- DL manuals

- Panasonic

- All in One Printer

- FA-DS72

- Service Manual & Parts Manual

Panasonic FA-DS72 Service Manual & Parts Manual

ORDER NO. OED9909380B8

© 1999 Matsushita Graphic Communication

Systems, Inc. All rights reserved. Unauthorized

copying and distribution is a violation of law.

FP-7818/7824/7830/7835/7845/7850 Service Manual

Service Manual

Parts Manual

Plain Paper Copier

FP-7818/7824/7830

FP-7835/7845/7850

Staple Sorter

FA-S620/660

System Console

FA-DS72/82

Summary of FA-DS72

Page 1

Order no. Oed9909380b8 © 1999 matsushita graphic communication systems, inc. All rights reserved. Unauthorized copying and distribution is a violation of law. Fp-7818/7824/7830/7835/7845/7850 service manual service manual parts manual plain paper copier fp-7818/7824/7830 fp-7835/7845/7850 staple sor...

Page 2

Warning this service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by electricit...

Page 3

This manual dose not contain descriptions of pcb connector and signal information and sub assemblies operation which are discribed and unchanged in the fp-7718/7722/7728/7735/7742/7750 service manual. For those items not covered in this manual, please refer to the fp-7718/7722/7728/7735/7742/7750 se...

Page 4

Contents / index i. Introduction 1.1 specification ..................................................................................... 1-1 1.2 features ............................................................................................ 1-3 1.3 system configuration ...........................

Page 5

Iv. Preventive maintenance 4.1 precautions for periodic maintenance service ................................. 4-1 4.2 maintenance chart ............................................................................ 4-2 4.3 cleaning method ..................................................................

Page 6

Caution: danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacture's instructions. For sweden, and denmark specialsÄkring: endast av apparatfabrinkanten levererad sÄkri...

Page 7

For u.K. For your safety please read the following text carefully. This appliance is supplied with a moulded three pin mains plug for your safety and convenience. A 13 amp fuse is fitted in this plug. Should the fuse need to be replaced please ensure that the replacement fuse has a rating of 13 amps...

Page 9

1-1 introduction section i introduction 1. 1 specifications 1.Type desk top 2.Copy process electrostatic photographic method 3.Development process two component magnetic brush 4.Maximum original size ledger(11"x17") / a3(297 x 420mm) 5.Copy speed fp-7818 fp-7824 fp-7830 fp-7835 fp-7845 fp-7850 (cpm)...

Page 10

1-2 15.Fusing system heat and pressure 16.Photoreceptor organic photo conductor(opc) 17.Exposure control 7 step digital+photo/auto button 18.Warm up time fp-7818 approx. 40 sec. Fp-7824 approx. 50 sec. Fp-7830 approx. 75 sec. Fp-7835 approx. 75 sec. Fp-7845 approx. 180 sec. Fp-7850 approx. 270 sec. ...

Page 11

1-3 introduction 1. 2 features • introducing qualitative reasoning based adaptive controller copy density control with qualitative reasoning based adaptive controller used for copy density control, optimum copies are maintained for a long time in variable environmental conditions. • user friendly op...

Page 12

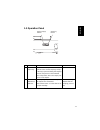

1-4 1. 3 system configuration i-adf adf main unit 50 adu 550 sorter paper drawer 550 system console 550 cover storage lcc 3000 accessories fp-7818 fp-7824 fp-7830 fp-7835 fp-7845 fp-7850 fa-ds72 x x fa-ds82 x x x x lcc ( fa-ma301 ) x x number of drawer 1 2 2 2 1 + adu 1 + adu auto duplex unit (fa-ma...

Page 13

1-5 introduction department counter 50 50 100 100 300 300 cover, interleaving, presentation no * no * no * no * yes yes job memory 2 2 2 2 5 5 this service manual is based on the fp-7850. To identify areas where the other models differ, please refer to this chart and the field service manual for eac...

Page 14

1-6 2 1 5 8 3 6 9 0 4 7 1. 4 operation energy saver interrupt key user preset key touch panel display manual key clear/stop key press to stop copy run or clear copy count in display. Print key reset key press to reset all features to initial power-on state. Original size keys multi size key job memo...

Page 15

1-7 introduction no. Keys 8 edge mode 9 book mode 10 memory in/job programs 11 duplexing mode selection (except fp-7818/7824) • using adu 12 2:1 copy (except fp-7818/7824) • using i-adf 13 2-page copy/2 in 1 mode selection (2 in 1 : except fp-7818/7824) no. Keys 1 multi-size feeding (except fp-7818/...

Page 16

1-8 % mm fp-7818/7824 fp-7830/7835 ledger legal letter letter invoice fp-7718 staple sort stack staple sort stack 1 1 2 3 4 5 6 7 13 14 15 16 9 8 17 10 11 18 12 (2) communications monitor (fp-7818/7824/7830/7835) no. Indicator 1 adding paper toner staple (except fp-7818) replacing waste toner bottle...

Page 17

1-9 introduction 1. 5 component location ( outer view ) control panel i-adf adf fp-7818 system console sorter lcc (except fp-7824) bypass sorter fp-7824/7830/7835 lcd touch panel control panel i-adf right cover bypass paper feed cover lcc fp-7845/7850 system console front panel sorter.

Page 18

1-10 (1) inner view 1 half-speed unit 2 full-speed unit 3 lens position sensor 4 thermistor 5 ae sensor 6 main motor 7 lens unit 8 charge corona 9 no.6 mirror 10 slit glass 11 no.4 mirror 12 no.5 mirror 13 led array 14 magnetic roller 15 registration roller 16 bypass pick-up roller 17 bypass paper f...

Page 19

1-11 introduction mirror stepping motor optics drive motor lens stepping motor developer cooling fan toner bottle motor dust collecting fan adu paper length guide motor (fp-7850) adu paper width guide motor (fp-7850) adu drive motor (fp-7850) optics fan optics fan main motor optics fan exhaust fan l...

Page 20

1-12 (3)sensor location mirror home position exposure lamp home position platen cover open/close platen cover angle ae (automatic original density sensor) original size adu detection (fp-7850) toner density copy density adu paper length (fp-7850) adu paper pass 1 (fp-7850) paper exit lens home posit...

Page 21

1-13 introduction (4) solenoid/clutch/discharge lamp location paper feed clutch registration roller clutch discharge lamp middle roller clutch bypass pick-up solenoid paper feed clutch (lower stage) separation solenoid paper exit solenoid (fp-7850) power switch door switch adu clutch (fp-7850) pick-...

Page 22

1-14 1. 6 copy process charger discharge lamp cleaning fusing exit adu paper feed separation transfer developer toner exposure original reduction discharge trimming –dc discharge lamp: transfer/separation fusing: cleaning: primary charge: image exposure: developing: drum surface approximately-800v d...

Page 23

1-15 introduction 1. 7 precautions on set up copy machine performance and the copy quality is subject to and dependant on environmental conditions. To maintain good performance, quality, and safe operation, observe the following precautions: 1) for safe operation and to avoid trouble do not install ...

Page 24

1-16 1. 8 precautions with consumables (1) photoreceptor drum • do not touch the surface (with the hand or anything else). • stand the drum with the drum gear up for storage. • be careful not to smear with saliva, water, oil and so on. • do not place a where the temperature is high. • do not place i...

Page 25

1-17 introduction • there are normally no special problems with storage and transport in a cold climate but, store in a low humidity condition. Do not put supplies near heaters. 5) safety and hygiene toner has the property of easily being wind blown. Toner on skin does not cause any damage to health...

Page 26

Control functions 2-1 section ii control functions 2. 1 image control qualitative reasoning based adaptive controller • even if the toner density is at it's standard level, the copy image may vary with time depending on the characteristics of drum and the environmental variations. To prevent this ch...

Page 27

2-2 • qualitative reasoning based adaptive controller qualitative reasoning based adaptive controller is adaptive control on the basis of quantative reasoning theory. While successively reasoning and learning the change of process characteristics regardless of environmental changes and the variation...

Page 28

Control functions 2-3 amount of carrier passing tdc sensor toner density condition sensor output voltage less high lower than normal much low higher than normal the following controls are necessary for normal control of toner density 1) automatic adjustment of tdc sensor gain (during execution of f8...

Page 29

2-4 2) maintain standard toner density while checking the output voltage of the tdc sensor for every copy, control the timing of toner supply to the developer unit so that the output voltage is 2.5v at all times to keep the toner density constant. Supply toner: supply from reserve tank for 6 seconds...

Page 30

Control functions 2-5 2. 3 trouble avoidance mechanism when some malfunction happens, this mechanism allows regular copy operation without error conditions (service man call) (providing the malfunction does not affect the basic copying operation and the appropriate function is not selected). Appropr...

Page 31

2-6 item error code copier paper feed ( upper ) e2-01 copier paper feed ( lower ) e2-02 system stand paper feed ( upper ) e2-03 system stand paper feed ( middle ) e2-04 system stand paper feed ( lower ) e2-05 system stand paper feed timing e2-10 lcc lift up e2-06 lcc lift down e2-07 duplex unit ( le...

Page 32

Control functions 2-7 2. 4 toner recycling system to maximize the number of copies which can be produced for each bottle, toner cleaned off of the drum needs to be returned to the developer for re-use. Under normal circumstances, the copy process can damage some toner. In addition, other undesireabl...

Page 33

2-8 2. 5 re-try control for paper misfeed • copy paper should pass the paper feed sensor within a specific time after the paper feed clutch turns on. To reduce paper misfeeds due to a slipping paper feed roller, the paper feed clutch turns on again (re-try operation). • when the paper does not reach...

Page 34

Sub assemblies 3-1 section iii sub assemblies 3.1 main drive the driving mechanism of this machine is as follows. Name of motor driving method driving unit main motor dc24v driving • rotation of photo receptor drum • developer unit, paper feed unit, paper transport, fuser unit and paper exit unit pa...

Page 35

3-2 paper size detecting sensor s1 s2 s4 ledger/a3 on off on legal/b4 on on on letter/a4 on off off letter-r/a4r off on off invoice/a5 off off off (1) detecting sheet bypass paper size • the paper size for the sheet bypass is detected by a matrix of sheet bypass paper size sensors which are installe...

Page 36

Sub assemblies 3-3 (2) developing • the developer mixing unit contains developer which is a mixture of fine powder (non-magnetic toner) and fine ferrite carrier. • the developer is mixed by the transport screw and the mixing mill. The toner becomes charged ( + ) and the carrier becomes charged ( – )...

Page 37

3-4 (3) supplying toner the toner hopper unit supplies toner to the developer mixing unit via the reserve tank, so toner addition is done in two stages, by turning the toner hopper motor in either direction: forward direction: the bottle turns (via a spring clutch) to supply toner from the toner bot...

Page 38

Sub assemblies 3-5 (4) toner level detection • when the toner level sensor in the toner hopper detects no toner remaining, and does not detect toner after continuously turning the toner bottle "add toner" is displayed. The copier is disabled. The machine can be used after the user's key input. After...

Page 39

3-6 (5) temperature control the heat roller is provided with two halogen lamps (main heater lamp and sub heater lamp). The main heater lamp turns on during warming up and copying operation. To control the maximum power consumption, the sub heater lamp turns on during warming up and after release of ...

Page 40

Sub assemblies 3-7 (6) automatic detection of original paper size • opening the platen cover by approx. 30 degrees to insert the original, the platen cover angle sensor turns on and four original size detection sensors operate simultaneously. • the original size detection sensors consists of light e...

Page 41

Preventive maintenance 4-1 section iv preventive maintenance the periodic maintenance service is performed by machine cleaning and parts replacements. It is essential to perform these service activities properly for customer satisfacation. The purpose of this service is to maintain the machine perfo...

Page 42

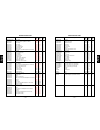

4-2 item service part number q'ty per maintenance cycle (x 1000) unit 80/120 160/240 240/360 320/480 400/600 paper paper feed roller ffpma05411 2 x feed dfp roller ffpma05411 2 x unit pick-up roller ffpma0542 2 x cleaning sheet ffphk0951 2 x (except fp-7818/7824) registration roller ffpma0539 1 repl...

Page 43

Preventive maintenance 4-3 item service part number q'ty per maintenance cycle (x 1000) unit 80/120 160/240 240/360 320/480 400/600 fuser separation finger (upper) ffplk0331 5 x unit separation finger (lower) ffplk0231 4 x thermister ffpbl0015 1 x fuser lamp (850w) h12v085wn2a 1 x cleaning web ffpkm...

Page 44

4-4 4.3 cleaning method • cleaning method for each pm service visit is shown below. 17 20 25 14 19 18 22 9 8 17 24 23 10 1 2 3 7 4 30 5 6 12 21 11 13 16 15.

Page 45

Preventive maintenance 4-5 cloth with water / ipa cloth with water brush / vacuum cleaner / cloth with water cloth with water - clean by cloth with water. - remove toner dust on separation finger. - don’t damage separation finger edge. Cleaning position tool/solvent work/precaution 1 sheet bypass pa...

Page 46

4-6 17 mirror (no.1 ~ 6) 18 lens 19 original size detecting sensor 20 reflector 21 copy density sensor 22 discharge lamp filter 23 led array 24 slit glass ipa 25 platen glass ipa 26 platen mat cloth 27 ozone filter 28 dust collection filter 29 outer cover 30 paper feed roller cleaning position tool/...

Page 47

Preventive maintenance 4-7 4. 4 disassembly and re-assembly pm parts replacement procedure • the replacement procedure of pm parts is as shown below. The replacement cycle of pm parts is shown for the fp-7750/7742. (for other models, refer to the correct service manual.) fuser unit 4-17 optics unit ...

Page 48

4-8 (1) multi-feed bypass part name 1 pick up roller 120k 2 paper feed roller 120k 3 dfp roller 120k 4 torque limiter 1200k 5 registration roller 1080k 6 registration roller 1080k bearing 7 cleaning sheet 600k item cycle 4 3 2 1 5, 6 7 caution magnet clutch welded point welded point “d” cut hook hoo...

Page 49

Preventive maintenance 4-9 sv103 2) replacement of the dfp roller and torque limiter 1) replacement of the pick-up roller/paper feed roller (1)remove the screws and covers. (x 2) (2)disconnect the harness. (3)remove the bypass tray. Note: remove right cover (2 screws). 1 (1)remove the touch ring. (2...

Page 50

4-10 3) replacement of the registration roller and cleaning sheet 4 1) remove the right cover and rear cover. 2) open the front cover. A) open the waste toner bottle cover and remove the bottle. B) turn the toner hopper 180°. 3) pull and turn the developer release knob. 4) remove the drum unit. 5) r...

Page 51

Preventive maintenance 4-11 2 1 4 3 5 (2) paper feed unit part name 1 paper feed roller 120k 2 pick-up roller 120k 3 dfp roller 120k 4 torque limiter 1200k 5 middle roller 1080k cycle item.

Page 52

4-12 1) replacement of the paper feed roller and the pick-up roller 1) remove the right cover and rear cover. 2) open the copier paper feed cover. 3) remove the paper feed cover stopper. Note: move the stopper to the larger hole and remove. 1 2 1) disconnect the harness of the paper feed unit. 2) re...

Page 53

Preventive maintenance 4-13 2) replacement of the dfp roller and the torque limiter 3) replacement of the middle roller 1) conduct the procedure 1 and 2. 2) remove the lower roller cover (2 screws) 3) remove the touch ring. 4) remove the dfp roller. 5) remove the torque limiter. Note: confirm the di...

Page 54

4-14 4 6 7 8 5 1 3 2 (3) developer unit part name 1 cleaning blade 120k 2 drum 120k 3 blade side seal (f) 120k 3 blade side seal (r) 120k 4 corona 360k 5 developer 120k 6 spacer ring (f) 120k 6 spacer ring (r) 120k 7 toner dispersion 600k prevention cover 8 mag-roll stopper (f) 600k 8 mag-roll stopp...

Page 55

Preventive maintenance 4-15 1 1) replacement of the cleaning blade 1) open the front cover. 2) move the toner hopper to front side. 3) pull and turn the developer release lever and release the developer unit. (refer to p. 4–8 step 4) 1) remove the drum unit solenoid cover (1 screw). 2) disconnect th...

Page 56

4-16 2) replacement of the drum / side seal 3) replacement of the charge corona 3a 3b 3c 5 1) conduct the procedure 1 and 2 and take the drum unit out. 2) remove the drum cleaning blade tension spring (refer to p.4-13 step 4). 3) remove the front side screw on the drum shaft. 4) remove the drum shaf...

Page 57

Preventive maintenance 4-17 5) replacement of the spacer ring 1) conduct the procedure 1 and 2 then remove the developer unit. 2) remove the bias terminal (2 screws). 3) remove the c ring and gears on mag-roller. 4) remove the spacer ring (rear). 5) remove the bushing support plate (1 screw). Note: ...

Page 58

4-18 a 7) replacement of the dust collecting filter 6) replacement of the toner dispersion prevention cover/magnetic roller stopper • conduct procedure 1 and 2 then pull out the developer unit. (1)remove the screws (x 2). (2)remove the toner dispersion prevention cover. (3)remove the magnetic roller...

Page 59

Preventive maintenance 4-19 2 1 4 9 10 11 8 3 5 6 7 13 12 (4) fuser unit part name 1 cleaning web roller 120k 2 web pressure roller 1200k 3 fuser lamp 240k 4 heat roller 360k 5 heat roller bearing 600k 6 insulating bushing 360k 7 heat roller gear 600k 8 thermistor 240k 9 separation finger (upper) 48...

Page 60

4-20 1) replacement of cleaning web/web pressure roller (1) open the front cover. (2) swing the toner hopper to the right. (3) remove the fuser unit manual paper feed knob. (1 screw reverse threaded) (4) remove the front cover. A) remove the band. B) slide out the hinge pins. (5) remove the fuser fr...

Page 61

Preventive maintenance 4-21 2) replacement of the fuser lamp/heat roller/heat roller bearing/insulating bushing/ heat roller gear • conduct procedure 1and 2. (1)remove the screws (x 4) (2)remove the heat insulating cover. Note: either loosen pressure screws (x 2) or install fuser shipping screws (x ...

Page 62

4-22 3) replacement of the thermistor 4) replacement of the separation finger (upper/lower) • conduct procedure 5. (3)(4) remove the screw. (5)remove the thermistor. • replace the thermistor. 9 (1)open the fuser exit cover. (2)remove the screws (x 2). (3)remove the separation finger (upper) bracket....

Page 63

Preventive maintenance 4-23 sv506 13 (1)remove the spring (x 2). (2)turn the separation fingers and remove them (x 5). 5) replacement of the pressure roller/roller bearing • remove the heat roller (refer to step 5 to 7). • remove the separation finger upper/lower brackets (refer to 10 and 12). Mark ...

Page 64

4-24 (5) optics unit part name 1 exposure lamp 120k 2 filter a 120k 2 filter b 120k 3 optics filter 120k 4 full speed unit drive belt ✻ 5 half speed unit drive belt ✻ 6 optics drive belt ✻ cycle item 2 1 3 4 5 6 2 ✻ : as required.

Page 65

Preventive maintenance 4-25 1) replacement of the exposure lamp remove upper covers (left/right). 1 (1)remove the screws (x 3). (2)remove the original guide. (3)remove the platen glass. (4)move the full speed unit to the right. 2 sv601 3 (1)remove the screws (x 2). (2)remove the main reflector. Remo...

Page 66

4-26 2) replacement of filter a and b. Replacement of the optics fan filter 4 • conduct the procedure 1. Remove both left and right copier side covers. • peel off the dust prevention filter and replace it with new one..

Page 67

Preventive maintenance 4-27 5 (1)remove the platen cover (or adf/i-adf if installed). (2)remove the copier front cover (refer to page 4-18 step 1). (3)disconnect the lattice connectors of any options (system console and lcc). (4)remove the rear cover (7 screws). 3) replacement of the optics motor be...

Page 68

4-28 sv632 sv630 9 12 remove the optics cover. (1)disconnect the 2 connectors. (2)remove the 2 screws. 10 (1)remove the adf lattice connector bracket (5 screws). (2)remove the optics motor tension spring. (3)remove the left adf hinge receiving bracket/key counter receptacle bracket (3 screws). (4)re...

Page 69

Preventive maintenance 4-29 13 15 (1)loosen the four idler pulley brackets (2 screws each). (2)remove the four optics drive belt tension springs. 16 remove the optics drive belts from the idler pulleys (4 belts). Move the full-speed unit to right until it stops. 14 (1)remove the 2 screws on the full...

Page 70

4-30 17 18 19 (1)remove the e rings (each side). (2)remove the bearings (each side). (3)slide the optics drive shaft to the rear, and remove it. (4)replace the optics drive belts (when one requires replacement, we recommend replacement of complete set of four, due to the complexity of the process). ...

Page 71

Preventive maintenance 4-31 connect the half-speed unit drive belt (1) move the half-speed unit to right until it stops. (2) connect the half speed drive belts (each side). Note: if the half-speed unit has not touched the stopper after the belt is connected, loosen screw on the half-speed unit suppo...

Page 72

4-32 (6) automatic duplex unit (adu) part name 1 paper feed roller 24k 2 storage roller 48k 3 f/r mylar 24k 4 paper feed pad 24k 5 dfp roller 24k item cycle 2 1 5 3 4.

Page 73

Preventive maintenance 4-33 1) replacement of the paper feed roller/storage roller/f/r mylar/feed roller pad (1) remove the screws (x 2). (2) remove the stopper plate. (3) remove the touch rings from the guide plates. (4) disconnect the feed clutch connector. (5) remove the touch rings (x2). (6) mov...

Page 74

4-34 2) replacement of the dfp roller • conduct procedure 1 and 2. • peel off the paper feed pad and replace it. 5 (1)remove the touch rings (x 2). (2)remove the bearing. (3)remove the roller shaft. (4)remove the dfp roller. Note: when re-installing the dfp roller, marked position is front side. • c...

Page 75

Preventive maintenance 4-35 8 5 4 7 3 1 2 (7) main body part name 1 corona cleaner 120k 2 transfer wire 120k 3 separation wire 120k 4 ozone filter 240k 5 ozone filters 240k 6 dust collecting filter 240k (main body) 7 transfer chager 360k 8 discharge lamp 240k item cycle 6.

Page 76

4-36 1) replacement of the charger wire/wire cleaner felt (1)open the front cover. (2)turn the transport lever and lower the transport unit. (3)press down the transfer charger and draw it toward you. 1 • remove the transfer corona. (1)remove the paper guide. (2)remove the charger cover. (3)replace t...

Page 77

Preventive maintenance 4-37 3 4 (rear side) 2) remove the suction fan and the ozone filter to replace them with new ones. (1)remove the rear cover. (2)replace the ozone filter. 4 (left side) 4) replacement of the discharge lamp. (1)open the front cover. (2)turn the toner hopper 180°. (3)remove the 1...

Page 78

5-1 troubleshooting v. Troubleshooting 5.1 service mode in service mode, the technician can check for abnormalities in the copier so the copier can always operate normally. The input/output of major components in every section can be checked. To select the service mode the service mode is selected w...

Page 79

5-2 mode item function remarks f1 1 when the print key is pressed, all displays light up. F2 2 1. One sheet is copied when the print key is pressed. 2. Duplex mode (1 sided original, 2 sided copy or 2 sided original, 2 sided copy) a. Select the 1 sided original 2 sided copy or 2 sided original, 2 si...

Page 80

5-3 troubleshooting mode item function remarks e. Repeat procedures b) and d). 4. 2 sided original, 1 sided copy mode. A. Select the 2 sided original, 1 sided copy mode. B. One sheet is copied normally when the print key is pressed. C. Repeat item b). F3 3 1. Multi copying is initiated by pressing t...

Page 81

5-4 (3) f4 mode 1) input check. Set the copier to service mode and press multi-copy key “4”. Press print key. Select desired code number with multi-copy key. Press print key. Check arrow mark on the touch panel display. Press clear/stop and user preset key to escape service mode. Code function condi...

Page 82

5-5 troubleshooting code function condition message display no. 7 6 5 4 3 2 1 0 04 a) sheet bypass paper detecting paper is not detected. Sensor b) sheet bypass paper size ledger/a3 detection sensor legal/b4-fls letter/a4 letter r/a4r invoice/a5 c) platen open/close sensor platen is open. D) platen ...

Page 83

5-6 code function condition message display no. 7 6 5 4 3 2 1 0 07 a) exhaust fan motor 1 motor is locked. B) exhaust fan motor 2 motor is locked. C) optics fan motor 1 motor is locked. D) optics fan motor 2 motor is locked. E) optics fan motor 3 motor is locked. F) exhaust fan motor 3 motor is lock...

Page 84

5-7 troubleshooting code function condition message display no. 7 6 5 4 3 2 1 0 11 a) system console motor motor is locked. Signal b) system console paper feed cover is closed. Cover sensor c) paper detection sensor 3 paper is not detected. (system console lower paper tray) d) paper limit sensor 3 p...

Page 85

5-8 code function condition message display no. 7 6 5 4 3 2 1 0 14 a) lcc detecting sensor 1 lcc is not installed. B) lcc door open/close sensor door closed. C) lcc detecting sensor 2 lcc is pulled out. D) lcc paper tray lower limit paper tray is beyond the sensor lower limit. E) lcc paper tray uppe...

Page 86

5-9 troubleshooting code function condition message display no. 7 6 5 4 3 2 1 0 20 for fa-s575 a) motor clock sensor signal is detected. B) bin ass'y upper/lower limit switch bin is beyond the upper limit or beyond the lower limit. C) cable safety switch cable is not loose. D) bin ass'y position sen...

Page 87

5-10 code function condition message display no. 7 6 5 4 3 2 1 0 24 for fa-s680 a) bin paper detecting sensor paper is detected. B) paper pass sensor paper is detected. C) staple detecting sensor staple is detected 25 for fa-s680 a) stapler cam sensor cam in home position. B) stapler swing home posi...

Page 88

5-11 troubleshooting 2) output check* activate the door switch before executing output check. Press the print key to start and press the clear/stop key to reset. Code item function 26 timing roller clutch when cn8-12 is +24v, clutch operates. 27 sheet bypass paper feed solenoid when cn5-6 is +24v, s...

Page 89

5-12 code item function 43 key counter when cn119-6 is +24v, count up by one. 44 not used 45 +24v output control when signal is sent from cpu cn1-6 to lvps cn117-5, +24v is supplied to +24v line. 46 lift motor 1 when cn603-1 is +24v, motor rotates, (when duplex unit is not installed.) lifting up (to...

Page 90

5-13 troubleshooting code item function 58 paper feed clutch 2 when cn609-3 is +24v, clutch operates. (system console middle) 59 paper feed solenoid 2 when cn609-4 is +24v, solenoid operates. (system console middle) 60 lift motor 3 when cn605-2 is +24v, motor rotates, (system console lower) lifting ...

Page 91

5-14 code item function 77 paper feed motor forward rotation the motor rotates forward. (fa-a888) 78 paper feed motor reverse rotation the motor rotates reverse. (fa-a888) (high speed) 79 paper feed motor reverse rotation the motor rotates reverse. (fa-a888) (middle speed) 80 paper feed motor revers...

Page 92

5-15 troubleshooting code item function 93 staple ready indicator (led) the ready indicator lights up. (only staple sorter) 94 stapler swing motor the swing motor drives in and out. (only staple sorter).

Page 93

5-16 (4) f5 mode copier function programming set the copler to service mode and press multi-copy key “5”. Press print key. Select desired code number with touch panel display and touch the ok key. If you wish to select other code number, scroll the menu with arrow keys ( ). Select desired function w...

Page 94

5-17 troubleshooting code item function (factory setting) 13 auto off timer 0: no auto off timer 0 (for european) 1: 30 m 2: 60 m 1 (for american 3: 1.5 hr 4: 3 hr fp-7818) 5: 4 hr 2 (for american fp-7824/7830/ 7835) 3 (for american fp-7845/7850) 14 copy paper size setting 0: none 1: ledger/a3 1 (co...

Page 95

5-18 code item function (factory setting) 28 total copy count 0: does not count up 0 (except fp-7818) 1: count up checking double feed by comparison between in/out copies. 29 not used 30 skyshot mode 0: not change registration void position 1 (using adf) 1: change registration void position 31 adf s...

Page 96

5-19 troubleshooting code item function (factory setting) 47-49 not used 50 auto exposure default 0: not detecting 2 1: auto mode priority 2: manual mode priority 51 2 in 1 mode copy ratio 0: full size 1 setting 1: reduction 52 auto original size 0: no detection - priority (manual key led lit) 0 (fp...

Page 97

5-20 code item function (factory setting) 70 preventive maintenance 0: no call 10 (fp-7818/7824) 1: 1.5k 2: 2.5k 3: 5k 12 (fp-7830/7835/ 4: 10k 5: 15k 6: 20k 7845/7850) 7: 30k 8: 40k 9:60k 10: 80k 11: 90k 12: 120k 13: 160k 71 preventive maintenance 0: no indication 1 (duplex unit) 1: indication 72 c...

Page 98

5-21 troubleshooting code item function (factory setting) 94* check size m2 x length of paper vertical position to paper 95 feed direction 95 factory use size unit change 0: ab, janpanese 1 (for american) 1: inch 2 (for european) 2: ab, european 96-97 not used 98 factory use paper size sensor 0: yes...

Page 99

5-22 to clear the service call indicator re-input the f5-70 and f5-73. Set the copier to service mode and press multi-copy key “5” press print key. Scroll the display menu until code number 70 is indicated with arrow keys ( ), then touch “70” key. Touch desired pm cycle key and ok key. When the canc...

Page 100

5-23 troubleshooting (5) f6 mode adjustment and programming set the copier to service mode and press muiti-copy key “6”. Press print key. Select desired code number with touch panel display and touch the ok key. If you wish to select other code number, scroll the menu with arrow keys ( ). The displa...

Page 101

5-24 code item function remarks 05 copy paper registration after 04 is adjusted, delay 0.425mm *same as f6-04 detecting timing time is adjusted from (fp-7850/7818) timing roller clutch on. 0.375mm (fp-7845) 0.525mm (fp-7824/7830/7835) (–30 to +20) (+): delayed (–): advanced 06 led array synchronized...

Page 102

5-25 troubleshooting code item function remarks 15-16 not used 17 grid standard voltage adjustment of grid –2.28v (standard = –810v) standard voltage. (–99 to +99) 18 photo mode grid voltage adjustment of photo –2.28v (standard = –480v) standard voltage. (–99 to +99) 19 bias standard voltage adjustm...

Page 103

5-26 code item function remarks 37 registration of original adjustment of registration 0.4mm with a888 for the automatic document timing (–32 to +32) feeder (2-side original feeding) 38 image density (black level) adjustment of judgment 19.5mv judgment standard voltage standard voltage. (–99 to +99)...

Page 104

5-27 troubleshooting code item function remarks 54 registration void of image adjustment of registration 0.425mm (during use with adf = no void. (fp-7850/7818) swing back condition) 0.375mm (fp-7845) 0.525mm (fp-7835/7830/7824) (0 to +99) 55 original stop position adjustment of original stop 0.4mm w...

Page 105

5-28 code item function remarks 75-79 not used 80 automatic compensation set by qualitative –81 to +92 value (read only) reasoning based adaptive 0.18v exposure voltage controller 81 not used 82 automatic compensation set by qualitative –92 to +55 value (read only) reasoning based adaptive 2.28v gri...

Page 106

5-29 troubleshooting (6) f7 mode electronic counter read procedure set the copier to service mode and press multi-copy key “7”. Press print key. Select the desired code number with multi-copy key. Indicates memorized count in the electric counter. Press clear/stop and user preset key to escape servi...

Page 107

5-30 code item function 39 system console lower total count of upper stage of optional system console. Paper drawer count 40 lcc count total count of optional lcc (3000 sheet paper drawer) 41 copier upper paper drawer total count of copies from upper paper drawer of the copier. Count note: when the ...

Page 108

5-31 troubleshooting (7) f8 mode copier operation adjustment set the copier to service mode and press multi-copy key “8”. Press print key. Select the desired code number with multi-copy key. Adjust the selected mode according with instructed procedure. Press clear/stop and user preset key to escape ...

Page 109

5-32 code item function 02 h) this adjustment may cause the factory setting of f6- 04 to change, so check the f6-04 setting once more. If it has changed, transfer the revised value the memory sheet. I) after completing this adjustment, check f6-05 once more. 03-05 not used 06 machine error and paper...

Page 110

5-33 troubleshooting code item function 12 not used 13 black density sensor reference level ( factory use only / need special fixtures ) adjustment ( factory use only ) 14 black density sensor output gain this adjustment should be performed when installing adjustment the copier, cleaning/replace bla...

Page 111

5-34 5.2 self-diagnostics/machine malfunctions the self-diagnostic functions detect troubles in important components of the copier. When any trouble occurs, the copier is stopped. 1. User error note: xxxx will appear in message display. Error code message item see page uo insert key key counter fail...

Page 112

5-35 troubleshooting error code message item see page of sorter full-empty if too many copies in bin or 4-37 press mode key too many bins selected. Remove copies and press the each sorter mode key on the touch panel. Not ready (red led flashes) power saving ---------- the ready indicator will light ...

Page 113

5-36 (1) u0: key counter failure or access code number was not input *the copier does not indicate ready to copy when the key is inserted. Is the key inserted correctly? No re-insert the key. Yes is cn119-2 connected to cn-2? No cn119-2, 4 of the cpu is defective. Or is cn119-4 contact to cn-4? Yes ...

Page 114

5-37 troubleshooting (5) u6: copier paper feed cover failure *the copier does not indicate ready to copy when the copier paper feed cover is closed. Is the paper feed cover closed securely? No close the paper feed cover securely. Yes does cn5-7, 9, 11 (output signal of cpu) no check dc5v of the tray...

Page 115

5-38 (9) u12: sorter with stapler *when the stapler mode is selected, and a staple cartridge is not inserted. (10) u13: toner level detection *"u13" does not reset after replacing the toner bottle. Is the toner caked in the bottle? Yes shake the toner bottle well. No or change the toner bottle. Is t...

Page 116

5-39 troubleshooting c g f d e b a (15) of: sorter bin capacity failure *too many copies in at least one bin or too many bins selected. Did the number of copies yes remove copies and press the sorter mode exceed the bin capacity? Select key..

Page 117

5-40 jam jam read condition code position j00 the registration roller paper pass sensor does not detect a paper within a predetermined time after sheet bypass paper feed roller starts rotating. J01 the copier upper paper feed unit paper pass sensor 1 does not detect paper within a predetermined time...

Page 118

5-41 troubleshooting jam jam read condition code position j12 paper feeding from copier lower stage: a the copier lower stage paper pass sensor 2 is detecting paper within a predetermined time after first detecting paper. J13 paper feeding from optional system console upper stage: b upper stage pape...

Page 119

5-42 jam jam read condition code position j50 transport operation for duplexing d the duplex unit paper pass sensor 1 does not detect paper within a predetermined time after copier paper exit sensor detected paper. J51 transport operation for duplexing d, e the duplex unit paper pass sensor 1 is det...

Page 120

5-43 troubleshooting 3. Machine error the machine system will detect problems in important areas of the copier. When any problems occurs the copier stops. Error codes indicate the mode number and code number which are alternately displayed in "digit" display area of touch screen. When there is troub...

Page 121

5-44 e3: developer unit and hopper unit error code function refer page e3-01 toner bottle motor rotation 5-50 e3-03 toner density sensor gain 5-50 e3-10 high voltage power supply leak (1) 5-51 e3-11 high voltage power supply leak (2) 5-51 e3-20 main motor rotation 5-51 e3-21 dust collection fan moto...

Page 122

5-45 troubleshooting e7: optional unit error *these errors are indicated when options are installed. Refer to optional unit service manual. Code function refer page e7-01 sorter bin movement sorter service e7-03 transport belt motor failure manual e7-06 stapler drive motor failure e7-07 tamper drive...

Page 123

5-46 e1-01: optical unit scan drive when the lamp unit scanner motor drives to the optics home position sensor and is not detected within a predetermined time. Does the lamp unit move when the power no lamp unit scanner motor connector is shorted switch is turned on? Or broken. Cn114 or cn123 (of lv...

Page 124

5-47 troubleshooting e1-21: mirror ratio drive when the mirror stepping motor drives to the mirror home position sensor and is not detected within a predetermined time. Does the mirror unit move when the no mirror stepping motor connector is shorted or power switch is turned on? Broken. Yes cn-115 o...

Page 125

5-48 e1-40: optics fan motor (1) rotation e1-41: optics fan motor (2) rotation e1-43: optics fan motor (4) rotation a lock signal is detected when the fan motor is rotating. Is dc24v, detected on cn 106-9, 12 or no lvps is defective. Cn 107-3 (on lvps pcb)? Yes connector is shorted or broken, harnes...

Page 126

5-49 troubleshooting e2-10: system console motor rotation when the system console main motor drives an abnormal signal is detected. Does the main motor rotate by hand? No main motor drive mechanism is defective. Yes locking mechanism of motor is defective. Is dc24v detected on cn-1, 2 ? No check dc2...

Page 127

5-50 e3-01: toner bottle motor rotation when the toner bottle motor drives to the toner bottle position and the toner bottle home position sensor is not detected. Does the toner bottle motor rotate no bottle motor connector is shorted or broken in manual toner addition mode? Bottle motor drive mecha...

Page 128

5-51 troubleshooting e3-10: high voltage power supply leak (1) when a leak is detected from the high voltage power supply charge/transfer corona. Is the charge/transfer corona dirty? Yes clean the charge/transfer corona. No does the ground terminal float yes tighten screw(s) on the ground terminal o...

Page 129

5-52 e3-21: dust collection fan motor rotation e3-22: exhaust fan motor rotation e3-23: suction fan motor rotation when the fan motor is rotated or stopped, fan motor rotation signal is/not detected. Is dc24v detected on cn8-1, 2 or 7? Yes fan motor connector is shorted or broken. Fan motor is defec...

Page 130

5-53 troubleshooting e3-50: transfer cleaner operation when the transfer cleaner motor drives, the transfer cleaner home position sensor is not on/off within a predetermined time. Is the wire cleaner felt no does the wire cleaner felt connect to at the home position sensor? The corona rail slider? N...

Page 131

5-54 e4-10: exhaust fan motor (1) rotation e4-11: exhaust fan motor (2) rotation e4-12: exhaust fan motor (3) rotation a lock signal is detected when the fanmotor is rotating. Is dc24v detected on cn106-3, 6 or no lvps is defective. Cn107-6 (on lvps pcb)? Yes connector is shorted or broken. Harness ...

Page 132

5-55 troubleshooting e5-04: vo (+10v) line when the power switch is turned on, dc10v is not detected. Is dc24v detected on between yes (ic16, ic9 or ic13) cpu pcb cn1-8 and 9? E5-10: +5v (for power saving mode) when the power saving mode is operated on and dc5v power supply is not 0v, the e5-10 is i...

Page 133

5-56 e5-41: registration timing control circuit abnormal when the copier stops, the optics scan and registration drive start driving or when the copier is operated, the optics scan and registration operating are not driven within a predetermined time. Ic5 on cpu pcb is defective. E5-42: total counte...

Page 134

5-57 troubleshooting e6-04: paper width home position detecting sensor when the paper width motor drives to home position, paper width home position detecting sensor is not sensed within a predetermined time. Does the paper width motor rotate? Yes check paper width home position no detecting sensor ...

Page 135

5-58 code item function (factory setting) up-00 paper size (copier and system refer to example copier: console) ledger/a3 system: not setting up-01 paper size priority 0: a4r, letter r 1: b4, legal 2 2: a4, letter 3: a3, ledger 4: invoice, a5 up-02 margin value default 0: 5mm 1: 10mm 1 2: 15mm 3: 20...

Page 136

5-59 troubleshooting code item function (factory setting) up-22 auto off timer 0: no auto off timer 1 1: 30 m 2: 60 m 3: 1.5 hr 4: 3 hr 5: 4 hr up-23 auto original density 0: not detecting 1: auto mode priority 1 (when power on) 2: manual mode priority up-24 message display 0: japanese 1: english 1 ...

Page 137

5-60 code item function (factory setting) up-34 indicate the access code number of press the access key and input the a specific department. Code number. Changing the access code number press the access key and input the of a specific department. Code number. Then press recall key and input the chan...

Page 138

6-1 unpacking/ installation vi. Unpacking/installation 6. 1 installation requirements make sure machine is properly leveled from left to right and from front to rear (use small carpenter level). The mains plug on this equipment must be used to disconnect mains power. Please ensure that the socket ou...

Page 139

6-2 6.4 installation procedure • remove the external packing/protection materials. • remove the shipping tape from the copier. • save the shipping materials for future use (transport of copier) location shipping material/procedure check 1 1. Optical unit (1) remove the original guide plate. (3 screw...

Page 140

6-3 unpacking/ installation location shipping material/procedure check 3 fuser unit (1) open the paper exit door. (2) open the fuser exit guide plate. (3) r e m o v e t h e f u s e r p r e s s u r e release screws. (2 screws) (4) close the fuser exit guide plate. (5) close the paper exit door. Devel...

Page 141

6-4 location shipping material/procedure check 5 magnet brush shield plate mag-roller mag-roller gear pour the developer into the unit (1) remove the developer unit lid. (2) pour the developer evenly into the unit. Note: pour in the entire bottle of developer, after shaking it well. (3) reinstall th...

Page 142

6-5 unpacking/ installation location shipping material/procedure check turn the power switch on tdc adjustment (1) press the “user preset”, “ledger/ a3 of original size” and “3” keys simultaneously to enter the f mode. (2) press the “8” key to enter the f8 mode. (3) press the “print” key. (4) press ...

Page 143

6-6 location shipping material/procedure check 9 10 hopper toner bottle paper guides (front/rear) toner bottle insertion (1) open the front cover. (2) take a fresh bottle of toner and shake it 10 to 15 times. (3) swing the toner bottle hopper open 90 degrees. (4) remove the toner bottle cap. (5) ins...

Page 144

6-7 unpacking/ installation 6.5 adjustment location shipping material/procedure check 1 exposure standard adjustment (1) enter the f6 mode. (2) confirm f6-11, 12, 17, 18 and 19 to “0”, and change as necessary. (3) enter the f2 mode and set the exposure to the center position in the document mode. (4...

Page 145

6-8 location shipping material/procedure check 2 side to side adjustment 1. Sheet bypass tray (1) l o o s e n a d j u s t i n g s c r e w s . (2 screws) (2) move the adjusting plate to the front or rear accordingly. Note: after this adjustment is done, duplex side to side adjustment must be done. (a...

Page 146

6-9 unpacking/ installation location shipping material/procedure check 3. Side to side adjustment (duplex) (1) pull the duplex unit tray out until it stops. (2) loosen the four screws of the front cover. (3) move the front cover as required, then tighten the screws. Note: move the front cover evenly...

Page 147

6-10 6.6 white density adjustment (when replacing the original guide for fa-a505) (1) check the rank of sensor mark sheet back side of the original guide. (2) select the f6 mode. (3) press “2” and “8” keys to enter f6 mode code “28” then press “print” key. (4) enter the new content according to the ...

Page 148

Fp-7818 / 7824 / 7830 / 7835/ 7845 / 7850 parts manual contents/index 1. Covers .................................................................................. 1 – 3 2. Frame ................................................................................... 4 – 13 3. Optics ........................

Page 149

Use and ordering information 1. Information contained in this parts manual is subject to change. Change notices and supplementary pages will be issued on a timely basis. 2. Electrical parts supplied may include previously used components. 3. A numerical part number list is located at the rear of thi...

Page 150

1-1 covers pm703 7 1 2 20 3 3 32 30 4 6 5 37 38 39 39 40 for japan 16 31 21 24 25 8 9 10 11 12 35 33 34 22 14 15 fp-7830 fp-7835 13 17 36 26 23 18 19 27 28 37 39 44 42 39 38 41.

Page 151

Ref. No. Part no. Description q'ty per unit com- mon remarks 1-1 cover covers 1 ffpxb08h00 top cover, right ass'y 1 c d 2 ffpgc0154 platen glass (7818/7824/7830/7835) 1 c d 2 ffpgc0202 platen glass (7830dc/7835dc/7835mx) 1 c d 3 ffpkn0271 glass cushion 2 c d 4 ffppa04055 paper size plate (for north ...

Page 152

1-2 covers pm703 7 1 2 20 3 3 32 30 4 6 5 37 38 39 39 40 for japan 16 31 21 24 25 8 9 10 11 12 35 33 34 22 14 15 fp-7830 fp-7835 13 17 36 26 23 18 19 27 28 37 39 44 42 39 38 41.

Page 153

Ref. No. Part no. Description q'ty per unit com- mon remarks 1-2 covers covers 25 ffpnd0176 led cover (7824 except north america) 1 c d 26 ffplb0234 start button key top 1 c d 27 ffpwb05758 pcb control panel 2 (7830/7835) 1 c c 28 ffpwc1580 ct cable 3 (7830/7835) 1 c d 29 ==not used== 30 ==not used=...

Page 154

2 covers pm703 7 1 2 20 3 3 32 4 6 5 22 25 8 39 10 29 28 9 12 33 34 34 13 14 15 16 17 a s8 36 a 31 30 21 35 18 19 11 26 27 24 23.

Page 155

Ref. No. Part no. Description q'ty per unit com- mon remarks 2 covers covers 1 ffpxb08h00 top cover, right 1 c d 2 ffpgc0202 platen glass 1 c d 3 ffpkn0271 glass cushion 2 c d 4 ffppa04055 paper size plate (for north america) 1 c d 4 ffppa04065 paper size plate (except north america) 1 c d 5 ffpna06...

Page 156

3-1 covers pm704 1 33 25 43 24 42 23 22 22 2 19 16 4 3 36 5 19 19 19 20 15 21 21 20 18 14 13 29 34 30 10 35 9 7 17 6 7 7 28 8 9 38 27 31 12 11 37 32 39 40 41.

Page 157

Ref. No. Part no. Description q'ty per unit com- mon remarks 3-1 covers covers 1 ffpna06102 right cover (except 7818) 1 c d 1 ffpna06192 right cover (7818) 1 c d 2 ffpke1021 cover, open/close (except 7718) 1 c d 2 ffpna0629 cover, open/close (7818) 1 c d 3 ffpke0999 inner cover 3 1 c d 4 ffpke1032 i...

Page 158

3-2 covers pm704 1 33 25 43 24 42 23 22 22 2 19 16 4 3 36 5 19 19 19 20 15 21 21 20 18 14 13 29 34 30 10 35 9 7 17 6 7 7 28 8 9 38 27 31 12 11 37 32 39 40 41.

Page 159

Ref. No. Part no. Description q'ty per unit com- mon remarks 3-2 covers covers 29 ffptd0936 operating guide 1 c d (einglish for north america) 1 c d 29 ffptd0937 operating guide (french for canada) 1 c d 29 ffptd0938 operating guide 1 c d (einglish ex. North america) 29 ffptd0939 operating guide (ge...

Page 160

4 frame pm701 34 31 32 18 30 35 36 29 23 22 20 17 19 4 5 16 s19 15 21 9 10 5 6 7 8 11 12 13 14 28 28 27 26 26 1 2 3 25 24 33 37 38.

Page 161

Ref. No. Part no. Description q'ty per unit com- mon remarks 4 frame (except 7818) frame 1 ffpmq0544 bushing, rear 1 c d 2 ffplp1040 spring 1 c c 3 ffpkf1261 developer rail, right 1 c d 4 ffpkf1260 drum rail, left 1 c d 5 ffpkd1335 cam holder 2 c d 6 ffplj0086 cam 2 1 c d 7 ffplp0989 pressure spring...

Page 162

5 frame pm701-s 31 32 13 18 30 35 36 29 25 24 23 22 20 16 19 4 5 15 9 10 5 6 7 8 11 12 14 28 33 28 27 26 26 1 2 3 34.

Page 163

Ref. No. Part no. Description q'ty per unit com- mon remarks 5 frame (7818) frame 1 ffpmq0544 bushing, rear 1 c d 2 ffplp1040 spring 1 c c 3 ffpkf1261 developer rail, right 1 c d 4 ffpkf1260 drum rail, left 1 c d 5 ffpkd1335 cam holder 2 c d 6 ffplj0086 cam 2 1 c d 7 ffplp0989 pressure spring 1 1 c ...

Page 164

Frame 6-1 pm702 19 6 22 11 56 56 60 61 62 50 59 58 49 2 5 6 7 49 11 6 13 17 49 15 53 8 9 10 31 32 32 27 25 24 26 27 a a 51 42 46 30 33 14 11 36 37 38 65 40 4 12 21 23 16 12 29 56 b 28 20 16 34 45 43 44 41 52 47 50 48 1 18 3 54 57 55 15 3 66 63 35 64 b.

Page 165

Ref. No. Part no. Description q'ty per unit com- mon remarks 1 ffpkr1710 bracket, pcb ac drive 1 c d 2 ffpkr1798 bracket, thermistor cable 1 c d 3 ffpfa0072 shoulder screw 2 c d 4 ffpnm0029 foot 1 c d 5 ffpwb05731 pcb ac driver 1 c c (7824/7830/7835 for north america) 5 ffpwb05734 pcb ac driver 1 c ...

Page 166

Frame 6-2 pm702 19 6 22 11 56 56 60 61 62 50 59 58 49 2 5 6 7 49 11 6 13 17 49 15 53 8 9 10 31 32 32 27 25 24 26 27 a a 51 42 46 30 33 14 11 36 37 38 65 40 4 12 21 23 16 12 29 56 b 28 20 16 34 45 43 44 41 52 47 50 48 1 18 3 54 57 55 15 3 66 63 35 64 b.

Page 167

Ref. No. Part no. Description q'ty per unit com- mon remarks 44 ffplk0332 separation finger, drum (7845/7850) 1 c d 45 ffplg1539 impulse shaft (7845/7850) 1 c d 46 ffplp1028 cancellation spring, finger (7845/7850) 1 c c 47 ffplp1026 impulse spring (7845/7850) 1 c c 48 ffpll0595 pressure lever (7845/...

Page 168

Frame 7 pm702-s 19 6 22 11 39 39 2 5 6 7 41 41 11 6 13 17 41 15 8 47 9 10 31 32 32 30 27 25 24 43 14 11 36 37 38 26 4 12 21 23 16 12 29 39 28 20 16 1 18 3 45 40 42 15 3 46 48.

Page 169

Ref. No. Part no. Description q'ty per unit com- mon remarks 1 ffpkr1710 bracket, pcb ac drive 1 c d 2 ffpkr1798 bracket, thermistor cable 1 c d 3 ffpfa0072 shoulder screw 2 c d 4 ffpnm0029 foot 4 c d 5 ffpwb05731 pcb ac driver (for north america) 1 c c 5 ffpwb05736 pcb ac driver (except north ameri...

Page 170

8-1 frame pm705 1 1 2 3 4 9 8 7 6 10 11 12 13 14 15 23 27 1 29 28 29 29 38 39 17 38 18 26 21 20 19 16 35 30 36 37 29 33 31 32 22 25 24 23 45 46 23 23 40 34 5 41 37 42 43 44.

Page 171

Ref. No. Part no. Description q'ty per unit com- mon remarks 8-1 frame (except 7818) frame 1 xpj2d16wv pin 7 c d 2 ffpmf0984 gear, paper feed drive (7845/7850) 1 c d 2 ffpmf0993 gear, paper feed drive (7824/7830/7835) 1 c d 3 ffplg14591 shaft, paper feed drive 1 c d 4 ffplg1458 shaft, drum drive 1 c...

Page 172

8-2 frame pm705 1 1 2 3 4 9 8 7 6 10 11 12 13 14 15 23 27 1 29 28 29 29 38 39 17 38 18 26 21 20 19 16 35 30 36 37 29 33 31 32 22 25 24 23 45 46 23 23 40 34 5 41 37 42 43 44.

Page 173

Ref. No. Part no. Description q'ty per unit com- mon remarks 8-2 frame (except 7818) frame 39 ffpmb0230 pulley 1 c d 40 ffpmb0231 delivery pulley 1 c d 41 ffpkf1366 slider 1 c d 42 ffpmf1083 drive gear 1 c d 43 ffpmf1082 decrease gear 1 c d 44 ffpmf1081 idle gear 1 c d 45 ffpmf1071 idle gear 1 1 c d...

Page 174

9 frame pm705-s 1 1 2 3 4 9 8 7 6 42 43 44 10 11 12 13 14 15 23 27 1 47 a 28 29 29 38 39 17 38 18 40 41 20 19 16 30 45 29 36 37 29 33 31 32 22 25 24 23 a 26 23 46 34 21 37 5.

Page 175

Ref. No. Part no. Description q'ty per unit com- mon remarks 9 frame (except 7818) frame 1 xpj2d16wv pin 7 c d 2 ffpmf1107 gear, paper feed drive 1 c d 3 ffplg14591 shaft, paper feed drive 1 c d 4 ffplg1458 shaft, drum drive 1 c d 5 ffpmv0006 polyslider 1 c d 6 ffpkd0694 spring holder 2 1 c d 7 ffpl...

Page 176

10 frame pm706 1 2 14 13 11 15 6 2 9 2 9 5 4 3 16 17 18 26 f 7850 c o f 7845/7850 25 24 23 22 20 21 34 32 35 36 42 41 39 38 37 40 31 8 30 29 28 27 33 19 10 12 7 43 44.

Page 177

Ref. No. Part no. Description q'ty per unit com- mon remarks 10 frame (except 7818) frame 1 ffpmf0989 drive gear 2 c d 2 ffpmq0540 bearing 1 (7845/7850) 4 c d 2 ffpmq0558 bearing 1 (7824/7830/7835) 4 c d 3 ffpxa49h001 tension bracket 3 ass'y 1 c d 4 ffplp10181 tension spring 3 1 c c 5 ffpfa0141 shou...

Page 178

11 frame 1 2 34 pm706-s 16 17 18 26 25 24 23 22 20 21 33 31 8 30 29 28 27 19 14 13 11 15 2 9 12 7 32 5 4 3.

Page 179

Ref. No. Part no. Description q'ty per unit com- mon remarks 11 frame (7818) frame 1 ffpmf0989 drive gear 1 c d 2 ffpmq0558 bearing 1 2 c d 3 ffpxa49h001 tension bracket 3 ass'y 1 c d 4 ffplp10181 tension spring 3 1 c c 5 ffpfa0141 shoulder screw 1 c d 6 ==not used== 7 ffpkd1299 rear frame, paper fe...

Page 180

12-1 frame pm707 2 23 31 4 5 6 8 7 13 10 9 51 55 35 56 32 34 55 54 32 63 38 24 14 62 41 60 50 57 59 37 25 52 11 3 22 21 20 19 18 1 33 30 36 29 28 26 53 27 69 66 65 67 17 16 15 68 58 17 17 64 55 55 61 42 43 44 45 46 47 48 49.

Page 181

Ref. No. Part no. Description q'ty per unit com- mon remarks 1 ffpdf0274 bias lead 1 1 c d 2 ffpde0072 bias terminal 1 c d 3 eds1 edge saddle 4 c d 4 ffpde0073 corona terminal 1 c d 5 ffpdf0277 shield lead 1 1 c d 6 ffpdf0281 corona lead 1 1 c d 7 ffpdf0276 grid lead 1 1 c d 8 ffpke1005 corona termi...

Page 182

12-2 frame pm707 2 23 31 4 5 6 8 7 13 10 9 51 55 35 56 32 34 55 54 32 63 38 24 14 62 41 60 50 57 59 37 25 52 11 3 22 21 20 19 18 1 33 30 36 29 28 26 53 27 69 66 65 67 17 16 15 68 58 17 17 64 55 55 61 42 43 44 45 46 47 48 49.

Page 183

Ref. No. Part no. Description q'ty per unit com- mon remarks 12-2 frame (execpt 7818) frame 38 ffpdf0282 connection terminal 1 c d 41 ffpwc1619 hvc cable 1 c d 42 ffpkr1716 bracket, option connector 1 c d 43 ffpwc1638 heater cable 1 1 c d 44 ffpwc1628 ac cable 1 1 c d 45 ffpev0125 power cord (others...

Page 184

13-1 frame pm707-s 2 31 4 5 6 8 7 16 15 13 10 9 51 55 56 35 32 34 55 54 32 63 38 24 14 62 41 60 50 57 59 37 25 52 11 3 53 1 33 36 45 46 47 48 49 28 64 67 66 65.

Page 185

Ref. No. Part no. Description q'ty per unit com- mon remarks 13-1 frame (7818) frame 1 ffpdf0274 bias lead 1 1 c d 2 ffpde0072 bias terminal 1 c d 3 eds1 edge saddle 3 c d 4 ffpde0073 corona terminal 1 c d 5 ffpdf0277 shield lead 1 1 c d 6 ffpdf0281 corona lead 1 1 c d 7 ffpdf0276 grid lead 1 1 c d ...

Page 186

13-2 frame pm707-s 2 31 4 5 6 8 7 16 15 13 10 9 51 55 56 35 32 34 55 54 32 63 38 24 14 62 41 60 50 57 59 37 25 52 11 3 53 1 33 36 45 46 47 48 49 28 64 67 66 65.

Page 187

Ref. No. Part no. Description q'ty per unit com- mon remarks 13-2 frame (7818) frame 57 ffpwb05724 pcb cpu w/o p-rom 1 c c 58 ==not used== 59 ffpks1047 shield plate, hvps 1 c d 60 ffpwb0598 pcb hvps 1 c c 61 ==not used== 62 ffpke1003 case, high voltage 1 c d 63 ffpah0264 p-rom 1 c d 63 ffpah0187 p-r...

Page 188

14-1 optics pm601 57 21 21 21 56 52 53 54 13 10 50 51 41 55 31 22 16 18 17 19 20 22 23 24 10 13 47 13 46 45 42 40 22 39 43 60 59 28 58 61 44 44 22 63 38 37 33 35 34 33 32 31 36 29 30 25 26 27 48 27 30 49 29 28 26 25 10 17 23 20 1 2 4 3 7 8 10 11 5 6 9 15 14 13 12 62.

Page 189

Ref. No. Part no. Description q'ty per unit com- mon remarks 14-1 optics optics 1 ffpet0013 thermostat 1 c d 2 ffpez0202 tube 1 c d 3 ffpdf0254 terminal plate 1 c d 4 ffpde0070 terminal f 1 c d 5 e08v025wn2a exposure lamp (for north america) 1 c d 5 e16v025wn2a exposure lamp (except north america) 1...

Page 190

14-2 optics pm601 57 21 21 21 56 52 53 54 13 10 50 51 41 55 31 22 16 18 17 19 20 22 23 24 10 13 47 13 46 45 42 40 22 39 43 60 59 28 58 61 44 44 22 63 38 37 33 35 34 33 32 31 36 29 30 25 26 27 48 27 30 49 29 28 26 25 10 17 23 20 1 2 4 3 7 8 10 11 5 6 9 15 14 13 12 62.

Page 191

Ref. No. Part no. Description q'ty per unit com- mon remarks 14-2 optics optics 45 ffpgc0190 no.3 mirror (except 7818) 1 c d 45 ffpgc0197 no.3 mirror (7818) 1 c d 46 ffpgc0189 no.2 mirror (except 7818) 1 c d 46 ffpgc0196 no.2 mirror (7818) 1 c d 47 ffpkd1313 no.2/3 mirror support, front 1 c d 48 ffp...

Page 192

15-1 optics pm602 43 13 40 38 39 21 33 31 27 1 2 3 49 4 4 36 34 35 30 16 19 20 10 26 32 10 8 6 5 5 7 45 37 28 23 24 25 22 18 17 14 16 15 14 12 11 9 42 41 47 46 48 29 50

Page 193

Ref. No. Part no. Description q'ty per unit com- mon remarks 15-1 optics optics 1 ffpke099411 optics cover (7818/7824) 1 c d 1 ffpke09949 optics cover (7830/7835/7845/7850) 1 c d 2 ffpwc1597 kst cable 3 1 c d 3 ffpxk34950 pcb paper size detection 2 ass'y 2 c d 4 ffpgc0191 no.4/5 mirror (except 7818)...

Page 194

15-2 optics pm602 43 13 40 38 39 21 33 31 27 1 2 3 49 4 4 36 34 35 30 16 19 20 10 26 32 10 8 6 5 5 7 45 37 28 23 24 25 22 18 17 14 16 15 14 12 11 9 42 41 47 46 48 29 50

Page 195

Ref. No. Part no. Description q'ty per unit com- mon remarks 15-2 optics optics 47 ffpjc02301 insulation sheet lens frame 1 c d 48 ffpkd07771 holder 1 c d 49 ffpwc1597 kst cable 1 c d 50 ffpkf13431 cable guide 1 c d.

Page 196

16 optics pm603 1 32 33 3 24 23 20 38 38 22 18 17 21 4 7 5 2 5 6 12 8 38 16 25 27 34 26 26 14 13 10 10 30 10 11 15 9 19 27 28 29 28 29 25 37 15 fp-7818/7824 31 36 35.

Page 197

Ref. No. Part no. Description q'ty per unit com- mon remarks 16 optics optics 1 ffpwc1630 opt2 cable 1 c d 2 ffpkr17014 bracket 4, adf 1 c d 3 ffpkr16971 bracket 2, adf 1 c d 4 ffpku0178 reinforcement frame, right 1 c d 5 ffpkr1790 bracket 5, adf 2 c d 6 ffpkr16981 bracket 3, adf 1 c d 7 ffpjd00421 ...

Page 198

17-1 toner hopper unit 47 pm302 2 4 5 6 8 12 13 14 16 15 21 18 39 38 36 3 15 40 41 7 19 20 17 15 21 22 37 23 25 24 26 27 28 30 31 32 33 34 35 29 15 9 11 3 1 43 53 42 52 15 50 51 44 46 48 49 10 45.

Page 199

Ref. No. Part no. Description q'ty per unit com- mon remarks 17-1 toner hopper unit toner hopper unit 0 ffpuh01h011 hopper unit (7830/7835/7845/7850) 1 c d 0 ffpuh01h411 hopper unit (7818/7824) 1 c d 1 ffpxa81h001 hopper bracket 1 c d 2 ffpkd1344 support 1 c d 3 eds2 edge saddle 2 c d 4 gp1a73a sens...

Page 200

17-2 toner hopper unit 47 pm302 2 4 5 6 8 12 13 14 16 15 21 18 39 38 36 3 15 40 41 7 19 20 17 15 21 22 37 23 25 24 26 27 28 30 31 32 33 34 35 29 15 9 11 3 1 43 53 42 52 15 50 51 44 46 48 49 10 45.

Page 201

Ref. No. Part no. Description q'ty per unit com- mon remarks 17-2 toner hopper unit toner hopper unit 46 xpl2a8wv pin 1 c d 47 ffphk09931 mylar 1 c d 48 ffphp07461 seal 1 c d 49 ffphp0764 seal 1 c d 50 ffphp0757 seal 1 c d 51 ffphp0765 seal 1 c d 52 ffpte2098 label 1 c d 53 ffpfj0033 touch ring 1 c ...

Page 202

18-1 developer section pm301 41 44 20 18 17 16 15 13 14 12 11 10 35 36 37 28 39 6 4 38 3 2 1 19 4 5 7 8 9 6 34 4 4 21 24 23 27 26 22 29 30 31 33 32 25 40 43.

Page 203

Ref. No. Part no. Description q'ty per unit com- mon remarks 18-1 developer section developer section 0 ffpug01h012 developer unit (7845/7850) 1 c d 0 ffpug01h211 developer unit (7830/7835/7845/7850) 1 c d 0 ffpug01h41 developer unit (7824) 1 c d 0 ffpug01h51 developer unit (7818) 1 c d 1 ffpha0075 ...

Page 204

18-2 developer section pm301 41 44 20 18 17 16 15 13 14 12 11 10 35 36 37 28 39 6 4 38 3 2 1 19 4 5 7 8 9 6 34 4 4 21 24 23 27 26 22 29 30 31 33 32 25 40 43.

Page 205

Ref. No. Part no. Description q'ty per unit com- mon remarks 18-2 developer section developer section 36 ffpmq0548 bushing 1 1 c d 37 ffpmf0995 gear, string paddle (except 7818) 1 c d 37 ffpmf1106 gear, string paddle (7818) 1 c d 38 ffphg00462 supply coil 1 c d 39 ffpmf0996 transfer gear 1 c d 40 ff...

Page 206

19-1 cleaning section pm401 1 2 46 39 41 37 36 35 34 33 32 31 30 29 28 27 26 25 24 38 20 23 17 18 13 14 11 7 10 47 9 8 6 5 4 42 44 45 43 48 49 51 53 59 57 60 58 52 49 54 55 56 61 62 50 3 7 12 16 71 15 19 40 65 64 63 69 68 70 64 21 22 66 67 72 a a.

Page 207

Ref. No. Part no. Description q'ty per unit com- mon remarks 19-1 cleaning section cleaning section 0 ffpug20h003 drum unit (7830/7835/7845/7850) 1 c d 0 ffpug20h403 drum unit (7818/7824) 1 c d 1 ffpxg53h00 cleaning cover ass'y 1 c d 2 ffpkd13402 toner support 1 c d 3 ffpxg51h001 side seal f ass'y 1...

Page 208

19-2 cleaning section pm401 1 2 46 39 41 37 36 35 34 33 32 31 30 29 28 27 26 25 24 38 20 23 17 18 13 14 11 7 10 47 9 8 6 5 4 42 44 45 43 48 49 51 53 59 57 60 58 52 49 54 55 56 61 62 50 3 7 12 16 71 15 19 40 65 64 63 69 68 70 64 21 22 66 67 72 a a.

Page 209

Ref. No. Part no. Description q'ty per unit com- mon remarks 19-2 cleaning section cleaning section 45 ffpll05541 pressure lever 1 c d 46 ffphk09421 cleaning blade 1 c d 47 ffphp0761 toner discharge seal 1 c d 48 ffpxg60h00 no.1 corona ass'y 1 c d 49 ffpjc01881 shield cover 2 c d 50 ffpks06751 coron...

Page 210

20-1 paper feed section pm101 1 65 3 4 61 13 14 15 11 16 17 17 19 22 28 58 69 57 56 55 13 15 54 53 50 50 49 3 48 40 37 35 32 35 36 33 34 41 13 42 17 64 63 39 70 17 45 44 3 47 46 43 52 51 77 29 25 27 30 31 24 13 23 22 26 27 25 68 20 21 13 67 18 12 71 60 59 5 6 4 66 7 8 2 62 s31 9 42 73 79 75 76 74 72...

Page 211

Ref. No. Part no. Description q'ty per unit com- mon remarks 20-1 paper feed section paper feed section 0 ffpuq01h002 sheet bypass unit (7845/7850) 1 c d 0 ffpuq01h203 sheet bypass unit (7824/7830/7835) 1 c d 0 ffpuq01h512 sheet bypass unit (7818) 1 c d 1 ffphk0951 cleaning sheet 1 1 c d 2 ffpkf1270...

Page 212

20-2 paper feed section pm101 1 65 3 4 61 13 14 15 11 16 17 17 19 22 28 58 69 57 56 55 13 15 54 53 50 50 49 3 48 40 37 35 32 35 36 33 34 41 13 42 17 64 63 39 70 17 45 44 3 47 46 43 52 51 77 29 25 27 30 31 24 13 23 22 26 27 25 68 20 21 13 67 18 12 71 60 59 5 6 4 66 7 8 2 62 s31 9 42 73 79 75 76 74 72...

Page 213

Ref. No. Part no. Description q'ty per unit com- mon remarks 20-2 paper feed section paper feed section 43 ffpwc1605 rst cable 2 (7824/7830/7835) 1 c d 43 ffpwc1668 rst cable 2 (7818) 1 c d 44 ffpkb09071 frame, sheet bypass 1 c d 45 ffpmf11081 dfp roller gear 1 c d 46 ffplr0261 return spring 1 c c 4...

Page 214

21-1 paper feed section pm202 26 46 30 45 10 41 43 44 35 40 35 38 2 1 3 4 5 6 7 8 9 10 11 12 14 13 14 54 19 21 20 22 26 23 24 17 18 16 15 39 57 48 52 26 49 fp-7845/7850 50 51 42 47 25 27 28 29 30 26 31 32 31 56 34 35 36 37 33 33 53 6 58 55.

Page 215

Ref. No. Part no. Description q'ty per unit com- mon remarks 21-1 paper feed section paper feed section 0 ffpuq02h00 feed unit (7845/7850) 1 c d 0 ffpuq02h20 feed unit (7818/7824/7830/7835) 1 c d 1 ffplp0973 return spring 1 (7845/7850) 1 c c 2 ffpll0567 pick up arm (7845/7850) 1 c d 3 ffpkd1353 sole...

Page 216

Paper feed section 21-2 pm202 26 46 30 45 10 41 43 44 35 40 35 38 2 1 3 4 5 6 7 8 9 10 11 12 14 13 14 54 19 21 20 22 26 23 24 17 18 16 15 39 57 48 52 26 49 fp-7845/7850 50 51 42 47 25 27 28 29 30 26 31 32 31 56 34 35 36 37 33 33 53 6 58 55.

Page 217

Ref. No. Part no. Description q'ty per unit com- mon remarks paper feed section paper feed section 44 ffpks1089 earth plate 1 c d 45 ffpmf1020 roller gear, paper feed 1 c d 46 ffpkf1282 bracket guide 1 c d 47 ffpxq14h00 paper feed roller shaft ass'y 1 c d 48 ffpma0542 pick up roller 1 c d 49 ffplp09...

Page 218

Paper transport section 22-1 pm708 3 7 5 6 3 15 16 15 15 16 15 11 18 17 15 16 15 5 5 5 4 8 20 21 30 26 27 37 36 48 35 49 7 33 32 31 2(fp-7845/7850) 34 fp-7818/7824 /7830/7835 1 19 26 27 17 38 24 23 31 28 22 47 41 42 43 29 10 12 9 13 44 45 46 40 50 14 39 39 30 27 33 27 24 23.

Page 219

Ref. No. Part no. Description q'ty per unit com- mon remarks paper transport section paper transport section 1 ffpue01h011 paper transport unit (7845/7850) 1 c d 1 ffpue01h211 paper transport unit (7824/7830/7835) 1 c d 1 ffpue01h511 paper transport unit (7818) 1 c d 2 ffpxe03h00 cleaning mechanism ...

Page 220

Paper transport section 22-2 pm708 3 7 5 6 3 15 16 15 15 16 15 11 18 17 15 16 15 5 5 5 4 8 20 21 30 26 27 37 36 48 35 49 7 33 32 31 2(fp-7845/7850) 34 fp-7818/7824 /7830/7835 1 19 26 27 17 38 24 23 31 28 22 47 41 42 43 29 10 12 9 13 44 45 46 40 50 14 39 39 30 27 33 27 24 23.

Page 221

Ref. No. Part no. Description q'ty per unit com- mon remarks paper transport section paper transport section 41 ffpja0295 terminal cover 2 1 c d 42 ffplp1039 spring 1 c c 43 ffpxl03h00 base, rear 1 c d 44 ffpke1031 transfer case 1 c d 45 ffplk0329 separation finger 1 c d 46 ffpja0292 base, front 1 c...

Page 222

Fuser 23-1 pm501 16 11 10 5 6 15 17 18 19 1 2 3 4 4 5 6 21 22 23 24 25 26 26 26 43 28 28 27 29 42 20 39 37 fp-7845/7850 37 39 39 41 40 7 8 14 13 12 37 38 36 30 32 33 34 31 31 35 26 26 28 27 29 fp-7818/7824 fp-7830/7835.

Page 223

Ref. No. Part no. Description q'ty per unit com- mon remarks fuser fuser 0 ffput01h011 fuser unit (7850 for north america) 1 c d 0 ffput01h032 fuser unit (7850 except north america) 1 c d 0 ffput01h112 fuser unit (7845 for north america) 1 c d 0 ffput01h132 fuser unit (7845 except north america) 1 c...

Page 224

Fuser 23-2 pm501 16 11 10 5 6 15 17 18 19 1 2 3 4 4 5 6 21 22 23 24 25 26 26 26 43 28 28 27 29 42 20 39 37 fp-7845/7850 37 39 39 41 40 7 8 14 13 12 37 38 36 30 32 33 34 31 31 35 26 26 28 27 29 fp-7818/7824 fp-7830/7835.

Page 225

Ref. No. Part no. Description q'ty per unit com- mon remarks fuser fuser 27 ffpkf1311 finger guide, lower (7845/7850) 1 c d 27 ffpkf1337 finger guide, lower (7818/7824) 1 c d 27 ffpkf1341 finger guide, lower (7830/7835) 1 c d 28 ffpln0007 spring, finger lower (7845/7850) 2 c d 28 ffpln0007 spring, f...

Page 226

Fuser 24-1 pm502 1 3 4 5 6 7 8 9 10 11 16 15 17 12 39 38 37 35 34 33 31 41 42 30 26 27 27 25 21 20 22 23 24 20 19 18 14 14 13 12 28 28 29 29 32 36 40 13 2 a 2 44 5 3 1 a (japan only) 4 43 43.

Page 227

Ref. No. Part no. Description q'ty per unit com- mon remarks 0 ffput01h011 fuser unit (7850 for north america) 1 c d 0 ffput01h032 fuser unit (7850 except north america) 1 c d 0 ffput01h112 fuser unit (7845 for north america) 1 c d 0 ffput01h132 fuser unit (7845 except north america) 1 c d 0 ffput01...

Page 228

Fuser 24-2 pm502 1 3 4 5 6 7 8 9 10 11 16 15 17 12 39 38 37 35 34 33 31 41 42 30 26 27 27 25 21 20 22 23 24 20 19 18 14 14 13 12 28 28 29 29 32 36 40 13 2 a 2 44 5 3 1 a (japan only) 4 43 43.

Page 229

Ref. No. Part no. Description q'ty per unit com- mon remarks 18 ffpxt18h001 lamp frame, front 1 ass'y (7845/7850) 1 c d 19 ffpxt19h001 lamp frame, front 2 ass'y (7845/7850) 1 c d 19 ffpxt18h201 lamp frame, front 1 c d 20 ffplp1006 lamp spring (7845/7850) 2 c c 20 ffplp1006 lamp spring (7818/7824/783...

Page 230

Fuser 24-3 pm502 1 3 4 5 6 7 8 9 10 11 16 15 17 12 39 38 37 35 34 33 31 41 42 30 26 27 27 25 21 20 22 23 24 20 19 18 14 14 13 12 28 28 29 29 32 36 40 13 2 a 2 44 5 3 1 a (japan only) 4 43 43.

Page 231

Ref. No. Part no. Description q'ty per unit com- mon remarks 42 ffpmf1079 idle gear 2 (7818/7824/7830/7835) 1 c d 43 ffpkh0332 spacer (except north america) 2 c d 44 ==not used== fuser fuser 24-3.

Page 232

25 paper exit section pm709 1 2 3 4 5 6a 7 16 15 14 13 6b 8a 9a 9c 9c 9a 11 s10 10 8a 8b 9b 17 8b 9b 12 19 18 12 18.

Page 233

Ref. No. Part no. Description q'ty per unit com- mon remarks 0 ffpuf01r001 paper exit unit (7818) 1 c d 0 ffpuf01r40 paper exit unit (7824/7830/7835) 1 c d 0 ffpuf01r50 paper exit unit (7845/7850) 1 c d 1 ffpla0099 knob, open/close 1 c d 2 ffplp1022 knob spring 1 c c 3 ffpkb0939 frame, paper exit 1 ...

Page 234

26 550 sheet paper tray pm201 19 20 21 17 22 15 15 20 19 25 24 23 26 16 1 2 3 4 13 14 6 6 8 11 12 10 7 5 27.

Page 235

Ref. No. Part no. Description q'ty per unit com- mon remarks 1 ffpkd13561 bottom frame 1 c d 2 ffpkm0318 pad 1 c d 3 ffpka0168 fulcrum block 1 c d 4 ffpqg0081 paper guide, rear 1 c d 5 ffpte2077 label, upper level 1 c d 6 ffpqg0083 paper guide plate 2 c d 7 ffpqg00802 paper guide, front 1 c d 8 ffpl...

Page 236

27 sheet bypass tray pm102 8 1 7 5 3 4 6 10 11 4 12 13 9 16 15 18 14 4 17 2.

Page 237

Ref. No. Part no. Description q'ty per unit com- mon remarks 0 ffpuq90h012 sheet bypass tray (for north america) 1 c d 0 ffpuq90h032 sheet bypass tray (except north america) 1 c d 1 ffpqb00474 tray cover 1, sheet bypass 1 c d 2 ffpkp0067 pad, sheet bypass 1 c d 3 ffpwc1616 hf cable 1 c d 4 gp1a73a s...

Page 238

28 adu pm801 16 8 1 4 14 12 10 11 11 13 13 6 7 8 16 9 5 3 2 15.

Page 239

Ref. No. Part no. Description q'ty per unit com- mon remarks 0 ffpuq03j001 middle roller unit 1 c d 1 ffpkf1305 paper guide a 1 c d 2 ffpwc1648 atq cable 1 c d 3 gp1a73a sensor 1 c b 4 ffplr0264 sensor spring 1 c c 5 ffpks1057 sensor plate 1 c d 6 ffpkb0930 rear frame 1 c d 7 ffplq0424 earth plate 1...

Page 240

Adu 29-1 pm802 9 3 1 8 2 2 2 3 2 73 4 5 6 s10 72 6 s8 77 62 58 64 64 66 67 60 59 58 57 72 56 s8 s13 55 54 71 65 46 44 43 61 71 a 53 52 51 s19 s19 s8 58 a 31 60 33 50 49 48 s8 s30 34 35 37 38 39 40 42 32 70 69 66 e4 e4 3 7 31 s8 s9 39 35 42 38 41 35 34 17 16 6 s18 64 s8 18 s8 19 e3 47 20 21 22 23 25 ...

Page 241

Ref. No. Part no. Description q'ty per unit com- mon remarks 1 ffpkm0308 slider 1 c d 2 ffplp0985 pressure spring 5 c c 3 ffpma05531 pinch roller 5 c d 4 ffpll0580 sensor lever c 1 c d 5 ffpkf12951 paper guide 1 1 c d 6 ffpfj0043 touch ring 4 c d 7 ffpla0097 knob 1 1 c d 8 ffplp0986 pressure spring ...

Page 242

Adu 29-2 pm802 9 3 1 8 2 2 2 3 2 73 4 5 6 s10 72 6 s8 77 62 58 64 64 66 67 60 59 58 57 72 56 s8 s13 55 54 71 65 46 44 43 61 71 a 53 52 51 s19 s19 s8 58 a 31 60 33 50 49 48 s8 s30 34 35 37 38 39 40 42 32 70 69 66 e4 e4 3 7 31 s8 s9 39 35 42 38 41 35 34 17 16 6 s18 64 s8 18 s8 19 e3 47 20 21 22 23 25 ...

Page 243

Ref. No. Part no. Description q'ty per unit com- mon remarks 51 ffpmn0110 timing belt 3 1 c d 52 ffpxd11j00 motor bracket ass'y 1 c d 53 ffpks1070 motor plate 1 c d 54 ffphl0010 damper 1 c d 55 ffpxd10j00 stepping motor 1 c d 56 ffpwc1642 adk cable 1 c d 57 ffplp0981 tension spring 1 c c 58 ffpfj003...

Page 244

Adu 30 pm803 32 33 6 31 30 29 28 27 26 25 24 23 22 21 20 19 19 18 14 13 11 12 15 17 16 34 10 9 8 3 2 1 4 7 35 s8 s10 5 6 6 36 36 36 36.

Page 245

Ref. No. Part no. Description q'ty per unit com- mon remarks 1 ffpkf1299 paper guide 1 c d 2 ffpkf1297 paper guide, rear 1 c d 3 ffpqb00502 paper feed case 1 c d 4 ffpkp00821 pad 1 c d 5 ffpkf1298 paper guide, front 1 c d 6 gp1a73a sensor 3 c b 7 ffpkd1362 lifting plate 2 1 c d 8 ffplp09801 pressure...

Page 246

Maintenance chart 31 item service part number q'ty per maintenance cycle (x 1000) unit 80/120 160/240 240/360 320/480 400/600 paper paper feed roller ffpma05411 2 x feed dfp roller ffpma05411 2 x unit pick-up roller ffpma0542 2 x cleaning sheet ffphk0951 2 x (except fp-7818/7824) registration roller...

Page 247

Maintenance chart 32 item service part number q'ty per maintenance cycle (x 1000) unit 80/120 160/240 240/360 320/480 400/600 fuser separation finger (upper) (7845/7850) ffplk0331 5 x unit separation finger (upper) ffplk0230 2 x (7818/7824/7830/7835) separation finger (lower) ffplk0231 4 x thermiste...

Page 248

Maintenance chart 33 item service part number q'ty per maintenance cycle (x 1000) unit 80/120 160/240 240/360 320/480 400/600 main suction/ozone filter ffphj0039 1 x body ozone filter 1 ffphj0038 1 x ozone filter 5 ffphj0042 1 x (fp-7830/7835/7845/7850) ozone filter 7 ffphj00461 1 x (fp-7818/7824) d...

Page 249

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 33.

Page 250

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 34 23x5a tray rivet 14 10 8 42s1a24dcsc stepping motor 15 14 2 42s1a24dcsc stepping motor (7818/7824) 17 40 1 42s1a24dcsc stepping motor (7845/7850) 22 35 1 42s1a24dcsc stepping motor 30 26 2 bj-2.6-w01 ...

Page 251

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 35 ffpah0269 p-rom (7845) 12 63 1 ffpah0270b p-rom (7850) 12 63 1 ffpah0271 p-rom 2 31 1 ffpbl0015 thermistor 24 7 1 ffpcv0009 total counter 3 35 1 ffpda0031 corona socket 12 9 1 ffpda0031 corona socket ...

Page 252

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 36 ffpet0015 thermostat 24 2 2 ffpev0125 power cord (others) 12 45 1 ffpev0125 power cord (others) 13 45 1 ffpev0126 power cord (for u.K.) 12 45 1 ffpev0126 power cord (for u.K.) 13 45 1 ffpev0127 power ...

Page 253

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 37 ffpfj00441 stopper ring 10 16 1 ffpfj00441 stopper ring 11 16 1 ffpga0065 lens (7845/7850) 15 38 1 ffpga0074 lens (7818/7824/7830/7835) 15 38 1 ffpgb0022 filter a 1 32 1 ffpgb0022 filter a 2 32 1 ffpg...

Page 254

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 38 ffphj00461 ozone filter 7 (7818/7824) 16 28 2 ffphk09361 sensor mark sheet 1 6 1 ffphk09361 sensor mark sheet 2 6 1 ffphk0937 doctor blade 18 28 1 ffphk0940 pipe seal 18 8 1 ffphk09421 cleaning blade ...

Page 255

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 39 ffphp07691 e shape mylar (7830/7835/7845/7850) 19 68 1 ffphp0772 mylar 1 18 43 1 ffphp0786 sponge 20 75 1 ffphq00322 drum cup ring 8 8 1 ffphq00322 drum cup ring 9 8 1 ffphq0055 spacer ring, front (78...

Page 256

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 40 ffpka0162 dfp bracket 29 28 1 ffpka0163 support 1 22 30 1 ffpka0164 support 2 22 24 1 ffpka0167 front cover support, left 4 35 1 ffpka0167 front cover support, left 5 35 1 ffpka0168 fulcrum block 26 3...

Page 257

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 41 ffpkd13361 blade stay 18 34 1 ffpkd1337 gear support plate 18 33 1 ffpkd13402 toner support 19 2 1 ffpkd1343 bottle support, left 17 31 1 ffpkd1344 support 17 2 1 ffpkd13461 hopper bracket 2 17 36 1 f...

Page 258

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 42 ffpke09971 inner cover 1 1 16 1 ffpke09971 inner cover 1 2 16 1 ffpke09983 inner cover 2 3 5 1 ffpke0999 inner cover 3 3 3 1 ffpke1001 waste toner cover 6 40 1 ffpke1001 waste toner cover 7 48 1 ffpke...

Page 259

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 43 ffpkf1260 drum rail, left 4 4 1 ffpkf1260 drum rail, left 5 4 1 ffpkf1261 developer rail, right 4 3 1 ffpkf1261 developer rail, right 5 3 1 ffpkf1262 front cover stopper 3 28 1 ffpkf1263 stopper 6 18 ...

Page 260

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 44 ffpkf1337 finger guide, lower (7818/7824) 23 27 1 ffpkf1338 front guide, upper (7818/7824) 24 9 1 ffpkf1339 paper guide 4 (7818/7824/7830/7835) 23 29 1 ffpkf1340 front guide, upper (7830/7835) 24 9 1 ...

Page 261

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 45 ffpkn0344 sponge seal (7830/7835/7845/7850) 12 23 1 ffpkn0349 cushion sheet 20 62 1 ffpkn0356 sponge 2 18 14 1 ffpkn0357 sponge 3 18 22 1 ffpkn0367 cushion sheet 20 65 1 ffpkn0375 seal 11 34 3 ffpkp00...

Page 262

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 46 ffpkr1723 bracket, stopper lever 20 6 1 ffpkr1724 sensor bracket 20 5 1 ffpkr1729 bracket, pick up roller 21 50 1 ffpkr1740 bracket c, power cord 12 48 1 ffpkr1740 bracket c, power cord 13 48 1 ffpkr1...

Page 263

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 47 ffpku01771 reinforcement frame, left 16 17 1 ffpku0178 reinforcement frame, right 16 4 1 ffpku0179 reinforcement bracket 28 12 1 ffpku0183 reinforcement stay 1 21 43 1 ffpku0184 support stay 2 21 41 1...

Page 264

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 48 ffplg1482 pick up roller shaft 20 21 1 ffplg1485 middle roller shaft (except 7818) 3 21 2 ffplg1485 middle roller shaft (7818) 3 21 1 ffplg1489 pick up shaft 21 52 1 ffplg1510 bushing plate 29 70 1 ff...

Page 265

Numerical parts index description part no. Q'ty per unit ref. No. Page no. Numerical parts index 49 ffpll0579 sensor lever (7845/7850) 10 32 1 ffpll0580 sensor lever c 29 4 1 ffpll0581 paper lifting lever 29 14 6 ffpll05821 sensor lever d 29 12 1 ffpll0584 lever a, holder roller 29 41 1 ffpll0585 le...

Page 266