© panasonic home appliances air-conditioning (guangzhou) co.,ltd (phaag) 2010. All rights reserved. Unauthorized copying and distribution is a violation of law. Order no: pha-ag1102003c2 indoor unit outdoor unit cs-ye9mke cs-ye12mke cs-ye18mke cu-ye9mke cu-ye12mke cu-ye18mke table of contents 1. Saf...

2 13.2 protection control for cooling and soft dry operation...............................................................35 13.3 indoor piping air temperature control (heating)................................................................36 14. Troubleshooting guide.................................

3 caution warning warning 1. Safety precautions • read the following “safety precautions” carefully before perform any servicing. • electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. •...

4 caution 16. After completion of installation, confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant contacts with fire. 17. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant contacts with fire. 18. R...

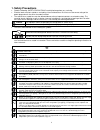

5 2. Specification indoor cs-ye9mke cs-ye12mke model outdoor cu-ye9mke cu-ye12mke phase, hz single, 50 single, 50 power supply v 230 230 min rate max min rate max kw 0.90 2.50 3.00 0.900 3.300 3.900 btu/h 3070 8530 10230 3070 11250 1330 capacity kcal/h 770 2150 2580 770 2840 3350 running current a -...

6 lo m 3 /min (ft 3 /m) 9.10 (321) 10.84 (383) me m 3 /min (ft 3 /m) 11.05(390) 12.23 (432) (heating) hi m 3 /min (ft 3 /m) 13.0 (459) 13.9 (491) hi (cooling) m 3 /min (ft 3 /m) 33.0 (1165) 34.5 (1218) outdoor airflow hi (heating) m 3 /min (ft 3 /m) 33.0 (1165) 34.5 (1218) control device capillary t...

7 indoor cs-ye18mke model outdoor cu-ye18mke phase, hz single, 50 power supply v 230 min rate max kw 1.00 5.00 5.30 btu/h 3410 17050 18080 capacity kcal/h 860 4300 4560 running current a - 7.90 - input power w 240 1660 1950 w/w 4.16 3.01 2.71 eer btu/hw 14.20 10.27 9.27 power factor % 91 db-a (h / l...

8 hi (cooling) m 3 /min (ft 3 /m) 36.0 (1271) outdoor airflow hi (heating) m 3 /min (ft 3 /m) 37.0 (1307) control device expansion valve refrigerant oil cm 3 rb 68a or freol alpha68m (320) refrigeration cycle refrigerant type g (oz) r410a, 1150 (40.5) height(i/d / o/d) mm (inch) 283 (11-5/32) 540 (2...

9 3. Features • inverter technology o wider output power range o energy saving o quick cooling o more precise temperature control • long installation piping o cs/cu-ye9/12/18mke, long piping up to 15 meters. • easy to use remote control • quality improvement o random auto restart after power failure...

10 4. Location of controls and components 4.1 indoor uni t 4.2 outdoor unit 4.3 remote control z for normal operation, the error reset button is not in use. Z press reset button to restore the remote control’s default setting. Power green timer orange quiet green indicator powerful red.

11 5. Dimensions 5.1 indoor unit 121 49 unit:mm.

12 5.2 outdoor unit unit: mm.

13 6. Refrigeration cycle diagram cs/cu-ye9mke, cs/cu- ye12mke cs/cu-ye18mke cooling heating.

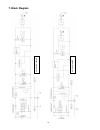

14 7. Block diagram cs/cu-ye18mke cs/cu-ye9/ 12mke.

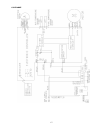

15 8. Wiring diagram cs-ye9mke, cs-ye12mke.

16 cu-ye9mke cu-ye12mke.

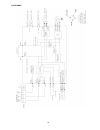

17 cs-ye18mke.

18 cu-ye18mke.

19 9. Printed circuit board 9.1 indoor unit 9.2 outdoor unit ic104 led3 led2 cn-stm3 cn-th sw ha cn-fb ic1 x1 ic103 ic2 ic.

20 10. Installation instruction 10.1 select the best location 10.1.1 indoor unit • there should not be any heat source or steam near the unit. • there should not be any obstacles blocking the air circulation. • a place where air circulation in the room is good. • a place where drainage can be easily...

21 wall indoor outdoor 15 mm sleeve for tube ass’y approx. 5 - 7 mm bushing for tube ass’y putty or caulking compound Ø 70 through hole 10.2 indoor unit 10.2.1 how to fix installation plate the mounting wall is strong and solid enough to prevent it from the vibration. The centre of installation plat...

22 10.2.3 indoor unit installation.

23 10.2.4 connect the cable to the indoor unit 1 the inside and outside connecting cable can be connected without removing the front grille. 2 connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4x 1.5mm 2 flexible cords, type designation 245 iec 57 or he...

24 t u c o t . 1 e h t f o e c a f r u s l a n r e t n i e h t , d e r a l f y l r e p o r p n e h w . S s e n k c i h t n e v e f o e b d n a e n i h s y l n e v e ll i w e r a l f e h t h t i w t c a t n o c o t n i s e m o c t r a p e r a l f e h t e c n i s . H s i n i f e r a l f e h t k c e h ...

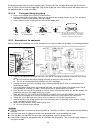

25 10.3.4 connect the cable to the outdoor unit 1 remove the control board cover from the unit by loosening the screw. 2 connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4x 1.5mm 2 flexible cords, type designation 245 iec 57 or heavier cord. 3 secure t...

26 11. Service mode 11.1 auto off/on button 1. Auto operation mode once the auto off/on button is slightly pressed, the unit will immediately operate in auto operation. This operation can be used to operate air conditioner with limited function if remote control is misplaced or malfunction. 2. Test ...

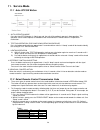

27 11.3 operate and display of remote control 11.3.1 original setting 11.3.2 mode selecting button a uto, heat, cool, dry can be selected by pressing “mode” button. Initial display of lcd is as follow *keeping the button depressed continuously, the operation mode will change in the following order i...

28 11.3.7 timer setting button there are 4 types of timer setting by pressing timer setting button: on-timer, off-timer, on-off timer, off-on timer. 1) select button when the air conditioner is on, off-timer or off-on timer can be selected by pressing select button. when the air conditioner is t...

29 12. Operation control 12.1 basic function 12.1.1 internal setting temperature once the operation starts, remote control setting temperature will be taken as base value for temperature shifting processes. These shifting processes are depending on the air conditioner settings and the operation envi...

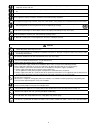

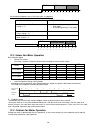

30 2nd & following judgment (every 15 minutes after 1st judgment) judge condition referance mode if indoor intake temp – remote control temp setting ≥ +3 ¾ cool mode if previously is cool / heat mode ¾ dry mode if previously is dry mode if -2 ≤ indoor intake temp. – remote control temp. Setting main...

31 30 s compressor outdoor fan on on off off on airflow direction 12.3.1 vertical airflow cooling operating mode 1 2 3 4 5 10 ~50 o o soft dry auto normal powerful 35 , 6 o o (begining of powerful mode) heating 12 o auto normal powerful 12 o 10 22 31 40 50 o o o o o 8 o o o o , 9 , 39 , 41 , auto no...

32 power button pressed piping temp. (cooling) fan speed ( rpm) on off auto 45 seconds 20 ‘ shi 20 ‘ fast cooling cooling, soft dry min.5’ correction factor( ) ℃ -0.25 +0.25 -1.67 -1.00 a b c d 20 ‘ 20 ‘ 1130 (max) 730 (min.) 2. For heating mode: power button pressed on off auto 45 seconds 20 ‘ shi ...

33 seconds to determine the indoor intake air temperature and outdoor air temperature in order to judge the operation mode. From the above judgment, the decided operation will start operate earlier than the set time as shown below. Timer signal receiving sound during operation. Timer signal receivin...

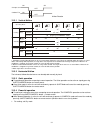

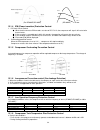

34 (for re9mke,re12mke) (re18mke) 13.1.4 ipm (power transistor) protection control. 1. Dc peak current control ● when electric current to ipm exceeds set value of dc17.3 1a, the compressor will stop. It will restart after three minutes. ● if the set value is exceeded again within 30 seconds, the ope...

35 indoor suction temperature - indoor piping temperature is below 4℃. Indoor temperature and outdoor temperature is 30±5℃. Remote control setting 16℃ and hi fan speed. • during heating operations: indoor piping temperature - indoor suction is under 5℃. Indoor temperature and outdoor temperature is ...

36 • this control starts if all conditions continue for 20 minutes: - operated with cooling or soft dry mode. - indoor intake temperature is between 25℃ and 29℃. - outdoor air temperature is less than 30℃. • this control stopped then receive air swing change signal from remote control. 13.2.4 overlo...

37 re9mke, re12mke indoor piping temp. 60 ℃ 55 ℃ 52 ℃ 49 ℃ 46 ℃ stop 8hz/15’’ down 1hz/15’’ down 110 hz,~ 35hz 110 hz,~ 35hz free re18mke.

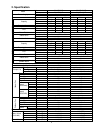

38 14. Troubleshooting guide 14.1 refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a f...

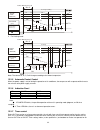

39 14.1.2 relationship between the condition of the air conditioner and pressure and electric current cooling mode heating mode condition of the air conditioner low pressure high pressure electric current during operation low pressure high pressure electric current during operation insufficient refr...

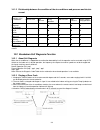

40 14.2.3 error codes table.

41 warning 15. Disassembly and assembly instructions high voltage is generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. 1. Open the intake grill...

42 2.Remove the air filters and then pull out the front grille form the unit body. 1. Separate the drain hose and the drain plate. 2. Pull out the discharge grille slightly. Front grille removal procedure for discharge grille.

43 1. Release fixing screws on both side, disassembly the fixing board from evaporator on the left side and pull out the whole evaporator. 2. Loose the fixing screw of the cross flow fan. 3. After removing the bearing, indoor fan can be taken out from the left side 4. Lift up the indoor fan slightly...

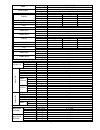

44 16. Exploded view and replacement pars list 16.1 indoor unit cs-ye9mke, cs-ye12mke, cs-ye18mke.

45 no. Parts name q't y cs-ye9mke cs-ye12mke cs-ye18mke re 1 chassis complete 1 cwd50c1686 cwd50c1686 cwd50c1686 2 fan motor 1 cwa921479 cwa921481 arw7643ac 3 cross flow fan complete 1 cwh02c1101 cwh02c1101 cwh02c1101 5 evaporator 1 cwb30c3356 cwb30c3356 cwb30c3406 6 auxiliary tube ass'y 1 cwt01c537...

46 16.2 outdoor unit cu-ye9mke, cu-ye12mke, cu-ye18mke.

47 no part name&description q'ty cu-ye9mke cu-ye12mke cu-ye18mke re 1 chassis ass'y 1 cwd52k1262a cwd52k1258a cwd52k1267a 2 fan motor bracket 1 cwd541146 cwd541146 cwd541146 3 screw-fan motor bracket 2 cwh551148a cwh551148a cwh551148a 4 fan motor 1 cwa951764 cwa951766 ars8405ac 5 screw-fan motor mou...