- DL manuals

- Panasonic

- Accessories

- HL-G1**-A-C5

- User Manual

Panasonic HL-G1**-A-C5 User Manual - 1-1

1-1

System Configuration

1-1-1

System Configuration

The system configuration and equipment connecting cables are shown below.

USB-RS-422/485 converter

Recommended: SI-35USB (LINEEYE made) or GT02 series or GT12 series

(Panasonic Industrial Devices SUNX made)

The user may use a different converter at the user's own discretion.

Dedicated software (to be downloaded from the website of Panasonic

Industrial Devices SUNX) is required if the GT02 or GT12 series is used

as a converter.

RS-485 wiring

can reach up to

16 units.

Sensor head

(Standard type)

Sensor head

(High-function

type)

Unilateral extension

cable connector

(2 m, 5 m, 10 m, and 20 m)

USB-RS-422/485 converter

PC

Setting and Monitoring

Software HL-G1SMI

USB cable

RS-422/485

Analog signal processing equipment

(A/D board and digital panel)

I /O control devices

(PLC etc.)

Analog output

Each I/O

System Configuration Example with Setting Tools (HL-G1SMI) Used

RS-422/485 communications

control equipment

RS-422/485 board

USB-RS-422/485 converter

Dedicated compact console

and others

Ramco National

800-280-6933 | nsales@ramcoi.com

www.panasonicsensors.com

Summary of HL-G1**-A-C5

Page 2

Introduction thank you for purchasing the hl-g1-series compact laser displacement sensor. Read this manual carefully and be sure you understand the information provided before attempting to install and operate the product so that the product will fully demonstrate its superior performance. Refer to ...

Page 3

About this manual chapter 1 chapter 2 chapter 3 chapter 4 chapter 5 chapter 6 1 2 3 4 5 6 introduction provides precautions on the safe and correct use of this system. Be sure to read the precautions provided in this section. Introduction 仕様 i/o terminal block before use chapter 1 provides informati...

Page 4

Table of contents about this manual······························· 1 table of contents ······························· 2 safety precautions ·····························4 warning ········································ 4 caution ············································ 4 correct handling ······...

Page 5

Measurement value display on panel ····· 3-29 3-3-6 analog settings ······················ 3-30 analog output selection ······················· 3-30 analog scaling ··································· 3-31 3-3-7 alarm settings ························ 3-33 analog output at alarm ·····················...

Page 6: Warning

Safety precautions this product is used to detect objects, and does not incorporate control functions for the purpose of maintaining safety including the prevention of accidents. Do not use this product as a human sensor to protect human bodies. Use products that conform to the laws, regulations, an...

Page 7

Correct handling pay attention to the following items when installing and using the system. Installation environment do not install the system in the following places. • places where the ambient temperature, humidity, or the illumination level of the light receiving surface is in excess of the opera...

Page 8

Ambient temperature is 40°c or higher. In the case of installing two or more sensor heads in parallel, mount each sensor head to an aluminum or steel plate with a minimum surface area of 200 cm 2 and make sure that the ambient temperature does not exceed 40°c. Ambient humidity • use the system withi...

Page 9

Warm-up time in order to ensure the performance of the system, allow a warm-up time of at least 30 minutes after the system is turned on. Countermeasures against noise • install the system separated as much as possible from noise generating sources, such as high-tension lines, high-voltage equipment...

Page 10

Power supply applicable power supply • select a power supply with a maximum ripple of 0.5 v (peak to peak) and a minimum current capacity of 0.5 a. • be sure to ground the fg terminal in order to prevent an adverse influence of high-frequency noise if a commercially available switching regulator is ...

Page 11

Applicable standards / regulations ce compliant conditions make sure that the length of signal and power lines connected to the product is less than 30 m. Attach a ferrite core to the head cable as shown below. Recommended ferrite core: seiwa electric mfg. Co., ltd.E04sr200935ab or equivalent one co...

Page 12

Laser product handling jis/iec/gb laser diode sensor the laser is classified in accordance with jis (jis c 6802: 2005), iec (iec 60825-1: 2007) and gb (gb 7247.1: 2012) standards. Model no. Hl-g1 □□ -a-c5 hl-g1 □□ -s-j hl-g1 □□ a-ra-c5 hl-g1 □□ a-rs-j wavelength 655 nm 655 nm max. Output 1 mw 0.39 m...

Page 14

Fda export to us the laser product mounted on equipment and exported to the united states is subjected to the regulation of the food and drug administration (fda). In order to prevent the users’ injury caused by laser products, the fda specifies part 1040 (performance standards for light-emitting pr...

Page 15

Fda standards requirements class *1 i iia ii iiia iiib iv performance (all laser products) protective housing [1040.10(f)(1)] safety interlock [1040.10 (f) (2)] location of controls [1040.10(f)(7)] viewing optics [1040.10(f)(8)] scanning safeguard [1040.10(f)(9)] r *2 r *3,4 n/a r r r *2 r *3,4 r r ...

Page 16

*1 class is based on the maximum level of laser exposure duringoperation. *2 required wherever and whenever such human access to laser radiation levels that exceed the limits of class i is not necessary for the product to perform its intended function. *3 required at the protective housing which is ...

Page 17

Maintenance and inspection maintenance instructions • be sure to turn off the system to stop laser emission before cleaning the system. • molded resin is used in some parts of the system. Do not use organic solvents such as paint thinner or benzine to wipe the dirt on the system. • do not wipe the g...

Page 19

1 before use this chapter provides information on the configuration, installation, and connection of the system (including the sensor head and setting and monitoring software hl-g1smi). 1-1 system configuration ········· 1-2 1-1-1 system configuration ·········· 1-2 1-1-2 list of system components &...

Page 20: 1-1

1-1 system configuration 1-1-1 system configuration the system configuration and equipment connecting cables are shown below. Usb-rs-422/485 converter recommended: si-35usb (lineeye made) or gt02 series or gt12 series (panasonic industrial devices sunx made) the user may use a different converter at...

Page 21: 1-1-2

1-1-2 list of system components & accessories sensor head accessories the accessories of the sensor head are shown below. Sensor head (high-function type) warning label sensor head instruction manual sensor head (standard type) japanese / english and chinese / korean sticker: english attachments: ja...

Page 22

Extension cable for sensor head (optional for high-function type only) setting and monitoring software hl-g1smi (optional for high-function type only) software for the setting and monitoring software hl-g1smi can be downloaded from the website of panasonic industrial devices sunx co., ltd. ( http://...

Page 23

Compact console (optional for high-function type only) the gt-series programmable display of panasonic industrial devices sunx co., ltd. Is available as a compact console for the hl-g1. Write dedicated screen data to the programmable display so that the programmable display will display hl-g1 settin...

Page 24: 1-2

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) 1-2 part names and functions (1) laser indicator (laser) lights up in green during laser emission. (2) alarm indicator (alarm) lights up in orange if a measurement alarm results. (3) out1 indicator (out1) lights up in yellow during out1 output. (4) out2 ...

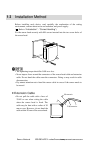

Page 25: 1-3

1-3 installation method before installing each device, read carefully the explanation of the setting environment, concern about noise and radiation, and power supply. ( refer to “introduction” – “correct handling” .) fix the sensor head securely with m4 screws inserted into the two screw holes of th...

Page 26

Mounting direction of sensor head mount the sensor head in the direction shown below toward the measuring target in order to ensure the precise and stable measurement operation of the sensor head. ● installation direction toward the moving target • measurement of targets with extremely different adj...

Page 27

• measurement of targets with level differences when measuring a moving target that has level differences, set the direction of the sensor head as shown below in order to minimize interference caused by the edges of the target. ● measurement of targets in narrow space or slots when measuring a targe...

Page 29

● sensor head angle to the center of measurement target for a diffuse reflection-type sensor mount the sensor head so that the emitter and receiver will be located in parallel to each other as shown in the illustration on the right-hand side. Refer to “ 6-1 sensor head specifications ” for the measu...

Page 30: 1-4

1-4 measurement of transparent objects because the measured value for the closest reflected wave will be output from the sensor when an hl-g1 series specular reflection-type unit measures a multi-reflecting reflector such as transparent glass, only surface measurement is possible. To accurately meas...

Page 31

2 i/o terminal block this chapter provides information on the i/o lines of the sensor head. 2-1 functions and arrangements of i/o terminal block ·························· 2-2 2-2 i/o circuit ··················· 2-4 2-3 analog output circuit ········· 2-6 2-4 timing chart ················ 2-7 2-5 co...

Page 32: 2-1

2-1 functions and arrangements of i/o terminal block analog output lines no. Name function wiring color 7 a(v) analog voltage output shield single conductor black 8 agnd analog ground 9 a(i) analog current output shield single conductor gray 10 agnd analog ground i/o terminal block no. Name function...

Page 33

* multi-input wire (mi) varies with the period of input as shown below. Period of input function 30 ms zero-set on 80 ms reset 130 ms memory change (m0) 180 ms memory change (m1) 230 ms memory change (m2) 280 ms memory change (m3) 330 ms teaching a (determines displacement judgment value a) 380 ms t...

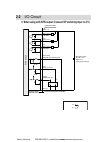

Page 34: 2-2

2-2 i/o circuit when using with npn output (connect np switching input to 0v) external connection example sensor head internal circuit (brown) + v (black) output 1: out1 load load load (pink/purple) npn/pnp type switching input (pink) timing input: tm (purple) multiple input: mi 3.3v 3.3v (blue) 0v ...

Page 35

When using with pnp output (connect np switching input to +v) external connection example sensor head internal circuit (brown) + v (black) output 1: out1 load load load (pink/purple) npn/pnp type switching input (pink) timing input: tm (purple) multiple input: mi (blue) 0v *1 main power supply 24 vd...

Page 36: 2-3

2-3 analog output circuit m a in c ir c u it +V analog input device 100 0 to 11 v 22 3.2 to 22 ma agnd agnd (shield) analog ground: agnd (shield) analog ground: agnd (black) analog voltage output: a (v) (gray) analog current output: a (i) external connection example sensor head internal circuit lead...

Page 37: 2-4

2-4 timing chart ● normal measurement (with timing mode set to “hold”) ● normal measurement (with timing mode set to “one - shot”) ● peak measurement * the function of multiple input varies with the period of input. Zero set on: 30ms zero set off: 430 ms reset: 80 ms laser on: 530 ms laser off: 580 ...

Page 38

• a zero set will be enabled by timing input while the hold status is valid. • a reset input by timing input during the hold status will cause a data unfixed status. The system will hold this status until the timing input is cancelled. • no zero set will be enabled while the data unfixed status is k...

Page 39: 2-5

2-5 conditions when output data become unfixed the operation status will be judged as a data unfixed status (i.E., there is no determined data) immediately after settings changes are made, the system is reset, or laser stop input is turned on. This status is not an alarm status. The data unfixed sta...

Page 40

The following conditions will result in the data unfixed status. • reset input after the power is turned on • sampling cycle switching • initialization • laser control interruption • average t imes switching * there are cases where the data unfixed status does not occur depending on the setting cond...

Page 41

3 functions this chapter provides information on the functions of the system. 3-1 classification of functions ···································3-2 3-2 function list & initial values ······························3-2 3-3 operation of each function ································3-5 3-3-1 basic ope...

Page 42: 3-1

3-1 classification of functions in this system, all functions are classified into eight categories to ensure stable measurement and various outputs. Classification panel display function sensing settings function settings for precise and stable measurement by controlling the received light intensity...

Page 43

Class function details initial value memory change* ref. Page ou tpu t s etti ng s judgment output selection sets the operation of the output block. Default: 2-state 3-23 displace ment judgment threshold a sets threshold a and threshold b. Default: +(detection range) default: -(detection range) 3-25...

Page 44

Class function details initial value memory change* ref. Page zero-set sets the measurement value to zero. - 3-47 reset resets the measurement value. Default: off - 3-49 buf fer ing s et tin gs buffering mode sets the buffering mode. Default: continuous mode 3-52 buffering rate loads measurement dat...

Page 45: 3-3

3-3 operation of each function 3-3-1 basic operation panel configuration (1) (2) (4) (3) (1) [enter] key used to enter items. (2) digital display displays measurement values, set values, and system errors. (3) [up] key used to select items. (4) [down] key used to select items. Digital display the de...

Page 46

Basic operation the following section explains how to operate the system in run mode after the system is turned on, make function changes in the system, and reset the system to run mode, along with the shortcut functions of the system in run mode. The operation of the system common to each function ...

Page 47

(1) run mode the measurement value will appear on the digital display in this mode. The system will be set to this mode when the system is turned on. Rs-422/485 write and read commands will be received while the system is in this mode. (2) setting mode use this mode to make setting changes. Rs-422/4...

Page 49

Screen transition in setting mode run mode setting mode 2 s sensing setting data processing settings output setting sampling cycle shutter time light intensity monitor average times analysis mode span offset zero set off judgment output selection threshold a threshold b hysteresis judgment output of...

Page 50

*1 not displayed when "voltage" is selected for "analog output selection." *2 not displayed when "current" is selected for "analog output selection." analog output selection measurement value a current a *1 voltage a *2 measurement value b current b *1 voltage b *2 analog output at alarm digital out...

Page 51: 3-3-2

3-3-2 memory change the memory to save setting contents can be changed with m0 through m3. Setting function panel display m0 memory m0 m1 memory m1 m2 memory m2 m3 memory m3 * indicates the default value. • select the first number to be changed when the system goes into setting mode. • data unstabil...

Page 52

Storable functions in memory the function settings that can be stored in the memory are divided into two types. One of them can be stored in each specified memory number and the other one can be stored as setting values common to all memories. For the above two types of storable functions in detail,...

Page 53: 3-3-3

3-3-3 sensing setting sampling cycle this function is used to make measurement cycle settings. When measuring an object with poor received light intensity, such as black rubber, extend the sampling cycle to get sufficient light to perform stable measurement. Cycle frequency panel display meas. Objec...

Page 54

Shutter time the shutter time controls the receiving light intensity of the sensor according to the amount of reflected light from measurement targets. If the shutter time is set to auto, the light intensity feedback function automatically controls the light intensity to an optimum level. In the cas...

Page 55

Light intensity monitor this functio n is used to check the current received light intensity. The peak light intensity will be displayed in a range of 0 to 4095. ● setting procedure 1 display the "sensing setting" screen while the system is in setting mode. 2 press the [enter] key. The "sampling cyc...

Page 56: 3-3-4

3-3-4 data processing settings average times this function is used to set the average number of times of moving average. Use the function to stabilize unstable measurement values (including variations). Setting function panel display 1 time 1-time moving average processing 4 times 4-time moving aver...

Page 57

Analysis mode this function is used to set the analysis mode. The following table shows the function of each analysis mode. Setting function panel display normal the measurement value is output in real time. Peak holds and outputs the maximum measurement value. Valley holds and outputs the minimum m...

Page 59

Span the system can output measurement values with a span (factor) multiplied. Final measurement value = span x measurement value + offset setting range function initial value 0.1000 to +9.9999 set a span in a range from 0.1000 to +9.9999. The display limit of the measurement value is ±95.000. Make ...

Page 61

Offset a desired setting value can be added to/subtracted from the measurement value. Measurement judgment will be possible from an offset in combination with “displacement judgment” by setting the size of the master workpiece (reference measurement object) for the offset, measuring the master workp...

Page 62

Zero-set off this function cancels the zero set for measurement values. Setting function panel display reset the zero set is not canceled. Hold the zero set is canceled. • external multi input (mi) can turn the zero set on and off. ( r efer to "2-1 functions and arrangements of i/o terminal block." ...

Page 63: 3-3-5

3-3-5 output settings judgment output selection this function makes it possible to select the operation of the output block. An alarm will not be output if "3-state" is selected. The final decision process is done in digital measurements. When an alarm is turned on, the value will be set to +999.999...

Page 64

Out3 settings are related to the operation of the output lines. An alarm is output through the out3 output line unless a 3-state value has been set. The out3 indicator on the sensor head and the out3 output readout function, however, will be turned off without being interlocked with the alarm. Check...

Page 65

Displacement judgment this function is used to set an upper limit (threshold a), lower limit (threshold b), and hysteresis for the judgment of measurement values. Item panel display setting range function threshold a -95000 to +95000 sets threshold a, threshold b and hysteresis. Threshold b -95000 t...

Page 66

5 press the [up]/ [down] keys together to change the selected digit. After all the changed digits have blinked the sign can be changed. For details, refer to page 3-8 "making setting value changes." 6 press the [up]/[down] key to change the selected digit or its sign. (example: changing the value to...

Page 67

Judgment output off delay this function delays the timing of switching on to off of judgment output. 測 setting function panel display off output according to the sampling cycle. 2 ms 2-ms off-delay 4 ms 4-ms off-delay 10 ms 10-ms off-delay 20 ms 20-ms off-delay 40 ms 40-ms off-delay 100 ms 100-ms of...

Page 68

● setting procedure 1 display the "output setting" screen while the system is in setting mode. 2 press the [enter] key. The "judgment output selection" screen will be displayed. 3 press the [down] key four times. The "off-delay" screen will be displayed. 4 press the [enter] key. Off -delay settings ...

Page 69

Measurement value display on panel the rightmost digits on the digital display can be turned off. Setting function panel display full all the digits are displayed. Set 1 the rightmost digit is off. Set 2 the rightmost two digits are off. * indicates the default value. ● setting procedure 1 display t...

Page 70: 3-3-6

3-3-6 analog settings analog output selection this function selects the desired output type from current output and voltage output. The accuracy of selected analog output will be guaranteed. Setting function panel display current output current voltage output voltage * indicates the default value. ●...

Page 71

Analog scaling this function scales analog current output or analog voltage output to any desired value. Measurement values a and b on any two measurement point can be scaled with currents a and b or voltages a and b on any two points. Analog output is turned on according to the scaling set for anal...

Page 72

• the display limit of the measurement value is ±95000. Make sure that the setting value does not exceed the display limit. • check the input range of your input device such as ad board before setting. • the decimal point position of measurement values varies with each model. ● setting procedure set...

Page 73: 3-3-7

3-3-7 alarm settings analog output at alarm this function is used to set the analog output status at alarm operation. Analog output in the alarm state (where measurement is disabled owing to lack of light) can be kept on hold or set to a fixed value selectively. Setting function panel display hold h...

Page 74

Digital output at alarm this function is used to set the digital output status at alarm operation. This function makes settings related to digital output (on the digital display block of the sensor head and measurement values over serial communication) in the alarm state (where measurement is disabl...

Page 75

Alarm delay times this function holds the previous normal value up to the setting number of times if an alarm is issued. The previous normal value will be kept on hold up to the setting number of delay times if an alarm is issued (where measurement is disabled owing to lack of light). Alarm output (...

Page 76: 3-3-8

3-3-8 com settings make com settings through the control panel. No com settings are possible with serial communications commands. Terminating resistor selection this function selects the terminating resistor for the sensor head connecting to the host device over rs-422/485. Be sure to select r3 if t...

Page 77

Sensor no. This function is used to set the number of each sensor head multi connected to an rs-485 device. Be sure to set each connecting sensor head number with no duplication. Setting range function initial value 01 to 16 set sensor numbers 01 through 16 in sequence. ● setting procedure 1 display...

Page 78

Baud rate this function is used to set the communication speed. Setting function panel display 9600 9,600 bps 19200 19,200 bps 38400 38,400 bps 115200 115,200 bps 230400 230,400 bps 460800 460,800 bps 921600 921,600 bps * indicates the default value. • lower the communication speed if stable communi...

Page 79

Connection mode this function is used to select the performance settings for measurement data output to the host device. Select the operation settings for measurement data output to the host device. This section provides information on the condition that the rs-422 device is connected 1-to-1 and the...

Page 80

Sending delay time this is a useful function if the connection mode is set to rs-485 multi. Select the sensor's delay time in response to each command transmitted from the host device. Setting function panel display setting function panel display 0 no delay time 10 delay time 10ms 0.1 delay time 0.1...

Page 81: 3-3-9

3-3-9 system settings timing mode this function is used to set the timing input mode. Set the operation of the system with timing input turned on. For the operation of the system in this mode, refer to "2-4 timing chart." setting function panel display hold measurement hold with timing input one sho...

Page 82

Laser control this function is used to select the laser emission/stop. This function makes it possible to stop unrequired laser emission while the system is not in measurement operation. Setting function panel display emission laser emission is on stop laser emission is off * indicates the default v...

Page 83

Eco mode this function turns off the led indicators on the control panel while in run mode for energy saving. Setting details panel display eco-off eco mode is off. Eco-on only leds on the digital display will be turned off. Eco-full other than laser indicator, all the leds will be turned off. * ind...

Page 84

View version this function is used to take the following procedure that disp lays the program version of the sensor. ● setting procedure 1 display the "system setting" screen while in setting mode. 2 press the [enter] key. The "timing mode" screen will be displayed. 3 press the [down] key three time...

Page 85: 3-3-10

3-3-10 other system settings initialize this function is used to delete all the setting contents in the memory and returns them to the factory default settings. • when the initialization of the system is executed through the operation of the panel, all settings will return to the factory default set...

Page 86

Save there is a difference in setting saving method between the operation of the panel and the use of the communications command. ● setting changes in control panel of sensor head press the [enter] key and save the change in each item. When the system is turned on again, the last saved settings will...

Page 87: 3-3-11

3-3-11 measurement control with external input timing this function makes it possible to hold the measurement value at the desired timing. The measurement value will be kept on hold with external input timing (tm). The judgment output is kept on hold as well simultaneously. Timing settings can be ex...

Page 89

Reset the function resets the measurement value. At the time of making a peak measurement, valley measurement, or peak-to-peak measurement with external multi input (mi), the measurement value kept on hold at the desired timing can be reset. Input a specified pulse width as multi input. The pulse wi...

Page 90: 3-3-12

3-3-12 buffering settings (high-function type only) buffering is a function to accumulate measurement data in the sensor head memory and load them to external control devices. A maximum of 3,000 measurement data items can be temporarily accumulated in the built-in memory of the sensor head before lo...

Page 91

Data buffering operation data buffering procedure 1 make necessary settings for buffering. • buffering mode • buffering rate • accumulation amount • trigger conditions • trigger delay • trigger point 2 transmit the start command and start buffering. • buffering operation start 3 start data accumulat...

Page 92

Buffering mode there are two types of buffering modes, either one of which can be selected. "continuous mode" is set by default. Continuous mode • data accumulation to the built-in memory of the sensor head start with the start of buffering. • accumulation will stop when the amount of accumulation r...

Page 93

Buffering rate the buffering rate can be set for accumulating the measurement data for a long duration by taking adequate sampling cycle intervals. Select from 1 (all measurement data), 1/2, 1/4, etc. To 1/65535. The buffering rate is set to “1/10” by default. If 1/4 is selected for example, measure...

Page 94

Trigger points when the buffering mode is set to trigger mode, measurement data can be loaded by setting the data as a trigger point at the generation of the trigger. The setting range is in a range of 1 to the "accumulated amount" of data items. The value is set to 300 by default. • accumulation wi...

Page 95

Trigger conditions this function is used for setting the trigger generation conditions when the buffering mode is set to trigger mode. A value the same as or higher or lower than a threshold or the time of alarm occurrence or release can be set as a trigger condition if timing input is on. The value...

Page 96

Buffering operation this function accumulates data while the system is in buffering operation. Set necessary parameters in advance and start buffering. • all settings related to buffering cannot be changed during buffering. • non-buffering status cannot be set by only stopping buffering. Status read...

Page 97

Binary readout of buffering data the accumulated measurement data in the sensor head memory can be read out. Data in a range from 1 to the readout result of the last data point is specified and read out. To read out the buffering data, stop buffering and check the "final data point." the accumulated...

Page 99

4 communications control this chapter provides information on rs-422 and rs-485 communications control. 4-1 communications specifications ··4-2 4-2 type and format of commands ··4-7 4-2-1 commands ········································ 4-7 4-2-2 command formats ························· 4-9 4-3 co...

Page 100: 4-1

4-1 communications specifications specifications the system has the following specifications. The user can make setting changes according to the external host device in use. Item setting rs-422 rs-485 communication mode full duplex semi-duplex communication speed 9,600/19,200/38,400/115,200/230,400/...

Page 101

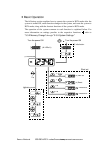

Connecting example with external device ● rs-422 1-to-1 connection select “rs-422 handshake”, “rs-422 timing”, or “rs-422 continuous” for the com setting connection mode. Set the prefix to 01. Terminator on rs-422 host device (green) transmission data:+sd +sd -sd +rd -rd sg (sky blue) transmission d...

Page 102

● rs-485 1-to-n connection select “rs-485 multi” for com setting connection mode. Set the prefix with no duplication. Terminator off hl-g1 area:01 hl-g1 area:02 hl-g1 area:16 (green) transmission data:+sd +sd -sd +rd -rd sg (sky blue) transmission data:-sd (orange) reception data:+rd (yellow) recept...

Page 104

Communications protocol ● make communications specification settings. 1. Make communications specification settings for the hl-g1. The table in "4-1 communications specifications" - "specifications" shows the communications specifications for the hl-g1. Make settings according to the operating condi...

Page 105: 4-2

4-2 type and format of commands 4-2-1 commands data transmission/reception ● data transmission/reception this section explains how to set or change various parameters or confirm and read measurement values by sending commands from an external host device to the hl-g1. (1) normal sequence to read set...

Page 106

(3) abnormal sequence to transmit/receive data the following data transmitting/receiving sequence will be used if request communication data transmitted from the external host device to the hl-g1 is abnormal (with data range error or garbled characters). External host device hl-g1 s r abnormal respo...

Page 107: 4-2-2

4-2-2 command formats the following section explains seven types of command formats transmitted from an external host device to the hl-g1. Format 1 general purpose the following command formats are used to read or make general measurement mode settings or operating conditions. ● read command read co...

Page 108

● data setting/operation instruction command data setting/operation instruction command formats are used to make data settings or give operating instructions. Request communication data normal response data setting an average number of 256 times for sensor 02 in the rs-485 multi-mode. Request commun...

Page 109

Normal response data reading the present measurement value for sensor 03 in the rs-485 multi-mode. Request communication data normal response data ● data setting/operation instruction command request communication data normal response data setting +5.5 [mm] as displacement judgment threshold a for s...

Page 110

Normal response data format 3 all outputs read the following special command formats are used to read all measurement value, received light intensity, and judgment output conditions together. Request communication data normal response data reading all “logic” outputs of judgment output selection for...

Page 111

Normal response data format 4 normal read of buffering data the following special command formats are used to read buffering measurement data in 7-digit numeric sequence format. Request communication data normal response data bcc % $ r l a cr command % # r l a destination no. Command bcc cr head poi...

Page 112

Format 5 read of differential data in buffering data the following special command formats are used to read buffering measurement data in signed differential sequence format. Request communication data normal response data data is stored in the following head data format in the specified head point....

Page 113

Normal response data * binary data on each point of response data is in 4 bytes in order of the lowest byte to highest byte. (little endian) example) head point → (binary) 0x0012d687 = (decimal) + 1234567 second point → (binary) 0x0012d71f → (decimal) + 1234719 format 7 rs-422 timing (or rs-422 cont...

Page 115

● error code error code code type description 01 command error the command is undefined. 02 address error the start address is larger than the end address or the address is larger than 999999 when the rdd or wdd command is executed. The address length has not reached the prescribed length when the r...

Page 116

Bcc bcc is a horizontal parity check code used to improve the reliability of data communication. The exclusive or is executed from the header ( )to final characters of communication data, and the exclusive or in 8-bit data is converted to 2-character ascii code. The sensor head is used to compare th...

Page 117: 4-3

4-3 command list basic settings item command data description format b as ic s e tt ings sampling cycle rsp wsp +00000 200 [μs] format 1 +00001 500 [μs] +00002 1 [ms] +00003 2 [ms] shutter time rfb wfb +00000 to +00031 +00000: auto +00001 to +00031: fixed *1. The data section consists of 5 digits (z...

Page 118

Output settings item command data description format o ut put s et ti ngs judgment output selection rod wod +00000 logic format 1 +00001 independent +00002 2-state +00003 3-state displacement judgment threshold a rha wha -9500000 to +9500000 -950.0000 to +950.0000 [mm] format 2 threshold b rhb whb -...

Page 119

Analog settings item command data description format a nal og s et ti ng s analog output selection ras was +00000 output current format 1 +00001 voltage output analog scaling measurement value a ral wal -9500000 to +9500000 -950.0000 to +950.0000 [mm] format 2 b rah wah -9500000 to +9500000 -950.000...

Page 120

System settings item command data description format s y s tem s et ti ng memory change rmc wmc +00000 m0 format 1 +00001 m1 +00002 m2 +00003 m3 timing mode rtm wtm +00000 hold +00001 one shot laser control rlr wlr +00000 stop +00001 emission eco mode rdp wdp +00000 eco-off +00001 eco-on +00002 eco-...

Page 121

Read commands item command data description format r ead c om m and measurement value read rmd - -9500000 to +9500000 -950.0000 to +950.0000[mm] format 2 read received light intensity rid - +00000 to +04095 +00000 to +04095 format 1 alarm status roa - +00000 alarm off +00001 measurement alarm on out...

Page 122

Buffering operation rbs wbs +00000 stop format 1 +00001 start status readout rts - +00000 non-buffering +00001 wait for trigger +00002 accumulating +00003 accumulation completed last data point rld - +00001 to +03000 +00001 to accumulated amount data read (normal) rla - - 5-character head point + 5-...

Page 123: 4-4

4-4 setting address list in the case of connecting the sensor to our programmable logic controller (plc) or programmable display (gt series), data can be exchanged by using data area write/read commands over mewtocol-com communications. Our fp-series plc is provided with data write (f145: data send)...

Page 124

Command formats(mewtocol) ● data area read request communication data normal response data ● data area write request communication data normal response data error response error response data is common to all formats. % $ r d × 16 1 × 16 0 sender no. Data (head) 4 character bcc × 16 2 × 16 3 × 16 0 ...

Page 125

Sensing settings address item data range write read remarks dt00050 sampling cycle 0 ~ +3 ok ok dt00051 shutter time 0 ~ +31 ok ok data processing settings address item data range write read remarks dt00056 average times 0 ~ +5 ok ok dt00053 analysis mode 0 ~ +3 ok ok dt00061 zero set 0 ~ +1 ok ok d...

Page 126

Output settings address item data range write read remarks dt00054 judgment output selection 0 ~ +3 ok ok dt00064 displacement judgment threshold a ( lo ) -9500000 ~ +9500000 ok ok data type: 2 word dt00065 ( hi ) dt00066 displacement judgment threshold b ( lo ) -9500000 ~ +9500000 ok ok data type: ...

Page 127

Alarm settings address item data range write read remarks dt00083 analog output at alarm 0 ~ +1 ok ok dt00084 digital output at alarm 0 ~ +1 ok ok dt00085 alarm delay times 0 ~ +65535 ok ok system settings address item data range write read remarks dt00104 memory change 0 ~ +3 ok ok dt00105 timing m...

Page 128

Buffering settings address item data range write read remarks dt01950 buffering mode 0 ~ +1 ok ok dt01951 buffering rate +1 ~ +65535 ok ok dt01952 accumulated amount +1 ~ +3000 ok ok dt01953 trigger point +1 ~ +3000 ok ok settings within sepecified no. Of the accumulated amount dt01954 trigger delay...

Page 129

Setting for programmable display (gt series) for more details about these settings, refer to the user's manual (dedicated console version). Address item data range write read remarks dt00113 display hold 0 off ok ok hold dt00400/00401 measurements +1 on dt00089 display console measurement value 0 fu...

Page 132: 5-1

5-1 corrective actions if an error or trouble occurs during use of the system or a system failure is suspected, read this chapter carefully first and carry out the corresponding corrective actions. Set trouble in sensor head settings. Com trouble in communication control. Meas trouble in the measure...

Page 133

Type problem cause corrective action ref. Page meas there is a difference between the actual distance to the measurement object and measurement value. The measurement object is fluctuating or vibrating. Stop the fluctuation or vibration of the measurement object. 1-8 the measurement object is tilted...

Page 134

Type problem cause corrective action ref. Page com rs-485 communication control cannot be done. Normal communication over rs-422/485 is impossible. The wiring is incorrect. Rs-422 and rs-485 are different in wiring. Connect the wires correctly. Use a twisted-pair cable to ensure stable communication...

Page 135

Type problem cause corrective action ref. Page meas led the alarm indicator lights up and measurement cannot be done. ↓ if an alarm occurs, check the error code of alarm output read by rs-422/485 communication. The reflected beam from the beam emitting spot is blocked. Move the position of the beam ...

Page 136: 5-2

5-2 initialization • initialization deletes all settings and returns them to the factory default settings. • for more information, refer to "3-3-10 other system settings - initialization". • after initialization, the default settings will not be saved if serial (rs-422/485) communication is used. To...

Page 137

6 specifications this chapter provides the specifications of the sensor head. 6-1 sensor head specifications ······················ 6-2 6-2 dimensions ······················································· 6-8 sensor head ································································ 6-8 6-3 char...

Page 138: 6-1

6-1 sensor head specifications ● diffuse reflection type model no. Standard type hl-g103-a- c5 hl-g105-a- c5 hl-g108-a- c5 hl-g112-a- c5 hl-g125-a- c5 high-func tion type hl-g103-s-j hl-g105-s-j hl-g108-s-j hl-g112-s-j hl-g125-s-j supply voltage 24 vdc ±10% including ripple 0.5 v (p-p) current consu...

Page 139

Timing input npn operation: on when connecting or connected to 0 v (depending on settings) pnp operation: on when connecting or connected to positive terminal of external power supply (depending on settings) multiple input zero set, zero set off, reset, memory change, teaching, save, or laser contro...

Page 140

The following measurement conditions are applied unless otherwise specified; power voltage: 24 vdc, ambient temperature: 20°c, sampling cycle: 5 00 μs, average number of sampling times: 1024 times, measurement center distance, and measurement object: white ceramic. * 1 the diameter is the size of th...

Page 141

● specular reflection type model no. Standard type hl-g103a-ra-c5 hl-g105a-ra-c5 hl-g108a-ra-c5 high-func tion type hl-g103a-rs-j hl-g105a-rs-j hl-g108a-rs-j supply voltage 24 vdc ±10% including ripple 0.5 v (p-p) current consumption 100 ma max. Measurement method specular reflection measurement cen...

Page 142

Multiple input zero set, zero set off, reset, memory change, teaching, save, or laser control depending on input time. Npn operation: depending on time to connect 0 v pnp operation: depending on time to connect positive terminal of external power supply communications interface (only high-function t...

Page 143

The following measurement conditions are applied unless otherwise specified; power voltage: 24 vdc, ambient temperature: 20°c, sampling cycle: 5 00 μs, average number of sampling times: 1024 times, measurement center distance, and measurement object: aluminum vapor deposition surface reflection mirr...

Page 144: 6-2

6-2 dimensions sensor head ● diffuse reflection standard type (hl- g1□□ -a-c5) unit: mm model no. Measurement center distance θ hl-g103-a-c5 30mm 30° hl-g105-a-c5 50mm 21° hl-g108-a-c5 85mm 15° hl-g112-a-c5 120mm 11° hl-g125-a-c5 250mm 6.2° Ø6.85 cable standard: 5m 6 0 3.8 49.4 5 1. 4 4 7. 5 4 .3 me...

Page 145

● diffuse reflection high-function type (hl- g1□□ -s-j) unit: mm model no. Measurement center distance θ hl-g103-s-j 30mm 30° hl-g105-s-j 50mm 21° hl-g108-s-j 85mm 15° hl-g112-s-j 120mm 11° hl-g125-s-j 250mm 6.2° 6 0 3.8 49.4 5 1. 4 4 7. 5 4 .3 measurement center distance 20.4 Ø6 .8 5 (4 3) (Ø 12. 5...

Page 146

● specular reflection standard type (hl-g103a-ra-c5) unit: mm ● specular reflection high-function type (hl-g103a-rs-j) alarm indicator(orange) laser indicator(green) 20.4 ( 72. 3 ) 66.6 17.5 26.3 34.41 72. 3 33 47. 5 62. 4 2 -φ 4.5 φ 6.85 30° 15° digital display(red) out1 indicator(yellow) measureme...

Page 147

● specular reflection standard type (hl-g105a-ra-c5) unit: mm ● specular reflection high-function type (hl-g105a-rs-j) unit: mm 20.4 ( 69 ) 64.2 13.4 47.3 39.32 69 32. 8 47. 5 59. 5 2 -φ 4.5 φ 6.85 20.77° 10.39° alarm indicator(orange) laser indicator(green) digital display(red) out1 indicator(yello...

Page 148

● specular reflection standard type (hl-g108a-ra-c5) unit: mm ● diffuse reflection high-function type (hl-g108a-rs-j) unit: mm 20.4 ( 66. 8 ) 62.3 82.9 42.24 66. 8 31. 2 47. 5 57. 4 2 -φ 4.5 φ 6.85 15.05° 7.53° alarm indicator(orange) laser indicator(green) digital display(red) out1 indicator(yellow...

Page 149: 6-3

6-3 characteristics beam diameter ●diffuse reflection type a b c d e f model no. Beam diameter a b c d e f hl-g103-s-j hl-g103-a-c5 0.15mm 0.15mm 0.1mm 0.1mm 0.15mm 0.15mm hl-g105-s-j hl-g105-a-c5 1.2mm 0.6mm 1.0mm 0.5mm 0.9mm 0.4mm hl-g108-s-j hl-g108-a-c5 1.5mm 0.9mm 1.25mm 0.75mm 1.0mm 0.6mm hl-g...

Page 150

● specular reflection type a b c d e f model no. Beam diameter a b c d e f hl-g103a-rs-j hl-g103a-ra-c5 0.15mm 0.15mm 0.1mm 0.1mm 0.15mm 0.15mm hl-g105a-rs-j hl-g105a-ra-c5 0.15mm 0.15mm 0.1mm 0.1mm 0.15mm 0.15mm hl-g108a-rs-j hl-g108a-ra-c5 0.2mm 0.2mm 0.2mm 0.2mm 0.2mm 0.2mm ramco national 800-280...

Page 151

Mutual interference area in the case of installing two or more diffuse reflective sensor heads side by side, mutual interference will occur if the laser spots of the other sensor heads fall within the shaded area ( ) shown below. Install the sensor heads so that the laser spots of the other sensor h...

Page 154

Output characteristics ● diffuse reflection type *1 in the figure above, analog output setting is used as the initial setting. Standard type high-function type measurement center distance (d) measurement method (r) 30-mm type hl-g103-a-c5 hl-g103-s-j 30 mm ±4 mm 50-mm type hl-g105-a-c5 hl-g105-s-j 5...

Page 155

● specular reflection type *1 in the figure above, analog output setting is used as the initial setting. Standard type high-function type measurement center distance (d) measurement method (r) 30-mm type hl-g103a-ra-c5 hl-g103a-rs-j 26.3 mm ±2 mm 50-mm type hl-g105a-ra-c5 hl-g105a-rs-j 47.3 mm ±5 mm...

Page 156

Revision history released date revision no. October 2010 a first release january 2011 the 1st edition march 2011 the 2nd edition january 2012 the 3rd edition march 2013 the 4th edition september 2013 the 5th edition december 2013 the 6th edition october 2014 the 7th edition january 2015 the 8th edit...

Page 158

Please contact .......... ■ overseas sales division (head office): 2431-1 ushiyama-cho, kasugai-shi, aichi, 486-0901, japan ■ telephone: +81-568-33-7861 ■ facsimile: +81-568-33-8591 panasonic.Net/id/pidsx/global about our sale network, please visit our website. © panasonic industrial devices sunx co...