Service manual heated incubator mir-h163 panasonic healthcare co., ltd. Biomedical division mir-h263 sm9910316.

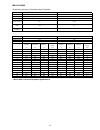

Effective models this service manual is effective for following models. Model name voltage frequency plug type mir-h163-pa 115v 60hz u3 mir-h163-pc 220v 50hz g3l mir-h163-pe 230/240v 50hz k3 mir-h163-pk 220v 50/60hz k3 mir-h163-pt 110v 60hz j3 model name voltage frequency plug type mir-h263-pa 115v ...

C o n t e n t s p a g e f e a t u r e a n d c a u t i o n - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1 s p e c i f i c a t i o n s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2 - s t r u c t u r ...

Features 1. Chamber temperature adjustment it is capable of cultivating the bacteria that prefer from medium temperature to high temperature. - constant temperature environment by microcomputer pid control + air jacket (natural convection) - achieve constant temperature environment with high accurac...

Specifications ■ structural specifications product name heated incubator model mir-h163 mir-h263 external dimensions w580 mm x d595 mm x h820 mm w730 mm x d645 mm x h870 mm internal dimensions w450 mm x d460 mm x h450 mm w600 mm x d510 mm x h500 mm effective capacity 93 l 153 l exterior painted stee...

■ alarm/safety functions types condition display buzzer action taken auto set upper/lower limit alarm temp. Deviated ±2.5℃ from set value alarm lamp lighting temp. Display blinking after 3sec. Intermittently ―― auto return no key operation for about 45 sec. In each setting mode display current value...

Dimensions mir-h163 -4-.

Mir-h263 -5-.

Mir-h163/h263 wiring diagram -6-.

Mir-h163/h263 circuit diagram -7-.

Control specifications 1. Keys on control panel bz (alarm stop key) to stop buzzer during intermittent buzzer is sounding (auto set temperature alarm). If this key is pressed again after buzzer is stopped, intermittent buzzer does not sound again. Even if this key is pressed when displayed numbers a...

Delay (delay timer key) press this key to delay operation start. Press this key at set delay time display, clear set delay time. Press this key again afterwards, store new set value and return to chamber temperature display. Press call key after delay key is pressed 3 times during temperature or ope...

4. Auto set temperature alarm condition of alarming: when chamber temperature (temp.Pv) is deviated more than ±2.5℃ from current set value (temp.Sv). Action: blinking all digits in temperature display area, alarm lamp lighting and intermittent buzzer sounds after 3 seconds. Operation continues. If c...

E05: when power relay on is not detected or temperature around pcb is 65℃ or more by at sensor on pcb, it is judged as abnormal. E05 display blinks, alarm lamp lights, intermittent buzzer sounds, relay and heater are turned off. 7. Function mode function mode> 1. Keep pressing up key for about 5 sec...

Not change. In this case, f07 can be used after inputting service code in f06. Above service code input can be valid unless inputting “000” in f06 again or switch off power supply. F07: display zero adjustment volume (vr1 on main pcb) set value. Input “f07” and press call key to show zero adjustment...

Initial values of non-volatile memory are followings. Set temperature operation time step during operation remained repeat number old set temperature 1 minute timer 0.3 seconds timer step1 temperature setting value step1 time setting value : 0℃ : 0.0 hour : 0 : 0 : 0.0℃ : 200 : 25 : 0.0℃ : continue ...

F21: set serial communication id. Input “f21” and press call key to show “000”. Input the product identified value (serial communication id number) and press call key to set serial communication id. Setting range is “000~255” (“000” is communication off). F22: set serial communication mode. Input “f...

Mir-h163 chamber temperature control specification (15 points measuring) * reference data ambient temperature: 20℃ power source: 1φ100v load: no load for ①②④⑤⑪⑫⑭⑮ w: 80% of internal width (each 10% from left and right) d: 50mm from wall h: 10% of internal height for ⑥⑦⑨⑩ w: 80% of internal width (ea...

Mir-h163/h263 temperature accuracy, fluctuation range, distribution * above data is not assured product performance. ⑭ ⑮ ⑤ ⑥ ⑦ ⑧ ⑨ ⑩ ⑪ ⑫ ⑬ ① ② ③ ④ 37.2 37.3 ±0.1 ±0 ±0.1 ±0.1 37.2 37.2 37.2 37.7 37.3 37.3 37.3 37.7 37.2 37.7 37.2 37.2 37.2 ±0.1 36.6 36.7 36.9 36.9 36.9 37.0 37.1 37.2 37.1 37.1 36.6 ...

Temp. (℃) temp. (℃) time (min.) time (min.) -17-.

Instruction this section is extracted and printed from instruction manual. if you find out "refer to page ● ●" in them, this page means not page in service manual but page in the lower corner of each page in the extract from instruction manual. This page number is not corresponded with serial nu...

Please read the operating instructions carefully before using this product, and save the operating instructions for future use. See page 26 for all model numbers. Mir-h163 mir-h263 series mir-h263 mir-h163 mir-h263 heated incubator operating instructions -19-.

-20-.

1 contents introduction p. 2 precautions for safe operation p. 3 environmental conditions p. 7 incubator components p. 8 control panel and keypad p. 10 installation site p. 12 installation p. 13 preliminary run p. 13 key operation flow p. 14 normal mode and timer mode c p. 15 stable running p. 16 st...

2 introduction ■ read the operating instructions carefully before using the product and follow the instructions for safety operation. ■ our company disavows any responsibility for safety if the product is used for other than the intended use or used with any procedures other than those given in the ...

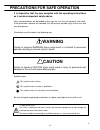

3 precautions for safe operation it is imperative that the user complies with the operating instructions as it contains important safety advice. Items and procedures are described so that you can use this unit correctly and safely. If the precautions advised are followed, this will prevent possible ...

4 precautions for safe operation do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to rain water. Only qualified engineers or service personnel should install the unit. The installation by unqualified personnel may cause electric shock or fire. Install...

5 precautions for safe operation ensure you do not inhale or consume medication or aerosols from around the unit at the time of maintenance. These may be harmful to your health. Never splash water directly onto the unit as this may cause electric shock or short circuit. Never put containers with liq...

6 precautions for safe operation this unit must be plugged into a dedicated circuit protected by branch circuit breaker. Use a dedicated power source as indicated on the rating label attached to the unit. A multiple-tap may cause fire resulting from abnormal heating. Never store corrosive substances...

7 environmental conditions this equipment is designed to be safe at least under the following conditions (based on the iec-61010-1): ■ indoor use; ■ altitude up to 2000 m; ■ temperature 5 o c to 40 o c ■ maximum relative humidity 80% for temperature up to 31 o c decreasing linearly to 50% relative h...

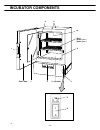

8 incubator components 8 outer door 2 1 5 3, 4 (inside) 6 11 12 7 shelf (h163: 2 pcs.) (h263: 3 pcs.) 9 10 -28-.

9 incubator components 1. Inner door: it is made of tempered glass. However, do not force the door. 2. Control panel: refer to page 10. 3. Separation plate: do not place objects directly on the plate. Culture containers made of resin may deform with heat. 4. Heater box (inside): the heater is attach...

10 incubator components control panel and keypad 1. Power switch (power): power switch of the control panel. 2. Delay timer key (delay): this key is to set a delay timer which controls the time from when the run/stop key (run/stop) is pressed till when the unit starts an operation. Refer to page 14~...

11 incubator components 10. Timer mode select key (timer mode): this key is to switch a normal mode and a timer mode c. Normal mode: the operation is finished when a set time of operation timer is expired. Timer mode c: the operation continues with a set temperature even when a set time of operation...

12 installation site to operate this unit properly and to obtain maximum performance, install the unit in a location with the following conditions: ■ a location not subjected to direct sunlight do not install the unit under direct sunlight. Installation in a place with direct sunlight cannot obtain ...

13 installation 1. Remove the packaging materials and tapes remove all transportation packaging materials and tapes. Open the doors and ventilate the unit. If the outside panels are dirty, clean them with a neutral detergent and wipe it up with a wet cloth. Note: remove the cable tie banding the pow...

14 key operation flow this flow chart shows the key operation from control panel. Press the power switch. Present temperature is displayed. Press the delay timer key. Saved delay time is displayed. Press the delay timer key. Saved delay time is reset. (00:00) input the delay time to set. Inputted de...

15 normal mode and timer mode c the operation flow of this unit in the normal mode and the timer mode c is shown in table 2 and table 3. Table 2 operation flow in normal mode (timer mode c lamp: off) ●: lamp on ○: lamp off table 3 operation flow in timer mode c (timer mode c lamp: on) ●: lamp on ○: ...

16 stable running table 4 shows the basic procedure for setting the chamber temperature. Perform key operations in the sequence indicated in the table. The example in the table is based on the assumption that the desired temperature is 37 o c and the operation status is a continuous running. Note: t...

17 stable running with delay time table 5 shows one of applications. Perform key operations in the sequence indicated in the table. The example in the table is the delay time that is 30 minutes, the chamber temperature is 50 o c, the running time is 1 hour and the timer mode is timer mode c. Table 5...

18 alarms and safety functions the incubator supports the following alarms, safety functions, and self-diagnostic functions. Alarms and safety functions alarm & safety situation indication buzzer safety operation automatic set temperature alarm the internal temperature is over +/-2.5 o c from the se...

19 routine maintenance warning always disconnect the power supply to the unit prior to any repair or maintenance of the unit in order to prevent electric shock or injury. Ensure you do not inhale or consume medication or aerosols from around the unit at the time of maintenance. These may be harmful ...

20 trouble shooting if the unit malfunctions, check out the following before calling for service. Malfunction check/remedy the unit does not operate at all. • the unit is not plugged correctly into a power outlet. • the circuit breaker at the power source is active. • a power failure has occurred. •...

21 disposal of unit waste electrical and electronic equipment (weee) directive (english) your panasonic product is designed and manufactured with high quality materials and components which can be recycled and reused. This symbol means that electrical and electronic equipment, at their end-of-life, ...

22 disposal of unit (french) votre produit panasonic est conçu et fabriqué avec des matèriels et des composants de qualité supérieure qui peuvent être recyclés et réutilisés. Ce symbole signifie que les équipements électriques et électroniques en fin de vie doivent être éliminés séparément des ordur...

23 disposal of unit (portuguese) o seu produto panasonic foi concebido e produzido com materiais e componentes de alta qualidade que podem ser reciclados e reutilizados. Este símbolo significa que o equipamento eléctrico e electrónico no final da sua vida útil deverá ser descartado separadamente do ...

24 disposal of unit (dutch) panasonic producten zijn ontwikkeld en gefabriceerd uit eerste kwaliteit materialen, de onderdelen kunnen worden gerecycled en weer worden gebruikt. Het symbool betekent dat de elektrische en elektronische onderdelen wanneer deze vernietigd gaan worden , dit separaat gebe...

25 specifications product name heated incubator mir-h163 heated incubator mir-h263 external dimensions w580 mm x d595 mm x h820 mm w730 mm x d645 mm x h870 mm internal dimensions w450 mm x d460 mm x h450 mm w600 mm x d510 mm x h500 mm effective capacity 93 l 153 l exterior painted steel interior sta...

26 performance product name heated incubator mir-h163 model number mir-h163-pt mir-h163-pa mir-h163-pk mir-h163-pe temperature control range ambient temp.+5 o c to 60 o c (ambient temp.: 0 o c to less than 20 o c, no load) ambient temp.+5 o c to 80 o c (ambient temp.: 20 o c to 35 o c, no load) temp...

27 2. Contamination of the unit unit interior no contamination decontaminated contaminated others: 3. Instructions for safe repair/maintenance of the unit a) the unit is safe to work on b) there is some danger (see below) procedure to be adhered to in order to reduce safety risk indicated in b) belo...

Printed in indonesia 7fb6p151756001 n0315-10415 1-1-1, sakata oizumi-machi ora-gun, gunma 370-0596, japan © panasonic healthcare co., ltd. 2015.