- DL manuals

- Panasonic

- Air Conditioner

- CS-PC12QKH

- Service Manual

Panasonic CS-PC12QKH Service Manual

© Panasonic Corporation 2013

Order No: PAPAMY1312019CE

Indoor Unit

Outdoor Unit

CS-PC9QKH

CS-PC12QKH

CS-PC18QKH

CS-PC24QKH

CS-PC28QKH

CU-PC9QKH

CU-PC12QKH

CU-PC18QKH

CU-PC24QKH

CU-PC28QKH

Destination

Myanmar

South East Asia

North Africa

Bangladesh

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the products dealt with in this service information by anyone else could result in serious injury or death.

WARNING

Summary of CS-PC12QKH

Page 1

© panasonic corporation 2013 order no: papamy1312019ce indoor unit outdoor unit cs-pc9qkh cs-pc12qkh cs-pc18qkh cs-pc24qkh cs-pc28qkh cu-pc9qkh cu-pc12qkh cu-pc18qkh cu-pc24qkh cu-pc28qkh destination myanmar south east asia north africa bangladesh this service information is designed for experienced...

Page 2: Table of Contents

2 table of contents page page 1. Safety precautions .............................................3 2. Specification .......................................................5 3. Features.............................................................15 4. Location of controls and components..........16 4...

Page 3: 1. Safety Precautions

3 caution warning warning 1. Safety precautions read the following “safety precautions” carefully before perform any servicing. Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. The c...

Page 4

4 caution 20. After completion of installation or service, confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant contacts with fire. 21. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant contacts with ...

Page 5: 2. Specification

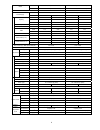

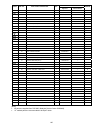

5 2. Specification indoor cs-pc9qkh (others/s. E. Asia) cs-pc12qkh (others/s. E. Asia) model outdoor cu-pc9qkh (others/s. E. Asia) cu-pc12qkh (others/s. E. Asia) performance test condition new jis new jis phase, hz single, 50 single, 50 power supply v 220 240 220 240 kw 2.65 2.70 3.49 3.54 btu/h 904...

Page 6

6 indoor cs-pc9qkh (others/s. E. Asia) cs-pc12qkh (others/s. E. Asia) model outdoor cu-pc9qkh (others/s. E. Asia) cu-pc12qkh (others/s. E. Asia) height(i/d / o/d) mm (inch) 290 (11-7/16) / 511 (20-1/8) 290 (11-7/16) / 511 (20-1/8) width (i/d / o/d) mm (inch) 850 (33-15/32) / 650 (25-19/32) 850 (33-1...

Page 7

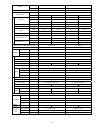

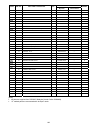

7 indoor cs-pc9qkh (myanmar) cs-pc12qkh (myanmar) model outdoor cu-pc9qkh (myanmar) cu-pc12qkh (myanmar) performance test condition new jis new jis phase, hz single, 50 single, 50 power supply v 220 240 220 240 kw 2.65 2.70 3.49 3.54 btu/h 9040 9210 11900 12100 capacity kj/h 9540 9720 12560 12740 ru...

Page 8

8 indoor cs-pc9qkh (myanmar) cs-pc12qkh (myanmar) model outdoor cu-pc9qkh (myanmar) cu-pc12qkh (myanmar) height(i/d / o/d) mm (inch) 290 (11-7/16) / 511 (20-1/8) 290 (11-7/16) / 511 (20-1/8) width (i/d / o/d) mm (inch) 850 (33-15/32) / 650 (25-19/32) 850 (33-15/32) / 650 (25-19/32) dimension depth (...

Page 9

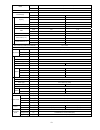

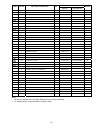

9 indoor cs-pc18qkh (others/s. E. Asia) cs-pc24qkh (others/s. E. Asia) model outdoor cu-pc18qkh (others/s. E. Asia) cu-pc24qkh (others/s. E. Asia) performance test condition new jis new jis phase, hz single, 50 single, 50 power supply v 220 240 220 240 kw 5.28 5.30 6.93 7.03 btu/h 18000 18100 23600 ...

Page 10

10 indoor cs-pc18qkh (others/s. E. Asia) cs-pc24qkh (others/s. E. Asia) model outdoor cu-pc18qkh (others/s. E. Asia) cu-pc24qkh (others/s. E. Asia) height(i/d / o/d) mm (inch) 290 (11-7/16) / 542 (21-11/32) 290 (11-7/16) / 695 (27-3/8) width (i/d / o/d) mm (inch) 1070 (42-5/32) / 780 (30-23/32) 1070...

Page 11

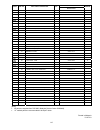

11 indoor cs-pc18qkh (myanmar) cs-pc24qkh (myanmar) model outdoor cu-pc18qkh (myanmar) cu-pc24qkh (myanmar) performance test condition new jis new jis phase, hz single, 50 single, 50 power supply v 220 240 220 240 kw 5.28 5.30 6.93 7.03 btu/h 18000 18100 23600 24000 capacity kj/h 19010 19080 24950 2...

Page 12

12 indoor cs-pc18qkh (myanmar) cs-pc24qkh (myanmar) model outdoor cu-pc18qkh (myanmar) cu-pc24qkh (myanmar) height(i/d / o/d) mm (inch) 290 (11-7/16) / 542 (21-11/32) 290 (11-7/16) / 695 (27-3/8) width (i/d / o/d) mm (inch) 1070 (42-5/32) / 780 (30-23/32) 1070 (42-5/32) / 875 (34-15/32) dimension de...

Page 13

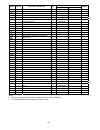

13 indoor cs-pc28qkh (others/s. E. Asia) model outdoor cu-pc28qkh (others/s. E. Asia) performance test condition new jis phase, hz single, 50 power supply v 220 240 kw 7.90 8.00 btu/h 26900 27300 capacity kj/h 28440 28800 running current a 14.0 13.1 input power w 2.99k 3.04k w/w 2.64 2.63 eer btu/hw...

Page 14

14 indoor cs-pc28qkh (others/s. E. Asia) model outdoor cu-pc28qkh (others/s. E. Asia) height(i/d / o/d) mm (inch) 290 (11-7/16) / 750 (29-17/32) width (i/d / o/d) mm (inch) 1070 (42-5/32) / 875 (34-15/32) dimension depth (i/d / o/d) mm (inch) 240 (9-15/32) / 345 (13-19/32) weight net (i/d / o/d) kg ...

Page 15: 3. Features

15 3. Features long installation piping o cs/cu-pc9qk long piping up to 10 meters. O cs/cu-pc12qk long piping up to 15 meters. O cs/cu-pc18qk, pc24qk long piping up to 25 meters. O cs/cu-pc28qk long piping up to 30 meters. Easy to use remote control quality improvement o random auto restart after po...

Page 16

16 4. Location of controls and components 4.1 indoor unit 4.2 outdoor unit 4.3 remote control.

Page 17: 5. Dimensions

17 5. Dimensions 5.1 indoor unit 5.1.1 cs-pc9qkh cs-pc12qkh.

Page 18

18 5.1.2 cs-pc18qkh cs-pc24qkh cs-pc28qkh.

Page 19

19 5.2 outdoor unit 5.2.1 cu-pc9qkh cu-pc12qkh 5.2.2 cu-pc18qkh.

Page 20

20 5.2.3 cu-pc24qkh 5.2.4 cu-pc28qkh.

Page 21

21 6. Refrigeration cycle diagram.

Page 22: 7. Block Diagram

22 7. Block diagram 7.1 cs-pc9qkh cu-pc9qkh cs-pc12qkh cu-pc12qkh cs-pc18qkh cu-pc18qkh.

Page 23

23 7.2 cs-pc24qkh cu-pc24qkh.

Page 24

24 7.3 cs-pc28qkh cu-pc28qkh.

Page 25

25 8. Wiring connection diagram 8.1 cs-pc9qkh cu-pc9qkh cs-pc12qkh cu-pc12qkh resistance of indoor fan motor windings resistance of indoor fan motor windings cs-pc9qkh cs-pc12qkh model others/s. E. Asia myanmar model others/s. E. Asia myanmar connection cwa921562 cwa921559 connection cwa921561 cwa92...

Page 26

26 8.2 cs-pc18qkh cu-pc18qkh resistance of indoor fan motor windings resistance of compressor windings cs-pc18qkh cu-pc18qkh model others/s. E. Asia myanmar model others/s. E. Asia myanmar connection cwa921459 connection 2ks314d5ca06 2ks314d5ba06 blue-yellow 230 Ω c-r 2.298 Ω 1.853 Ω yellow-red 298 ...

Page 27

27 8.3 cs-pc24qkh cu-pc24qkh resistance of outdoor fan motor windings resistance of compressor windings model cu-pc24qkh cu-pc24qkh connection cwa951697 model others/s. E. Asia myanmar blue-yellow 70 Ω connection 2js438d3ga04 2js438d3ea04 yellow-red 51 Ω c-r 1.338 Ω 1.156 Ω yellow-orange 69 Ω c-s 2....

Page 28

28 8.4 cs-pc28qkh cu-pc28qkh resistance of outdoor fan motor windings resistance of compressor windings model cu-pc28qkh model cu-pc28qkh connection cwa951697 connection 2jd514e3aa03 blue-yellow 70 Ω c-r 1.022 Ω yellow-red 51 Ω c-s 2.142 Ω yellow-orange 69 Ω note: resistance at 20°c of ambient tempe...

Page 29

29 9. Electronic circuit diagram 9.1 cs-pc9qkh cu-pc9qkh cs-pc12qkh cu-pc12qkh.

Page 30

30 9.2 cs-pc18qkh cu-pc18qkh.

Page 31

31 9.3 cs-pc24qkh cu-pc24qkh.

Page 32

32 9.4 cs-pc28qkh cu-pc28qkh.

Page 33: 10. Printed Circuit Board

33 10. Printed circuit board 10.1 indoor unit 10.1.1 main printed circuit board 10.1.1.1 cs-pc9qkh cs-pc12qkh.

Page 34

34 10.1.1.2 cs-pc18qkh.

Page 35

35 10.1.1.3 cs-pc24qkh.

Page 36

36 10.1.1.4 cs-pc28qkh.

Page 37

37 10.1.2 indicator and receiver printed circuit board 10.1.2.1 cs-pc9qkh cs-pc12qkh 10.1.2.2 cs-pc18qkh cs-pc24qkh cs-pc28qkh.

Page 38: 11. Installation

38 11. Installation instruction (for pc9qkh, pc12qkh, pc18qkh, pc24qkh only) 11.1 select the best location 11.1.1 indoor unit do not install the unit in excessive oil fume area such as kitchen, workshop and etc. There should not be any heat source or steam near the unit. There should not be any obst...

Page 39

39 11.2 indoor unit 11.2.1 how to fix installation plate the mounting wall shall be strong and solid enough to prevent it from the vibration. Dimension model 1 2 3 4 5 6 pc9***, pc12*** 480 mm 82 mm 425 mm 425 mm 93 mm 145 mm dimension model 1 2 3 4 5 6 pc18***, pc24*** 590 mm 82 mm 539 mm 532 mm 21...

Page 40

40 11.2.2 to drill a hole in the wall and install a sleeve of piping 1 insert the piping sleeve to the hole. 2 fix the bushing to the sleeve. 3 cut the sleeve until it extrudes about 15 mm from the wall. Caution when the wall is hollow, please be sure to use the sleeve for tube assembly to prevent d...

Page 41

41 11.2.3 indoor unit installation 11.2.3.1 for the right rear piping 11.2.3.2 for the right and right bottom piping 11.2.3.3 for the embedded piping (this can be used for left rear piping and bottom piping also.).

Page 42

42 11.2.4 connect the cable to the indoor unit the power supply cord, indoor and outdoor unit connection cable can be connected without removing the front grille. 1 install the indoor unit on the installing holder that mounted on the wall. 2 open the front panel and grille door by loosening the scre...

Page 43

43 7 remove the tapes and connect the power supply cord and connection cable between indoor unit and outdoor unit according to the diagram below. 8 secure the power supply cord and connection cable onto the control board with the holder. 9 close grille door by tighten with screw and close the front ...

Page 44

44 11.3 outdoor unit 11.3.1 install the outdoor unit after selecting the best location, start installation to indoor/outdoor unit installation diagram. 1 fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2 when installing at roof, please consider strong wind and e...

Page 45

45 for environmental protection, manufacturer strongly recommends to use evacuation method. 11.3.3 evacuation of the equipment 1 connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. O be sure to connect the end of the charging hose with t...

Page 46

46 11.3.4 air purging of the piping and indoor the remaining air in the refrigeration cycle which contains moisture may cause malfunction on the compressor. 1 remove the caps from the 2-way and 3-way valves. 2 remove the service-port cap from the 3-way valves. 3 to open the valve, turn the valve ste...

Page 47

47 11.3.6 piping insulation 1 please carry out insulation at pipe connection portion as mentioned in indoor/outdoor unit installation diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2 if drain hose or connecting piping is in the room (where dew may form),...

Page 48: 12. Installation

48 12. Installation instruction (for pc28qkh only) 12.1 select the best location 12.1.1 indoor unit do not install the unit in excessive oil fume area such as kitchen, workshop and etc. There should not be any heat source or steam near the unit. There should not be any obstacles blocking the air cir...

Page 49

49 12.2 indoor unit 12.2.1 how to fix installation plate the mounting wall shall be strong and solid enough to prevent it from the vibration. Dimension model 1 2 3 4 5 6 pc28*** 590 mm 82 mm 539 mm 532 mm 219 mm 269 mm the centre of installation plate should be at more than 1 at right and left of th...

Page 50

50 12.2.3 indoor unit installation 12.2.3.1 for the right rear piping 12.2.3.2 for the right and right bottom piping 12.2.3.3 for the embedded piping (this can be used for left rear piping and bottom piping also.).

Page 51

51 12.2.4 connect the cable to the indoor unit 1 the inside and outside connection cable can be connected without removing the front grille. 2 connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 x 1.5 mm 2 flexible cord, type designation 60245 iec 57 or...

Page 52

52 12.2.5 wire stripping and connecting requirement.

Page 53

53 12.3 outdoor unit 12.3.1 install the outdoor unit after selecting the best location, start installation to indoor/outdoor unit installation diagram. 1 fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2 when installing at roof, please consider strong wind and e...

Page 54

54 for environmental protection, manufacturer strongly recommends to use evacuation method. 12.3.3 evacuation of the equipment 1 connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. O be sure to connect the end of the charging hose with t...

Page 55

55 12.3.4 air purging of the piping and indoor the remaining air in the refrigeration cycle which contains moisture may cause malfunction on the compressor. 1 remove the caps from the 2-way and 3-way valves. 2 remove the service-port cap from the 3-way valves. 3 to open the valve, turn the valve ste...

Page 56

56 12.3.5 connect the cable to the outdoor unit 1 remove the control board cover from the unit by loosening the screw. 2 cable connection to the power supply through isolating devices (disconnecting means). O connect the approved polychloroprene sheathed power supply cord 3 x 4.0 mm 2 type designati...

Page 57: 13. Operation

57 13. Operation control 13.1 cooling operation cooling operation can be set using remote control. This operation is applied to cool down the room temperature to the setting temperature set on the remote control. The remote control setting temperature, which takes the reading of intake air temperatu...

Page 58

58 13.1.2 cooling operation time diagram (for pc18/24/28qkh).

Page 59

59 13.2 soft dry operation soft dry operation can be set using remote control. Soft dry operation is applied to dehumidify and to perform a gentle cooling to the room. This operation starts when the intake air temperature sensor reaches -1.5°c from the setting temperature on the remote control. When...

Page 60

60 13.2.2 soft dry operation time diagram (for pc18/24/28qkh).

Page 61

61 13.3 iauto operation iauto operation can be set using remote control. This operation is applied to faster cool down time of the room and comfort feel by thermal shift and fan speed control. Thermal control - the internal setting temperature will shift 1°c lower than remote control setting tempera...

Page 62

62 auto fan speed during cooling operation: 1 indoor fan will rotate alternately between off and on as shown in below diagram. 2 at the beginning of each compressor starts operation, indoor fan speed increases gradually for deodorizing purpose. 3 for the first time the compressor operates, indoor fa...

Page 63

63 13.5 outdoor fan speed control outdoor fan speed can be changes to hi or lo according to outdoor temperature. (for pc24/28qkh) there is only one speed for outdoor fan motor. (for pc9/12/18qkh) when the air conditioner is turned on, the compressor and the outdoor fan will operate simultaneously. L...

Page 64

64 13.6.2 manual control when the vertical airflow direction is set to manual using the remote control, the automatic airflow is released and the airflow direction louver move up and down in the range shown in the diagram. The louver can be adjusted by pressing the button to the desired louver posit...

Page 65

65 13.9 random auto restart control if there is a power failure during operation, the air conditioner will automatically restart after 3 to 4 minutes when the power is resumed. It will start with previous operation mode and airflow direction. If there are more than one air conditioner unit in operat...

Page 66: 14. Protection

66 14. Protection control 14.1 restart control (time delay safety control) when the thermo-off temperature (temperature which compressor stops to operate) is reached during: o cooling operation – the compressor stops for 3 minutes (minimum) before resume operation. O soft dry operation – the compres...

Page 67

67 rpm shift +0 +20 +40 +70 (id temp) pipe 6.0°c 4.0°c 2.0°c 5.0°c 7.0°c 3.0°c compressor starts for ≥ 5 minutes ▲ t ≤ 2.5°c for 2 minutes compressor off compressor restart ▲ t = intake air temperature – indoor heat exchanger temperature (for pc9/12qkh) the current fan speed will change to freeze pr...

Page 68: 15. Servicing

68 15. Servicing mode 15.1 auto off/on button auto off/on button pressed auto off/on button pressed auto off/on button pressed 5 sec 5 sec iauto operation test run operation (forced cooling operation) stop various setting mode stop “beep” 2 x “beep” 1 iauto operation mode the iauto operation will be...

Page 69

69 15.2 remote control button 15.2.1 set button to check current remote control transmission code and store the transmission code to eeprom: o press “set” button for more than 10 seconds by using pointer o press “timer set” button until a “beep” sound is heard as confirmation of transmission code ch...

Page 70: 16. Troubleshooting

70 16. Troubleshooting guide 16.1 refrigeration cycle system in order to diagnose malfunctions, ensure the air conditioner is free from electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compre...

Page 71

71 16.1.1 relationship between the condition of the air conditioner and pressure and electric current cooling mode condition of the air conditioner low pressure high pressure electric current during operation insufficient refrigerant (gas leakage) clogged capillary tube or strainer short circuit in ...

Page 72

72 warning 17. Disassembly and assembly instructions high voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. 17.1 cs-pc9/12qkh 17.1.1...

Page 73

73 17.1.1.3 to remove discharge grille.

Page 74

74 17.1.1.4 to remove control board 17.1.1.5 to remove cross flow fan and indoor fan motor.

Page 75

75.

Page 76

76 warning high voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. 17.2 cs-pc18/24/28qkh 17.2.1 indoor electronic controllers, cross ...

Page 77

77 17.2.1.3 to remove main electronic controller (fig. 3).

Page 78

78 17.2.1.4 to remove discharge grille (fig. 6) 17.2.1.5 to remove control board (fig. 7).

Page 79

79 17.2.1.6 to remove cross flow fan and indoor fan motor (fig. 8) (fig. 9).

Page 80

80 (fig. 10) (fig. 11).

Page 81: 18. Technical

81 18. Technical data 18.1 thermostat characteristics cooling soft dry.

Page 82

82 18.2 operation characteristics 18.2.1 cs-pc9qkh cu-pc9qkh cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 7.5 m.

Page 83

83 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 84

84 18.2.2 cspc9qkh cupc9qkh (myanmar only) cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 7.5 m.

Page 85

85 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 86

86 18.2.3 cs-pc12qkh cu-pc12qkh cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 7.5 m.

Page 87

87 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 88

88 18.2.4 cs-pc12qkh cu-pc12qkh (myanmar only) cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 7.5 m.

Page 89

89 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 90

90 18.2.5 cs-pc18qkh cu-pc18qkh cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 5.0 m.

Page 91

91 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 92

92 18.2.6 cs-pc18qkh cu-pc18qkh (myanmar only) cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 5.0 m.

Page 93

93 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 94

94 18.2.7 cs-pc24qkh cu-pc24qkh cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 5.0 m.

Page 95

95 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 96

96 18.2.8 cs-pc24qkh cu-pc24qkh (myanmar only) cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 5.0 m.

Page 97

97 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 98

98 18.2.9 cs-pc28qkh cu-pc28qkh cooling characteristic [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed piping length: 5.0 m.

Page 99

99 piping length characteristic cooling [condition] room temperature: 27°c (dbt), 19°c (wbt) operation condition: high fan speed outdoor temperature: 35°c (dbt), 24°c (wbt).

Page 100

100 19. Exploded view and replacement parts list 19.1 indoor unit 19.1.1 cs-pc9qkh cs-pc12qkh note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 101

101 cs-pc9qkh safety ref. No. Part name & description qty myanmar other/s.E.Asia remark 1 chassis complete 1 cwd50c1829 ← 2 fan motor 1 cwa921559 cwa921562 o 3 cross flow fan complete 1 cwh02c1159 ← 4 screw - cross flow fan 1 cwh551146 ← 5 bearing ass’y 1 cwh64k007 ← 6 evaporator 1 cwb30c4606 ← 7 fl...

Page 102

102 cs-pc12qkh safety ref. No. Part name & description qty myanmar other/s.E.Asia remark 1 chassis complete 1 cwd50c1829 ← 2 fan motor 1 cwa921559 cwa921561 o 3 cross flow fan complete 1 cwh02c1159 ← 4 screw - cross flow fan 1 cwh551146 ← 5 bearing ass’y 1 cwh64k007 ← 6 evaporator 1 cwb30c4637 ← 7 f...

Page 103

103 19.1.2 cs-pc18qkh cs-pc24qkh cs-pc28qkh note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 104

104 cs-pc18qkh safety ref. No. Part name & description qty myanmar other/s.E.Asia remark 1 chassis complete 1 cwd50c1654 ← 2 fan motor 1 cwa921459 ← o 3 cross flow fan complete 1 cwh02c1077 ← 4 bearing ass’y 1 cwh64k007 ← 5 screw - cross flow fan 1 cwh551146 ← 7 evaporator 1 cwb30c4656 ← 8 flare nut...

Page 105

105 cs-pc24qkh safety ref. No. Part name & description qty myanmar other/s.E.Asia remark 1 chassis complete 1 cwd50c1654 ← 2 fan motor 1 arw7627ac l6cbyyyl0039 o 3 cross flow fan complete 1 cwh02c1077 ← 4 bearing ass’y 1 cwh64k007 ← 5 screw - cross flow fan 1 cwh551146 ← 7 evaporator 1 cwb30c4331 ← ...

Page 106

106 cs-pc28qkh safety ref. No. Part name & description qty other/s.E.Asia remark 1 chassis complete 1 cwd50c1654 2 fan motor 1 l6cbyyyl0039 o 3 cross flow fan complete 1 cwh02c1077 4 bearing ass’y 1 cwh64k007 5 screw - cross flow fan 1 cwh551146 7 evaporator 1 cwb30c4232 8 flare nut (liquid) 1 cwt25...

Page 107

107 19.2 outdoor unit 19.2.1 cu-pc9qkh cu-pc12qkh note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 108

108 cu-pc9qkh safety ref. No. Part name & description qty myanmar other/s.E.Asia remark 1 chassis ass’y 1 cwd50k2241 ← 2 sound proof material 1 cwg302403 ← 3 fan motor bracket 1 cwd541233 ← 4 screw - fan motor bracket 2 cwh551217 ← 5 fan motor 1 cwa951673 cwa951852 o 6 screw - fan motor mount 3 cwh5...

Page 109

109 cu-pc12qkh safety ref. No. Part name & description qty myanmar other/s.E.Asia remark 1 chassis ass’y 1 cwd50k2241 ← 2 sound proof material 1 cwg302882 ← 3 fan motor bracket 1 cwd541235 ← 4 screw - fan motor bracket 2 cwh551217 ← 5 fan motor 1 cwa951673 cwa951852 o 6 screw - fan motor mount 3 cwh...

Page 110

110 19.2.2 cu-pc18qkh note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 111

111 cu-pc18qkh safety ref. No. Part name & description qty myanmar other/s.E.Asia remark 1 chassis ass’y 1 cwd50k2088 ← 2 sound proof material 1 cwg302673 cwg302256 3 fan motor bracket 1 cwd541030 ← 4 screw - fan motor bracket 2 cwh551217 ← 5 fan motor 1 cwa951851 cwa951688 o 6 screw - fan motor mou...

Page 112

112 19.2.3 cu-pc24qkh note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts.

Page 113

113 cu-pc24qkh safety ref. No. Part name & description qty myanmar others/s.E.Asia remark 1 chassis ass’y 1 cwd52k1248 ← 2 sound proof material 1 cwg302406 ← 3 fan motor bracket 1 cwd541154 ← 4 screw - fan motor bracket 2 cwh551217 ← 5 fan motor 1 cwa951697 ← o 6 screw - fan motor mount 3 cwh55406j ...

Page 114

114 19.2.4 cu-pc28qkh note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 115

115 cu-pc28qkh safety ref. No. Part name & description qty other/s.E.Asia remark 1 chassis ass’y 1 cwd50k2100 2 sound proof material 2 cwg302408 3 fan motor bracket 1 cwd541055 4 screw - fan motor bracket 3 cwh551217 5 fan motor 1 cwa951697 o 6 screw - fan motor mount 3 cwh55252j 7 propeller fan ass...