 51 3 2 db01 1 1 2 c1 3300u 35v 12v ic3 3 1 2 5v ic2 3 53 c19 470u 25v 54 55 56 57 58 c2 100u 16v r45 12k 12k r46 d2 d1 r49 1k r50 1k 150 a55c2412ktx q1 c18 128 r47 1.3k r48 1.2k 0.01u c29 0.1u 149 05 9 71c7g 61c7f 51c7e 41c7d 31c7c 21c7b 11c7a...

Page 61

11 12 1 2 3 4 ac1 ssr m cn-disp (ylw) ph11 1 2 3 4 5 6 7 8 9 10 11 oxygen/clam grn d101 air temp sensor (15k 3950) timer org d103 off/0n d102 grn d104 2 3 1 sen2 3 2 1 4 r201 3 vcc ic201 r vout gnd pd receiver c201 22u 6.3v 2 1 5 4 100 erlocking ventilator unit(optional) table1 a53d0877 a53d0878 non...

Page 62

62 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd.

Page 63

63 cs-pc12dkd / cu-pc12dkd / cs-pa12dkd / cu-pa12dkd.