- DL manuals

- Panasonic

- Accessories

- HL-C2 Series

- User manual

Panasonic HL-C2 Series User manual - 2-3

Chapter 2 I/O Terminal Block

2-6

2

2-3

Interlock Circuit

■ NPN Type

Connect IL and Common (-) in case of NPN output type.

■ PNP Type

Connect IL+ and IL- in case of PNP output type.

IL+ is connected to the 24V power supply at the internal circuit. Do not

connect the voltage input or PNP transistor open collector output to it.

Summary of HL-C2 Series

Page 1

Ultra high-speed, high-accuracy laser displacement sensor hl-c2 series user's manual me-hlc2-16 2017.5 panasonic.Net/id/pidsx/global.

Page 2

Preface thank you for purchasing ultra high-speed, high-accuracy laser displacement sensor “hl-c2 series”. To fully use this product safely and properly, please read this manual carefully. Please check our website ( http://panasonic.Net/id/pidsx/global ) about new info of the product and new version...

Page 3

Preface 1 whole user’s manual construction the hl-c2 series is prepared for the following user’s manuals. Read them as necessary. The application software “ adobe reader ” is required for viewing the files. The latest application (adobe reader ® 11.0 as of may, 2013) can be freely downloaded from th...

Page 4

Preface 2 hl-c2 series user’s manual: ethernet communication control (pdf) this manual explains various settings to acquire measurement information of the hl-c2 system by plc using ethernet communication. For detailed explanation concerning the system’s functions, precautions for use, etc., refer to...

Page 5

Preface 3 manual construction 小型 1 2 3 4 5 6 7 8 appendix 1 2 3 4 5 6 7 8 this chapter provides cautions for safe and correct operation of the product. Be sure to read this chapter. Preface troubleshooting appendix specification maintenance and service communication control explanation of functions ...

Page 6

Preface 4 contents whole user’s manual construction 1 ■ user’s manual for intelligent monitor aim ·························································· 2 manual construction ··································· 3 contents ·························································· 4 safety precau...

Page 7

Preface 5 2 i/o terminal block ······················· 2-1 2-1 functions and arrangements of i/o terminal block ·············································· 2-2 2-2 i/o circuit ··········································· 2-4 ■ npn type ······················································· 2-4 ■ ...

Page 8

Preface 6 4-4 supplemental explanation ············· 4-84 4-4-1 alarm setting and outputs ············ 4-84 4-4-2 conditions when output data become unfixed ························································ 4-85 4-4-3 memory save and terminal setting ·· 4-88 ■ storable functions in memory ···...

Page 9

Preface 7 safety precautions this product is intended to detect the objects and does not have the control function to ensure safety such as accident prevention. Do not use the product as a sensing device to protect human body. Please use the products that comply with local laws and standards for hum...

Page 10

Preface 8 correct handling note the following points when installing and using hl-c2 series. Installation environment ■ do not install the product in the following conditions. • where the ambient temperature, ambient humidity or ambient illuminance of beam receiving surface is beyond the range of sp...

Page 11

Preface 9 ambient humidity use the sensor within a range of 35 to 85% rh. Avoid using it in places that may be exposed to dew condensation due to rapid temperature change. Ambient illuminance of light receiving surface use the sensor in locations where illuminance from incandescent lamps is 3,000 lx...

Page 12

Preface 10 warming up time allow at least 30 minutes of warming up after turning on the power to ensure the performance of the product. Measures to noise • install the product as far away as possible from noise source such as high-voltage lines, high-voltage device, power lines, power device, machin...

Page 13

Preface 11 power supply ■ power supply • select a power supply with a ripple 0.5v or less (p-p) and a current capacity 2a or more. • when using a commercial switching regulator, be sure to ground the frame ground (f.G.) terminal to avoid the influence of high frequency noise. • when using a transfor...

Page 14

Preface 12 grounding ■ ground the device when noise influence is large • under normal use, the product has sufficient noise resistance. In an environment with particularly high noise levels, however, ground it securely. ■ use an exclusive ground • use wires of 1.5 mm 2 or more and establish a class ...

Page 15

Preface 13 precautions for positive ground environment the gnd terminals of 24vdc (-) and usb port, sg of rs-232c, and common terminal (-) of the input / output circuit are connected inside the hl-c2. The fg terminal, usb port connector shell, rs-232c connector shell and ethernet connector shell are...

Page 16

Preface 14 installation ■ controller ・ install the controller unit according to “1-3 installation method” , assuring plenty of space around it. If it is installed in a manner other than specified, failures may occur due to temperature rise. ・ if the controller is mounted internally on the place wher...

Page 17

Preface 15 cautions on handling laser light jis/iec/gb/ks ■ semiconductor laser is used as the light source of sensor the laser is classified based on jis (jis c 6802:2014) and iec (iec 60825-1:2014), gb (gb 7247.1:2012), ks (ks c iec 60825-1:2013) standards. Class max. Output wavelength model no. 1...

Page 18

Preface 16 ■ warning label ● 10mm type (hl-c201a) in japanese / english / korean in chinese (e type only) ● 30mm type (hl-c203b) in japanese / english / korean in chinese (e type only).

Page 19

Preface 17 ● 5mm type (hl-c205b) in japanese / english / korean in chinese (e type only) ● 50mm type (hl-c205c) in japanese / english / korean in chinese (e type only).

Page 20

Preface 18 ● 85mm type (hl-c208b) in japanese / english / korean in chinese (e type only) ● 85mm type (hl-c208c) in japanese / english / korean in chinese (e type only).

Page 21

Preface 19 ● 110mm type (hl-c211b) in japanese / english / korean in chinese (e type only) ● 110mm type (hl-c211c) in japanese / english / korean in chinese (e type only).

Page 22

Preface 20 ● 350mm type (hl-c235be) in japanese / english / korean in chinese ● 350mm type (hl-c235ce) in japanese / english / korean in chinese.

Page 23

Preface 21 ● 350mm type (hl-c235ce-w) in japanese / english / korean in chinese ● 8mm type (hl-c201a□-sp2□) in japanese / english / korean in chinese (e type only) ● 15mm type (hl-c201a□-sp3□) in japanese / english / korean in chinese (e type only) hl-c201a □ -sp2 □ hl-c201a □ -sp3 □.

Page 24

Preface 22 ce make sure to use ce compliant sensor head and programmable display for making this product ce compliant. ■ ce compliant condition to meet the ce compliant condition, attach ferrite cores (seiwa electric mfg. Co., ltd. E04sr200935a) to the power supply cable and the head cable shown as ...

Page 25

Preface 23 fda ■ export to us when the laser product mounted on equipment is exported to the united states, they are subjected to the regulation of the food and drug administration. In order to prevent the injury on users due to laser products from happening, fda has established part 1040 (performan...

Page 26

Preface 24 ■ labeling the product uses the following labels in accordance with fda standards. ● aperture/warning label, protective housing label ● certification/identification label the figures above show the examples of major model (for l-c203f(e)/ hl-c203f(e)-mk). As for label positions of other m...

Page 27

Preface 25 ■ beam attenuator use the attached beam attenuator if there is a danger of getting laser beam into your eyes during operation. Beam attenuator fix the beam attenuator with the attached screws to cover the light emitting surface. When the beam attenuator is not used, fix it to either side ...

Page 28

Preface 26 ■ fda standard requirements class *1 i iia ii iiia iiib iv performance (all laser products) protective housing [1040.10(f)(1)] safety interlock [1040.10(f)(2)] location of controls [1040.10(f)(7)] viewing optics [1040.10(f)(8)] scanning safeguard [1040.10(f)(9)] r *2 r *3,4 n/a r r r *2 r...

Page 29

Preface 27 *1 class is based on the maximum level of laser exposure during operation. *2 required wherever and whenever such human access to laser radiation levels that exceed the limits of class i is not necessary for the product to perform its intended function. *3 required at the protective housi...

Page 30

Preface 28 export regulations by japanese government ■ compliance with export regulations by japanese government some models are subject to export control, which is defined by “foreign exchange and foreign trade act”. ● export controlled products below products fall under the export control, which i...

Page 31

Preface 29 ■ specification of export uncontrolled product the specification of display resolution and measurement resolution for the export uncontrolled products are shown below. Other specifications not mentioned here are the same as export controlled products. Resolution 0.25µm * the programmable ...

Page 32

Preface 30 memo.

Page 33

1-1 1 1 prior to use this chapter explains the configuration, installation method, and connection method of the system (controller, sensor head, compact programmable display, and intelligent monitor aim). 1-1 system configuration ··················· 1-2 1-1-1 system configuration ···················...

Page 34: 1-1

Chapter 1 prior to use 1-2 1 1-1 system configuration 1-1-1 system configuration the system configuration and the cables for connecting the devices are shown as below. In case of connecting one sensor head to the controller, be sure to connect the sensor head to the sensor head a connection (head a)...

Page 35: 1-1-2

Chapter 1 prior to use 1-3 1 1-1-2 system components & accessories list ■ controller accessories the accessories of the controller are as shown below. Main unit of controller analog output/laser control terminal block i/o terminal block hl-c2 series setup cd-rom hl-c2 series instruction manuals shor...

Page 36

Chapter 1 prior to use 1-4 1 ■ sensor head accessories the accessories of the sensor head are as shown below. ■ nd filter unit (optional) main unit of sensor head warning label instruction manual of sensor head nd filter unit (type: hl-c2f01 ) mounting screws in japanese / english / korean in chines...

Page 37

Chapter 1 prior to use 1-5 1 ■ extension cable for sensor head (optional) ■ compact programmable display (optional) refer to the "hl-c2 series user's manual: programmable display" for handling regarding installation and connection. Refer to "chapter 3 programmable display operation" for the operatio...

Page 38

Chapter 1 prior to use 1-6 1 ■ connection cable for compact programmable display (3m) (optional) ■ intelligent monitor aim intelligent monitor aim and “hl-c2 series user’s manual: intelligent monitor aim” can be downloaded on our internet website (http://panasonic.Net/id/pidsx/global). ■ ethernet co...

Page 39: 1-2

Chapter 1 prior to use 1-7 1 1-2 part names and functions 1-2-1 controller 1 2 3 4 5 6 7 8 9 10 11 15 14 16 13 12 1 2 3 4 5 17 6 7 8 9 10 15 14 16 13 12 ●hl-c2c□ ●hl-c21c□ 1. Power indicator lights up in green when electricity is provided to the controller. 2. Alm1 (alarm) indicator abnormal conditi...

Page 40

Chapter 1 prior to use 1-8 1 6. Analog output terminal terminal for analog data output. 7. Laser control terminal stops laser emission in case of short-circuiting. 8. Remote interlock terminal stops laser emission when its opened. 9. Usb connector used for communication with pc using usb. 10. Progra...

Page 41: 1-2-2

Chapter 1 prior to use 1-9 1 1-2-2 sensor head (1) laser emission indicator (laser on) lights up in green during laser emission. (2) measurement range indicator (range) lights up in yellow when the target reaches at approximately center of the measurement. Blinks in yellow when the target enters wit...

Page 42: 1-3

Chapter 1 prior to use 1-10 1 1-3 installation method before installing each device, read carefully the explanation of the setting environment, concerning about noise or radiation, and the power supply. Refer to “correct handling”. 1-3-1 controller the controller can be installed by using din rail o...

Page 43: 1-3-2

Chapter 1 prior to use 1-11 1 1-3-2 sensor head securely fix the sensor head in two screw holes using m5 screws. •the tightening torque should be 1.2n·m or less. •the depth of both screw holes is 10mm, not through-holes. Be careful to choose screws with considering its length. ■ installation directi...

Page 44

Chapter 1 prior to use 1-12 1 • measurement of a rotating target when measuring a rotating target, the direction of the sensor head should be as shown below to minimize the effect of vertical oscillation or displacement. • measurement of step detection when measuring a moving target that has differe...

Page 45

Chapter 1 prior to use 1-13 1 ● measurement of a black target or low-light intensity when measuring a low-reflectance black target, light intensity reflected from the target decreases and the signal from the linear image sensor is also getting smaller. As a result, it decreases the resolution. So mo...

Page 46

Chapter 1 prior to use 1-14 1 ● angle between the measurement center and the sensor head diffuse reflection surface mount the sensor head as shown at the right, so the emitter surface and receiver surface of sensor head is parallel to a measuring target. For the measurement center distance and measu...

Page 47: 1-4

Chapter 1 prior to use 1-15 1 1-4 connection 1-4-1 connection method of power supply ♦ connect 24vdc power supply wiring with “24v” and “0v” terminals of the terminal 3. ♦ use twisted wires to minimize the effect of noise. Rated voltage 24vdc tolerance voltage variation range 21.6 to 26.4vdc consump...

Page 48

Chapter 1 prior to use 1-16 1 1 strip insulation from the end of the wire. 2 insert the wire in the terminal block until it contacts the back, then, secure it by tightening the screw. 3 if two or more terminals are connected, twist wires before inserting them. ・ be sure to turn off the power supply ...

Page 49: 1-4-3

Chapter 1 prior to use 1-17 1 1-4-3 connection of intelligent monitor aim (pc) a usb driver must be installed to a pc before connecting a controller and pc installed intelligent monitor aim. For installation of the usb driver, refer to the “hl-c2 series intelligent monitor aim user’s manual” . The b...

Page 50

Chapter 1 prior to use 1-18 1 memo.

Page 51

2-1 2 2 i/o terminal block this chapter explains i/o terminal blocks on the controller. 2-1 functions and arrangements of i/o terminal block ··························· 2-2 2-2 i/o circuit ································· 2-4 2-3 interlock circuit ·························· 2-6 2-4 analog output ci...

Page 52: 2-1

Chapter 2 i/o terminal block 2-2 2 2-1 functions and arrangements of i/o terminal block analog output terminal block/laser control terminal block terminal function npn pnp (v)1 analog voltage output (for out1) agnd analog ground (i)1 analog current output (for out1) (v)2 analog voltage output (for o...

Page 53

Chapter 2 i/o terminal block 2-3 2 i/o terminal block terminal function npn pnp zs2 zero set input (for out2) on during short circuit * tm2 timing input (for out2) on during short circuit rs2 reset input (for out2) on during short circuit (-) common (-) al2 alarm output (for out2) st2 strobe output ...

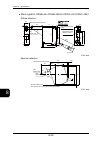

Page 54: 2-2

Chapter 2 i/o terminal block 2-4 2 2-2 i/o circuit ■ npn type the common (-) and the power supply (0v) for main unit are internally connected. Be sure not to cause the potential difference at operation..

Page 55

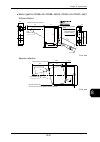

Chapter 2 i/o terminal block 2-5 2 ■ pnp type the common (-) and the power supply (0v) for main unit are internally connected. Be sure not to cause the potential difference at operation..

Page 56: 2-3

Chapter 2 i/o terminal block 2-6 2 2-3 interlock circuit ■ npn type connect il and common (-) in case of npn output type. ■ pnp type connect il+ and il- in case of pnp output type. Il+ is connected to the 24v power supply at the internal circuit. Do not connect the voltage input or pnp transistor op...

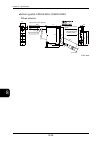

Page 57: 2-4

Chapter 2 i/o terminal block 2-7 2 2-4 analog output circuit *: either “1” or “2” is entered. · do not short-circuit analog output terminals or apply voltage to them. · use shielded wires for analog outputs..

Page 58: 2-5

Chapter 2 i/o terminal block 2-8 2 2-5 timing chart • normal measurement • peak/bottom measurement the above chart uses peak measurement for explanation. • peak to peak measurement.

Page 59

Chapter 2 i/o terminal block 2-9 2 • zero set by timing input during hold status is valid. • reset input by timing input during hold status causes data unfixed status. The system holds this status until the timing input is cancelled. • zero set input during data unfixed status is invalid. • the syst...

Page 60

Chapter 2 i/o terminal block 2-10 2 ● laser control ● interlock control *1 sampling period (ts) × average number of times laser stability time is also required. *2 for laser stop input, remote interlock input and memory change input, the setting should be on2 (continuous input for more than 100ms), ...

Page 61

3-1 3 3 programmable display operation 3-1 operation screens ····························· 3-2 3-2 basic operation ································· 3-6 3-2-1 first measurement ··································· 3-6 3-3 screen transition diagram ················· 3-10 3-3-1 display waveform of rece...

Page 62: 3-1

Chapter 3 programmable display operation 3-2 3 3-1 operation screens ■ screens ● top menu and setting menu the left figure shows the top screen. All kinds of screens displayed on the programmable display can be changed through any of the keys on the top menu. ·············· touch the key to display ...

Page 63

Chapter 3 programmable display operation 3-3 3 ■ shift screen levels the operation screen consists of hierarchical tree structure. Touch the keys to move to the desired screen and set the required items. Touch the keys to shift the screen among the same hierarchical level. ······ shift to lower tier...

Page 64

Chapter 3 programmable display operation 3-4 3 ■ enter value this section explains how to enter the numerical value for upper/lower limit value or offset. A numerical keypad is displayed on the screen for numerical input. 1 touch the frame above the setting value. The cursor blinks and numerical val...

Page 65

Chapter 3 programmable display operation 3-5 3 memo.

Page 66: 3-2

Chapter 3 programmable display operation 3-6 3 3-2 basic operation 3-2-1 first measurement this section explains the basic operating procedures of measurement with hl-c2 series product. Step1 initial power-on connect the controller, sensor head and compact programmable display. “1-1 system configura...

Page 67: Step3

Chapter 3 programmable display operation 3-7 3 step3 position adjustment of sensor head check the mounting direction of sensor head. Select the optimum direction according to the shape or moving direction of measurement object. Note that a different installation method is used between specular refle...

Page 68: Step6

Chapter 3 programmable display operation 3-8 3 step6 thickness measurement this step explains the basic setting procedures of thickness measurement. The example below shows the procedures for thickness measurement using two sensor heads. Set the installation mode to “diffuse reflection” and the meas...

Page 69: Step7

Chapter 3 programmable display operation 3-9 3 step7 thickness measurement: glass material set the installation mode to specular reflection and measurement mode to specular reflection [standard]. Refer to step2 “basic setting” . Set output selection to transparent object a when measuring glass thick...

Page 70: 3-3

Chapter 3 programmable display operation 3-10 3 3-3 screen transition diagram ■ screen flow whole waveform measurement value menu received light intensity at peak memory change enlarged waveform screen out1 ( out2 ) display out1 ( out2 ) operation out1 & 2 display digit number update cycle.

Page 71

Chapter 3 programmable display operation 3-11 3 setting menu head a head b the setting items of head b are the same as head a. The setting items of out2 are the same as out1. Refer to page 3-12. Refer to page 3-12. Refer to page 3-13. Refer to page 3-13. Out1 out2 common system.

Page 72

Chapter 3 programmable display operation 3-12 3 head a (head b) menu 1/2 installation mode emission adjustment emitted light intensity search alarm delay times measurement mode measurement surface reference laser control calibration upper limit/lower limit hysteresis out1 (out2) menu 1/2 output sele...

Page 73

Chapter 3 programmable display operation 3-13 3 analog output at alarm analog output at data unfixed digital output at alarm alarm output delay operation coefficient common menu terminal input control chattering prevention for terminal input sampling cycle type/version system menu 2/2 out1 (out2) me...

Page 74: 3-3-1

Chapter 3 programmable display operation 3-14 3 3-3-1 display waveform of received light intensity the compact programmable display can display the signal of received light intensity at sensor head a and b. When the measurement object is transparent, adjust the position while viewing the waveform to...

Page 75

4-1 4 4 explanation of functions this chapter describes various functions of the system. 4-1 data flow ································· 4-2 4-2 classification of function·············· 4-3 4-3 function list & initial values ········· 4-3 4-3-1 head setting ····························· 4-7 4-3-2 ou...

Page 76: 4-1

Chapter 4 explanation of functions 4-2 4 4-1 data flow up to two sensor heads can be connected to the controller. Individual measurement by each of sensor head and calculation of measurement values for two sensor heads can be performed. Operation flow of each function is shown as below..

Page 77: 4-2

Chapter 4 explanation of functions 4-3 4 4-2 classification of function in this system, all functions are classified into four categories for fixing stable measurement and various outputs. Classification details head setting function setting for stable measurement by improving accuracy of laser emis...

Page 78

Chapter 4 explanation of functions 4-4 4 cl a s s function details initial value memory change*1 ref. Page h ea d s et ti ng calibration measurement value a corrects the measurement value to the measurement object’s color, material, surface condition. Upper measurement limit (positive number) 4-19 c...

Page 79

Chapter 4 explanation of functions 4-5 4 cl as s function details initial value memory change*1 ref. Page o u t s et ti ng analog output at alarm sets the analog output status at alarm operation. Hold previous value 4-48 fixed value fixes the analog output status at alarm operation. +10.800[v] analo...

Page 80

Chapter 4 explanation of functions 4-6 4 cla s s function details initial value memo ry chang e* ref. Page s y s te m s e tt in g rs-232c output makes the settings of the measurement data output for rs-232c communication. 4-70 rs-232c output mode sets the output mode of the measurement data. Handsha...

Page 81: 4-3-1

Chapter 4 explanation of functions 4-7 4 4-3-1 head setting ■ installation mode measurement type can be selected from the diffuse reflection and specular reflection according to the kind of measurement object. Diffuse reflection is set as a default. Be sure to set to “specular reflection” when measu...

Page 82

Chapter 4 explanation of functions 4-8 4 ■ measurement mode the optimum digital processing type can be selected to measurement object types. The measurement mode is a function for selecting the optimum measurement algorithm such as unbalance correction of received light waveform. Select the optimum ...

Page 83

Chapter 4 explanation of functions 4-9 4 ● how to use 1 display the “measurement mode” screen. 2 touch the appropriate measurement mode key to a target object. Setting screen of sensor head a setting screen of sensor head b.

Page 84

Chapter 4 explanation of functions 4-10 4 ■ emission adjustment this function sets an appropriate emitted light intensity to a measurement object. Auto is set as a default. “auto” automatically sets optimum emitted light intensity to meet the reflection light amount of the measurement target. When t...

Page 85

Chapter 4 explanation of functions 4-11 4 ■ emission adjustment area this function specifies an emission auto adjustment area. The light intensity feedback function operates between the two cells from starting cell to ending cell. In case of measuring a transparent object where the high reflectance ...

Page 86

Chapter 4 explanation of functions 4-12 4 2 touch head a ( or area b ) in order to input the values. 3 touch the number keys to specify the area. 4 touch key to decide on the specified area..

Page 87

Chapter 4 explanation of functions 4-13 4 ■ emitted light intensity search this function searches the received light intensity of a measurement surface and sets the appropriate emitted light intensity automatically. Set this function when measuring the thickness of a transparent object with low rece...

Page 88

Chapter 4 explanation of functions 4-14 4 ■ alarm delay times this function holds the previous (latest) normal value up to the setting number of times when an alarm is issued. This function relates to the digital measurement value, analog output, alarm terminal output, controller alarm indicator und...

Page 89

Chapter 4 explanation of functions 4-15 4 ■ measurement surface reference this function selects the counting reference of the setting surface at “output selection”. Before measuring a transparent object, select the measurement surface reference from “near setting” (counting the layer of the measurem...

Page 90

Chapter 4 explanation of functions 4-16 4 ■ measuring range a given range can be specified for measurement. When you want to measure thickness, etc. Of a transparent object, operation in “output selection” becomes impossible if there are seven or more measurement faces. Measurement becomes possible ...

Page 91

Chapter 4 explanation of functions 4-17 4 ● how to use 1 display the “measuring range” screen. 2 switch between “measuring point a” and “measuring point b” by touching the keys. 3 touch head a (or head b ) and enter the setting value. 4 specify the area by touching the numeric keys. 5 enable the spe...

Page 92

Chapter 4 explanation of functions 4-18 4 ■ laser control this function switches on/off of the laser emission. With this function, laser emission, that is unnecessary except at measurement, can be stopped. · while the laser emission stop is input (with lsra and lsrb short-circuited) from the laser c...

Page 93

Chapter 4 explanation of functions 4-19 4 ■ calibration this function corrects the deviation of the measurement value caused from the color, material, or surface condition of the measurement object. As shown below, the value can be corrected by setting two points of “a” and “b” respectively to the p...

Page 94

Chapter 4 explanation of functions 4-20 4 3 set/change the measurement value or correction value. For setting or changing method of the measurement value and correction value, refer to “ for inputting the measurement value or correction value ” and “ for loading the measurement value from the curren...

Page 95

Chapter 4 explanation of functions 4-21 4 ■peak recognition sensitivity this function sets the peak of the received light waveform and the peak recognition level. This function is effective when you cannot acquire the measurement value properly due to waveform instability. Setting range is 100 to 40...

Page 96

Chapter 4 explanation of functions 4-22 4 ■median filter cut off changes in measurement values in order to prevent variation in measurement. The setting of median filter can be selected from “off”, “7 points”, “15 points” and “31 points”. Median filter is effective to cut off sudden changes in measu...

Page 97: 4-3-2

Chapter 4 explanation of functions 4-23 4 4-3-2 out setting ■ output selection this function selects the output pattern of measurement values. The below list shows the setting items and the output details. Setting item function a outputs the measurement value of the sensor head a. B outputs the meas...

Page 98

Chapter 4 explanation of functions 4-24 4 ● how to use 1 display the “output selection” screen. 2 touch the key (1) to change the list display. The list display is changed each time the key is touched. 3 touch your desired key (2) for performing “output selection”. Selection screen of out1 selection...

Page 99

Chapter 4 explanation of functions 4-25 4 ■ transparent object this function selects a measurement surface from several surfaces in a transparent object. According to the setting of “measurement surface reference”, select a measurement surface in a transparent object. Single or several surfaces can ...

Page 100

Chapter 4 explanation of functions 4-26 4 ● how to use 1 display the “output selection” screen. 2 touch the key to select your setting of “output selection”. “ ■ output selection” 3 touch the key to change the screen for selecting the measurement surface of “transparent object”. *the setting of the ...

Page 101

Chapter 4 explanation of functions 4-27 4 ■ refractive index calculation this function reflects the setting refractive index to the measurement result. When the “refractive index calculation” function is set to “on” for measuring a transparent object, the setting refractive index becomes effective a...

Page 102

Chapter 4 explanation of functions 4-28 4 2 touch the key to change the setting and select the key of your choice. ” ■ output selection” 3 touch the key to change the screen for selecting a measurement surface of “transparent object”. *the setting of the transparent object is valid only when “transp...

Page 103

Chapter 4 explanation of functions 4-29 4 ■ refractive index this function is used for setting the refractive index of a transparent object to be measured. Sets the refractive index of the measurement object. The setting range is 0.500000 to 2.000000. “1.000000” is set as a default. · this function ...

Page 104

Chapter 4 explanation of functions 4-30 4 5 touch the “refractive index calculation” key to change the setting to on . 6 touch the key to change the screen for setting “refractive index”. 7 touch out1 (or out2 ) key to input the setting value. 8 set the refractive index by the numeric keys. The sett...

Page 105

Chapter 4 explanation of functions 4-31 4 ■ zero set this function is used for forcibly setting the measurement value to “0”. Normally, the amount of displacement is displayed in reference to the center of measurement of the sensor head. However, after this function is set to “on”, the amount of dis...

Page 106

Chapter 4 explanation of functions 4-32 4 2 touch the zero set key to set the measurement value to “0”. 3 touch the zero set key again to return to the measurement reference position to the center of measurement (default) by zero set function. Zero set “off” zero set “on”.

Page 107

Chapter 4 explanation of functions 4-33 4 ■ timing the measurement value can be on hold at the desired timing. The measurement value is on hold by the timing terminal (tm1, tm2) of the external terminal input or by pressing the timing input button of compact programmable display. The judgment output...

Page 108

Chapter 4 explanation of functions 4-34 4 ■ reset this function resets the measurement value. The measurement value can be reset by touching the “reset” button. When executing the “peak measurement”, “bottom measurement”, or “peak to peak measurement”, the measurement value that has been on hold can...

Page 109

Chapter 4 explanation of functions 4-35 4 ■ hold this function stops the updating of the measurement value display. The updating of the measurement value display is stopped by touching the hold button on the compact programmable display. This is a function only available for compact programmable dis...

Page 110

Chapter 4 explanation of functions 4-36 4 ■ analysis mode this function performs the setting of the analysis mode. The below shows the function of each analysis mode. Setting item function normal outputs the displacement in the center of measurement at a real time. Peak holds and outputs the maximum...

Page 111

Chapter 4 explanation of functions 4-37 4 ■ filter operation this function cuts the unnecessary signal element to stabilize the measurement data. The filter operation is selectable from the moving average, low-pass filter, and high-pass filter. The filter picks out the measurement data for required ...

Page 112

Chapter 4 explanation of functions 4-38 4 · make sure to perform the actual measurement and confirm the results before setting the cutoff frequency because of the different conditions. ● how to use 1 display the “filter operation” screen. 2 touch the “filter selection” key to select the desired filt...

Page 113

Chapter 4 explanation of functions 4-39 4 ■operation coefficient this function is used for multiplying the measurement value by the operation coefficient and outputting the data. Final measurement value = operation coefficient x measurement value + offset value ● how to use 1 display “ope. Coef.” sc...

Page 114

Chapter 4 explanation of functions 4-40 4 ■ offset the desired setting value can be added to/subtracted from the measurement value. Set the offset value by measuring the size of a master (reference) measurement object. When measuring an object, set the zero set “on” so that the judgment of the size ...

Page 115

Chapter 4 explanation of functions 4-41 4 ■ upper/lower limit value of judgment output this function sets the upper and lower limit values for judgment of the measurement value. The output status changes in three types as the below: measurement value > upper limit value: hi output lower limit value ...

Page 116

Chapter 4 explanation of functions 4-42 4 2 touch the keys to change the screen between “up lmt val” and “lo lmt val”. 3 touch the out1 (or out2 ) key to prepare for inputting the setting value. 4 set the setting value by touching the numeric keys. The input range is -950.000000 to +950.000000[mm]. ...

Page 117

Chapter 4 explanation of functions 4-43 4 ■ upper/lower hysteresis of judgment output this function stabilizes the judgment output against the chattering of the measurement value. The below example graphically shows the correlation between the hysteresis value and on/off of the output. The function ...

Page 118

Chapter 4 explanation of functions 4-44 4 4 set the setting value by touching the numeric keys. The input range is +000.000000 to +950.000000[mm]. 5 touch the key to confirm the offset value..

Page 119

Chapter 4 explanation of functions 4-45 4 ■ analog scaling this function executes scaling of the analog voltage output to a desired value. The system performs scaling of the analog voltage output to the desired value within ±10v. Fix two points of the desired voltages to “a” and “b” for each a and b...

Page 120

Chapter 4 explanation of functions 4-46 4 3 change the screen by each key. Meas a --- measurement value a input screen volt a --- voltage value a input screen meas b --- measurement value b input screen volt b --- voltage value b input screen load (top) --- measurement value a load screen load (bott...

Page 121

Chapter 4 explanation of functions 4-47 4 for loading the measurement value from the current value 1 touch the key you want to load the value. Touch the load key of the measurement value a or b. The screen is changed. 2 touch the load meas val a from curr val. Key. The current value is input at the ...

Page 122

Chapter 4 explanation of functions 4-48 4 ■ analog output at alarm this function sets the analog output status when an alarm is issued. It can select whether holding the previous value or setting a fixed value for the analog output under an alarm operation status (poor light intensity, or measuremen...

Page 123

Chapter 4 explanation of functions 4-49 4 ■ analog output at data unfixed this function sets the analog output when the data is unfixed. “-999.999999” is displayed for the measurement value of the digital output at data unfixed and aim. · the output range is -10.800 to +10.800[v], and the initial va...

Page 124

Chapter 4 explanation of functions 4-50 4 ■ digital output at alarm this function sets the digital output status when an alarm is issued. It can select whether holding the previous value or setting a fixed value for the digital output (measurement value display of compact programmable display and th...

Page 125

Chapter 4 explanation of functions 4-51 4 ■ alarm output delay this function delays the output from the alarm terminal. It can select whether outputting at a real time or holding the previous normal value up to the setting number of times under an alarm operation status (poor light intensity, or mea...

Page 126

Chapter 4 explanation of functions 4-52 4 ■ digit number of measurement value this function sets the display digit number of the measurement value. It can set the display of the number of decimal places on compact programmable display. The display of the number of decimal places can be selected amon...

Page 127: 4-3-3

Chapter 4 explanation of functions 4-53 4 4-3-3 common setting ■ sampling period this function sets the sampling cycle of measurement. When measuring an object with poor received light intensity such as black rubber, extend the sampling cycle to get sufficient light for performing stable measurement...

Page 128

Chapter 4 explanation of functions 4-54 4 ● how to use 1 display the “sampling cycle” screen. 2 touch the keys of sampling cycle to change the setting. The sampling cycle display is changed as below by touching the key. Also, it is changed in counterclockwise by touching the key. 40µs 200µs 100µs 40...

Page 129

Chapter 4 explanation of functions 4-55 4 ■ terminal input control using this function, two outputs (out1 & out2) can be controlled by one input operation. Two outputs (out1 & out2) can be operated by inputting only out1 (the timing input, zero set input, and reset input). Select “all” to control th...

Page 130

Chapter 4 explanation of functions 4-56 4 ■ chattering prevention of terminal input this function can prevent the chattering of the terminal input. This function is used to prevent chattering for terminal input using the relay contact or switch contact. The below list shows three settings of the fun...

Page 131

Chapter 4 explanation of functions 4-57 4 ■judgment output off delay this function is used for delaying the timing of switching off from on of judgment output. 測 setting function off output corresponding with a sampling cycle 2ms off delay for 2ms 10ms off delay for 10ms 100ms off delay for 100ms ho...

Page 132

Chapter 4 explanation of functions 4-58 4 ■interference prevention this function is used for preventing interference between 2 sensor heads. Set this function when beam from the other sensor head enters into the mutual interference area. “8-6 characteristics” – “mutual interference area” when connec...

Page 133: 4-3-4

Chapter 4 explanation of functions 4-59 4 4-3-4 system setting ■ display update cycle of measurement value this function sets the display update cycle of the measurement value on the compact programmable display. Set the display update cycle to slower (longer) as possible because fast (short) displa...

Page 134

Chapter 4 explanation of functions 4-60 4 setting at “measurement value” menu 1 display “update cycle of meas val” screen. 2 touch the “update cycle of meas val” key to select the setting. The display is changed as below each time the key is touched. 3 touch key to return to the “measurement value d...

Page 135

Chapter 4 explanation of functions 4-61 4 ■change indication unit this function is used for changing the indication unit of the measurement value on compact programmable display. The indication unit of the measurement value is selectable from mm unit and µm unit. ・ this function is invalid for the s...

Page 136

Chapter 4 explanation of functions 4-62 4 ■output setting copy “out setting” contents can be copied between out1 and out2. The setting contents related to the memory output that is specified at “memory change” function can be copied between out1 and out2 (out1 →out2, out2 →out1). This function canno...

Page 137

Chapter 4 explanation of functions 4-63 4 ■ priority setting of memory change this function sets priorities among command or terminal memory changes. In case that the command is received a higher priority for memory change, memory change by the terminal is ignored (set the priority to “terminal” bef...

Page 138

Chapter 4 explanation of functions 4-64 4 ■ memory change this function specifies the destination (memory) for storing the setting contents. When starting up the system with the specified memory no. (other than the default setting), set the priority to command or terminal as below. “priority setting...

Page 139

Chapter 4 explanation of functions 4-65 4 ■ memory copy the stored contents in the memory can be copied to the other memories. If the destination and source memory is the same, the data in the memory is just overwritten. · note that the copied setting contents are deleted at the next start-up if the...

Page 140

Chapter 4 explanation of functions 4-66 4 ■ initialization this function deletes all setting contents in the memory and initializes the settings again. If the initialization is not saved, the system operates with the previous settings at the next start-up. Setting function initialize initializes the...

Page 141

Chapter 4 explanation of functions 4-67 4 in case of initializing the settings of all memories 1 display the “initialize” screen. 2 touch the initialize all memory key. The confirmation message appears. 3 touch the yes key. The message of notifying the completion of initialization appears. *touch th...

Page 142

Chapter 4 explanation of functions 4-68 4 ■ save this function saves the setting contents in all memories. Be sure to “save” the setting change before turning off the system. Failure to do deletes all setting change when the system is turned off. When re-starting up the system, the last setting cont...

Page 143

Chapter 4 explanation of functions 4-69 4 ■ communication: com port this function specifies the baud rate, the data length, and parity for rs-232c communication. These settings are used for communication with pc using rs-232c connector. Make sure to save the changed setting values, and then restart ...

Page 144

Chapter 4 explanation of functions 4-70 4 ■rs-232c output this function is used for performance setting of the measurement data output from rs-232c to an external device. ● rs-232c output mode rs-232c output is selectable from three modes. The initial value is set to “handshake”. Setting item conten...

Page 145

Chapter 4 explanation of functions 4-71 4 ● how to use 1 display “rs-232c output” screen. For rs-232c output mode: 2 touch the “output mode” key to select the output mode. The display is changed as below each time the key is touched. For rs-232c output type: 2 touch the “output type” key to select t...

Page 146

Chapter 4 explanation of functions 4-72 4 ■ console setting this function sets “panel lock” and “start-up screen” of compact programmable display. Panel lock “panel lock” is used for prohibiting the setting change on the compact programmable display to prevent any setting error occurrence due to uni...

Page 147

Chapter 4 explanation of functions 4-73 4 displays the measurement value of out1. Sets the measurement value of out1, output (alarm, strobe, judgment output), and status of the hold, timing, zero set, and reset input. Displays the measurement value of out2. Sets the measurement value of out2, output...

Page 148

Chapter 4 explanation of functions 4-74 4 displays the head a menu screen. Displays the head b menu screen. Displays the out1 menu1/2 screen. Displays the out2 menu1/2 screen. Displays the common menu screen. Displays the system menu1/2 screen. Displays the measurement value menu screen. Meas val me...

Page 149: 4-3-5

Chapter 4 explanation of functions 4-75 4 4-3-5 buffering setting buffering is a function for accumulating the measurement data in the controller memory and loading them to the external control device (pc). Maximum 65,000 measurement data can be temporarily accumulated in the controller memory befor...

Page 150

Chapter 4 explanation of functions 4-76 4 ■ data buffering operation data buffering procedure 1 perform necessary setting for buffering. · buffering mode · buffering type · buffering rate · accumulation amount · sample trigger accumulation amount · self-stop · trigger conditions · trigger delay · tr...

Page 151

Chapter 4 explanation of functions 4-77 4 ■ buffering operation this function accumulates the data during buffering operation. Set necessary parameters in advance and start buffering operation. · the starting of the buffering operation requires the buffering type and the accumulation amount to be se...

Page 152

Chapter 4 explanation of functions 4-78 4 timing mode ・ when buffering operation starts, the timing input is turned to stand-by status. ・ changing the timing input from “on” to “off” during stand-by status starts data accumulation to the controller memory. ・ timing input stops when the accumulation ...

Page 153

Chapter 4 explanation of functions 4-79 4 ■ buffering type this function selects individual data accumulation or simultaneous data accumulation on out1 and out2. Out1 is set as a default. The maximum accumulation data amount differs depending on buffering type. ■ buffering rate the buffering rate ca...

Page 154

Chapter 4 explanation of functions 4-80 4 ■ trigger conditions this function is used for setting the trigger generation conditions when the buffering mode is set to trigger mode or sample trigger mode. The trigger conditions are selectable from “at timing input on”, the results of “judgment output” ...

Page 155

Chapter 4 explanation of functions 4-81 4 ■ trigger delay this function is used for delaying the timing of trigger detection when the buffering mode is set to trigger mode or sample trigger mode. Sets number of sampling times as the trigger delay value. Setting range is 0 to 100000000. The status du...

Page 156

Chapter 4 explanation of functions 4-82 4 ■ status readout this function checks the status of the measurement data accumulation. Use this function for checking the accumulation status before reading the accumulated data. After having checked the status, the controller replies one of the next status....

Page 157

Chapter 4 explanation of functions 4-83 4 ■ data read the accumulated measurement data in the controller memory can be read out. The below shows two reading methods. Read method contents normal read simply reads the accumulated measurement data as is. Rapid read reads the accumulated data by the dif...

Page 158: 4-4

Chapter 4 explanation of functions 4-84 4 4-4 supplemental explanation this section provides supplemental explanation for enhancing understandings of the system functions. 4-4-1 alarm setting and outputs “alarm status” means the measurement disabled status due to poor light intensity or out of measu...

Page 159: 4-4-2

Chapter 4 explanation of functions 4-85 4 4-4-2 conditions when output data become unfixed at immediately after change of “head setting” or “out setting”, or when the reset or laser emission stop is input, the operation status becomes “data unfixed status” (data is not determined). This status is no...

Page 160

Chapter 4 explanation of functions 4-86 4 alarm code in case an alarm occurs, check the alarm code of alarm output read by rs-232c or usb communication. Alarm code name description 0 normal normal measurement status. 1 measurement alarm measurement is not possible due to insufficient light intensity...

Page 161

Chapter 4 explanation of functions 4-87 4 the conditions of causes of data unfixed status and the measurement status are shown as below. Conditions when output data become unfixed status measurement status remote interlock is input at power-on both out1 and out2 become the data unfix status. “sampli...

Page 162: 4-4-3

Chapter 4 explanation of functions 4-88 4 4-4-3 memory save and terminal setting the setting contents for each function can be stored in 16 different patterns in the controller memory. This function stores the measurement or judgment conditions for each measurement object respectively, so without re...

Page 163

Chapter 4 explanation of functions 4-89 4 ■ external input terminal setting memory no. External input terminal m0 m1 m2 m3 0 off off off off 1 on off off off 2 off on off off 3 on on off off 4 off off on off 5 on off on off 6 off on on off 7 on on on off 8 off off off on 9 on off off on 10 off on of...

Page 164

Chapter 4 explanation of functions 4-90 4 memo.

Page 165

5-1 5 5 external communication control this chapter explains control method of system by rs-232c/usb/ethernet communication. 5-1 communication control by rs-232c ····· 5-2 5-1-1 specifications ·············································· 5-2 5-1-2 type and format of commands ··········· 5-5 5-1-3 ...

Page 166: 5-1

Chapter 5 external communication control 5-2 5 5-1 communication control by rs-232c 5-1-1 specifications ■ communication specifications the specifications related to communication are listed in the table below. The configurations can be changed to the requirements of external host device. Item setti...

Page 167

Chapter 5 external communication control 5-3 5 ■ connecting example with external device ● configuration ● connection hl-c2 and external host device should be connected as below. Signals other than rd, sd, sg and shield should be kept unused. Do not connect with hl-c2. Pin no. Signal 1 cd 2 rd 3 sd ...

Page 168

Chapter 5 external communication control 5-4 5 ■ communication procedures ● configure communication specifications 1. Configure communication specifications of hl-c2 the communication specifications of rs-232c on hl-c2 are listed in the table in “5-1-1 communication specifications” . Set them accord...

Page 169: 5-1-2

Chapter 5 external communication control 5-5 5 5-1-2 type and format of commands ■ data transmission/reception ● data transmission/reception this section explains how to set or change various parameters or to confirm or read measurement values by sending a command from the external host device to hl...

Page 170

Chapter 5 external communication control 5-6 5 ● error code code no. Code type description 01 format error the first four characters are not . 02 command error the command is undefined. 03 command code error the forth character from the head is neither nor . 04 code error the code is other than that...

Page 171

Chapter 5 external communication control 5-7 5 ■ command classification ● communication data format the figure below shows the basic format of request communication data and response communication data. The specifications of respective sections are explained in the table below. For ascii and alphabe...

Page 172

Chapter 5 external communication control 5-8 5 ■ request communication data format this section explains the 6 format patterns of request communication data transmitted from the external host device to hl-c2. ● read request the figures below show the format for read request. There are two types of p...

Page 173

Chapter 5 external communication control 5-9 5 format 5 value setting command 2 format 6 normal write of buffering data ■ response communication data format this section explains the 10 format patterns of response communication data transmitted from hl-c2 to the external host device. ● read response...

Page 174

Chapter 5 external communication control 5-10 5 format 4 special format 1:2 output measurement value format 5 special format 2:2 output check the measurement value consists of 1-character symbol, 3-digit integral part (no zero suppress), decimal point and 6-digit decimal part . The following outputs...

Page 175

Chapter 5 external communication control 5-11 5 format 7 special format 5: read of differential data in buffering data the data of specified head point is stored with the head data format shown below. For the data of second point and subsequent points, the differential by the previous data (the data...

Page 176

Chapter 5 external communication control 5-12 5 format 8 special format 7: exclusive output format for rs232c output mode for rs232c output type out1 or out2 for rs232c output type out1&out2 the measurement value consists of 1-character symbol, 3-digit integral part (no zero suppress), and 6-digit d...

Page 177

Chapter 5 external communication control 5-13 5 ■ bcc bcc is the code for horizontal parity check to improve the reliability of communication data. The exclusive logical sum from the header ( ) to the final character of communication data is calculated and resultant 8-bit data is converted to 2-char...

Page 178: 5-1-3

Chapter 5 external communication control 5-14 5 5-1-3 command list refer to “hl-c2 series user’s manual rs-232c communication control” for the details of respective commands. Item command code subdata *1 setting value h ead installation mode rmm wmm 1/2 00000 diffuse reflection 00001 specular reflec...

Page 179

Chapter 5 external communication control 5-15 5 item command code subdata *1 setting value h ead emission search rfc wfc 1/2 00000 none 00001 execute 00002 searching alarm delay times rhc whc 1/2 - 00000: off to 65535: hold previous normal value measurement mode rsm wsm 1/2 00000 diffuse [standard] ...

Page 180

Chapter 5 external communication control 5-16 5 item command code subdata *1 setting value o ut output selection ros wos 3/4 00000 a 00001 b 00002 -a 00003 -b 00004 a+b 00005 -(a+b) 00006 a-b 00007 b-a 00008 [a] [tr] 00009 [b] [tr] 00010 [-a] [tr] 00011 [-b] [tr] 00012 a1+b1 [tr] 00013 -a1+b1 [tr] 0...

Page 181

Chapter 5 external communication control 5-17 5 item command code subdata *1 setting value o ut timing rti wti 3/4 00000 off 00001 on reset rrs wrs 3/4 00000 off 00001 on hold rhd whd 3/4 00000 off 00001 on analysis mode rhm whm 3/4 00000 normal 00001 peak 00002 bottom 00003 peak to peak filter oper...

Page 182

Chapter 5 external communication control 5-18 5 item command code subdata *1 setting value o ut cutoff frequency rco wco 3/4 00000 1[hz] 00001 2[hz] 00002 4[hz] 00003 10[hz] 00004 20[hz] 00005 40[hz] 00006 100[hz] 00007 200[hz] 00008 400[hz] 00009 1000[hz] 00010 2000[hz] operation coefficient rmk wm...

Page 183

Chapter 5 external communication control 5-19 5 item command code subdata *1 setting value o ut digit number of measurement value rkt wkt 3/4 00000 6 decimal places 00001 5 decimal places 00002 4 decimal places 00003 3 decimal places 00004 2 decimal places 00005 1 decimal places measurement value re...

Page 184

Chapter 5 external communication control 5-20 5 item command code subdata *1 setting value c om m on judgment output off delay rof wof 5 00000 off 00001 2ms 00002 10ms 00003 100ms 00004 hold interference prevention rxt wxt 5 00000 off 00001 on 2 outputs measurement value read rma - 5 - -999.999999 t...

Page 185

Chapter 5 external communication control 5-21 5 item command code subdata *1 setting value s ys te m save - wwr 0 00000 none 00001 save all memory rs-232c baud rate rsa wsa 0 00000 9600[bps] 00001 19200[bps] 00002 38400[bps] 00003 115200[bps] rs-232c data length rsb wsb 0 00000 7-bit 00001 8-bit rs-...

Page 186

Chapter 5 external communication control 5-22 5 item command code subdata *1 setting value b uf fer ing self-stop rss wss 0 00000 off 00001 on buffering mode rbd wbd 5 00000 continuous 00001 trigger 00002 timing 00003 sample trigger buffering type rtt wtt 5 00000 out1 & 2 00001 out1 00002 out2 buffe...

Page 187

Chapter 5 external communication control 5-23 5 item command code subdata *1 setting value b uf fer ing status readout rts - 3/4 00000 non-buffering 00001 wait for trigger 00002 accumulating 00003 accumulation completed final data point rld - 3/4 - read one time data read (normal) rla - 3/4 - 5-char...

Page 188: 5-2

Chapter 5 external communication control 5-24 5 5-2 usb communication control hl-c2 can be controlled through the external host device (personal computer) through usb interface by using the api function. Refer to “hl-c2 series user ’ s manual usb communication control” (pdf data) for the details. Us...

Page 189

Chapter 5 external communication control 5-25 5 ■ operating environment the following operating environments are required to use hl-c2. Operating environment os microsoft windows® 7 professional 32bit/64bit microsoft windows® 8.1 pro 32bit/64bit microsoft windows® 10 professional 32bit/64bit (japane...

Page 190: 5-3

Chapter 5 external communication control 5-26 5 5-3 ethernet communication control the hl-c21c makes it possible to read a variety of settings and measured values over ethernet communication. Refer to “hl-c2 series user ’ s manual ethernet communication control” (pdf data) for the details. ■ specifi...

Page 191

6-1 6 6 maintenance and inspection 6-1 maintenance ······························6-2 6-2 inspection ··································6-2.

Page 192: 6-1

Chapter 6 maintenance and inspection 6-2 6 6-1 maintenance ■ maintenance instructions · before cleaning the unit, be sure to turn off the power and stop laser emission. · molded resin is used in some parts of the unit. Do not use organic solvents such as thinner or benzene to wipe dirt on it. · do n...

Page 193

7-1 7 7 troubleshooting this chapter explains corrective actions against abnormal state. Read this chapter if failures are suspected. 7-1 corrective actions ······················ 7-2 7-2 lock ········································ 7-7 7-3 initialization······························· 7-7.

Page 194: 7-1

Chapter 7 troubleshooting 7-2 7 7-1 corrective actions in case an error or trouble occurs during use of the system or a system failure is suspected, read this chapter carefully first and carry out the corresponding corrective actions. Set troubles in the settings of controller com troubles in commun...

Page 195

Chapter 7 troubleshooting 7-3 7 type problem cause corrective action ref. Page laser laser beam is not emitted. Laser control setting is saved with off. Save the setting of laser control with on. 4-16 4-65 laser control terminal is short-circuited. Open the laser control terminal ( lsra or lsrb ). 2...

Page 196

Chapter 7 troubleshooting 7-4 7 type problem cause corrective action ref. Page meas measurement values vary. Moving average is small. Increase the number of moving average . 4-34 measurement mode is not set correctly. Set the measurement mode according to applications or measurement object. Select t...

Page 197

Chapter 7 troubleshooting 7-5 7 type problem cause corrective action ref. Page meas led alarm indicator lights up and measurement can not be done. ↓ in case an alarm occurs, check the alarm code of alarm output read by rs-232c or usb communication. Head is not connected. The alarm indicator lights u...

Page 198

Chapter 7 troubleshooting 7-6 7 type problem cause corrective action ref. Page set led measurement range indicator on the sensor head does not light up/blink. Sensor head is not installed correctly. Install the head correctly. The installation method is different between specular reflection and diff...

Page 199: 7-2

Chapter 7 troubleshooting 7-7 7 7-2 lock · “panel lock” is used for prohibiting the setting change on the compact programmable display to prevent any setting error occurrence due to unintentional operation on the compact programmable display. · set or release panel lock referring to “panel lock” ( p...

Page 200

Chapter 7 troubleshooting 7-8 7 memo.

Page 201

8-1 8 8 specifications this chapter describes the specifications of system components (controller and sensor head). 8-1 controller specifications ····························· 8-2 8-2 sensor head specifications ······················ 8-8 8-3 nd filter specifications ····························· 8-3...

Page 202: 8-1

Chapter 8 specifications 8-2 8 8-1 controller specifications ● rs-232c type model no. Hl-c2c(e) hl-c2c(e)-p supply voltage 24vdc ±10% including ripple 0.5v (p-p) current consumption approx. 500ma at 2 sensor heads connected approx. 350ma at 1 sensor head connected (approx. 100ma is additionally requ...

Page 203

Chapter 8 specifications 8-3 8 hl-c2c(e) hl-c2c(e)-p remote interlock input laser emission is delayed when connected to common (-). Laser emission stop at open laser emission is delayed when connected to il (+). Laser emission stop at open laser control input laser emission is stopped when connected...

Page 204

Chapter 8 specifications 8-4 8 hl-c2c(e) hl-c2c(e)-p ambient humidity 35 to 85%rh ambient height 2000m or less material case: polycarbonate weight approx. 450g applicable standards conformed to emc directive, attained korea's s-mark certification measurement conditions are as follows unless otherwis...

Page 205

Chapter 8 specifications 8-5 8 ● ethernet type model no. Hl-c21c(e) hl-c21c(e)-p supply voltage 24vdc ±10% including ripple 0.5v (p-p) current consumption approx. 500ma at 2 sensor heads connected approx. 350ma at 1 sensor head connected (approx. 100ma is additionally required when the compact progr...

Page 206

Chapter 8 specifications 8-6 8 hl-c21c(e) hl-c21c(e)-p remote interlock input laser emission is delayed when connected to common (-). Laser emission stop at open laser emission is delayed when connected to il (+). Laser emission stop at open laser control input laser emission is stopped when connect...

Page 207

Chapter 8 specifications 8-7 8 hl-c21c(e) hl-c21c(e)-p ambient humidity 35 to 85%rh ambient height 2000m or less material case: polycarbonate weight approx. 450g applicable standards conformed to emc directive measurement conditions are as follows unless otherwise specified; power voltage: 24vdc, am...

Page 208: 8-2

Chapter 8 specifications 8-8 8 8-2 sensor head specifications ■ sensor head model the model of hl-c2 sensor head is indicated as shown below. In “8-2 sensor head specifications” , “8-5 outside dimension” , and “8-6 characteristics” , the type of sensor head is classified by the kind of measurement c...

Page 209

Chapter 8 specifications 8-9 8 ■check in specifications measuring conditions are as follows unless otherwise specified; connection with controller, power voltage: 24vdc, ambient temperature: 20°c, sampling cycle: 40μs, average number of samples: 256 times, measurement center distance, measurement ob...

Page 210

Chapter 8 specifications 8-10 8 ● 10mm type model no. Hl-c201a, hl-c201f hl-c201ae, hl-c201fe hl-c201a-mk, hl-c201f-mk hl-c201ae-mk, hl-c201fe-mk measurement method specular reflection measurement center distance 10mm measurement range *1 ±1mm beam source red semiconductor laser class 1 (jis/iec/gb/...

Page 211

Chapter 8 specifications 8-11 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 the measurement range is between +0.1 and +1.0mm (in case the sampling cycle is 20µs), or between +0.8 and +1.0mm (in case the sampling cycle is 10µs). *2 fda-compliant...

Page 212

Chapter 8 specifications 8-12 8 ● 30mm type model no. Hl-c203b, hl-203f hl-c203be, hl-c203fe hl-c203b-mk, hl-203f-mk hl-c203be-mk, hl-c203fe-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection measurement cente...

Page 213

Chapter 8 specifications 8-13 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited between...

Page 214

Chapter 8 specifications 8-14 8 ● 50mm type (class2) model no. Hl-c205b, hl-c205be hl-c205b-mk, hl-c205be-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection measurement center distance 50mm 46mm 50mm 46mm meas...

Page 215

Chapter 8 specifications 8-15 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited between...

Page 216

Chapter 8 specifications 8-16 8 ● 50mm type (class3r) model no. Hl-c205c, hl-c205ce hl-c205c-mk, hl-c205ce-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection measurement center distance 50mm 46mm 50mm 46mm mea...

Page 217

Chapter 8 specifications 8-17 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications".. *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited betwee...

Page 218

Chapter 8 specifications 8-18 8 ● 85mm type (class2) model no. Hl-c208b, hl-c208be hl-c208b-mk, hl-c208be-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection measurement center distance 85mm 81.4mm 85mm 81.4mm ...

Page 219

Chapter 8 specifications 8-19 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited between...

Page 220

Chapter 8 specifications 8-20 8 ● 85mm type (class3r) model no. Hl-c208c, hl-c208ce hl-c208c-mk, hl-c208ce-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection measurement center distance 85mm 81.4mm 85mm 81.4mm...

Page 221

Chapter 8 specifications 8-21 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications".. *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited betwee...

Page 222

Chapter 8 specifications 8-22 8 ● 110mm type (class2 *3 ) model no. Hl-c211b, hl-211f hl-c211be, hl-c211fe hl-c211b-mk, hl-211f-mk hl-c211be-mk, hl-c211fe-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection mea...

Page 223

Chapter 8 specifications 8-23 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited between...

Page 224

Chapter 8 specifications 8-24 8 ● 110mm type (class3r *3 ) model no. Hl-c211c, hl-211f5 hl-c211ce, hl-c211f5e hl-c211c-mk, hl-211f5-mk hl-c211ce-mk, hl-c211f5e-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflectio...

Page 225

Chapter 8 specifications 8-25 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications".. *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited betwee...

Page 226

Chapter 8 specifications 8-26 8 ● 350mm type (class2) model no. Hl-c235be hl-c235be-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection measurement center distance 350mm 348mm 350mm 348mm measurement range *2 ±...

Page 227

Chapter 8 specifications 8-27 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited between...

Page 228

Chapter 8 specifications 8-28 8 ● 350mm type (class3r) model no. Hl-c235ce hl-c235ce-mk diffuse reflection specular reflection diffuse reflection specular reflection measurement method *1 diffuse reflection/specular reflection measurement center distance 350mm 348mm 350mm 348mm measurement range *2 ...

Page 229

Chapter 8 specifications 8-29 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limited between...

Page 230

Chapter 8 specifications 8-30 8 ● 350mm type (class3r) model no. Hl-c235ce-w hl-c235ce-wmk measurement method *1 diffuse reflection measurement center distance 350mm 350mm measurement range *2 ±200mm ±200mm beam source red semiconductor laser class 3r (jis/iec/gb/ks/fda) max output: 5mw, emission pe...

Page 231

Chapter 8 specifications 8-31 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 use the external nd filter (optional) in case the amount of reflected beam is too large on specular reflection installation. *2 the measurement range is limites between...

Page 232

Chapter 8 specifications 8-32 8 ● 8mm type (class1) model no. Hl-c201a(e)-sp2 hl-c201a(e)-sp2m measurement method specular reflection measurement center distance 8mm measurement range *1 ±0.8mm beam source red semiconductor laser class 1 (jis/iec/gb/ks) max output: 0.1mw, emission peak wavelength: 6...

Page 233

Chapter 8 specifications 8-33 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 the measurement range is between +0.1 and +0.8mm (in case the sampling cycle is 20μs), or between +0.7 and +0.8mm (in case the sampling cycle is 10μs). *2 the figure sh...

Page 234

Chapter 8 specifications 8-34 8 ● 15mm type (class1) model no. Hl-c201a(e)-sp3 hl-c201a(e)-sp3m measurement method specular reflection measurement center distance 15mm measurement range *1 ±1mm beam source red semiconductor laser class 1 (jis/iec/gb/ks) max output: 0.3mw, emission peak wavelength: 6...

Page 235

Chapter 8 specifications 8-35 8 for measuring conditions, refer to "8-2 sensor head specifications" - "check in specifications". *1 the measurement range is between +0.1 and +1.0 mm (in case the sampling cycle is 20μs), or between +0.8 and +1.0 mm (in case the sampling cycle is 10μs). *2 the figure ...

Page 236: 8-3

Chapter 8 specifications 8-36 8 8-3 nd filter specifications model no. Hl-c2f01 applicable head hl-c203 □ /hl-c203 □ -mk hl-c205 □ /hl-c205 □ -mk hl-c208 □ /hl-c208 □ -mk hl-c211 □ /hl-c211 □ -mk hl-c235 □ e/hl-c235 □ e-mk fading rate 98% *1 shock resistance 196m/s 2 or more in x, y, and z direction...

Page 237: 8-4

Chapter 8 specifications 8-37 8 8-4 outside dimension ■ controller ● rs-232c type [hl-c2c(e) / hl-c2c(e)-p] (leading dimension) for installation to 35mm width din rail unit: mm.

Page 238

Chapter 8 specifications 8-38 8 ● ethernet type [hl-c21c(e) / hl-c21c(e)-p] (leading dimension) for installation to 35mm width din rail unit: mm.

Page 239

Chapter 8 specifications 8-39 8 ■ sensor head ● 10mm type ( hl- c201□□/hl-c201□□-mk ) reference surface 2-m5 mounting hole, depth:8 (opposite surface) measurement range indicator (yellow) laser emission indicator (green) unit: mm ● 30mm type ( hl- c203b□/hl-c203b□-mk ) diffuse reflection (measuremen...

Page 240

Chapter 8 specifications 8-40 8 ● 50mm type ( hl-c205 b□/hl-c205b□-mk/hl-c205c□/hl-c205c□-mk ) diffuse reflection 26 50 5 36° 74 64 ø6.6 6.2 13 9 75 90 64 69 5 (ø14.7) (550) (measurement center distance) light reception axis laser emission indicator (green) measurement range indicator (yellow) light...

Page 241

Chapter 8 specifications 8-41 8 ● 85mm type ( hl-c208 b□/hl-c208b□-mk/hl-c208c□/hl-c208c□-mk ) diffuse reflection 26 85 5 28° 74 64 6.2 13 9 75 90 64 69 5 ø6.6 (ø14.7) (550) (measurement center distance) light reception axis laser emission indicator (green) measurement range indicator (yellow) light...

Page 242

Chapter 8 specifications 8-42 8 ● 110mm type ( hl-c211 b□/hl-c211b□-mk/hl-c211c□/hl-c211c□-mk ) diffuse reflection light reception axis measurement range indicator (yellow) (measurement center distance) 2-m5 mounting hole depth:10 (opposite surface) light emission axis laser emission indicator (gree...

Page 243

Chapter 8 specifications 8-43 8 ● 350mm type ( hl-c235be/hl-c235be-mk/hl-c235ce/hl-c235ce-mk ) diffuse reflection light reception axis measurement range indicator (yellow) (measurement center distance) 2-m5 mounting hole depth:10 (opposite surface) laser emission indicator (green) light emission axi...

Page 244

Chapter 8 specifications 8-44 8 ●350mm type ( hl-c235ce-w/hl-c235ce-wmk ) diffuse reflection 26 350 5 8.8° 74 64 ø6.6 6.2 13 9 75 90 64 69 5 (ø14.7) (550) (measurement center distance) light reception axis laser emission indicator (green) measurement range indicator (yellow) light emission axis unit...

Page 245

Chapter 8 specifications 8-45 8 ● 8mm type [hl-c201a(e)-sp2/hl-c201a(e)-sp2m] 33.5 17 135 24 16 12 45 32 41 127 27 8 φ 4.5 φ 8 10 2 17 9 7 4 ( φ 14.7) φ 6.6 62 64.5 5 18 39 27 80 2-ø4.5 (mounting hole) light emission axis light reception axis measurement range indicator (yellow) laser emission indic...

Page 246

Chapter 8 specifications 8-46 8 ● 30mm type (hl-c203f□/hl-c203f□-mk) diffuse reflection measurement range indicator (yellow) laser emission indicator (green) (measurement center distance) 2-m5 mounting hole depth:10 (opposite surface) unit: mm specular reflection specular reflection line the referen...

Page 247

Chapter 8 specifications 8-47 8 ● 110mm type (hl-c211f □ /hl-c211f □ -mk/hl-c211f5 □ /hl-c211f5 □ -mk) diffuse reflection beam attenuator light reception axis measurement range indicator (yellow) (measurement center distance) 2-m5 mounting hole depth:10 (opposite surface) light emission axis laser e...

Page 248

Chapter 8 specifications 8-48 8 ■ nd filter ( hl-c2f01 ) unit: mm diffuse reflection (nd filter attached) (hl-203 □□/hl-c203□□-mk) unit: mm specular reflection (nd filter attached) (hl-203 □□/hl-c203□□-mk) unit: mm * the measurement in installation is also the same in hl- c211□□/ hl-c211□□-mk. * for...

Page 249: 8-5

Chapter 8 specifications 8-49 8 8-5 characteristics ■ beam diameter ● 10mm type unit: mm ● 30mm type unit: mm.

Page 250

Chapter 8 specifications 8-50 8 ● 50mm type unit: mm ● 85mm type unit: mm.

Page 251

Chapter 8 specifications 8-51 8 ● 110mm type unit: mm ● 350mm type ( hl-c235 □e/hl-c235□e-mk ) unit: mm ● 350mm type (hl-c235ce-w/hl-c235ce-wmk) unit: mm.

Page 252

Chapter 8 specifications 8-52 8 ● 8mm type unit: mm ● 15mm type unit: mm.

Page 253

Chapter 8 specifications 8-53 8 ■ mutual interference area when installing 2 or more sensor heads side by side, mutual interference occurs if the laser spots from other sensor heads fall within the shaded areas in the figure below. Install sensor heads as the laser spots from other sensor heads fall...

Page 254

Chapter 8 specifications 8-54 8 ● 85mm type ( hl-c208 □/hl-c208□-mk ) unit: mm ● 110mm type ( hl-c211 □/hl-c211□-mk ) unit: mm.

Page 255

Chapter 8 specifications 8-55 8 ● 350mm type ( hl-c235 □e/hl-c235□e-mk ) unit: mm ● 350mm type ( hl-c235ce-w/hl-c235ce-wmk ) unit: mm if beam from the other sensor head enters into the mutual interference area when two sensor heads are connected, set the “interference prevention” function to on. “4-...

Page 256

Chapter 8 specifications 8-56 8 ■ output characteristics and measurement range indicator ● 10mm type ( hl- c201□/hl-c201□-mk ) *1 in the figure above, analog output setting is used as the initial setting. *2 the measurement range is limited between +0.1 and +1.0mm (in case the sampling cycle is 20µs...

Page 257

Chapter 8 specifications 8-57 8 ● 30mm type ( hl- c203□/hl-c203□-mk ) diffuse reflection *1 in the figure above, analog output setting is used as the initial setting. *2 the measurement range is limited between 0 and +5.0mm (in case the sampling cycle is 20µs) or between +3.8 and +5.0mm (in case the...

Page 258