- DL manuals

- Panasonic

- Air Conditioner

- S-100PF1E5A

- Technical Data & Service Manual

Panasonic S-100PF1E5A Technical Data & Service Manual

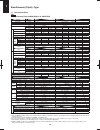

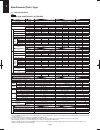

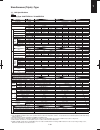

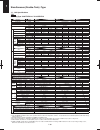

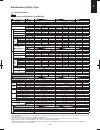

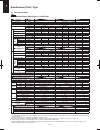

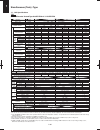

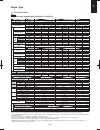

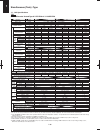

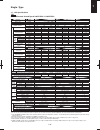

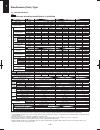

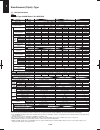

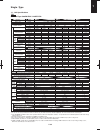

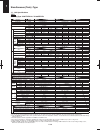

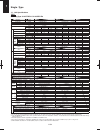

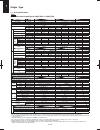

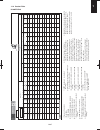

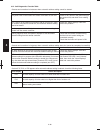

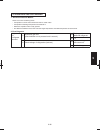

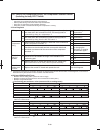

85464849331000

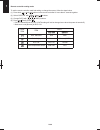

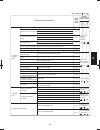

REFERENCE NO.

SM830231-00

Order No. SBPAC1403009CE

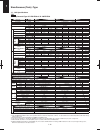

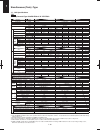

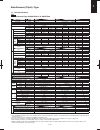

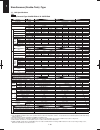

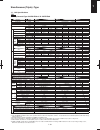

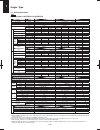

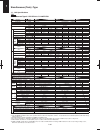

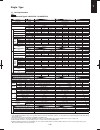

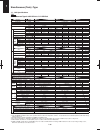

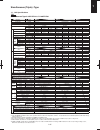

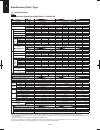

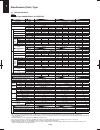

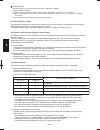

TECHNICAL DATA & SERVICE MANUAL

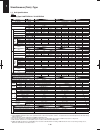

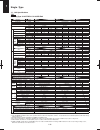

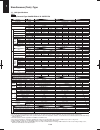

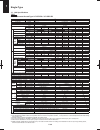

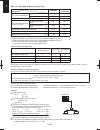

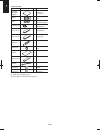

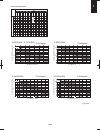

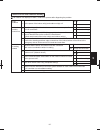

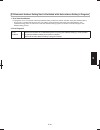

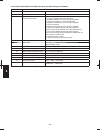

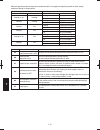

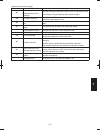

R410A Models

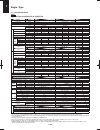

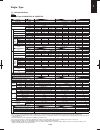

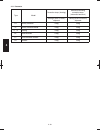

Model No.

Indoor Units

50

60

71

100

125

140

Outdoor Units

–

–

U-60PE1E5A U-71PE1E5A U-100PE1E5A U-125PE1E5A U-140PE1E5A

U-71PE1E8A U-100PE1E8A U-125PE1E8A U-140PE1E8A

U-50PE1E5

Type

PE1

PEY1

–

–

–

Outdoor Units Type

Single Split (1-phase)

Single Split (3-phase)

Single Split (1-phase)

Single Split (3-phase)

U-100PEY1E8 U-125PEY1E8

U-60PEY1E5

–

U-71PEY1E5 U-100PEY1E5 U-125PEY1E5

–

U-140PEY1E8

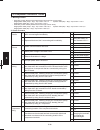

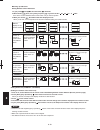

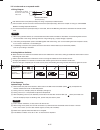

Indoor Unit

Outdoor Unit

Wall Mounted

Ceiling

Low Silhouette Ducted

4-Way Cassette

Ducted

Type

Indoor

Units Type

36

45

50

60

71

100

125

140

4-Way Cassette

S-36PU1E5A S-45PU1E5A S-50PU1E5A S-60PU1E5A S-71PU1E5A S-100PU1E5A S-125PU1E5A S-140PU1E5A

S-36PF1E5A S-45PF1E5A S-50PF1E5A S-60PF1E5A S-71PF1E5A S-100PF1E5A S-125PF1E5A S-140PF1E5A

S-36PN1E5A S-45PN1E5A S-50PN1E5A S-60PN1E5A S-71PN1E5A S-100PN1E5A S-125PN1E5A S-140PN1E5A

S-36PT2E5A S-45PT2E5A S-50PT2E5A S-60PT2E5A S-71PT2E5A S-100PT2E5A

S-100PK1E5A

S-125PT2E5A S-140PT2E5A

–

–

S-36PK1E5A S-45PK1E5A S-50PK1E5A S-60PK1E5A S-71PK1E5A

Wall Mounted

Low Silhouette

Ducted

Ducted

U1

K1

F1

N1

T2

Ceiling

SM830231-00̲Single̲欧州.indb 1

SM830231-00̲Single̲欧州.indb 1

2014/04/04 13:13:49

2014/04/04 13:13:49

Summary of S-100PF1E5A

Page 1

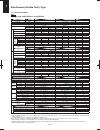

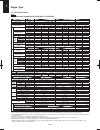

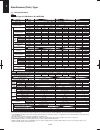

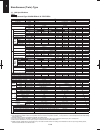

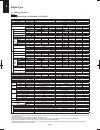

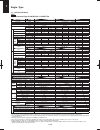

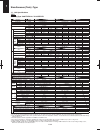

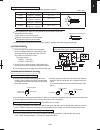

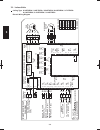

85464849331000 reference no. Sm830231-00 order no. Sbpac1403009ce technical data & service manual r410a models model no. Indoor units 50 60 71 100 125 140 outdoor units – – u-60pe1e5a u-71pe1e5a u-100pe1e5a u-125pe1e5a u-140pe1e5a u-71pe1e8a u-100pe1e8a u-125pe1e8a u-140pe1e8a u-50pe1e5 type pe1 pey...

Page 2

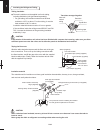

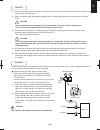

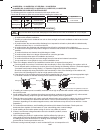

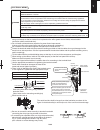

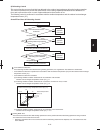

Ii important! Please read before starting this air conditioner must be installed by the sales dealer or installer. This information is provided for use only by authorized persons. For safe installation and trouble-free operation, you must: carefully read this instruction booklet before beginning. Fo...

Page 3

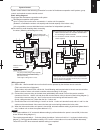

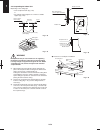

Ii when connecting refrigerant tubing warning • when performing piping work do not mix air except for specified refrigerant (r410a) in refrigeration cycle. It causes capacity down, and risk of explosion and injury due to high tension inside therefrigerant cycle. • refrigerant gas leakage may cause f...

Page 4

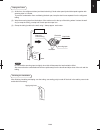

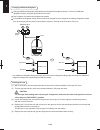

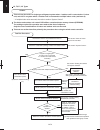

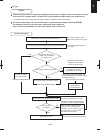

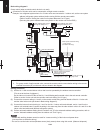

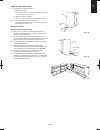

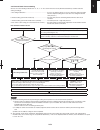

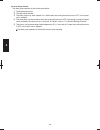

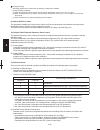

Iii rohs · this product does not contain any hazardous substances prohibited by the rohs directive. Warning · you are requested to use rohs compliant for maintenance or repair. 2. The standards for minimum room volume are as follows. (1) no partition (shaded portion) (2) when there is an effective o...

Page 5

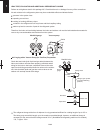

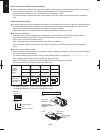

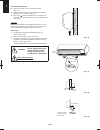

Iv important information regarding the refrigerant used this product contains fluorinated greenhouse gases covered by the kyoto protocol. Do not vent gases into the atmosphere. Refrigerant type: r410a gwp (1) value: 1975 (1) gwp = global warming potential periodical inspections for refrigerant leaks...

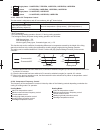

Page 6

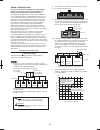

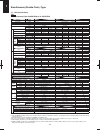

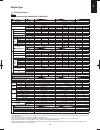

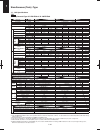

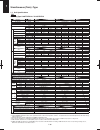

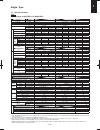

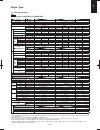

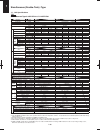

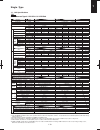

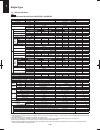

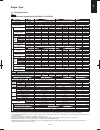

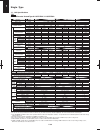

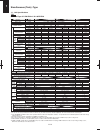

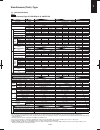

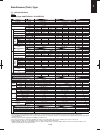

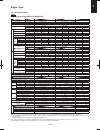

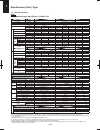

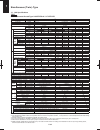

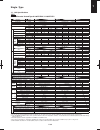

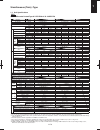

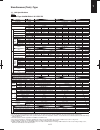

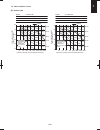

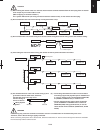

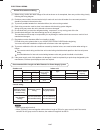

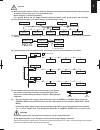

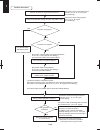

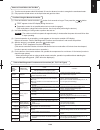

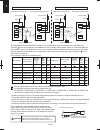

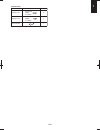

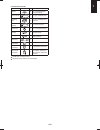

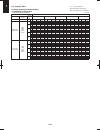

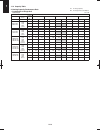

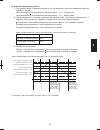

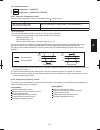

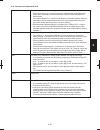

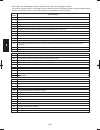

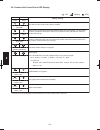

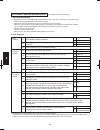

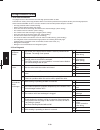

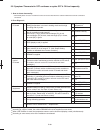

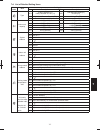

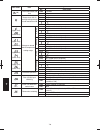

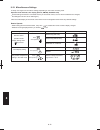

V combination of indoor and outdoor units single-phase pe1 v u1 36 45 50 60 71 100 125 140 s-140pu1e5a u-140pe1e5a s-45pu1e5a x3 u-125pe1e5a s-50pu1e5a x3 u-140pe1e5a s-60pu1e5a u-60pe1e5a s-36pu1e5a x4 u-125pe1e5a s-36pu1e5a x2 u-71pe1e5a s-36pu1e5a x3 u-100pe1e5a s-60pu1e5a x2 u-125pe1e5a s-50pu1e...

Page 7

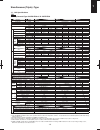

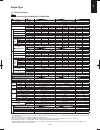

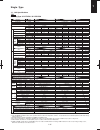

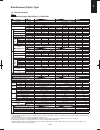

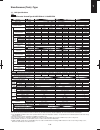

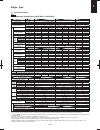

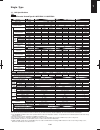

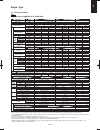

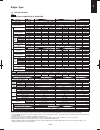

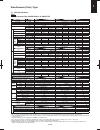

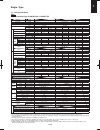

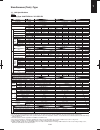

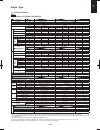

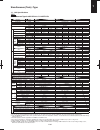

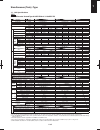

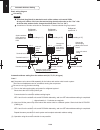

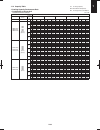

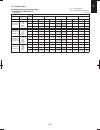

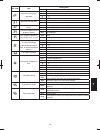

Vi combination of indoor and outdoor units pe1 vi s-140pu1e5a u-140pe1e8a s-45pu1e5a x3 u-125pe1e8a s-60pu1e5a x2 u-125pe1e8a s-36pu1e5a x4 u-125pe1e8a s-36pu1e5a x2 u-71pe1e8a s-36pu1e5a x3 u-100pe1e8a s-50pu1e5a x2 u-100pe1e8a s-50pu1e5a x3 u-140pe1e8a s-71pu1e5a u-71pe1e8a s-71pu1e5a x2 u-140pe1e...

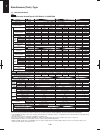

Page 8

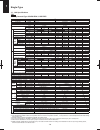

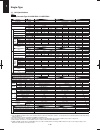

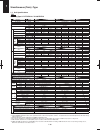

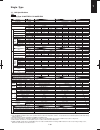

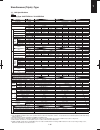

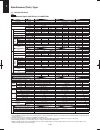

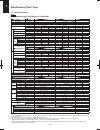

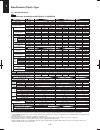

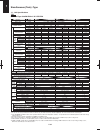

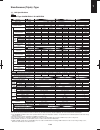

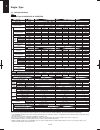

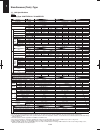

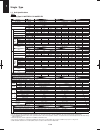

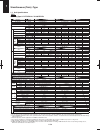

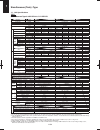

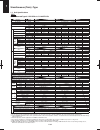

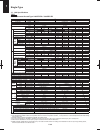

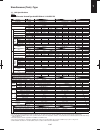

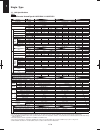

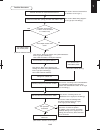

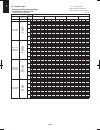

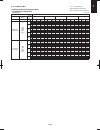

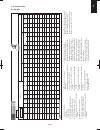

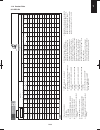

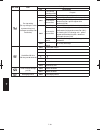

Vii combination of indoor and outdoor units single-phase u1 pey1 36 s-36pu1e5a x2 u-71pey1e5 p128 vii 50 60 71 100 125 140 s-60pu1e5a u-60pey1e5 s-60pu1e5a x2 u-125pey1e5 s-50pu1e5a x2 u-100pey1e5 s-71pu1e5a u-71pey1e5 s-100pu1e5a u-100pey1e5 s-125pu1e5a u-125pey1e5 p129 p130 p134 p132 p133 p131 u1 ...

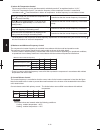

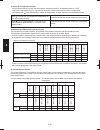

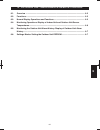

Page 9: —— Contents ——

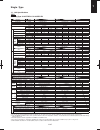

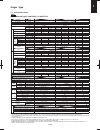

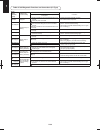

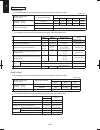

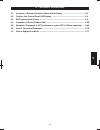

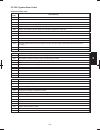

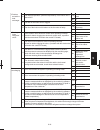

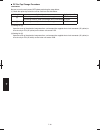

Viii section 1. Specifications................................................................................................. 1-1 1-1. Unit specifications 1-2 1-2. Dimensional data 1-241 1-3. Refrigerant flow diagram 1-255 1-4. Operating range .........................................................

Page 10

Ix section 6. Outdoor unit maintenance remote control .................................... 6-1. 6-2 6-2. 6-2 6-3 6-6 6-7 6-7 6-3. 6-4. 6-5. 6-6. Overview ............................................................................................................................... Functions............

Page 11: 1. Specifications

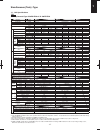

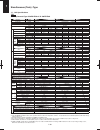

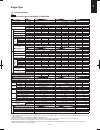

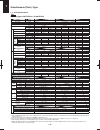

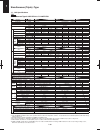

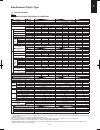

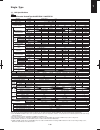

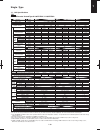

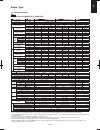

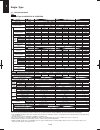

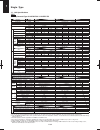

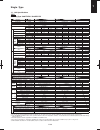

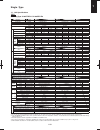

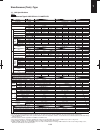

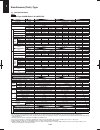

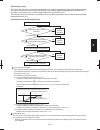

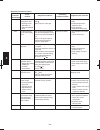

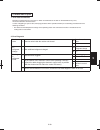

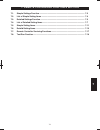

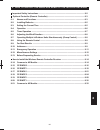

1-1 1 1. Specifications 1-1. ................................................................................................... 1-2 1. 4-way cassette type (u1) pe1 ............................................................................................................... 1-2 2. Ceiling type (t2...

Page 12

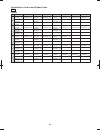

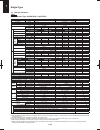

1-2 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb t...

Page 13

1-3 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-36pu1e5a×3 / u-100pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent cert...

Page 14

1-4 1 simultaneous (double-twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-36pu1e5a×4 / u-125pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent...

Page 15

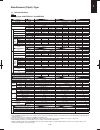

1-5 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-45pu1e5a×3 / u-125pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent cert...

Page 16

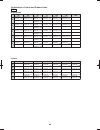

1-6 1 single-type 1-1. Unit specifications pe1 1. 4-way cassette type s-50pu1e5a / u-50pe1e5 indoor model s-50pu1e5a panel model cz-kpu21 - outdoor model u-50pe1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 22...

Page 17

1-7 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-50pu1e5a×2 / u-100pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certif...

Page 18

1-8 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-50pu1e5a×3 / u-140pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent cert...

Page 19

1-9 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb t...

Page 20

1-10 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-60pu1e5a×2 / u-125pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certi...

Page 21

1-11 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-71pu1e5a / u-71pe1e5a indoor model s-71pu1e5a panel model cz-kpu21 - outdoor model u-71pe1e5a branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 24...

Page 22

1-12 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-71pu1e5a×2 / u-140pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certi...

Page 23

1-13 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-100pu1e5a / u-100pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models ca...

Page 24

1-14 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-125pu1e5a / u-125pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models ca...

Page 25

1-15 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-140pu1e5a / u-140pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models ca...

Page 26

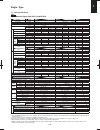

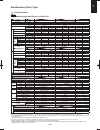

1-16 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 27

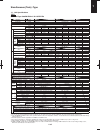

1-17 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-36pu1e5a×3 / u-100pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent cer...

Page 28

1-18 1 simultaneous (double-twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-36pu1e5a×4 / u-125pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the euroven...

Page 29

1-19 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-45pu1e5a×3 / u-125pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent cer...

Page 30

1-20 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-50pu1e5a×2 / u-100pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certi...

Page 31

1-21 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-50pu1e5a×3 / u-140pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent cer...

Page 32

1-22 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-60pu1e5a×2 / u-125pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certi...

Page 33

1-23 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-71pu1e5a / u-71pe1e8a indoor model s-71pu1e5a panel model cz-kpu21 - outdoor model u-71pe1e8a branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 24...

Page 34

1-24 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-71pu1e5a×2 / u-140pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certi...

Page 35

1-25 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-100pu1e5a / u-100pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models ca...

Page 36

1-26 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-125pu1e5a / u-125pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models ca...

Page 37

1-27 1 single-type 1-1. Unit specifi cations pe1 1. 4-way cassette type s-140pu1e5a / u-140pe1e8a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models ca...

Page 38

1-28 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 39

1-29 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 40

1-30 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 41

1-31 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 42

1-32 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 43

1-33 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 44

1-34 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 45

1-35 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 46

1-36 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 47

1-37 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 48

1-38 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 49

1-39 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 50

1-40 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 51

1-41 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 52

1-42 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 53

1-43 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 54

1-44 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 55

1-45 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 56

1-46 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 57

1-47 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 58

1-48 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 59

1-49 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 60

1-50 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 61

1-51 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 62

1-52 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 63

1-53 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 64

1-54 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 65

1-55 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 66

1-56 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 67

1-57 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 68

1-58 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 69

1-59 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 70

1-60 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 71

1-61 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 72

1-62 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 73

1-63 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 74

1-64 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 75

1-65 1 indoor model s-100pk1e5a panel model - - outdoor model u-100pe1e5a branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min max c o o l i n g capacity kw 9.5 9.5 9.5 3.3 10.5 btu/h 32400 32400 32400 1...

Page 76

1-66 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 77

1-67 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 78

1-68 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 79

1-69 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 80

1-70 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 81

1-71 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 82

1-72 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 83

1-73 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 84

1-74 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 85

1-75 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb ...

Page 86

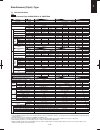

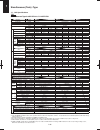

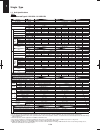

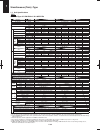

1-76 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-36pf1e5a×2 / u-71pe1e5a indoor model s-36pf1e5a×2 outdoor model u-71pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz ...

Page 87

1-77 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-36pf1e5a×3 / u-100pe1e5a indoor model s-36pf1e5a×3 outdoor model u-100pe1e5a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50...

Page 88

1-78 1 simultaneous (double-twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-36pf1e5a×4 / u-125pe1e5a indoor model s-36pf1e5a×4 outdoor model u-125pe1e5a branch pipe model cz-p155bk1×3 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz...

Page 89

1-79 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-45pf1e5a×3 / u-125pe1e5a indoor model s-45pf1e5a×3 outdoor model u-125pe1e5a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 2...

Page 90

1-80 1 single-type 1-1. Unit specifications pe1 4. Low silhouette ducted type s-50pf1e5a / u-50pe1e5 indoor model s-50pf1e5a panel model - - outdoor model u-50pe1e5 branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 ...

Page 91

1-81 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-50pf1e5a×2 / u-100pe1e5a indoor model s-50pf1e5a×2 outdoor model u-100pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50h...

Page 92

1-82 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-50pf1e5a×3 / u-140pe1e5a indoor model s-50pf1e5a×3 outdoor model u-140pe1e5a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 2...

Page 93

1-83 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-60pf1e5a / u-60pe1e5a *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed mod...

Page 94

1-84 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-60pf1e5a×2 / u-125pe1e5a indoor model s-60pf1e5a×2 outdoor model u-125pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 23...

Page 95

1-85 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-71pf1e5a / u-71pe1e5a indoor model s-71pf1e5a outdoor model u-71pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 ...

Page 96

1-86 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-71pf1e5a×2 / u-140pe1e5a indoor model s-71pf1e5a×2 outdoor model u-140pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 23...

Page 97

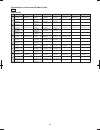

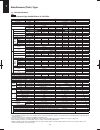

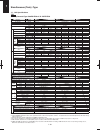

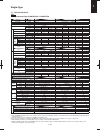

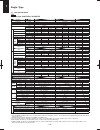

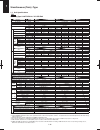

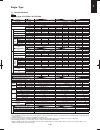

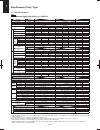

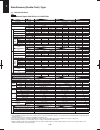

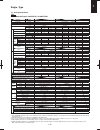

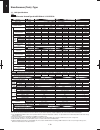

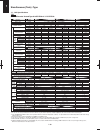

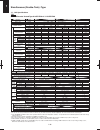

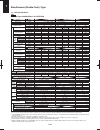

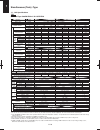

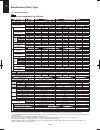

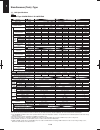

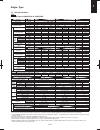

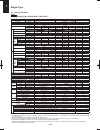

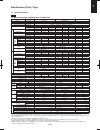

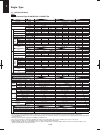

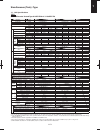

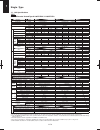

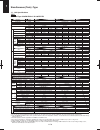

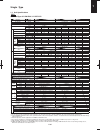

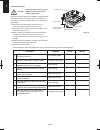

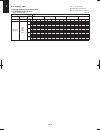

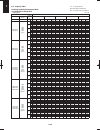

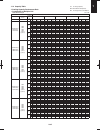

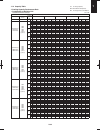

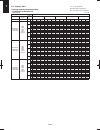

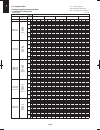

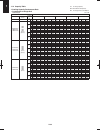

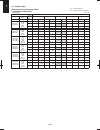

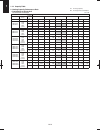

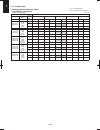

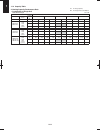

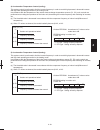

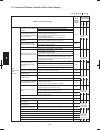

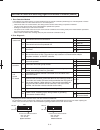

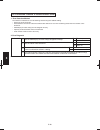

1-87 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-100pf1e5a / u-100pe1e5a indoor model s-100pf1e5a outdoor model u-100pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 ...

Page 98

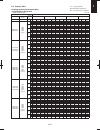

1-88 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-125pf1e5a / u-125pe1e5a indoor model s-125pf1e5a outdoor model u-125pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min ma...

Page 99

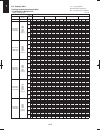

1-89 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-140pf1e5a / u-140pe1e5a indoor model s-140pf1e5a outdoor model u-140pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min ma...

Page 100

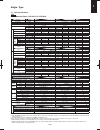

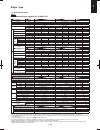

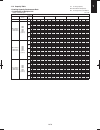

1-90 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-36pf1e5a×2 / u-71pe1e8a indoor model s-36pf1e5a×2 outdoor model u-71pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz ...

Page 101

1-91 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-36pf1e5a×3 / u-100pe1e8a indoor model s-36pf1e5a×3 outdoor model u-100pe1e8a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50...

Page 102

1-92 1 simultaneous (double-twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-36pf1e5a×4 / u-125pe1e8a indoor model s-36pf1e5a×4 outdoor model u-125pe1e8a branch pipe model cz-p155bk1×3 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz...

Page 103

1-93 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-45pf1e5a×3 / u-125pe1e8a indoor model s-45pf1e5a×3 outdoor model u-125pe1e8a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 2...

Page 104

1-94 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-50pf1e5a×2 / u-100pe1e8a indoor model s-50pf1e5a×2 outdoor model u-100pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50h...

Page 105

1-95 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-50pf1e5a×3 / u-140pe1e8a indoor model s-50pf1e5a×3 outdoor model u-140pe1e8a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 2...

Page 106

1-96 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-60pf1e5a×2 / u-125pe1e8a indoor model s-60pf1e5a×2 outdoor model u-125pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 23...

Page 107

1-97 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-71pf1e5a / u-71pe1e8a indoor model s-71pf1e5a outdoor model u-71pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 ...

Page 108

1-98 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-71pf1e5a×2 / u-140pe1e8a indoor model s-71pf1e5a×2 outdoor model u-140pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 23...

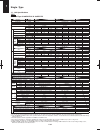

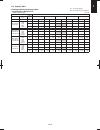

Page 109

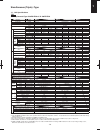

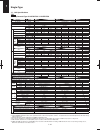

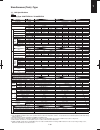

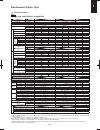

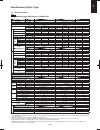

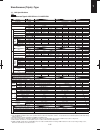

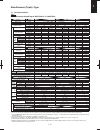

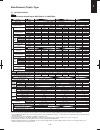

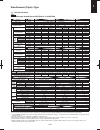

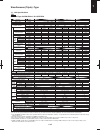

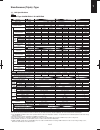

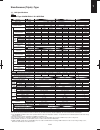

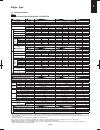

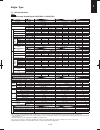

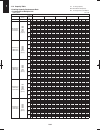

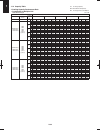

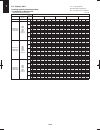

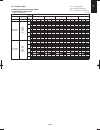

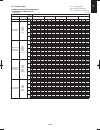

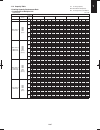

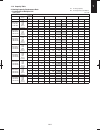

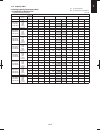

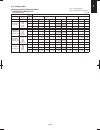

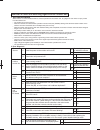

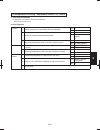

1-99 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-100pf1e5a / u-100pe1e8a indoor model s-100pf1e5a outdoor model u-100pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 ...

Page 110

1-100 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-125pf1e5a / u-125pe1e8a indoor model s-125pf1e5a outdoor model u-125pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min m...

Page 111

1-101 1 single -type 1-1. Unit specifi cations pe1 4. Low silhouette ducted type s-140pf1e5a / u-140pe1e8a indoor model s-140pf1e5a outdoor model u-140pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min m...

Page 112

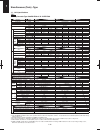

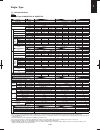

1-102 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-36pn1e5a×2 / u-71pe1e5a indoor model s-36pn1e5a×2 outdoor model u-71pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 ...

Page 113

1-103 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 5. Ducted type s-36pn1e5a×3 / u-100pe1e5a indoor model s-36pn1e5a×3 outdoor model u-100pe1e5a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 2...

Page 114

1-104 1 simultaneous (double-twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-36pn1e5a×4 / u-125pe1e5a indoor model s-36pn1e5a×4 outdoor model u-125pe1e5a branch pipe model cz-p155bk1×3 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240...

Page 115

1-105 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 5. Ducted type s-45pn1e5a×3 / u-125pe1e5a indoor model s-45pn1e5a×3 outdoor model u-125pe1e5a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230...

Page 116

1-106 1 *1 : in case it is necessary to indicate the air fl ow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certifi ed models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb...

Page 117

1-107 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-50pn1e5a×2 / u-100pe1e5a indoor model s-50pn1e5a×2 outdoor model u-100pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 24...

Page 118

1-108 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 5. Ducted type s-50pn1e5a×3 / u-140pe1e5a indoor model s-50pn1e5a×3 outdoor model u-140pe1e5a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230...

Page 119

1-109 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-60pn1e5a / u-60pe1e5a indoor model s-60pn1e5a outdoor model u-60pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min max c o o ...

Page 120

1-110 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-60pn1e5a×2 / u-125pe1e5a indoor model s-60pn1e5a×2 outdoor model u-125pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 ...

Page 121

1-111 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-71pn1e5a / u-71pe1e5a indoor model s-71pn1e5a outdoor model u-71pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min max c o o ...

Page 122

1-112 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-71pn1e5a×2 / u-140pe1e5a indoor model s-71pn1e5a×2 outdoor model u-140pe1e5a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 ...

Page 123

1-113 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-100pn1e5a / u-100pe1e5a indoor model s-100pn1e5a outdoor model u-100pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min max c ...

Page 124

1-114 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-125pn1e5a / u-125pe1e5a indoor model s-125pn1e5a outdoor model u-125pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min max c o o l i n ...

Page 125

1-115 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-140pn1e5a / u-140pe1e5a indoor model s-140pn1e5a outdoor model u-140pe1e5a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min max c o o l i n ...

Page 126

1-116 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-36pn1e5a×2 / u-71pe1e8a indoor model s-36pn1e5a×2 outdoor model u-71pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 ...

Page 127

1-117 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 5. Ducted type s-36pn1e5a×3 / u-100pe1e8a indoor model s-36pn1e5a×3 outdoor model u-100pe1e8a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 2...

Page 128

1-118 1 simultaneous (double-twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-36pn1e5a×4 / u-125pe1e8a indoor model s-36pn1e5a×4 outdoor model u-125pe1e8a branch pipe model cz-p155bk1×3 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240...

Page 129

1-119 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 5. Ducted type s-45pn1e5a×3 / u-125pe1e8a indoor model s-45pn1e5a×3 outdoor model u-125pe1e8a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400...

Page 130

1-120 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-50pn1e5a×2 / u-100pe1e8a indoor model s-50pn1e5a×2 outdoor model u-100pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 24...

Page 131

1-121 1 simultaneous (triple) -type 1-1. Unit specifi cations pe1 5. Ducted type s-50pn1e5a×3 / u-140pe1e8a indoor model s-50pn1e5a×3 outdoor model u-140pe1e8a branch pipe model cz-p3hpc2 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400...

Page 132

1-122 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-60pn1e5a×2 / u-125pe1e8a indoor model s-60pn1e5a×2 outdoor model u-125pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 ...

Page 133

1-123 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-71pn1e5a / u-71pe1e8a indoor model s-71pn1e5a outdoor model u-71pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min max c o o ...

Page 134

1-124 1 simultaneous (twin) -type 1-1. Unit specifi cations pe1 5. Ducted type s-71pn1e5a×2 / u-140pe1e8a indoor model s-71pn1e5a×2 outdoor model u-140pe1e8a branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 ...

Page 135

1-125 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-100pn1e5a / u-100pe1e8a indoor model s-100pn1e5a outdoor model u-100pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min max c ...

Page 136

1-126 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-125pn1e5a / u-125pe1e8a indoor model s-125pn1e5a outdoor model u-125pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min max c o o l i n ...

Page 137

1-127 1 single -type 1-1. Unit specifi cations pe1 5. Ducted type s-140pn1e5a / u-140pe1e8a indoor model s-140pn1e5a outdoor model u-140pe1e8a branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min max c o o l i n ...

Page 138

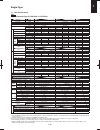

1-128 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

Page 139

1-129 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-50pu1e5a×2 / u-100pey1e5 indoor model s-50pu1e5a×2 panel model cz-kpu21×2 outdoor model u-100pey1e5 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, ...

Page 140

1-130 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

Page 141

1-131 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-60pu1e5a×2 / u-125pey1e5 indoor model s-60pu1e5a×2 panel model cz-kpu21×2 outdoor model u-125pey1e5 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz...

Page 142

1-132 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

Page 143

1-133 1 single -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-100pu1e5a / u-100pey1e5 indoor model s-100pu1e5a panel model cz-kpu21 outdoor model u-100pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 2...

Page 144

1-134 1 single -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-125pu1e5a / u-125pey1e5 indoor model s-125pu1e5a panel model cz-kpu21 outdoor model u-125pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220...

Page 145

1-135 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-50pu1e5a×2 / u-100pey1e8 indoor model s-50pu1e5a×2 panel model cz-kpu21×2 outdoor model u-100pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, ...

Page 146

1-136 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-60pu1e5a×2 / u-125pey1e8 indoor model s-60pu1e5a×2 panel model cz-kpu21×2 outdoor model u-125pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz...

Page 147

1-137 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-71pu1e5a×2 / u-140pey1e8 indoor model s-71pu1e5a×2 panel model cz-kpu21×2 outdoor model u-140pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz...

Page 148

1-138 1 single -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-100pu1e5a / u-100pey1e8 indoor model s-100pu1e5a panel model cz-kpu21 outdoor model u-100pey1e8 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 2...

Page 149

1-139 1 single -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-125pu1e5a / u-125pey1e8 indoor model s-125pu1e5a panel model cz-kpu21 outdoor model u-125pey1e8 branch pipe model - performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380...

Page 150

1-140 1 single -type 1-1. Unit specifi cations pey1 1. 4-way cassette type s-140pu1e5a / u-140pey1e8 indoor model s-140pu1e5a panel model cz-kpu21 outdoor model u-140pey1e8 branch pipe model - performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380...

Page 151

1-141 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 2. Ceiling type s-36pt2e5a×2 / u-71pey1e5 indoor model s-36pt2e5a×2 panel model outdoor model u-71pey1e5 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v...

Page 152

1-142 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 2. Ceiling type s-50pt2e5a×2 / u-100pey1e5 indoor model s-50pt2e5a×2 panel model outdoor model u-100pey1e5 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz...

Page 153

1-143 1 single -type 1-1. Unit specifi cations pey1 2. Ceiling type s-60pt2e5a / u-60pey1e5 indoor model s-60pt2e5a panel model outdoor model u-60pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 m...

Page 154

1-144 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 2. Ceiling type s-60pt2e5a×2 / u-125pey1e5 indoor model s-60pt2e5a×2 panel model outdoor model u-125pey1e5 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230...

Page 155

1-145 1 single -type 1-1. Unit specifi cations pey1 2. Ceiling type s-71pt2e5a / u-71pey1e5 indoor model s-71pt2e5a panel model outdoor model u-71pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 m...

Page 156

1-146 1 single -type 1-1. Unit specifi cations pey1 2. Ceiling type s-100pt2e5a / u-100pey1e5 indoor model s-100pt2e5a panel model outdoor model u100pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 24...

Page 157

1-147 1 single -type 1-1. Unit specifi cations pey1 2. Ceiling type s-125pt2e5a / u-125pey1e5 indoor model s-125pt2e5a panel model outdoor model u-125pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min max...

Page 158

1-148 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 2. Ceiling type s-50pt2e5a×2 / u-100pey1e8 indoor model s-50pt2e5a×2 panel model outdoor model u-100pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz...

Page 159

1-149 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 2. Ceiling type s-60pt2e5a×2 / u-125pey1e8 indoor model s-60pt2e5a×2 panel model outdoor model u-125pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230...

Page 160

1-150 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 2. Ceiling type s-71pt2e5a×2 / u-140pey1e8 indoor model s-71pt2e5a×2 panel model outdoor model u-140pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230...

Page 161

1-151 1 single -type 1-1. Unit specifi cations pey1 2. Ceiling type s-100pt2e5a / u-100pey1e8 indoor model s-100pt2e5a panel model outdoor model u-100pey1e8 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 4...

Page 162

1-152 1 single -type 1-1. Unit specifi cations pey1 2. Ceiling type s-125pt2e5a / u-125pey1e8 indoor model s-125pt2e5a panel model outdoor model u-125pey1e8 branch pipe model - performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min max...

Page 163

1-153 1 single -type 1-1. Unit specifi cations pey1 2. Ceiling type s-140pt2e5a / u-140pey1e8 indoor model s-140pt2e5a panel model outdoor model u-140pey1e8 branch pipe model - performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min max...

Page 164

1-154 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-36pk1e5a×2 / u-71pey1e5 indoor model s-36pk1e5a×2 panel model - outdoor model u-71pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 2...

Page 165

1-155 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-50pk1e5a×2 / u-100pey1e5 indoor model s-50pk1e5a×2 panel model - outdoor model u-100pey1e5 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz ...

Page 166

1-156 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

Page 167

1-157 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-60pk1e5a×2 / u-125pey1e5 indoor model s-60pk1e5a×2 panel model - outdoor model u-125pey1e5 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v ...

Page 168

1-158 1 single -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-71pk1e5a / u-71pey1e5 indoor model s-71pk1e5a panel model - outdoor model u-71pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 23...

Page 169

1-159 1 single -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-100pk1e5a / u-100pey1e5 indoor model s-100pk1e5a panel model - outdoor model u-100pey1e5 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 22...

Page 170

1-160 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-50pk1e5a×2 / u-100pey1e8 indoor model s-50pk1e5a×2 panel model - outdoor model u-100pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz ...

Page 171

1-161 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-60pk1e5a×2 / u-125pey1e8 indoor model s-60pk1e5a×2 panel model - outdoor model u-125pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v ...

Page 172

1-162 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-71pk1e5a×2 / u-140pey1e8 indoor model s-71pk1e5a×2 panel model - outdoor model u-140pey1e8 branch pipe model cz-p155bk1 performance test condition iso5151 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v ...

Page 173

1-163 1 single -type 1-1. Unit specifi cations pey1 3. Wall mounted type s-100pk1e5a / u-100pey1e8 indoor model s-100pk1e5a panel model - outdoor model u-100pey1e8 branch pipe model - performance test condition iso5151 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 38...

Page 174

1-164 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

Page 175

1-165 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-50pf1e5a×2 / u-100pey1e5 indoor model s-50pf1e5a×2 panel model outdoor model u-100pey1e5 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz ...

Page 176

1-166 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

Page 177

1-167 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-60pf1e5a×2 / u-125pey1e5 indoor model s-60pf1e5a×2 panel model outdoor model u-125pey1e5 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø...

Page 178

1-168 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

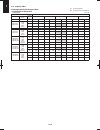

Page 179

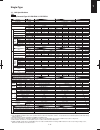

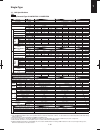

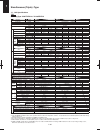

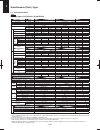

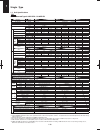

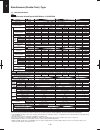

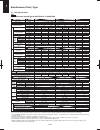

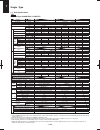

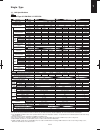

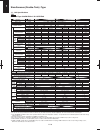

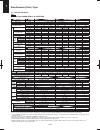

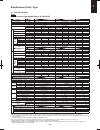

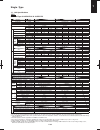

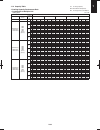

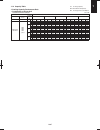

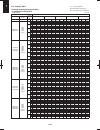

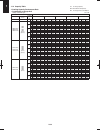

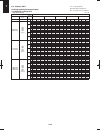

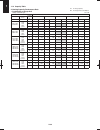

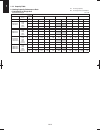

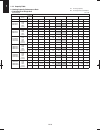

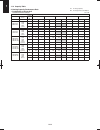

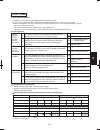

1-169 1 single -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-100pf1e5a / u-100pey1e5 indoor model s-100pf1e5a panel model outdoor model u-100pey1e5 branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 23...

Page 180

1-170 1 single -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-125pf1e5a / u-125pey1e5 indoor model s-125pf1e5a panel model outdoor model u-125pey1e5 branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 ...

Page 181

1-171 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-50pf1e5a×2 / u-100pey1e8 indoor model s-50pf1e5a×2 panel model outdoor model u-100pey1e8 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz ...

Page 182

1-172 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-60pf1e5a×2 / u-125pey1e8 indoor model s-60pf1e5a×2 panel model outdoor model u-125pey1e8 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø...

Page 183

1-173 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-71pf1e5a×2 / u-140pey1e8 indoor model s-71pf1e5a×2 panel model outdoor model u-140pey1e8 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø...

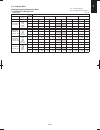

Page 184

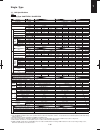

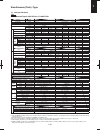

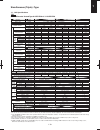

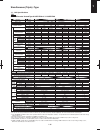

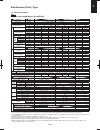

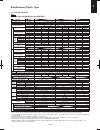

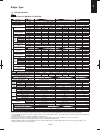

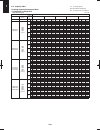

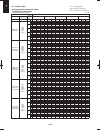

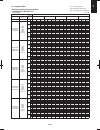

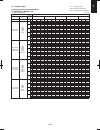

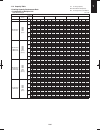

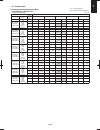

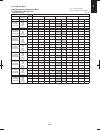

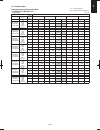

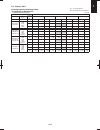

1-174 1 single -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-100pf1e5a / u-100pey1e8 indoor model s-100pf1e5a panel model outdoor model u-100pey1e8 branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 23...

Page 185

1-175 1 single -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-125pf1e5a / u-125pey1e8 indoor model s-125pf1e5a panel model outdoor model u-125pey1e8 branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 ...

Page 186

1-176 1 single -type 1-1. Unit specifi cations pey1 4. Low silhouette ducted type s-140pf1e5a / u-140pey1e8 indoor model s-140pf1e5a panel model outdoor model u-140pey1e8 branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 ...

Page 187

1-177 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 5. Ducted type s-36pn1e5a×2 / u-71pey1e5 indoor model s-36pn1e5a×2 panel model - outdoor model u-71pey1e5 branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 23...

Page 188

1-178 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 5. Ducted type s-50pn1e5a×2 / u-100pey1e5 indoor model s-50pn1e5a×2 panel model - outdoor model u-100pey1e5 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50...

Page 189

1-179 1 *1 : in case it is necessary to indicate the air flow volume in (l/s), the value in (m 3 /min.) shall be multiplied by 16.7 and rounded down the decimal point. *2 : if the eurovent certified models can be operated under the “extra-low” temperature condition, -7°c dry bulb and -8°c wet-bulb tem...

Page 190

1-180 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 5. Ducted type s-60pn1e5a×2 / u-125pey1e5 indoor model s-60pn1e5a×2 panel model - outdoor model u-125pey1e5 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 2...

Page 191

1-181 1 single -type 1-1. Unit specifi cations pey1 5. Ducted type s-71pn1e5a / u-71pey1e5 indoor model s-71pn1e5a panel model - outdoor model u-71pey1e5 branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240...

Page 192

1-182 1 single -type 1-1. Unit specifi cations pey1 5. Ducted type s-100pn1e5a / u-100pey1e5 indoor model s-100pn1e5a panel model - outdoor model u-100pey1e5 branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230...

Page 193

1-183 1 single -type 1-1. Unit specifi cations pey1 5. Ducted type s-125pn1e5a / u-125pey1e5 indoor model s-125pn1e5a panel model - outdoor model u-125pey1e5 branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 1ø 50hz v 220 230 240 220 230 240 min m...

Page 194

1-184 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 5. Ducted type s-50pn1e5a×2 / u-100pey1e8 indoor model s-50pn1e5a×2 panel model - outdoor model u-100pey1e8 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50...

Page 195

1-185 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 5. Ducted type s-60pn1e5a×2 / u-125pey1e8 indoor model s-60pn1e5a×2 panel model - outdoor model u-125pey1e8 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 2...

Page 196

1-186 1 simultaneous (twin) -type 1-1. Unit specifi cations pey1 5. Ducted type s-71pn1e5a×2 / u-140pey1e8 indoor model s-71pn1e5a×2 panel model - outdoor model u-140pey1e8 branch pipe model cz-p155bk1 performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 2...

Page 197

1-187 1 single -type 1-1. Unit specifi cations pey1 5. Ducted type s-100pn1e5a / u-100pey1e8 indoor model s-100pn1e5a panel model - outdoor model u-100pey1e8 branch pipe model - performance test condition iso13253 / en14511 / en14825 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400...

Page 198

1-188 1 single -type 1-1. Unit specifi cations pey1 5. Ducted type s-125pn1e5a / u-125pey1e8 indoor model s-125pn1e5a panel model - outdoor model u-125pey1e8 branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min m...

Page 199

1-189 1 single -type 1-1. Unit specifi cations pey1 5. Ducted type s-140pn1e5a / u-140pey1e8 indoor model s-140pn1e5a panel model - outdoor model u-140pey1e8 branch pipe model - performance test condition iso13253 / en14511 / en12102 power supply ø, hz 1ø 50hz 3ø 50hz v 220 230 240 380 400 415 min m...

Page 200

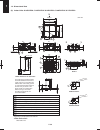

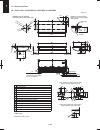

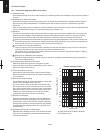

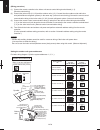

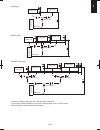

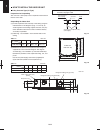

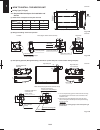

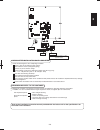

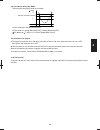

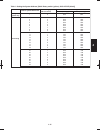

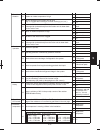

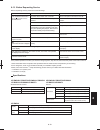

1-190 1 1-2. Dimensional data (a) indoor units: s-36pu1e5a / s-45pu1e5a / s-50pu1e5a / s-60pu1e5a / s-71pu1e5a 1 2 3 4 5 6 7 8 9 10 air intake discharge outlet refrigerant tubing (liquid tube) 36-50 type ø6.35 (flared), 60 • 71 type ø9.52 (flared) refrigerant tubing (gas tube) 36-50 type ø12.7 (flar...

Page 201

1-191 1 1-2. Dimensional data (a) indoor units: s-100pu1e5a / s-125pu1e5a / s-140pu1e5a unit: mm 30 18 118 187 2 480 840 167 187 180 319 95 80 80 1 2 3 4 5 6 7 8 9 10 air intake discharge outlet refrigerant tubing (liquid tube) ø9.52 (flared) refrigerant tubing (gas tube) ø15.88 (flared) drain tube ...

Page 202

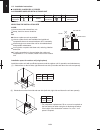

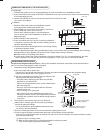

1-192 1 1-2. Dimensional data (a) indoor units: s-36pt2e5a, s-45pt2e5a, s-50pt2e5a (suspension bolt pitch) suspension bolt ceiling surface bracket distance of each exposed bolt must be of equal length within 50mm. Hole position of indoor unit rear-side (figure shows view from front) tubing hole posi...

Page 203

1-193 1 1-2. Dimensional data (a) indoor units: s-60pt2e5a, s-71pt2e5a suspension bolt ceiling surface bracket hole position of indoor unit rear-side (figure shows view from front) (suspension bolt pitch) 1226 unit within 50mm (suspension bolt pitch) air intake service space over 250 service space o...

Page 204

1-194 1 1-2. Dimensional data (a) indoor units: s-100pt2e5a, s-125pt2e5a, s-140pt2e5a suspension bolt ceiling surface bracket hole position of indoor unit rear-side (figure shows view from front) unit within 50mm air intake air discharge minimum 50cm 5 14 10 11 12 6 131 196 235 185 105 196 176 96 12...

Page 205

1-195 1 1-2. Dimensional data (a) indoor units: s-36pk1e5a, s-45pk1e5a, s-50pk1e5a, s-60pk1e5a, s-71pk1e5a, s-100pk1e5a filter size (418.5 x 342 x 2) x 2 pcs. 1 2 3 refrigerant tubing (liquid tube) s36 - s50: ø6.35 (flared) s60 - s100: ø9.52 (flared) s36 - s50: ø12.7 (flared) s60 - s100: ø15.88 (fla...

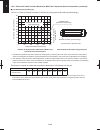

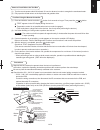

Page 206

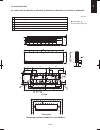

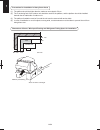

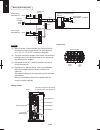

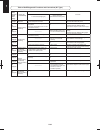

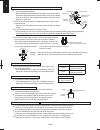

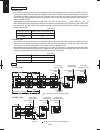

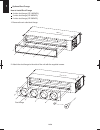

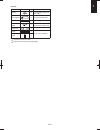

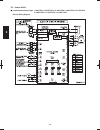

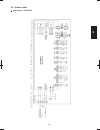

1-196 1 1-2. Dimensional data (a) indoor units: s-36pf1e5a, s-45pf1e5a, s-50pf1e5a, s-60pf1e5a, s-71pf1e5a, s-100pf1e5a, s-125pf1e5a, s-140pf1e5a 636 33.4 33.4 b d c d 154 (150) 54 700 30 290 255 15 140 23 23 113 65 70 90 26.1 300 186 27 256 172 280 g h f i c d b a e j type a b c d e f 36, 45, 50 86...

Page 207

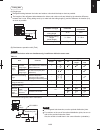

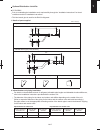

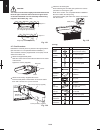

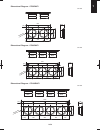

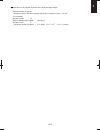

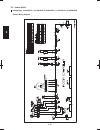

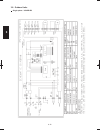

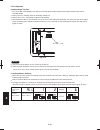

1-197 1 1-2. Dimensional data (a) indoor units: s-36pn1e5a, s-45pn1e5a, s-50pn1e5a position of suspension bolt a b c d e (unit:mm) a type b c d e s-36pn1e5a s-45pn1e5a s-50pn1e5a s-60pn1e5a s-71pn1e5a s-100pn1e5a s-125pn1e5a s-140pn1e5a 840 780 523 64 650 1060 1000 523 64 650 1260 1200 523 64 650 ai...

Page 208

1-198 1 1-2. Dimensional data (a) indoor units: s-60pn1e5a, s-71pn1e5a (a) indoor units: s-100pn1e5a, s-125pn1e5a, s-140pn1e5a drain pipe connection 30-Ø4.5 28-Ø4.5 780 (p65 x 12) 845 (p65 x 13) air flow outside dimensions model no. Unit:mm air flow hanger drain pipe connection pipe connection (liqu...

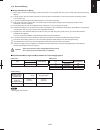

Page 209

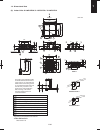

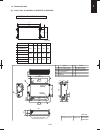

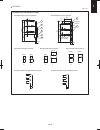

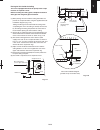

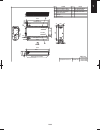

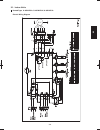

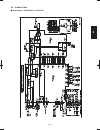

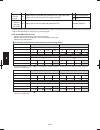

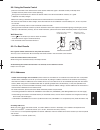

1-199 1 o18 o19 4-o12 790 70 569 15 12 50 50 249 320 100 (97) 46 (13) (23.5) 27.5 13 50 50 12 46 85 608 285 336 310 (157) 153 (161) 51 149 25 110 109 1-2. Dimensional data (b) outdoor unit: u-50pe1e5 u-60pey1e5 / u-71pey1e5 air intake air intake drain port drain port air discharge anchor bolt hole (...

Page 210

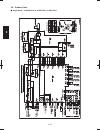

1-200 1 1 1-2. Dimensional data (b) outdoor units: u-60pe1e5a / u-71pe1e5a/ u-100pey1e5/ u-125pey1e5 u-71pe1e8a / u-100pey1e8/ u-125pey1e8 unit: mm b 2-u shaped hole electrical wiring port (ø27) handle 2-18x13 anchor hole enlarged view a hole electrical wiring port (ø22) electrical wiring port (ø13)...

Page 211

1-201 1 1 1-2. Dimensional data (b) outdoor units: u-100pe1e5a / u-125pe1e5a / u-140pe1e5a u-100pe1e8a / u-125pe1e8a / u-140pe1e8a / u-140pey1e8 handle space for piping,wiring and maintenance 100 or more 2-18x13 2-u shaped hole 380.5 170 620 150 340 940 340 1416 39 48 81 120 3 2 6 7 6 7 8 5 5 8 39 4...

Page 212

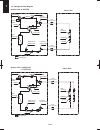

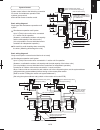

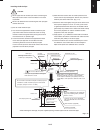

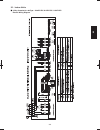

1-202 1 ø15.88 ø9.52 ec p 1-3. Refrigerant flow diagram outdoor unit : u-60pey1e5 u-71pey1e5 indoor unit: compressor muffler heat exchanger accumulator gas line service valve muffler 4-way valve electronic ref. Control valve liquid line service valve cooling cycle heating cycle strainer heat exchang...

Page 213

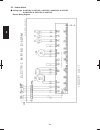

1-203 1 1-3. Refrigerant flow diagram indoor unit outdoor units: u-60pe1e5a / u-71pe1e5a u-71pe1e8a indoor unit outdoor units: u-100pe1e5a / u-125pe1e5a / u-140pe1e5a u-100pe1e8a / u-125pe1e8a / u-140pe1e8a / u-140pey1e8 ø15.88 ø9.52 compressor heat ec p defrost temp expantion valve cooling cycle he...

Page 214

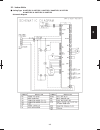

1-204 1 1-3. Refrigerant flow diagram outdoor units: u-100pey1e5 / u-100pey1e8 outdoor units: u-125pey1e5 / u-125pey1e8 ø9.52 ø15.88 ø9.52 ø15.88 distributor heat exchanger strainer indoor unit: outdoor unit: compressor expansion valve strainer strainer heat exchanger ec p 4-way valve accumulator mu...

Page 215

1-205 1 1-4. Operationg range type pe1 temperature indoor air intake temp. Outdoor air intake temp. Cooling maximum minimum heating maximum minimum 32°c db / 25°c wb 18°c db / 14°c wb 30°c db / − wb 16°c db / − wb 46°c db -15°c db 24°c db/18°c wb -20°c db / -20°c wb type pey1 temperature indoor air ...

Page 216

1-206 1 60 70 80 90 100 110 120 130 140 50 60 70 80 90 100 110 120 -30 -20 -10 0 10 20 30 40 50 input coefficient (%) capacity coefficient (%) outdoor air intake temp ( °c db) cooling capacity ratio (maximum capacity) u-50pe1e5 (for 50 hz) input coefficient (%) outdoor air intake temp ( °c wb) capac...

Page 217

1-207 1 input coefficient (%) capacity coefficient (%) outdoor air intake temp ( °c db) 20 40 60 80 100 120 140 20 40 60 80 100 120 140 -15 -5 5 15 25 35 45 cooling capacity ratio (maximum capacity) u-60pe1e5a (for 50 hz) input coefficient (%) 40 60 80 100 120 outdoor air intake temp ( °c wb) -20 -1...

Page 218

1-208 1 input coefficient (%) capacity coefficient (%) outdoor air intake temp ( °c db) 40 60 80 100 120 140 20 40 60 80 100 120 140 -15 -5 5 15 25 35 45 -20 -15 -10 -5 0 5 10 15 cooling capacity ratio (maximum capacity) input coefficient (%) 0 40 60 80 100 120 outdoor air intake temp ( °c wb) capac...

Page 219

1-209 1 1-5. Capacity correction graph according to temperature condition u-100pe1e5a (for 50 hz) / u-100pe1e8a (for 50 hz) cooling capacity ratio (maximum capacity) heating capacity ratio (maximum capacity) heating cooling input coefficient (%) capacity coefficient (%) input coefficient (%) capacit...

Page 220

1-210 1 1-5. Capacity correction graph according to temperature condition u-125pe1e5a (for 50 hz) / u-125pe1e8a (for 50 hz) cooling capacity ratio (maximum capacity) heating capacity ratio (maximum capacity) capacity (kw) capacity (kw) pe1 20 0 40 60 80 100 120 140 -20 -10 0 10 20 30 40 50 indoor ai...

Page 221

1-211 1 1-5. Capacity correction graph according to temperature condition u-140pe1e5a (for 50 hz) / u-140pe1e8a (for 50 hz) outdoor air intake temp ( °c db) input coefficient (%) capacity coefficient (%) cooling capacity (kw) input coefficient (%) capacity (kw) heating input coefficient (%) cooling ...

Page 222

1-212 1 1-5. Capacity correction graph according to temperature condition pey1 input coefficient (%) capacity coefficient (%) outdoor air intake temp ( °c db) cooling capacity ratio (maximum capacity) u-60pey1e5 (for 50 hz) input coefficient (%) outdoor air intake temp ( °c wb) capacity coefficient ...

Page 223

1-213 1 input coefficient (%) capacity coefficient (%) outdoor air intake temp ( °c db) cooling capacity ratio (maximum capacity) u-71pey1e5 (for 50 hz) input coefficient (%) outdoor air intake temp ( °c wb) capacity coefficient (%) heating capacity ratio (maximum capacity) cooling capacity (kw) inp...

Page 224

1-214 1 1-5. Capacity correction graph according to temperature condition u-100pey1e5 (for 50 hz) / u-100pey1e8 (for 50 hz) heating capacity ratio (maximum capacity) g n i t a e h g n i l o o c capacity (kw) capacity (kw) pey1 input coefficient (%) capacity coefficient (%) input coefficient (%) capa...

Page 225

1-215 1 indoor air intake temp ( °c wb) indoor air intake temp ( °c db) indoor air intake temp ( °c wb) indoor air intake temp ( °c db) 1-5. Capacity correction graph according to temperature condition u-125pey1e5 (for 50 hz) / u-125pey1e8 (for 50 hz) outdoor air intake temp ( °c db) input coefficie...

Page 226

1-216 1 1-5. Capacity correction graph according to temperature condition u-140pey1e8 (for 50 hz) cooling capacity ratio (maximum capacity) heating capacity ratio (maximum capacity) 20 0 40 60 80 100 120 140 20 0 40 60 80 100 120 140 180 160 input coefficient (%) capacity coefficient (%) input coeff...

Page 227

1-217 1 1-6. Noise criterion curves (a) indoor units: 4 way cassette type low model sound level condition source : s-36pu1e5a : high low 30 db(a) 27 db(a) : under the unit 1.5m : 220-230-240v, 1 phase, 50hz high octa v e band le v e l (db) *0db = 0.0002 µbar octa v e band le v e l (db) *0db = 0.0002...

Page 228

1-218 1 1-6. Noise criterion curves (a) indoor units: 4 way cassette type remarks: note 1. Value obtained in the actual place where the unit is installed may be slightly higher than the values shown in this graph because of the conditions of operation, the structure of the building, the background n...

Page 229

1-219 1 㻌 1-6. Noise criterion curves (a) indoor units: ceiling type model sound level : condition : s-36pt2e5a high 36 db(a) low 29 db(a) : 1 m from front of outlet at height of 1 m high low model sound level : condition : s-45pt2e5a s-50pt2e5a high 37 db(a) low 29 db(a) : 1 m from front of outlet ...

Page 230

1-220 1 1-6. Noise criterion curves (a) indoor units: ceiling type model sound level : condition : s-100pt2e5a high 42 db(a) low 35 db(a) : 1 m from front of outlet at height of 1 m high low model sound level : condition : s-125pt2e5a high 46 db(a) low 36 db(a) : 1 m from front of outlet at height o...

Page 231

1-221 1 1-6. Noise criterion curves (a) indoor units: wall mounted type strong weak model : : : : : : s-45pk1e5a sound level 38 db(a) low high 30 db(a) 34 db(a) condition 1m in front of air discharge and then 1m below 60 50 40 30 10 20 approximate minimum audible limit for continuous noise overall f...

Page 232

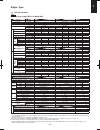

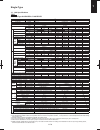

1-222 1 1-6. Noise criterion curves (a) indoor units low model sound level condition source : s-36pf1e5a : high low 33 db(a) 25 db(a) : under the unit 1.5m : 220-230-240v, 1 phase, 50hz high octa v e band le v el (db) *0db = 0.0002 μbar octa v e band le v el (db) *0db = 0.0002 μbar octa v e band le ...

Page 233

1-223 1 1-6. Noise criterion curves (a) indoor units low model sound level condition source : s-100pf1e5a : high low 38 db(a) 31 db(a) : under the unit 1.5m : 220-230-240v, 1 phase, 50hz high octa v e band le v el (db) *0db = 0.0002 μbar octa v e band le v el (db) *0db = 0.0002 μbar octa v e band le...

Page 234

1-224 1 1-6. Noise criterion curves (a) indoor units ducted type model sound level source : s-36pn1e5a : high 40 db(a) low 35 db(a) : 220-230-240v , single phase , 50hz condition : under the unit 1.5m model sound level source : s-60pn1e5a : high 43 db(a) low 36 db(a) : 220-230-240v , single phase , ...

Page 235

1-225 1 4000 8000 2000 1000 500 63 125 250 10 20 30 40 50 60 70 nc-70 nc-60 nc-50 nc-40 nc-30 nc-20 1-6. Noise criterion curves (b) outdoor unit model sound level condition source : u-50pe1e5 : cooling 46 db(a) : 1 m in front at height of 1.5 m : 220-230-240v, 1 phase, 50hz octa v e band le v el (db...

Page 236

1-226 1 1-6. Noise criterion curves (b) outdoor unit model sound level condition source : u-60pe1e5a : heating 50 db(a) : 1 m in front at height of 1.5 m : 220-230-240v, 1 phase, 50hz heating model sound level condition source : u-60pe1e5a : cooling 48 db(a) : 1 m in front at height of 1.5 m : 220-2...

Page 237

1-227 1 1-6. Noise criterion curves (b) outdoor unit model sound level condition : u-100pe1e5a, u-100pe1e8a : heating 52 db(a) : 1 m in front at height of 1.5 m model sound level condition : u-100pe1e5a, u-100pe1e8a : cooling 52 db(a) : 1 m in front at height of 1.5 m octave band level (db) *0db = 0...

Page 238

1-228 1 1-6. Noise criterion curves (b) outdoor unit model sound level condition : u-140pe1e5a, u-140pe1e8a : heating 55 db(a) : 1 m in front at height of 1.5 m model sound level condition : u-140pe1e5a, u-140pe1e8a : cooling 54 db(a) : 1 m in front at height of 1.5 m octave band level (db) *0db = 0...

Page 239

1-229 1 1-6. Noise criterion curves (b) outdoor unit model sound level condition source : u-60pey1e5 : cooling 46 db(a) : 1 m in front at height of 1.5 m : 220-230-240v, 1 phase, 50hz 4000 8000 2000 1000 500 63 125 250 frequency at center of sound pressure band (hz) overall octa v e band le v el (db...

Page 240

1-230 1 1-6. Noise criterion curves (b) outdoor unit frequency at center of sound pressure band (hz) frequency at center of sound pressure band (hz) 8000 4000 2000 1000 500 250 125 63 8000 4000 2000 1000 500 250 125 63 model sound level condition : u-125pey1e5, u-125pey1e8 : heating 56 db(a) : 1 m i...

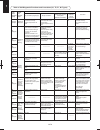

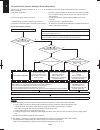

Page 241