- DL manuals

- Panasonic

- Accessories

- MCO-170AICL

- Operating Instructions Manual

Panasonic MCO-170AICL Operating Instructions Manual - Electric Lock (Option)

68

ELECTRIC LOCK (OPTION)

Auto lock function is that the outer door is locked automatically when the setting time passed after the door

closed. Auto lock function is workable under any of the following conditions.

・

MCO-230AICUVH

・

When an optional electric lock MCO-170EL is installed in the MCO-230AICUV/230AIC.

The modes of unlocking the outer door are as follows.

・

Quick mode: Press the Unlock key.

・

User-ID mode: Input the User-ID and release password of Auto-Lock, after pressing the Unlock key.

Setting User-ID

Before turning the User-ID mode to ON, use the following procedure to register a User-ID and a release

password of Auto-Lock.

1. Press Menu key to lead the Menu screen.

2. Press Lock key to lead the Lock screen.

3. Press Auto-Lock User key to lead the

Auto-Lock User screen.

Summary of MCO-170AICL

Page 1

Please read the operating instructions carefully before using this product, and save the operating instructions for future use. See page 96 for all model numbers. Mco-230aic mco-230aicuv mco-230aicuvh series co 2 incubator operating instructions mco-230aic mco-230aicuv mco-230aicuvh.

Page 3

1 contents introduction p. 3 intended use and precautions p. 3 precautions for safe operation p. 4 labels on incubator p. 8 symbols on incubator p. 9 environmental conditions p. 9 incubator components unit p. 10 lcd touch panel p. 12 remote alarm terminal p. 14 installation installation site p. 15 i...

Page 4

2 contents uv lamp parameters p. 57 using uv lamp p. 57 setting uv lamp on period p. 58 lighting uv lamp for 24 hours p. 60 h 2 o 2 decontamination p. 62 h 2 o 2 decontamination p. 63 precautions when handling h 2 o 2 reagent p. 67 using unlock key p. 67 electric lock (option) p. 68 setting user-id ...

Page 5: Introduction

3 introduction ■ read the operating instructions carefully before using the product and follow the instructions for safety operation. ■ our company disavows any responsibility for safety if the product is used for other than the intended use or used with any procedures other than those given in the ...

Page 6: Warning

4 precautions for safe operation it is imperative that the user complies with the operating instructions as it contains important safety advice. Items and procedures are described so that you can use this unit correctly and safely. If the precautions advised are followed, this will prevent possible ...

Page 7: Warning

5 do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to rain water. Only qualified engineers or service personnel should install the unit. The installation by unqualified personnel may cause electric shock or fire. Install the unit on a sturdy floor and...

Page 8: Warning

6 precautions for safe operation ensure you do not inhale or consume medication or aerosols from around the unit at the time of maintenance. These may be harmful to your health. Never splash water directly onto the unit as this may cause electric shock or short circuit. Never put containers with liq...

Page 9: Caution

7 do not position this unit and the other unit so that it is difficult to operate the disconnection of the power supply plug. Failure to disconnect the power supply plug may cause fire if there is something wrong with the unit. This unit must be plugged into a dedicated circuit protected by branch c...

Page 10: Labels On Incubator

8 labels on incubator warning safety labels applied to the incubator users are advised to avoid accidents by carefully reading the warnings and cautions contained on warning stickers at key locations on the interior and exterior of the incubator. Possible danger warning/caution type location of dang...

Page 11: Symbols On Incubator

9 symbols on incubator the symbols are attached to the incubator. The following table describes the symbols. This symbol is attached to covers that access high-voltage electrical components to prevent electric shock. Only a qualified engineer or service personnel should be allowed to open these cove...

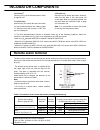

Page 12: Incubator Components

10 incubator components unit 1 2 3 tray 4 5 6 7* 1 8 13 12* 2 electric key* 2 11 10 9 *1: mco-230aicuvh/230aicuv or when an optional uv system set mco-170uvs is installed. *2: mco-230aicuvh or when an optional electric lock mco-170el is installed. (when some inner attachments are removed) 19 levelin...

Page 13

11 1. Outer door: the outer door is held to the frame with the magnetic seal. The door heater is installed in the door panel. The door opening is reversible. Contact our sales representative or agent to change the door hinge from left to right or vice versa. 2. Inner door: the inner door is made of ...

Page 14: Incubator Components

12 incubator components lcd touch panel the following display (called the top screen) will appear when the power switch is turned on. Note: it takes approximately 20 seconds until top screen is displayed. During warming-up, “status: gas sensor initializing” is displayed in the message display field ...

Page 15

13 10 11 9 12 13 18 17 16 15 9. Present date/time display field normally, this indicator shows date and time. The date and time is simply set when the incubator is shipped from the factory. Refer to page 53 for details. 10. Over heat display high limit temperature alarm is activated: “over heat” is ...

Page 16: Incubator Components

14 incubator components 16. H 2 o 2 key* 3 this key is to run h 2 o 2 decontamination. Refer to page 62 to 67. 17. Unlock key* 2 press this key is to unlock the outer door when it is auto-locked by electric lock. Refer to page 72. When the auto lock function is off, this key is not displayed. 18. Bu...

Page 17: Installation

15 installation installation site for correct operation of the incubator, install it in a location with the following conditions. Warning when using co 2 gas for control, make sure that there is an adequate ventilation. Using co 2 gas in a small room without adequate ventilation may cause gas poison...

Page 18: Installation

16 installation low humidity select a site with a relative humidity of 80 %r.H. Or lower. Using the incubator in high humidity may result in current leakage or electric shock. Warning do not use the incubator outdoors. If the incubator is exposed to rain water, it may result in current leakage or ...

Page 19: Installation

17 installation 1. Remove the packing tape and clean up. Remove all the tapes that are securing the doors and the inner attachments. Open the doors for ventilation. If the outer panels are dirty, wet a cloth with a diluted neutral detergent and wipe them. (undiluted detergent can damage the plastic ...

Page 20: Installation

18 installation 4. Adjust the leveling feet. Adjust the leveling feet by turning them counterclockwise to level the incubator (fig. 3). Note: incubating on a leaning tray may have a bad influence on the cultivation. 5. Ground the incubator. Ground the incubator during installation to prevent electri...

Page 21

19 in case of double stack for stacking the incubators surely, refer to the procedure included with the optional double stacking bracket mco-170ps or the stacking plate mco-230sb. Note: two hooks are attached to the rear of the upper incubator. When stacking incubators, fix the upper incubator to th...

Page 22: Installation

20 installation connecting co 2 gas cylinder warning when connecting a gas cylinder to the incubator, confirm the gas type. Confirm that the connections are secure and that no gas will leak. Be sure to use the specified pressure. Using an incorrect gas or pressure may result in explosion or fire, or...

Page 23: Before Commencing Operation

21 before commencing operation initial cleaning method before using the incubator for the first time, clean dirt (tape residue, smear, etc.) from the chamber and the inner attachments thoroughly. To keep the chamber clean is essential to get the proper performance out of the incubator. Use the follo...

Page 24: Before Commencing Operation

22 before commencing operation removing inner attachments caution wear rubber gloves when performing maintenance on the chamber. Failure to wear gloves may result in cuts or abrasions from sharp edges or corners. Always replace the inner attachments removed for the cleaning to keep the intended perf...

Page 25

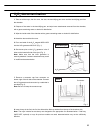

23 6. Lift the duct and remove it from the pins on the rear side (fig. 5). 7. Pull out the fan (fig. 6). 8. Remove the silicon caps of each access port from interior (fig. 7) and exterior (fig. 8). Duct silicon cap fig. 5 fig. 6 fig. 7 fig. 8 silicon cap.

Page 26: Before Commencing Operation

24 before commencing operation installing inner attachments to re-install all the attachments, perform the procedure in reverse order from step 8 on page 23. Note: when installing the fan, insert it to the motor shaft securely. Lightly turn and pull the fan manually to make sure that it does not tou...

Page 27: Filling Humidifying Pan

25 filling humidifying pan use the following procedure to fill the humidifying pan with water or to replace water in the humidifying pan. 1. Pull out the humidifying pan toward you. (fig. 1) 2. Dispose of the remaining water in the humidifying pan and clean the humidifying pan with a diluted deterge...

Page 28: For Better Cultivation

26 for better cultivation precautions for cultures leave space between culture containers. Always leave space for ventilation between culture containers (petri dishes, flasks, etc.). Inadequate spacing may result in uneven temperature distribution and co 2 gas density. do not place harmful mater...

Page 29: Preventing Contamination

27 preventing contamination to prevent contamination of the chamber, select a suitable installation site. avoid locations with high temperatures or humidity. Avoid locations with high temperatures or humidity, because of a greater presence of microorganisms in the air. avoid locations with passe...

Page 30: Correct Operation

28 correct operation use the following procedure to start trial operation or actual operation of the incubator. 1. Install the incubator correctly, referring to “installation” on page 16 to 20. 2. Remove the packing materials from the chamber and inner attachments. Clean and disinfect the chamber an...

Page 31

29 basic operation on lcd touch panel ● operation from menu key ■ menu screen page ◆set → ■stand-by setting screen (setting) temp., co 2 density, high limit temp. Alarm 32~33 ◆log → ■log screen ◆ chart → ■chart screen ◆ actual temp. (display) chamber temp. Log graph (can be exported) 42~44 ◆ actual ...

Page 32

30 basic operation on lcd touch panel *1: mco-230aicuvh or when an optional electric lock mco-170el is installed. *2: mco-230aicuvh/230aicuv or when an optional uv system set mco-170uvs is installed. *3: when an optional std gas autocalibration kit mco-sg is installed. *4: only when using an optiona...

Page 33: Basic Parameters

31 basic parameters numerical input to input window on each screen in the lcd touch panel, it may be necessary to input numerical values on the numerical input box. 1. By pressing numerical input box, input window is displayed. 2. Press numerical key or up/down key to input numerical value, and pres...

Page 34: Basic Parameters

32 basic parameters setting temperature, co 2 density and high limit temperature alarm set the chamber temperature, the co 2 density and the temperature of the high limit temperature alarm for normal operation according to the following procedure. The incubator automatically starts operation using t...

Page 35

33 3. Input each parameter. Press apply key to save the input value. The display returns to the menu screen. ● each parameter setting ・ temperature: set value of chamber temperature. Settable range: 0.0 o c~50.0 o c, factory setting: 37.0 o c. ・ co 2 density: set value of chamber co 2 density. Setta...

Page 36: Basic Parameters

34 basic parameters setting key lock 1. Press menu key to lead the menu screen. 2. Press lock key to lead the lock screen. 3. Press keylock key to lead the key lock screen..

Page 37

35 4. On the key lock screen, it is possible to set each setting of key lock. Press apply key to change key lock on and to save the password. The display returns to the lock screen. ● each setting of key lock ・ key lock: by holding key lock slide key and sliding it to the right, key lock turns to on...

Page 38: Basic Parameters

36 basic parameters ● operation for keylock-on ・ when pressing any key except the co 2 gas supply line select key, buzzer key and unlock key, password input box is displayed, and input of the release password of key lock is required. ・ when the inputted password is incorrect, notice dialog box is di...

Page 39

37 3. Press lock key to lead the lock screen. 4. Press keylock key to lead the key lock screen. 5. On the key lock screen, by holding key lock slide key and sliding to the left, change to off. Press apply key to turn the key lock off. The display returns to the lock screen. Note: the release passwor...

Page 40: Alarm Parameters

38 alarm parameters 1. Press menu key to lead the menu screen. 2. Press tools #1 key to lead the tools #1 screen. 3. On the tools #1 screen, ・ press alarm setting #1 key to lead the alarm setting #1 screen, it is possible to set automatic set temperature alarm and automatic set co 2 density alarm (g...

Page 41

39 5. On the alarm setting #2 screen, it is possible to set each alarm. Press apply key to save the input value and setup. The display returns to the tools #1 screen. ● each setting ・ alarm delay: the function is that when the incubator is in the alarm state of automatic set temperature or of automa...

Page 42: Alarm Parameters

40 alarm parameters ● at the alarm state ・ while the incubator’s alarm is being activated and the buzzer is being sounding, the buzzer is silenced by pressing buzzer key. For the behavior at the time of pressing buzzer key and the re-activation of alarm, under each setting condition, refer to table ...

Page 43: Operation/alarm Log

41 operation/alarm log setting log interval the incubator is equipped with a function of saving operation log data (chamber temperature, co 2 density and open/close state of outer door). Use the following procedure to set the log interval (interval of acquiring the operation log). 1. Press menu key ...

Page 44: Operation/alarm Log

42 operation/alarm log 4. On the setting screen, input log interval. Press apply key to save the input value. The display returns to the log screen. Settable range: 2 minutes~30 minutes. Factory setting: 6 minutes. Note: it is possible to register 8-digit alphanumeric characters as the unique id. Re...

Page 45

43 3. Press chart key to lead the chart screen. 4. On the chart screen, input the date (year / month / day) of the operation log you want to display graphically. 5. On the chart screen, by pressing show key after pressing the item you want to display graphically, the graph of each operation log is d...

Page 46: Operation/alarm Log

44 operation/alarm log 6. Actual temp. Log graph is displayed. ・ press back key to return to the chart screen. ・ press top key to return to the top screen. 7. Actual co 2 level log graph is displayed. ・ press back key to return to the chart screen. ・ press top key to return to the top screen. 8. Doo...

Page 47: Exporting Operation Log

45 exporting operation log operation log data saved in the incubator can be exported in csv format to the usb memory inserted into the usb port. 1. Insert the usb memory into the usb port. Note: it is not possible to use a usb memory with security functions that requires entering password. 2. Press ...

Page 48: Operation/alarm Log

46 operation/alarm log 5. On the export screen, select the time period you want to export. ・ to export the saved operation log data over the entire period, press all radio button. ・ to export the operation log data of a specified date, press 1 day radio button and input the date (year / month / day)...

Page 49

47 note: when the specified operation log data doesn't exist, notice dialog box is displayed. Press ok key, and then re-specified according to procedure 4 and 5. 7. When the export is complete, information dialog box is displayed. Press ok key. Note: even after the export of operation log data is co...

Page 50: Operation/alarm Log

48 operation/alarm log displaying alarm log the incubator is equipped with a function of saving alarm log data (max. 256 logs). Alarm log saved in the incubator can be displayed graphically on the lcd touch panel. Note: when saving alarm logs more than 257, the oldest alarm log is deleted, and then ...

Page 51

49 4. On the alarm screen, the newest 7 days’ alarm logs (containing that day) are displayed. Note: when the number of applicable alarm log is 6 or more, by pressing the top (▲) or the bottom (▼) log, the log table currently displayed scrolls and hidden alarm logs can be seen. ・ press back key to re...

Page 52: Operation/alarm Log

50 operation/alarm log exporting alarm log it is possible to export saved alarm log data to a usb memory inserted in the usb port by csv format. 1. Insert a usb memory in the usb port. Note: it is not possible to use a usb memory with security functions that requires entering password. 2. Press menu...

Page 53

51 5. On the alarm export screen, select the period to export. ・ to export the saved alarm log data over the entire period, press all radio button. ・ to export the alarm log data for the specified days (the newest period containing that day), press last xx days radio button and input days. Settable ...

Page 54: Operation/alarm Log

52 operation/alarm log 7. Even after completion the export of alarm log data, information dialog box is displayed. Press ok key. Note: after completing the export of alarm log data, alarm log data saved at co 2 incubator is not deleted. 8. Remove a usb memory from the usb port. Note: a log folder is...

Page 55: Other Parameters

53 other parameters setting date and time 1. Press menu key to lead the menu screen. 2. Press tools #2 key to lead the tools #2 screen. 3. Press date & time key to lead the date & time screen. 4. On the date & time screen, input the present date and time. Press apply key to save the input value. The...

Page 56: Other Parameters

54 other parameters setting brightness and sleep 1. Press menu key to lead the menu screen. 2. Press tools #2 key to lead the tools #2 screen. 3. Press brightness/sleep key to lead the brightness/sleep screen. 4. On the brightness/sleep screen, each setting of brightness and sleep is available. Pres...

Page 57

55 ● each setting ・ brightness(active): brightness of lcd touch panel of the usual state. Adjust brightness(active) slide bar or input set value into the brightness(active) input box. Settable range: 50~100, factory setting: 80. ・ sleep: the function is that the rightness of lcd touch panel is lower...

Page 58: Other Parameters

56 other parameters setting daq it is necessary to set several parameters when using our optional software product data acquisition system (daq) mtr-5000. 1. Press menu key to lead the menu screen. 2. Press tools #2 key to lead the tools #2 screen. 3. Press daq setting key to lead the daq setting sc...

Page 59: Uv Lamp Parameters

57 uv lamp parameters mco-230aicuvh/230aicuv or when an optional uv system set mco-170uvs is installed to the mco-230aic, uv lamp is workable. After closing the outer door, uv lamp lights for the preset period*, to disinfect the water in the humidifying pan, and the air circulating in the chamber. U...

Page 60: Uv Lamp Parameters

58 uv lamp parameters if the uv lamp burns out, “err18: uv lamp abnormal” is displayed in the message display field. If this occurs, replace the uv lamp. When replacing the uv lamp, replace the glow starter at the same time. Contact our sales representative or agent for information on replacing th...

Page 61

59 4. On the uv setting screen, each setting of uv is available. Press apply key to save the input value and setup. The display returns to the tools #1 screen. ● each setting ・ uv timer: set value of period to light uv lamp after closing the outer door. Settable range: 0 minute~30 minutes, factory s...

Page 62: Uv Lamp Parameters

60 uv lamp parameters lighting uv lamp for 24 hours if the chamber has been contaminated by dirt or by spilling the medium, use the following procedure to decontaminate the chamber by lighting the uv lamp for 24 hours. 1. Remove all attachments from the chamber, including the trays, the fan cover, t...

Page 63

61 7. On the uv setting screen, by holding the uv 24h mode slide key and sliding it right, the uv 24h mode is turned to on. Press apply key to start the uv 24-hour mode. The display returns to the tools #1 screen. 8. The uv lamp lights continuously for 24 hours. “uv : on” is displayed on the uv lamp...

Page 64: Decontamination

62 h 2 o 2 decontamination when the chamber is contaminated or when cleaning the chamber prior to starting a culture, it is possible to perform h 2 o 2 decontamination. H 2 o 2 decontamination function is workable under any of the following conditions. When the condition is not fulfilled, h 2 o 2 de...

Page 65: Decontamination

63 h 2 o 2 decontamination 1. Take out all the trays, the fan cover, the duct, the humidifying pan cover and the humidifying pan from the chamber. 2. Dispose of the water in the humidifying pan, and wipe inner attachments removed from the chamber, with a gauze containing water or alcohol for disinfe...

Page 66: Decontamination

64 h 2 o 2 decontamination 9. Set the humidifying pan cover, the humidifying pan removed in the procedure 1 (fig. 3). Note: h 2 o 2 decontamination can be performed only for the chamber and inner attachments with standard specifications, not for any other objects. 10. Make sure that the duct, the fa...

Page 67

65 13. On the h 2 o 2 decontamination step1 screen, the system check starts automatically. If the system is normal, the display leads the h 2 o 2 decontamination step2 screen. When the system is abnormal, refer to table 8 on page 85. 14. On the h 2 o 2 decontamination step2 screen, press ok key to l...

Page 68: Decontamination

66 h 2 o 2 decontamination ● step4 is the process to decontaminate in the chamber by generating h 2 o 2 vapor from h 2 o 2 generator. Note: by pressing abort key, h 2 o 2 decontamination is stopped in the middle of decontamination and go to step7 (the process to resolve h 2 o 2 vapor by uv lamp). It...

Page 69: Precautions When Handling H

67 18. After h 2 o 2 decontamination, surplus h 2 o 2 liquid will remain at the bottom of the chamber and in the bottom part of the h 2 o 2 generator duct. This solution contains h 2 o 2 at a low density, so put on protective glasses and rubber gloves and wipe it up with a non-woven cloth. 19. Venti...

Page 70: Electric Lock (Option)

68 electric lock (option) auto lock function is that the outer door is locked automatically when the setting time passed after the door closed. Auto lock function is workable under any of the following conditions. ・ mco-230aicuvh ・ when an optional electric lock mco-170el is installed in the mco-230...

Page 71

69 4. On the auto-lock user screen, it is possible to register a user-id and its password. Press apply key to save the user-id and its password. ● each setting of auto-lock ・ user-id: the alphanumeric characters (max. 8-digit) inputted here are registered as a new user-id. ・ password: the number (ma...

Page 72: Electric Lock (Option)

70 electric lock (option) ● changing a registered user-id’s password input the registered user-id into user-id input box, and input its new password into password input box and confirm password box. Press add key to re-write the new password. ● deleting a registered user-id input the registered user...

Page 73

71 4. On the auto-lock screen, each setting of auto lock is available. Press apply key to turn the auto lock on and save the set value. The display returns to the lock screen. ● each setting of auto lock ・ auto-lock: auto lock function is that the outer door is locked automatically when the setting ...

Page 74: Electric Lock (Option)

72 electric lock (option) ● unlocking the outer door ・ in the quick mode, press the unlock key on the top screen to unlock the outer door. ・ in the user-id mode, when pressing unlock key on the top screen, user-id input box is displayed. Input the user-id and its release password of auto-lock. Note:...

Page 75: Using Unlock Key

73 using unlock key unlocking when power is interrupted mco-230aicuvh or when an optional electric lock mco-170el is installed to the mco-230aicuv/ 230aic, outer door is locked with electric lock under a power outage. To unlock the outer door while the power is interrupted, use the unlock key that...

Page 76: Electric Lock (Option)

74 electric lock (option) removing auto lock 1. Press menu key to lead the menu screen. 2. Press lock key to lead the lock screen. 3. Press auto-lock key to lead the auto-lock screen. 4. On the auto-lock screen, by holding the auto-lock slide key and sliding it left, the auto-lock is turned to off. ...

Page 77: Gas Auto Changer (Option)

75 gas auto changer (option) when an optional gas auto changer mco-21gc is installed, there are two connecting ports for co 2 gas pipe, a and b. By connecting two co 2 gas cylinders, this kit switches the co 2 gas supply line when one of the co 2 gas cylinders becomes empty. Connecting co 2 gas cyli...

Page 78: Gas Auto Changer (Option)

76 gas auto changer (option) automatic co 2 gas supply line changeover when an optional gas auto changer mco-21gc is installed, co 2 gas supply line indicator a・b and co 2 gas supply line select key are displayed in the top screen. Co 2 gas supply line indicator a or b being used is lighted. Co 2 ga...

Page 79

77 when the co 2 density level remains unchanged, even though the co 2 gas valve in the unit is opened, the unit regards the present connecting co 2 gas cylinder as an empty. The co 2 gas supply line is changed over automatically. These movements are displayed (table. 2). 1. When co 2 gas is remaini...

Page 80: Gas Auto Changer (Option)

78 gas auto changer (option) manual co 2 gas supply line changeover it is possible to change co 2 gas supply line manually anytime. Example) change co 2 gas supply line a to b. 1. Press co 2 gas supply line select key for a few seconds. 2. Co 2 gas supply line a is changed to b. Note: the behavoir f...

Page 81

79 std gas auto calibration kit (option) when a std gas auto calibration kit mco-sg is installed, by connecting standard gas cylinder for calibration, it is possible to calibrate co 2 density manually. 1. Connect a standard gas cylinder to connecting port for standard gas cylinder on lower right sid...

Page 82

80 std gas auto calibration kit (option) 5. On the std gas setting screen, input co 2 density of the connected standard co 2 gas cylinder. Press apply key to save the input value. The display returns to the tools #1 screen. Settable range: 4.0 %~21.0 %. Factory setting: 5.0 %. 6. Press std gas calib...

Page 83

81 9. On the std gas calibration step3 screen, co 2 density calibration starts. Calibration go to step5 (procedure 10) automatically. 10. After completion of co 2 density calibration, display leads the std gas calibration step5 screen. Co 2 incubator returns to the normal operation. 11. On the std g...

Page 84: Routine Maintenance

82 routine maintenance to use this unit in a clean condition, clean the chamber and all the inner attachments at least once a month. 1. Remove all the inner attachments by the procedures shown on page 22. 2. Clean the chamber and all the inner attachments by the procedures shown on page 21. 3. Insta...

Page 85

83 alarms, safety, and self-diagnosis the incubator supports the following alarms, safety functions, and self-diagnostic functions. If an error from err05 to err18, or err56 is activated, contact our sales representative or agent. Table 4 alarms, safety, and self-diagnosis for culture operations ala...

Page 86

84 alarms, safety, and self-diagnosis alarm or safety function conditions display buzzer remote alarm safety operation uv lamp failure (mco-230aicuvh/mco-230aicuv, or when an optional mco-170uvs is installed) the uv lamp burns out. “err18: uv lamp abnormal” is displayed in the message display field....

Page 87

85 table 8 alarms and safety functions for h 2 o 2 decontamination alarm or safety function conditions display buzzer remote alarm safety operation system check error at start of h 2 o 2 decontamination the h 2 o 2 generator is not connected. “err31: h2o2 unit not connected” is displayed in the mess...

Page 88: Troubleshooting

86 troubleshooting if the incubator does not seem to be working properly, check the following items before calling for service. Symptom items to check and countermeasures the incubator does not operate at all. is the incubator plugged in? is there a power outage, or has a circuit breaker interru...

Page 89

87 symptom items to check and countermeasures normal cultures are not possible, and the co 2 gas density is suspect. is the ambient air environment around the incubator normal? Is there a source of polluted gas in the vicinity? Co 2 gas is not being injected. the co 2 control method for the incu...

Page 90: Troubleshooting

88 troubleshooting symptom items to check and countermeasures h 2 o 2 decontamination cannot be performed. if the mco-230aicuvh is being used, is the optional mco-hp installed? if the mco-230aicuv is being used, are the optional mco-hp, the optional mco-170hb and the mco-170el installed? if th...

Page 91: Disposal Of Unit

89 disposal of unit when disposing of the co 2 incubator, contact our sales representative or agent. Warning the co 2 incubator must be dismantled and disposed of by qualified personnel only. If the co 2 incubator is left where outsiders enter, it may result unexpected accident (for example, childre...

Page 92: Disposal Of Unit

90 disposal of unit waste electrical and electronic equipment (weee) directive (english) your panasonic product is designed and manufactured with high quality materials and components which can be recycled and reused. This symbol means that electrical and electronic equipment, at their end-of-life, ...

Page 93

91 (french) votre produit panasonic est conçu et fabriqué avec des matèriels et des composants de qualité supérieure qui peuvent être recyclés et réutilisés. Ce symbole signifie que les équipements électriques et électroniques en fin de vie doivent être éliminés séparément des ordures ménagères. Nou...

Page 94: Disposal Of Unit

92 disposal of unit (portuguese) o seu produto panasonic foi concebido e produzido com materiais e componentes de alta qualidade que podem ser reciclados e reutilizados. Este símbolo significa que o equipamento eléctrico e electrónico no final da sua vida útil deverá ser descartado separadamente do ...

Page 95

93 (dutch) panasonic producten zijn ontwikkeld en gefabriceerd uit eerste kwaliteit materialen, de onderdelen kunnen worden gerecycled en weer worden gebruikt. Het symbool betekent dat de elektrische en elektronische onderdelen wanneer deze vernietigd gaan worden , dit separaat gebeurt van het norma...

Page 96: Specifications

94 specifications product name co 2 incubator mco-230aic co 2 incubator mco-230aicuv co 2 incubator mco-230aicuvh medical purpose culture of cell tissues, organs, embryos. External dimensions w770 mm x d730 mm x h905 mm internal dimensions w643 mm x d523 mm x h700 mm interior volume 230 l exterior p...

Page 97

95 product name co 2 incubator mco-230aic co 2 incubator mco-230aicuv co 2 incubator mco-230aicuvh optional accessories (refer to table 10) uv system set (mco-170uvs) standard equipment h2o2 decon board (mco-170hb) electric lock (mco-170el) standard equipment h 2 o 2 generator (mco-hp) optional acce...

Page 98: Specifications

96 specifications table 11 required bracket/plate for each incubator combination of double stacking upper product mco-230aic mco-230aicuv mco-230aicuvh mco-19aic mco-19aicuv mco-19aicuvh mco-19m mco-19muv mco-19muvh km-cc17r2 km-cc17ru2 km-cc17rh2 mco-170aic mco-170aicuv mco-170aicuvh mco-18ac lower...

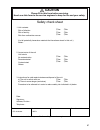

Page 99: Caution

97 caution please fill in this form before servicing. Hand over this form to the service engineer to keep for his and your safety. Safety check sheet 1. Unit contents : risk of infection: risk of toxicity: risk from radioactive sources: (list all potentially hazardous materials that have been stored...

Page 100

Original operating instructions 0123 panasonic marketing europe gmbh panasonic testing centre winsbergring 15, 22525 hamburg, germany © panasonic healthcare co., ltd. 2015 printed in japan ldcl001000-2 s0115-20916 2015.09.06 1-1-1 sakata, oizumi-machi, ora-gun, gunma 370-0596 japan.