- DL manuals

- Panasonic

- Inverter

- S-200PE1E8

- Technical Data & Service Manual

Panasonic S-200PE1E8 Technical Data & Service Manual

Summary of S-200PE1E8

Page 1

85464849294003 reference no . Sm830194-03 technical data & service manual outdoor unit indoor unit s-200pe1e8, s-250pe1e8 type e1 u-200pe1e8, u-250pe1e8 sm830194-03̲bigpac-i.Indb 1 sm830194-03̲bigpac-i.Indb 1 2012/10/11 20:58:27 2012/10/11 20:58:27.

Page 2

I important! Please read before starting this air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently. For safe installation and trouble-free op...

Page 3

Ii when connecting refrigerant tubing warning • when performing piping work do not mix air except for specified refrigerant (r410a) in refrigeration cycle. It causes capacity down, and risk of explosion and injury due to high tension inside the refrigerant cycle. • refrigerant gas leakage may cause ...

Page 4

Iii 2. The standards for minimum room volume are as follows. (1) no partition (shaded portion) (2) when there is an effective opening with the adjacent room for ventilation of leaking refrigerant gas (opening without a door, or an opening 0.15% or larger than the respective floor spaces at the top o...

Page 5

Iv —— contents —— section 1. Specifications ................................................................................................. 1-1. Unit specifications ............................................................................................................... 1-2. Major component ...

Page 6

V 7-1 7-2 7-3 section 7. Remote controller functions section............................................... 7-2. List of simple setting items................................................................................................. 7-4 7-3. Detailed settings function ............................

Page 7: 1. Specifications

1-1 1 1. Specifications 1-1. Unit specifications..................................................................................................... 1-4 1-2 1-22 1-18 1-15 1-14 1-13 1-13 1-10 1-2. Major component specifications ..........................................................................

Page 8

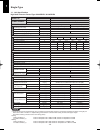

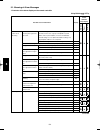

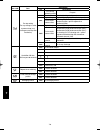

1-2 1 single-type 1-1. Unit specifications high static pressure ducted type s-200pe1e8 / u-200pe1e8 model no. Indoor unit outdoor unit power source indoor unit outdoor unit performance capacity [min~max] kw btu / h cooling 20.0 [6.0~22.4] 68,200 [20,500~76,400] heating 22.4 [6.0~25.0] 76,400 [20,500...

Page 9

1-3 1 single-type 1-1. Unit specifications high static pressure ducted type s-250pe1e8 / u-250pe1e8 – 57 indoor unit 12.7 (1 / 2) 25.4 (1) – indoor unit 467 (18-12 / 32) 1,428 (56-7 / 32) 1,230 (48-14 / 32) 614 (24-11 / 64) 1,536 (60-15 / 32) 1,339 (52-23 / 32) 120 (256) 144 (317) 1.268 (44.8) outdo...

Page 10

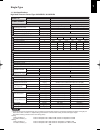

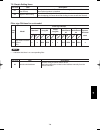

1-4 1 1-2. Major component specifications (a) indoor units high static pressure ducted type s-200pe1e8 model no. Source controller p.C.B. Ass'y fan (number...Diameter) mm fan motor w model...Nominal output power source rpm no. Of pole...R.P.M. (230v, high) coil resistance (ambient temperature 20°c) ...

Page 11

1-5 1 1-2. Major component specifications (a) indoor units high static pressure ducted type s-250pe1e8 brn – wht : 6,159 wht – vlt : 1.08 vlt – org : 0.77 org – yel : 0.87 yel – blk : 2.87 blk – pnk : 5.98 model no. Source controller p.C.B. Ass'y fan (number...Diameter) mm fan motor w model...Nomina...

Page 12

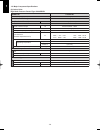

1-6 1 1-2. Major component specifications (b) outdoor units u-200pe1e8 model no. Source controller p.C.B. Ass'y control circuit fuse compressor model....Number source w nominal output cc compressor oil coil resistance (ambient temperature 25°c) Ω c – r : 0.552 r – s : 0.552 c – s : 0.552 safety cont...

Page 13

1-7 1 1-2. Major component specifications (b) outdoor units u-250pe1e8 c – r : 0.608 r – s : 0.608 c – s : 0.608 model no. Source controller p.C.B. Ass'y control circuit fuse compressor model....Number source w nominal output cc compressor oil coil resistance (ambient temperature 25°c) Ω safety cont...

Page 14

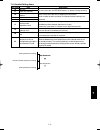

1-8 1 1-3. Other component specifications outdoor units u-200pe1e8 model no. Outdoor unit power transformer rated vac, hz source secondary coil resistance Ω thermistor (coil / air sensor): th1, th2, th3, th4 resistance kΩ –10°c: 23.7±5% 20°c: 6.5±5% –5°c: 18.8±5% 30°c: 4.4±5% 0°c: 15.0±5% 40°c: 3.1±...

Page 15

1-9 1 1-3. Other component specifications outdoor units u-250pe1e8 – – – – – – – ktm-35d-s1, dtn-c532g3h cm-12 – – – ukv-25d18 ukv-u030e, dc 12 v stf-0712g stf-01ai518a1, ac 220-240 v, 50hz / 60hz model no. Outdoor unit power transformer rated vac, hz source secondary coil resistance Ω thermistor (c...

Page 16

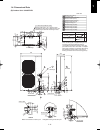

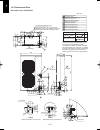

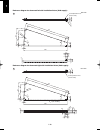

1-10 1 1-4. Dimensional data (a) indoor units: high static pressure ducted type s-200pe1e8 s-250pe1e8 479 300 100 2 100 100 42 1428 1310 71 1100 51 964 9×100p=900 4 - 37×12 10×100p=1000 106 44 1070 1310 67 67 113 (236) 364 364 1334 60 43 320 100 50 178 23 209 344 1222 41 1170 1100 55 55 1200 1310 re...

Page 17

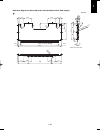

1-11 1 1 2 3 4 5 6 7 8 8 8 57 60 42 49 111 586 30 77 22 39 940 a 18 410 10 20 380 26 290 105 219 75 75 170 660 110 13 60 340 40 13 b 340 42 49 111 30 77 85 64 22 60 1526 25 4 8 7 6 5 8 7 6 5 4 3 2 1 r30 63 80 58 61 49 7 59 60 3 33 52 46 65 121 43 4 8 6 5 7 5.5 62 49 67 7.5 1-4. Dimensional data (b) ...

Page 18

1-12 1 air discharge air intake unit: mm view a air discharge air intake anchor bolt anchor bolt air intake anchor bolt anchor bolt view b anchor bolt 2 x ø32 holes (holes for drain) of the 4 ø32 holes , use 1 of the 2 holes specified for drain use to install the port. Use rubber plugs to seal the r...

Page 19

1-13 1 s hp m m ec p ø9.52 (3/4") s hp m m ec p ø12.7 (3/4") 1-5. Refrigerant flow diagram outdoor unit : u-200pe1e8 outdoor unit : u-250pe1e8 indoor unit : s-200pe1e8 compressor high pressure switch heat exchanger accumulator gas line service valve check valve 4-way valve liquid line service valve ...

Page 20

1-14 1 1.0 1.0 0.97 0.96 0.96 0.95 0.94 0.89 0.91 0.88 0.87 0.87 0.87 0.88 0.89 -20 -15 -10 -9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 6 5 4 3 1.0 0.95 0.91 0.92 60 80 80 60 40 100 120 140 35 25 15 5 45 -15 100 120 -5 -10 5 0 10 -5 120 40 60 80 100 120 40 60 80 100 15 -15 -20 0 0 20 40 60 80 100 120 140 20 40...

Page 21

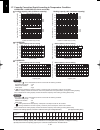

1-15 1 500 1000 2000 8000 250 10 20 30 40 50 60 70 80 90 4000 500 1000 2000 8000 4000 125 nc-70 nc-60 nc-50 nc-40 nc-30 nc-20 63 250 10 20 30 40 50 60 70 80 90 125 nc-70 nc-60 nc-50 nc-40 nc-30 nc-20 63 1-8. Noise criterion curves high static pressure ducted type model sound level condition conditio...

Page 22

1-16 1 nc-20 nc-30 nc-40 nc-50 nc-60 nc-70 60 70 80 90 50 40 30 20 10 4000 0 0 0 8 0 5 2 5 2 1 3 6 2000 1000 500 1-8. Noise criterion curves (b) outdoor unit : u-200pe1e8 : 72 db(a) : cooling model sound power level model sound level condition : u-200pe1e8 : standard 57 db(a) quiet mode 50 db(a) coo...

Page 23

1-17 1 1-8. Noise criterion curves (b) outdoor unit nc-20 nc-30 nc-40 nc-50 nc-60 nc-70 60 70 80 90 50 40 30 20 10 4000 0 0 0 8 0 5 2 5 2 1 3 6 2000 1000 500 model sound level condition : u-250pe1e8 : standard 58 db(a) quiet mode 50 db(a) : 1 m in front at height of 1.5 m approximate minimum audible...

Page 24

1-18 1 1-9. Electrical wiring general precautions on wiring (1) before wiring, confirm the rated voltage of the unit as shown on its nameplate, then carry out the wiring closely following the wiring diagram. (2) provide a power outlet to be used exclusively for each unit and a circuit breaker for ov...

Page 25

1-19 1 note wiring system diagrams l2 l1 u2 u1 l3 n a l1 l2 l3 n u2 u1 l n 1 2 2 1 d b l n 2 1 c (1) refer to “recommended wire length and wire diameter for power supply system” for the explanation of “a”, “b”, “c” and “d” in the above diagrams. (2) the basic connection diagram of the indoor unit sh...

Page 26

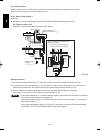

1-20 1 (3) use shielded wires for inter-unit control wiring (c) and ground the shield on both sides, otherwise misoperation from noise my occur. (fig. 1-2) connect wiring as shown in wiring system diagram.” fig. 1-2 fig. 1-4 fig. 1-3 (4) use the standard power supply cables for europe (such as h05rn...

Page 27

1-21 1 wiring sample indoor unit use this screw when connecting to ground the shield for the inter-unit control wiring. Remote control wiring power supply functional ground screw (external electronic expansion valve kit and schedule timer) inter-unit control wiring 1. 2. Outdoor unit earth use this ...

Page 28

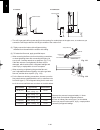

1-22 1 1-10. Installation instructions outdoor unit tubing length 1. Single type during tubing work, try to make both the tubing length (l) and the difference in elevation (h1) as short as possible. Refer to table 1-1. H1 single main tubing l table 1-1 tubing data for models (single) models tubing d...

Page 29

1-23 1 this unit requires no additional refrigerant charge up to tubing length 30 m. In case of more than 30 m, additional refrigerant charge is required. Refer to table 1-1. In case of multi type installation, indoor units should be installed within the same room. If multi type indoor units are ins...

Page 30

1-24 1 3. Selecting the installation site when moving the unit during or after unpacking, make sure to lift it by holding its lifting lugs. Do not exert any pressure on other parts, especially the refrigerant piping, drain piping and flange parts. If you think the humidity inside the ceiling might e...

Page 31

1-25 1 installation space install the outdoor unit with a sufficient space around the outdoor unit for operation and maintenance. (1) obstructions on the left side, right side and rear side (front side and above the unit are opened). (fig. 1-10) * necessary space is required to unscrew on the rear s...

Page 32

1-26 1 precautions for installation in heavy snow areas (1) the platform should be higher than the max. Snow depth. (fig. 1-15) (2) the 2 anchoring feet of the outdoor unit should be used for the platform, and the platform should be installed beneath the air intake side of outdoor unit. (3) the plat...

Page 33

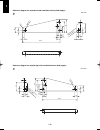

1-27 1 2 3 4 1 5 6 7 8 9 25 25 9 550 518 518 550 568 568 cl 62.4 110 110 110 5 (106.3) 110 110 110 5.2 31 50 441.5 90 110 8-o4.5 1 1526 940 568 5 6 4 (316) 56 170 (110) 660 20 10 380 20 21 340 60 (178) 167 555 (303) 217 643 566 8 3 1 2 7 4. Dimensions of air-discharge chamber : in snowy regions, if ...

Page 34

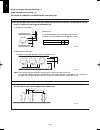

1-28 1 7 15 3 18 90 90 224 518 34.5 579 45 562 9 18 87 27 11 33 23 21 15 3-o6 o5 2 3-o6 o5 7 15 3 18 90 90 224 518 579 45 562 9 18 87 34.5 8 25 15 11 33 23 21 32 3 reference diagram for downward left side installation fi xture (fi eld supply) : reference diagram for downward right side installation ...

Page 35

1-29 1 2-o5 70 32.5 32.5 7 14 90 90 18 35 28 18 16 93 212 r 25 70 212 100 100 50 25 50 25 r 25 r 25 r 25 560 (495) 100 100 75 75 (135) 125 300 4 reference diagram for downward center side installation fi xture (fi eld supply) : unit: mm hole cyclic bending same on reverse side 3-ø3.3 protr usion hol...

Page 36

1-30 1 reference diagram for upward left side installation fi xture (fi eld supply) : reference diagram for upward right side installation fi xture (fi eld supply) : unit: mm unit: mm hole hole ø3.3 protr usion hole (re verse side) ø3.3 protr usion hole (re verse side) 3-o5 3-o5 5 6 10.5 25 r 5 20 1...

Page 37

1-31 1 reference diagram for upward left side installation fi xture (fi eld supply) : reference diagram for upward right side installation fi xture (fi eld supply) : unit: mm unit: mm hole hole 2-ø3.3 protrusion hole (reverse side) 2-ø3.3 protrusion hole (reverse side) cyclic bending o5 7 8 15 7 53 ...

Page 38

1-32 1 required space around outdoor unit if the air discharge chamber is used, the space shown below must be secured around the outdoor unit. If the unit is used without the required space, a protective device may activate, preventing the unit from operating. (1) single-unit installation the top an...

Page 39

1-33 1 660 97 940 340 450 74 544 20 380 575 39 575 164 1526 130 494 25 25 25 60 50 50 50 50 450 180 6 10- 308 121.5 10.5 18 10.5 18 114 104 300 20 10 20 544 575 5. Dimensions of wind-proof duct : in snowy regions, if there is concern that snow may enter the wind-proof duct, remove the base of the ch...

Page 40

1-34 1 1 2 3 4 5 6 7 8 1529 (320) 1209 997 691 20 10 380 20 21 340 (295) 110 (227) 702 660 733 340 (303) 2 645 1 700 276.5 733 232 1209 1498 302 645 98 10 100 120 102.5 614 518 149.5 7 500 450 150 20 614.5 234 716 11 55.5 25 3 7 8 2 1 5 6 4 6. Dimensions of snow-proof duct : reference diagram for u-...

Page 41

1-35 1 reference diagram for snow-proof duct - 1 space requirements for setting - (1) the models of u-200pe1e8 / u-250pe1e8 with snow-proof duct [obstacle to the rear of unit] [obstacle to the front of unit] top is open: (1) single-unit installation (2) obstacles on both sides (3) multiple-unit inst...

Page 42

1-36 1 q q reference diagram for snow-proof duct - 2 space requirements for setting - (2) the models of u-200pe1e8 / u-250pe1e8 with snow-proof duct [obstacles to the front and rear of unit] the top and both sides must remain open. Either the obstacle to the front or the obstacle to the rear must be...

Page 43

1-37 1 caution 7. How to install the outdoor unit 1. Installing the outdoor unit use concrete or a similar material to make the base, and ensure good drainage. Ordinarily, ensure a base height of 5 cm or more. If a drain pipe is used, or for use in cold-weather regions, ensure a height of 15 cm or m...

Page 44

1-38 1 8. Selecting the installation site indoor unit avoid: areas where leakage of flammable gas may be expected. Places where large amounts of oil mist exist. Direct sunlight. Locations near heat sources which may affect the performance of the unit. Locations where external air may enter the room ...

Page 45

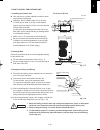

1-39 1 9. How to install the indoor unit high static pressure ducted type (e1 type) 1. Required minimum space for installation and service (200, 250 types) the installation instructions that come with the indoor unit describe how to use it in combination with the u-200pe1e8 and u-250pe1e8 outdoor un...

Page 46

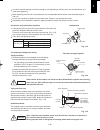

1-40 1 2. Suspending the indoor unit it is important that you use extreme care in supporting the indoor unit inside the ceiling. Ensure that the ceiling is strong enough to support the weight of the unit. Before hanging the unit, test the strength of each attached suspension bolt. (1) when placing t...

Page 47

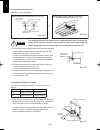

1-41 1 the type 200 indoor unit comes with a tube connector that is for liquid tubing. Configure as shown in the illustration and connect it. When flaring the tube, put the flare nut onto it first and then flare it. Be sure to insulate both the gas tubing and liquid tubing. In addition, wrap the sup...

Page 48

1-42 1 1-11. How to process tubing the liquid tubing side is connected by a flare nut, and the gas tubing side is connected by brazing. 1. Connecting the refrigerant tubing use of the flaring method many of conventional split system air conditioners employ the flaring method to connect refrigerant t...

Page 49

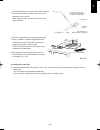

1-43 1 cautions during brazing replace air inside the tube with nitrogen gas to prevent copper oxide film from forming during the brazing process. (oxygen, carbon dioxide and freon are not acceptable.) do not allow the tubing to get too hot during brazing. The nitrogen gas inside the tubing may over...

Page 50

1-44 1 fig. 1-31 fig. 1-32 3. Out rear 60 flare process 4. Out bottom 260 190 flare process the ø25.4 gas main will not pass easily into the opening for coolant pipes in the pipe cover, so make sure you connect the ø25.4 pipe with the ø19.05 pipe outside of the outdoor unit. (2) tightly connect the ...

Page 51

1-45 1 in order to prevent damage to the flare caused by over-tightening of the flare nuts, use the table above as a guide when tightening. When tightening the flare nut on the liquid tube, use an adjustable wrench with a nominal handle length of 200 mm. Do not use a spanner to tighten the valve ste...

Page 52

1-46 1 4. Taping the tubes (1) at this time, the refrigerant tubes (and electrical wiring if local codes permit) should be taped together with armoring tape in 1 bundle. To prevent condensation from overflowing the drain pan, keep the drain hose separate from the refrigerant tubing. (2) wrap the arm...

Page 53

1-47 1 1-12. Leak test, evacuation and additional refrigerant charge perform an air-tightness test for this package a/c. Check that there is no leakage from any of the connections. Air and moisture in the refrigerant system may have undesirable effects as indicated below. Pressure in the system rise...

Page 54

1-48 1 fig. 1-41 fig. 1-42 fig. 1-43 caution caution 2. Evacuation be sure to use a vacuum pump that includes a function for prevention of back-flow, in order to prevent back-flow of pump oil into the unit tubing when the pump is stopped. Perform vacuuming of the indoor unit and tubing. Connect the ...

Page 55

1-49 1 1-13. How to select ahu system system lineup ahu system selection guideline * mix connection with standard indoor units is not allowed. * the system is applicable to the above models. * single connection type only system overview piping design regulation connecting pipe dimension to heat exch...

Page 56

1-50 1 attach the heat exchanger pipe thermistor in the middle of each pass-line (pipe) in the heat exchanger. The thermistor is fixed in band. Then, it must not make tension to the wire. Cover the aluminum tape with thermal insulation. And also cover sensor (copper portion) with thermal insulation ...

Page 57

1-51 1 blower operation signal and protection signal power supply sw1 x1 : relay (field supply) limitation of ahu when the ahu is selected, there are some limitations. Cooling heating max. Max. -10 (db) (wb) -20 (db) 43 (wb) 15 (db) 18 (db) 16 (db) 32 / 23 (db) 30 outdoor temperature blower protect ...

Page 58

1-52 1 restriction on the number of passes of the heat exchanger hairpin minimum number of passes = number of steps × distance between tube sheets × number of rows × 1.5 ×10 -4 number of steps 12 distance between tube sheets 1000 [mm] : : : number of rows 3 minimum number of passes = 12 × 1000 × 3 ×...

Page 59: 2. Test Run

2 2-1 2-1. Preparing for test run .............................................................................................................................. 2-2 2-2 2-2 2-3 2-3 2-3 2-4 2-5 2-8 2-9 2-9 2-10 2-10 2-11 2-12 2-15 2-16 2-17 2-17 2-17 2-18 2-21 2-23 caution 2-2. .........................

Page 60

2 2-2 2-1. Preparing for test run before attempting to start the air conditioner, check the following: (1) all loose matter is removed from the cabinet especially steel filings, bits of wire, and clips. (2) the control wiring is correctly connected and all electrical connections are tight. (3) the p...

Page 61

2 2-3 2-4. Items to check before the test run (1) turn the remote power switch on at least 12 hours in advance in order to energize the crankcase heater. (2) (2) fully open the closed valves on the liquid-tube and gas-tube sides. 2-5. Test run using the remote controller (1) press and hold the remot...

Page 62

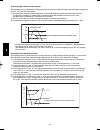

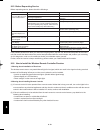

2 2-4 2-7. Table of self-diagnostic functions and corrections (e1 type) wired remote controller display indoor unit receiver lamp cause correction 1:1 connection (single type) group connection simultaneous-operation multi system (flexible combination) control by main-sub remote controllers nothing i...

Page 63

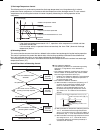

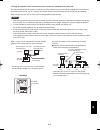

2 2-5 2-8. System control system control refers to the link wiring connection for control of simultaneous-operation multi systems, group control, and main-sub remote controller control. 2-8-1. Basic wiring diagram single type be careful to avoid miswiring when connecting the wires. (miswiring will d...

Page 64

2 2-6 2-8-2. Setting the outdoor unit system addresses for basic wiring diagram (set the system address: 1) on 1 2 fig. 2-6 dip switch system address system address rotary switch (set to “0” at time of shipment) system address rotary switch 10s 20s on off outdoor unit control pcb 8 – 10 hp system ad...

Page 65

2 2-7 2-8-4. Indicating (marking) the indoor and outdoor unit combination number indicate (mark) the number after automatic address setting is completed. (1) so that the combination of each indoor unit can be easily checked when multiple units are installed, ensure that the indoor and outdoor unit n...

Page 66

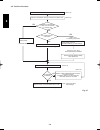

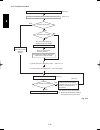

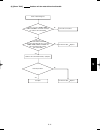

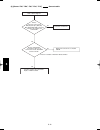

2 2-8 2-9. Test run procedure fig. 2-7 no yes no yes no yes recheck the items to check before the test run. (see 2-10) check the combination (wiring) of indoor and outdoor units. (see 2-15) is system “single-type”? (1 indoor unit is connected to 1 outdoor unit) are multiple outdoor units used? Turn ...

Page 67

2 2-9 2-10. Items to check before the test run (1) (2) turn the remote power switch on at least 12 hours in advance in order to energize the crankcase heater. Fully open the closed valves on the liquid-tube and gas-tube sides. Note 2-11. Preparation for test run 2-11-1. Switching the temperature sen...

Page 68

2 2-10 note 2-12. Test run using the control unit (1) change the indoor control unit switch from “on” “test”. (the outdoor unit will not operate for 3 minutes after the power is turned on and after operation is stopped.) (2) all the indicator lamps blink while the test run is in progress. (3) temper...

Page 69

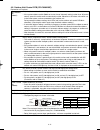

2 2-11 2-14. Table of self-diagnostic functions and corrections wired remote controller display (field supply) indoor unit receiver lamp cause correction 1:1 connection (single type) group connection (simultaneous multi system) nothing is displayed nothing is displayed • indoor operation switch is o...

Page 70

2 2-12 2-15. System control system control refers to the link wiring connection for control of simultaneous-operation multi systems, group control, and main-sub remote controller control. 2-15-1. Basic wiring diagram 1 single type be careful to avoid miswiring when connecting the wires. (miswiring w...

Page 71

2 2-13 outdoor unit control pcb 8 – 10 hp 8 – 10 hp 2-15-2. Setting the outdoor unit system address for basic wiring diagram (set the system address: 1) on 1 2 fig. 2-11 dip switch system address system address rotary switch (set to “0” at time of shipment) system address rotary switch 10s 20s on of...

Page 72

2 2-14 2-15-5. Indoor unit address setting if multiple single-type units are installed in the same room, the addresses can be set to prevent signal interference. By coordinating the numbers of the indoor unit (wireless pcb) and remote controller addresses, up to 6 indoor units can be controlled inde...

Page 73

2 2-15 outdoor unit control pcb 8 – 10 hp e1 type (for link wiring) 2-16. Caution this unit may be used in a single-type refrigerant system where 1 outdoor unit is connected to 1 indoor unit. This test run explanation describes primarily the procedure when using the wired remote controller. If link ...

Page 74

2 2-16 2-17. Test run procedure yes no yes yes no no fig. 2-14 recheck the items to check before the test run. (see 2-18) check the combination (wiring) of indoor and outdoor units. (see 2-21-1) is system “single-type”? Is outdoor unit multiple? (see 2-21-2) how to set the outdoor unit system addres...

Page 75

2 2-17 note 2-18. Items to check before the test run (1) (2) turn the remote power switch on at least 12 hours in advance in order to energize the crank case heater. Fully open the closed valves on the liquid-tube and gas-tube sides. 2-19. Test run using the remote controller (1) press and hold the ...

Page 76

2 2-18 2-21. Automatic address setting 2-21-1. Basic wiring diagram link wiring a terminal plug (black) is attached to each of the outdoor unit control pcbs. At only one outdoor unit, leave the terminal plug short-circuit socket on the “yes” side. At all the other outdoor units, change the socket (f...

Page 77

2 2-19 case 2 if the power cannot be turned on separately for the indoor and outdoor units in the system: the compressors must be run in order to automatically set the indoor unit addresses. Therefore perform this step after completing the refrigerant tubing work. (1) turn on the power to the indoor...

Page 78

2 2-20 case 4 if the power cannot be turned on separately for the indoor and outdoor units in each system: (the compressors must be run in order to automatically set the indoor unit addresses. Therefore perform this step after completing the refrigerant tubing work.) all-systems automatic address se...

Page 79

2 2-21 2-21-3. Checking indoor unit addresses use the remote controller to check the addresses of the indoor units. Press and hold the button and button for 4 seconds or longer (simple settings mode, “all” appears on the remote controller). Then press the button and select the indoor address. (for t...

Page 80

2 2-22 outdoor unit control pcb 8 – 10 hp 2-22-2. Setting outdoor unit system addresses for the basic wiring diagram (set the system addresses: 1, 2, 3...) on 1 2 8 – 10 hp fig. 2-20 system address rotary switch system address rotary switch (set to “0” at time of shipment) system address 10s 20s dip...

Page 81

2 2-23 pump down cannot be performed when the tubing length exceeds 30m. (there is a possiblilty of generating the actuation of the excessive load protection system.) in this case, collect the refrigerant by the refrigeant collecting system. Note 2-22-4. Indicating (marking) the indoor and outdoor u...

Page 82: – Memo –

– memo – 2-24 sm830194-00.Indb 24 sm830194-00.Indb 24 2011/04/06 19:12:50 2011/04/06 19:12:50

Page 83: 3. Electrical Data

3-1 3 3. Electrical data 3-1. Outdoor units (electric wiring diagram, schematic diagram) ................................ 3-2 3-2. Indoor units (electric wiring diagram, schematic diagram) ................................... 3-4 high-static pressure ducted type sm830194-00.Indb 1 sm830194-00.Indb 1 ...

Page 84

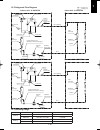

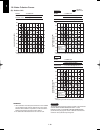

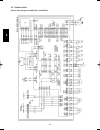

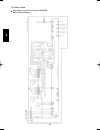

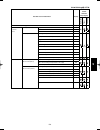

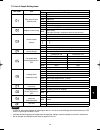

3-2 3 3-1. Outdoor units electric wiring diagram u-200pe1e8 / u-250pe1e8 sm830194-00.Indb 2 sm830194-00.Indb 2 2011/04/06 19:14:50 2011/04/06 19:14:50

Page 85

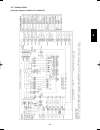

3-3 3 3-1. Outdoor units schematic diagram u-200pe1e8 / u-250pe1e8 sm830194-00.Indb 3 sm830194-00.Indb 3 2011/04/06 19:14:50 2011/04/06 19:14:50

Page 86

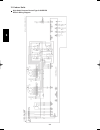

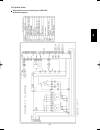

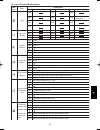

3-4 3 3-2. Indoor units high-static pressure ducted type s-200pe1e8 electric wiring diagram sm830194-00.Indb 4 sm830194-00.Indb 4 2011/04/06 19:14:50 2011/04/06 19:14:50

Page 87

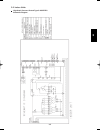

3-5 3 3-2. Indoor units high-static pressure ducted type s-200pe1e8 schematic diagram sm830194-00.Indb 5 sm830194-00.Indb 5 2011/04/06 19:14:50 2011/04/06 19:14:50

Page 88

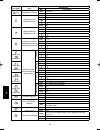

3-6 3 3-2. Indoor units high-static pressure ducted type s-250pe1e8 electric wiring diagram sm830194-00.Indb 6 sm830194-00.Indb 6 2011/04/06 19:14:50 2011/04/06 19:14:50

Page 89

3-7 3 3-2. Indoor units high-static pressure ducted type s-250pe1e8 schematic diagram sm830194-00.Indb 7 sm830194-00.Indb 7 2011/04/06 19:14:51 2011/04/06 19:14:51.

Page 90: – Memo –

– memo – 3-8 sm830194-00.Indb 8 sm830194-00.Indb 8 2011/04/06 19:14:51 2011/04/06 19:14:51.

Page 91: 4. Process and Functions

4-1 4 4. Process and functions 4-1. Control functions ....................................................................................................... 4-2 4-2. Outdoor unit control pcb ......................................................................................... 4-8 4-3. Outdoor u...

Page 92

4-2 4 4-1. Control functions 1. Indoor air temprature control the thermostat is switched on and off in accordance with t shown below. T= (indoor air temperature) - (temperature set with the remote controller) in the body thermostat mode (setting at factory shipment) indoor air temperature = (body se...

Page 93

4-3 4 max. (c2, c1) a 64 b c d 2) maximum and minimum frequency control the compressor's inverter frequency is controlled in accordance with the model and operation mode. The maximum and minimum frequencies for each model are shown in the chart below. * there are cases in which frequency is limited ...

Page 94

4-4 4 max. (e1, e2) 58 53(52) 48 l m ( * ) i h a j e1 (or e2) 22 17 5 2 5) heating high-load prevention control the following control is performed in the heating mode in accordance with the indoor heat exchanger temperature max (e1, e2). (see the chart below.) (1) the operational frequency of the co...

Page 95

4-5 4 frost adherence detection • if the following conditions are satisfied during heating operations, it is regarded as "frost adherence is detected". • frost adherence detection is performed in accordance with the outdoor air temperature (to) and the outdoor heat exchanger temperature sensor (c1)....

Page 96

4-6 4 heating mask time this refers to the shortest time that heating operations must be performed without defrosting operations being executed. The mask time for this model is 25 minutes. * defrosting operations will not be commenced until the defrosting mask time has elapsed, even if frost adheren...

Page 97

4-7 4 12) demand control there are two styles of demand operations available as methods of restraining power consumption. (1) demand via external input demand input from an external source is carried out from the outdoor unit exct (cn030) pcb or the outdoor unit's serial/parallel i/o (optional). • d...

Page 98

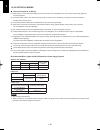

4-8 4 4-2. Outdoor unit control pcb layout diagram (cr-c906vh8p) fuse (f101) rc_p (cn039) led2 led1 mode (cn038) r.C.Add s002 s003 eeprom memory ic test (cn033) exct (cn030) silent (cn037) pump down (cn048) sensor at upper side of heat exchanger (c2) sensor at lower side of heat exchanger (c1) a.Add...

Page 99

4-9 4 4-3. Outdoor unit filter pcb fil-c906vh8 sm830194-03̲bigpac-i.Indb 9 sm830194-03̲bigpac-i.Indb 9 2012/10/11 20:59:21 2012/10/11 20:59:21.

Page 100

4-10 4 4-4. Outdoor unit hic board hic-c906vh8 sm830194-03̲bigpac-i.Indb 10 sm830194-03̲bigpac-i.Indb 10 2012/10/11 20:59:27 2012/10/11 20:59:27.

Page 101

4-11 4 4-5. Outdoor unit control pcb (cr-c906vh8p) explanation of functions auto address pin (cn047) 2p (white): automatic address setting switch • if the system address switch (s002: set to 0 at time of shipment) setting is other than “0”(central control), press this switch once to automatically se...

Page 102

4-12 4 quiet mode plug (cn037) 2p plug (white): enables operation in quiet mode. • • the outdoor unit fan and compressor frequencies are subject to limits during operation. Low-noise operation is enabled when the relay is turned on. (non-voltage contact "a" ) • example of wiring note 2:the maximum l...

Page 103

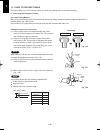

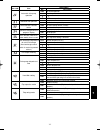

4-13 4 1(l) 2(n) power supply u1 inter-unit control wiring u2 remote controller r1 r2 indoor unit 7p terminal board 4-6. Indoor unit control pcb switches and functions [indoor unit control pcb] t10 (cn061): 6p plug (yel) / used for remote control operation. (refer to the remote control section.) con...

Page 104

4-14 4 for ac fan motor (cr-uxrp71b-p) x emg (cn044) disp (cn072) chk (cn071) t10 (cn061) exct (cn073) grl (cn020) jp001 fan drive (cn032) power led (d002) oc (cn040) eeprom (ic010) sm830194-03̲bigpac-i.Indb 14 sm830194-03̲bigpac-i.Indb 14 2012/10/11 20:59:34 2012/10/11 20:59:34.

Page 105: 5. Service Procedures

5-1 5 5. Service procedures 5-1. Meaning of alarm messages ........................................................................................ 5-2 5-2. Contents of led display on the outdoor unit control pcb ..................................... 5-4 5-3. Symptoms and parts to inspect .............

Page 106

5-2 5 5-1. Meaning of alarm messages 1. Contents of the alarm display on the remote controller on: blinking: off: possible cause of malfunction display wireless remote controller lamp display operation timer preparing serial commu- nication errors mis-setting remote controller is detecting error sig...

Page 107

5-3 5 on: blinking: off: possible cause of malfunction display wireless remote controller lamp display operation timer preparing ceiling panel connection failure p09 activation of protective device indoor protection fan protective thermostat p01 float switch p10 dc fan error. P12 outdoor protection ...

Page 108

5-4 5 5-2. Contents of led display on the outdoor unit control pcb led 1 led 2 remarks power on sequence 1. No communication from indoor units in system 2. Communication received from 1 or more indoor units in system 3. Regular communication ok (capacity and unit quantity match) if it is not possibl...

Page 109

5-5 5 5-3. Symptoms and parts to inspect remote controller alarm display alarm contents judgement conditions eliminating condition of alarm judgement and correction p03 abnormal discharge temperature error. •discharge temp. Detected at or above the specifi ed value. Stops when temp. Exceeds 115 . Al...

Page 110

5-6 5 remote controller alarm display alarm contents judgement conditions eliminating condition of alarm judgement and correction p29 error in current detection circuit. •ac current value is high, even while compressor is halted. Inverter halted after alarm detected. Alarm output on 4 consecutive (p...

Page 111

5-7 5 remote controller alarm display alarm contents judgement conditions eliminating condition of alarm judgement and correction e14 settings failure main unit in simultaneous operation multi control duplicated. (outdoor unit detected) power reset recovery 1.Check inter-unit control wiring. 2.Check...

Page 112

5-8 5 no no yes yes yes yes yes yes yes yes yes no no no no no 5-4. Details of alarm messages alarm details (1-1) [alarm “p29”] start-up failure of the compressor (will not start up) related parts • hic pcb (model: [u-200pe1e8, u-250pe1e8] hic-c906vh8) • outdoor unit control pcb (model: [u-200pe1e8,...

Page 113

5-9 5 no start of defect diagnosis no no no 1. Potential causes • refrigerant overcharge has the refrigerant been overcharged? *verifying overcharge there is no problem if the difference between the temperature on the indoor unit "e2" and the saturated temperature of the outdoor unit's gas pipe serv...

Page 114

5-10 5 hic-c906vh8 resistance between terminals resistance between terminals resistance tester terminal (+) tester terminal (-) tester terminal (+) tester terminal (-) hic + hic + hic + hic + hic – 5 k ~ 10 k hic – hic – hic – hic – hic + 100 k 100 k 100 k 100 k ~ u 1 k ~ 5 k u u ~ v 1 k ~ 5 k v v ~...

Page 115

5-11 5 (4) [alarm "p22"] outdoor unit fan motor drive circuit trouble no are the connectors cn003, cn005, cn041 and cn042 connected correctly to the outdoor unit control pcb? Yes start of defect diagnosis does the fan rotate without resistance when spun manually after the connectors cn003, cn005, cn...

Page 116

5-12 5 (5) [alarms “f04,” “f06,” “f07,” “f08,” “f12”] sensor trouble no are the connectors of the sensor 020 (c2), 021 (c1), 022 (ts), 023 (to) and 024 (td) connected correctly to the outdoor unit control pcb ? Yes start of defect diagnosis correct the connections. Are the characteristics of resista...

Page 117

5-13 5 sensor temperature display function (displayed regardless of operation and stop) the below check procedure can be used to display all remote controller, indoor unit, and outdoor unit sensor temperatures. (1) press and hold the button and button simultaneously for 4 seconds or longer. (2) unit...

Page 118

5-14 5 40 35 30 25 20 15 10 5 0 -20 -15 -10 - 5 0 5 10 15 20 8 7 6 5 4 3 2 1 0 20 30 40 50 60 0 10 20 30 40 50 60 70 80 90 100 110 0 40 60 80 100 120 140 160 180 200 20 5-5. Table of thermistor characteristics (1) outdoor air temp. (to) sensor, intake temp. (ts) sensor, heat exchanger temp. (c1) sen...

Page 119

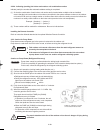

5-15 5 5-6. How to remove the compressor pay careful attention to prevent water or foreign objects from entering into the refrigerant tubing when removing or installing the compressor. Removing 1.After collecting the refrigerant in the system, replace nitrogen gas from the service port of the gas tu...

Page 120

5-16 5 5-7. How to remove the electrical component box removing 1.Remove the front panel and inspection panel from the outdoor unit. 2.Remove all local wires connected to the electrical component box. 3.Remove the wires (temperature sensor, coils of every sort of valve, pressure switch, fan motor an...

Page 121

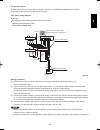

5-17 5 1-1 adjust setting temperature 1-2 yes no connect correctly 1-3 yes no 1 check if the sensors are connected correctly. Are all connection made properly? Room temp. (ta) in yellow, heat exchanger (e1) in red, heat exchanger (e2) in black, heat exchanger (e3) in brown, air outlet (bl) in green ...

Page 122: – Memo –

– memo – 5-18 sm830194-00.Indb 18 sm830194-00.Indb 18 2011/11/15 23:10:59 2011/11/15 23:10:59.

Page 123

6-1 6 6. Outdoor unit maintenance remote control 6-1. Overview ..................................................................................................................... 6-2 6-2. Functions .......................................................................................................

Page 124

6-2 6 6-1. Overview what is the outdoor unit maintenance remote controller? Beginning with the dc-inv series of outdoor units, nonvolatile memory (eeprom) is used in the outdoor unit pcb. In this way, the setting switches that were located on earlier pcbs have been converted to eeprom data. This rem...

Page 125

6-3 6 * it is not necessary to disconnect the communications line in the inter-unit control wiring if it has already been con- nected at this time. * setting modes 1 and 2 can be used even when the outdoor unit is independent (when 1 maintenance remote con- troller is connected to 1 outdoor unit and...

Page 126

6-4 6 display (functions) • use the temperature setting and buttons to change the item code. Item code display contents remarks 00 (1) outdoor unit alarm contents (code): off when normal blinking 8-alarm code display at pre-trip, led (2) at initial status 01 no. Of indoor units connected in that ref...

Page 127

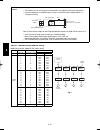

6-5 6 — — — — — — — — 1 2 7 12 17 3 13 18 8 4 14 19 9 5 10 15 20 6 11 16 21 22 27 32 37 23 33 38 28 24 34 39 29 25 30 35 40 26 31 36 *2: 7-segment, 4-digit display for remote controller timer display the connected unit nos. Are displayed as shown below, using the 7-segment 4-digit ( ) display and th...

Page 128

6-6 6 6-4. Monitoring operations: display of indoor unit and outdoor unit sensor temperatures (1) press and hold the button and button simultaneously for 4 seconds or longer to switch to temperature monitor mode. During temperature monitoring, “service monitor” is lit. (the display and operations ar...

Page 129

6-7 6 6-5. Monitoring the outdoor unit alarm history: display of outdoor unit alarm history displays outdoor unit alarms only. Does not display indoor unit alarms. Check the indoor unit alarm histories separately using the indoor unit remote controllers or other control device. (1) press and hold th...

Page 130

6-8 6 list of item codes (some item codes cannot be set due to the type of models.) item code parameter 01 control system schedule do not set 02 control system schedule do not set 03 control system schedule do not set 04 snowfall sensor operation 0 = no sensor, control performed 1 = no sensor, contr...

Page 131

6-9 6 setting mode 2 (1) press and hold the button, button, and button simultaneously for 4 seconds or longer. (2) use the temperature setting and buttons to change the item code. The item codes and setting data are shown in the table below. (3) use the timer time and buttons to change the setting d...

Page 132: – Memo –

– memo – 6-10 sm830194-00.Indb 10 sm830194-00.Indb 10 2011/03/30 17:20:26 2011/03/30 17:20:26.

Page 133

7 7-1. Simple settings function .......................................................................................... 7-2 7-2. List of simple setting items ...................................................................................... 7-3 7-3. Detailed settings function ...................

Page 134

7 7-1. Simple settings function this allows the filter lifetime, operating mode priority change, central control address, and other settings to be made for an individual or group- control indoor unit to which the remote controller used for simple settings is connected. When simple settings mode is e...

Page 135

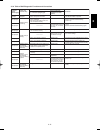

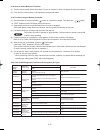

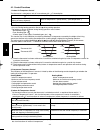

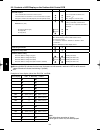

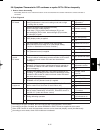

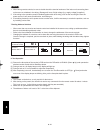

7 7-2. List of simple setting items item code item setting data no. Description filter sign on time (filter life time) 0000 not displayed 0001 150 hours 0002 2,500 hours 0003 5,000 hours 0004 10,000 hours 0005 use the filter clogging sensor. Degree of filter fouling 0000 standard (setting at time of...

Page 136

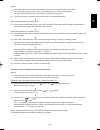

7 this allows the system address, indoor unit address, and other settings to be made for the individual or group-control indoor unit to which the remote controller used for detailed settings is connected. When detailed settings mode is engaged, operation stops at the individual or group-control indo...

Page 137

7 item code item setting data no. Description no. Description no. Description type 0000 0001 0002 0003 0005 0006 high static pressure ducted (e1) 0007 0008 0010 0011 indoor unit capacity 0001 0003 0005 0007 0009 0011 0012 0015 0017 0018 0021 224 (type 200) 0023 280 (type 250) system address 0001 uni...

Page 138

7 item code item setting data no. Description (1b) forced thermostat on 0000 5 minutes 0001 4 minutes cooling discharge temperature shift –010 –10°c –009 –9°c –008 –8°c 0010 10°c heating discharge temperature shift –010 –10°c –009 –9°c –008 –8°c 0010 10°c temperature shift for cooling/heating change...

Page 139

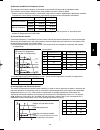

7 item code item setting data no. Description automatic drain pump operation 0000 no forced operation 0001 forced operation for 1 minute 0060 continuous operation ventilation fan operation 0000 none 0001 ventilation fan operated by remote controller. Wired remote controller sensor 0000 not used. (bo...

Page 140

7 item code item setting data no. Description fan tap setting (fan tap change in order to prevent drop in air discharge caused by filter installation) dc fan tap operating mode purpose 0000 standard standard (setting at shipment) 0001 high ceiling use high ceiling setting 1 (with standard panel) for...

Page 141

7 description item item code description item item code 01 filter sign on time setting (filter lifetime) changes the indoor unit filter lifetime when a high-performance filter or other optional product is installed. 02 degree of filter fouling reduces the filter sign on time to 1/2 of the standard t...

Page 142

7 when the operating mode at the priority remote controller is changed, the operating modes of other remote controllers change as shown below. Mode change at priority remote controller operating modes at other remote controllers current mode new mode current mode new mode cooling or dry heating cool...

Page 143

7 item code item description 10 unit type set when the indoor unit eeprom memory is replaced during servicing. 11 indoor unit capacity 12 system (outdoor unit) address these are not set at the time of shipping from the factory. These must be set after installation if automatic address setting is not...

Page 144

7 item code item description 1f (upper limit) 20 (lower limit) change to the remote control temperature setting range cooling this setting changes the temperature range (upper limit and lower limit) which is set from the remote controller or central control device. The set upper limit must be greate...

Page 145

7 (continued from previous page) item code item description 3c heat exchanger temperature for cold air discharge the heat exchanger temperature control point for prevention of cold air discharge during heating operation can be changed. 3d fan output switching the indoor unit pcb optional output for ...

Page 146

7 7-7. Remote controller servicing functions the remote controller includes a number of servicing functions. Use these as needed for test runs and inspections. List of servicing functions functions description button operation reset operation unit status test run operation with forced thermostat on ...

Page 147

7 the procedure below displays the sensor temperatures from the remote controller, indoor unit, and outdoor unit on the remote controller. 1 press and hold the and buttons simultaneously for 4 seconds or longer. 2 the unit no. “x-x” (main unit no.), item code “xx” (sensor address), and servicing mon...

Page 148: – Memo –

– memo – 7-16 sm830194-00.Indb 16 sm830194-00.Indb 16 2011/03/30 17:21:32 2011/03/30 17:21:32.

Page 149

8 warning 8-1. Warning about installation of receivers .................................................................... 8-2 8-2 8-3 8-3 8-5 8-5 8-5 8-6 8-7 8-7 8-7 8-8 8-8 8-9 8-9 8-10 8-10 8-2. Warning about installing remote controls ...............................................................

Page 150

8 warning 8-1. Warning about installation of receivers the wireless remote uses a very weak infrared light for its signal, which can result in the signal not being received because of the following influences, so take care in where the unit is installed. · inverter or rapid-start type fluorescent ...

Page 151

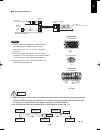

8 optional controller (remote controller) wireless remote controller / cz-rwsc2 one remote control can control a group of up to eight indoor units. 8-3. Names and functions remote controller 1. Operation display displays the operation status. (the figure shows all the statuses.) 2. Start/stop button...

Page 152

8 1. Receiver receives the signal sent from the remote control. 2. Emergency operation button display lamps when an error occurs, one of the lamps flashes. When a display lamp is blinking, refer to " before requesting service ". 3. This lamp is lit when the unit is operating. 4. This lamp is lit whe...

Page 153

8 8-4. Installing batteries 1. Remove the cover. 2. Insert two aaa alkaline batteries. Put the batteries in with the polarity [+/–] as shown in the figure. 3. Gently insert one end of an unfolded paper clip (or a similar object that can fit) into the reset hole and press the reset button inside the ...

Page 154

8 8-7. Timer operation • • • when setting the timer, make sure the current time on the remote control is accurate. The timer’s clock can only be set when the display of the remote control is on. After setting the timer, put the remote control in a place where its signal will reach the receiver of th...

Page 155

8 8-9. Operating multiple in/outdoor units simultaneously (group control) group control works well for providing air conditioning to one, large room with more than one air conditioning units. • • • one remote control can operate up to eight indoor units. All the indoor units have identical settings....

Page 156

8 address display on the remote control cz-rwsc.2 position of the receiver’s address switch the position of the receiver’s address switch does not matter. For 1, 2 and 3, set the switch on the left and for 4, 5 and 6, to the right. Note • please do not hold the [emergency operation] button of the in...

Page 157

8 8-13. Emergency operation use [emergency operation] in the following situations when there is an urgent need. • when the remote control's batteries have failed. • when the remote control is broken. • when the remote control is lost. 1. Press [emergency operation] of the receiver if the indoor temp...

Page 158

8 8-15. Before requesting service before requesting service, please check the followings. Solution cause problem the unit doesn’t work even when is pressed on the remote control. The power to the indoor unit is not on. Make sure the power to the indoor unit is on. Is the normal/stop all switch in th...

Page 159

8 3. Things to remember when wired and wireless remotes are installed at the same time two remote controls can be used to control the unit if the wireless remote control kit is installed at the same time as the wired remote control. (up to 2 remotes [a wireless remote kit and the wired remote contro...

Page 160

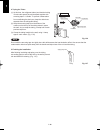

8 4. Accessories no. Accessories quantity 1 receiver (enclosed 200 mm wiring) 1 2 1 3 remote controller's holder 1 4 remote controller aaa alkaline batteries 2 no. Accessories quantity 5 users manual 1 6 truss self-tapping screws 4 x 16 2 7 machine screws 2 8 2 9 wood screws cable tie 1 5. Installin...

Page 161

8 when using a receiver that has been installed separately into the ceiling, use the enclosed fittings for installing to a ceiling. (1) remove the metal plate of the receiver by slipping a flathead screwdriver or the like into the cut-out on the bottom. (2) cut out a hole in the ceiling to match the...

Page 162

8 7. Setting address switches • them to avoid interfering with each other. • • when more than one receiver and remote control are installed in the same room, setting up addresses allows refer to the users manual for information on how to change the addresses of the remote controls. Changing the addr...

Page 163

8 9. The self-diagnosis function display and what is detected alarm display in the table below indicates the content of alarms that are displayed when a wired remote control is connected. For information on how to deal with the alarms, refer to the mounting instructions for the indoor unit or to tes...

Page 164

8 1 4 3 2 6 11. Setting up remote control functions the functions of the wireless remote can be set on site. (these settings are saved in nonvolatile memory in the remote control, so even when its batteries are changed, the settings do not revert to the defaults.) note the operation of the air condi...

Page 165

201210 sm830194-03̲bigpac-i.Indb 1 sm830194-03̲bigpac-i.Indb 1 2012/10/11 21:01:19 2012/10/11 21:01:19.