- DL manuals

- Panasonic

- Inverter

- : S-26PU1U6

- Technical Data & Service Manual

Panasonic : S-26PU1U6 Technical Data & Service Manual

85464849303001

REFERENCE NO

.

SM830203-01

TECHNICAL DATA

&

SERVICE MANUAL

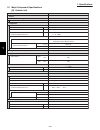

Model No.

Outdoor Units

Remarks

Remarks

42

36

26

42

36

26

Type

Type

U

Single

U-26PE1U6

U-36PE1U6

U-42PE1U6

Cooling/Heating

U-26PS1U6

U-36PS1U6

U-42PS1U6

Cooling

Indoor Units

Indoor Units Type

Outdoor Units

U1

K1

4-Way Cassette

S-26PU1U6

S-36PU1U6

S-42PU1U6

with Wired Remote Controller: CZ-RTC2

with Wireless Remote Controller: CZ-RWSK1U

S-26PK1U6

Wall Mounted

T1

Ceiling

S-26PT1U6

S-36PT1U6

S-42PT1U6

with Wired Remote Controller: CZ-RTC2

with Wired Remote Controller: CZ-RTC2

S-36PF1U6

S-26PF1U6

Low Silhouette Duct

F1

Outdoor Unit

Shows S-26PU1U6

Shows U-26PE1U6

Indoor Unit

SM830203-01̲PAC-i̲US-letter.indb1 1

SM830203-01̲PAC-i̲US-letter.indb1 1

2012/01/20 13:46:35

2012/01/20 13:46:35

Summary of : S-26PU1U6

Page 1

85464849303001 reference no . Sm830203-01 technical data & service manual model no. Outdoor units remarks remarks 42 36 26 42 36 26 type type u single u-26pe1u6 u-36pe1u6 u-42pe1u6 cooling/heating u-26ps1u6 u-36ps1u6 u-42ps1u6 cooling indoor units indoor units type outdoor units u1 k1 4-way cassette...

Page 2

Important! Please read before starting this air conditioning system meets strict safety and oper- ating standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently. For safe installation and trouble-free op...

Page 3

Check of density limit the room in which the air conditioner is to be installed requires a design that in the event of refrig- erant gas leaking out, its density will not exceed a set limit. The refrigerant (r410a), which is used in the air condition- er, is safe, without the toxicity or combustibil...

Page 4

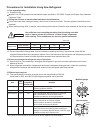

Precautions for installation using new refrigerant 1. Care regarding tubing 1-1. Process tubing material: use c1220 phosphorous deoxidized copper specified in jis h3300 “copper and copper alloy seamless pipes and tubes.” tubing size: be sure to use the sizes indicated in the table below. Use a tube ...

Page 5

Iv 3-2. Use r410a exclusive cylinder only. When charging with a refrigerant cylinder, use an electronic scale for charging refrigerant. In this case, if the volume of refrigerant in the cylinder becomes less than 20% of the fully-charged amount, the composition of the refrigerant starts to change. T...

Page 6: Contents

Vi section 1: specifications ..................................................................................................... 1-1 1-1 unit specifications .............................................................................................. 1-2 1-2 major component specifications ..........

Page 7: 1. Specifications

1. Specifications 1-1. Unit specifications.................................................................................................... 1-2 1-2. 1-20 major component specifications .......................................................................... 1-63 1-3. 1-35 other component specif...

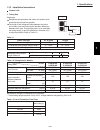

Page 8

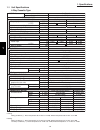

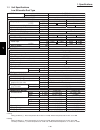

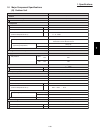

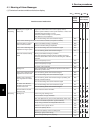

1-2 1. Specifications 1-1 unit specifications 4-way cassette type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp con...

Page 9

1-3 1. Specifications 1-1 unit specifications 4-way cassette type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp con...

Page 10

1-4 1. Specifications 1-1 unit specifications 4-way cassette type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp con...

Page 11

1-5 1. Specifications 1-1 unit specifications 4-way cassette type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp con...

Page 12

1-6 1. Specifications 1-1 unit specifications 4-way cassette type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp con...

Page 13

1-7 1. Specifications 1-1 unit specifications 4-way cassette type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp con...

Page 14

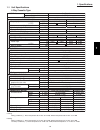

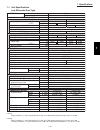

1-8 1. Specifications 1-1 unit specifications wall mounted type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp condi...

Page 15

1-9 1. Specifications 1-1 unit specifications wall mounted type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low temp condi...

Page 16

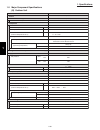

1-10 1. Specifications 1-1 unit specifications ceiling type s-26pt1u6 t i n u r o o d n i u-26pe1u6 t i n u r o o d t u o power source 230 - 208 v / 1 phase / 60 hz performance cooling heating capacity * [minimum~muximum] btu / h 24,400 [9,500~24,400] 30,800 [8,000~30,800] 0 0 9 , 7 1 h / u t b * * ...

Page 17

1-11 1. Specifications 1-1 unit specifications ceiling type s-36pt1u6 t i n u r o o d n i u-36pe1u6 t i n u r o o d t u o power source 230 - 208 v / 1 phase / 60 hz performance cooling heating capacity * [minimum~muximum] btu / h 31,200 [9,500~31,200] 37,400 [8,000~37,400] 0 0 0 , 1 2 h / u t b * * ...

Page 18

1-12 1. Specifications 1-1 unit specifications ceiling type s-42pt1u6 t i n u r o o d n i u-42pe1u6 t i n u r o o d t u o power source 230 - 208 v / 1 phase / 60 hz performance cooling heating capacity * [minimum~muximum] btu / h 39,000 [9,500~39,000] 44,500 [8,000~44,500] 0 0 8 , 8 2 h / u t b * * ...

Page 19

1-13 1. Specifications 1-1 unit specifications ceiling type s-26pt1u6 t i n u r o o d n i u-26ps1u6 t i n u r o o d t u o power source 230 - 208 v / 1 phase / 60 hz performance cooling capacity * [minimum~muximum] btu / h 24,400 [9,500~24,400] (17˚f)** btu / h 7 . 7 h / s t n i p ) h g i h ( l a v o...

Page 20

1-14 1. Specifications 1-1 unit specifications ceiling type s-36pt1u6 t i n u r o o d n i u-36ps1u6 t i n u r o o d t u o power source 230 - 208 v / 1 phase / 60 hz performance cooling capacity * [minimum~muximum] btu / h 31,200 [9,500~31,200] (17˚f)** btu / h 0 . 0 1 h / s t n i p ) h g i h ( l a v...

Page 21

1-15 1. Specifications 1-1 unit specifications ceiling type s-42pt1u6 t i n u r o o d n i u-42ps1u6 t i n u r o o d t u o power source 230 - 208 v / 1 phase / 60 hz performance cooling capacity * [minimum~muximum] btu / h 39,000 [9,500~39,000] (17˚f)** btu / h 6 . 2 1 h / s t n i p ) h g i h ( l a v...

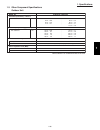

Page 22

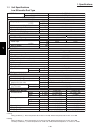

1-16 1. Specifications 1-1 unit specifications low silhouette duct type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low te...

Page 23

1-17 1. Specifications 1-1 unit specifications low silhouette duct type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low te...

Page 24

1-18 1. Specifications 1-1 unit specifications low silhouette duct type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low te...

Page 25

1-19 1. Specifications 1-1 unit specifications low silhouette duct type cooling: rating conditions (*) : room temperature 80 °f db / 67 °f wb, ambient temperature 95 °f db / 75 °f wb heating: rating conditions (*) : room temperature 70 °f db / 60 °f wb, ambient temperature 47 °f db / 43 °f wb low te...

Page 26

1-20 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-26pu1u6 source 230 - 208 vac / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specifications) controller p. C. B ass'y cr-26pu1u6-p control circuit fuse 250 vac, 5 a fan (number ...

Page 27

1-21 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-36pu1u6 source 230 - 208 vac / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specifications) controller p. C. B ass'y cr-26pu1u6-p control circuit fuse 250 vac, 5 a fan (number ...

Page 28

1-22 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-42pu1u6 source 230 - 208 vac / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specifications) controller p. C. B ass'y cr-26pu1u6-p control circuit fuse 250 vac, 5 a fan (number ...

Page 29

1-23 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-26pk1u6 source 230 - 208 v / 1 phase / 60 hz remote controller ( optional / supplied) wired / wireless (see unit specifications) controller p. C. B ass'y cb-kr254gxh56a a 5 , v 0 5 2 e s u f t i u c r i c l o r t n...

Page 30

1-24 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-26pt1u6 source 230 - 208 v / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specification) controller p. C. B ass'y cr - th2672 control circuit fuse 250 v, 5 a fan (number … diam...

Page 31

1-25 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-36pt1u6 source 230 - 208 v / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specification) controller p. C. B ass'y cr - th2672 control circuit fuse 250 v, 5 a fan (number … diam...

Page 32

1-26 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-42pt1u6 source 230 - 208 v / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specification) controller p. C. B ass'y cr - th2672 control circuit fuse 250 v, 5 a fan (number … diam...

Page 33

1-27 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-26pf1u6 source 230 - 208 v / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specification) controller p. C. B ass'y cr - th2672 control circuit fuse 250 v, 5 a fan (number … diam...

Page 34

1-28 1. Specifications 1-2 major component specifications (a) indoor unit model no. S-36pf1u6 source 230 - 208 v / 1 phase / 60 hz remote controller (supplied / optional) wired / wireless (see unit specification) controller p. C. B ass'y cr - th2672 control circuit fuse 250 v, 5 a fan (number … diam...

Page 35

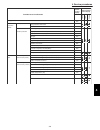

1-29 1. Specifications 1-2 major component specifications (b) outdoor unit model no. Source controller p.C.B. Ass'y control circuit fuse (on the p.C.B.“fil-ch4872r”) compressor model....Number w t u p t u o l a n i m o n c c li o r o s s e r p m o c coil resistance Ω c – r : 0.665 r – s : 0.665 (amb...

Page 36

1-30 1. Specifications 1-2 major component specifications (b) outdoor unit model no. Source controller p.C.B. Ass'y control circuit fuse (on the p.C.B.“fil-ch4872r”) compressor model....Number w t u p t u o l a n i m o n c c li o r o s s e r p m o c coil resistance Ω c – r : 0.665 r – s : 0.665 (amb...

Page 37

1-31 1. Specifications 1-2 major component specifications (b) outdoor unit model no. Source controller p.C.B. Ass'y compressor model....Number w t u p t u o l a n i m o n c c li o r o s s e r p m o c coil resistance Ω c – r : 0.169 r – s :0.169 (ambient temperature 25 ° c ) c – s :0.169 safety contr...

Page 38

1-32 1. Specifications 1-2 major component specifications (b) outdoor unit model no. Source controller p.C.B. Ass'y compressor model....Number w t u p t u o l a n i m o n c c li o r o s s e r p m o c coil resistance Ω c – r : 0.665 r – s : 0.665 (ambient temperature 25 ° c ) c – s : 0.665 safety con...

Page 39

1-33 1. Specifications 1-2 major component specifications (b) outdoor unit model no. Source controller p.C.B. Ass'y compressor model....Number w t u p t u o l a n i m o n c c li o r o s s e r p m o c c e c n a t s i s e r li o c – r : 0.665 r – s : 0.665 (ambient temperature 25 ° c ) c – s : 0.665 s...

Page 40

1-34 1. Specifications 1-2 major component specifications (b) outdoor unit model no. Source controller p.C.B. Ass'y compressor model....Number w t u p t u o l a n i m o n c c li o r o s s e r p m o c c e c n a t s i s e r li o c – r : 0.169 r – s :0.169 (ambient temperature 25 ° c ) c – s :0.169 saf...

Page 41

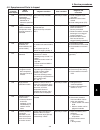

1-35 1. Specifications 1-3 other component specifications outdoor unit u-26pe1u6, u-26ps1u6 . O n l e d o m thermistor (coil sensor) : th2 to 5 coil resistance k Ω 14 °f : 23.7 , 50 °f : 9.7 23 °f : 18.8 , 68 °f : 6.5 32 °f : 15.0 , 86 °f : 4.4 41 °f : 12.1 , 104 °f : 3.1 113 °f : 2.6 thermistor (co...

Page 42

1-36 1. Specifications 1-3 other component specifications outdoor unit u-36pe1u6, u-36ps1u6 . O n l e d o m thermistor (coil sensor) : th2 to 5 coil resistance k Ω 14 °f : 23.7 , 50 °f : 9.7 23 °f : 18.8 , 68 °f : 6.5 32 °f : 15.0 , 86 °f : 4.4 41 °f : 12.1 , 104 °f : 3.1 113 °f : 2.6 thermistor (co...

Page 43

1-37 1. Specifications u-42pe1u6, u-42ps1u6 . O n l e d o m thermistor (coil sensor) : th2 to 5 coil resistance k Ω 14 °f : 23.7 , 50 °f : 9.7 23 °f : 18.8 , 68 °f : 6.5 32 °f : 15.0 , 86 °f : 4.4 41 °f : 12.1 , 104 °f : 3.1 113 °f : 2.6 thermistor (comp. Discharge gas sensor) : th6 coil resistance ...

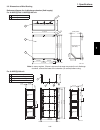

Page 44

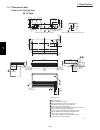

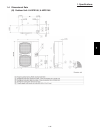

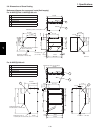

1-38 1. Specifications 1-4 dimensional data indoor unit : 4-way cassette type 26 type 33-27/32 3-15/16 30-9/16 19-11/16 19-11/16 12-1/8 1-3/16 4-7/8 15/32 15/32 1-7/8 33-27/32 32-9/32 (ceiling opening) grille center 29-13/16 (suspention bolt pitch) 14-1/2 1 air intake grille air outlet refrigerant l...

Page 45

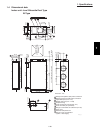

1-39 1. Specifications 1-4 dimensional data indoor unit : 4-way cassette type 36, 42type 45-9/32 41-31/32 31-3/32 19-11/16 13-5/16 1-3/16 4-7/8 15/32 15/32 1-7/8 33-27/32 32-9/32 (ceiling opening) grille center 29-13/16 (suspention bolt pitch) 20-3/16 1 air intake grille air outlet refrigerant liqui...

Page 46

1-40 1. Specifications 1-4 dimensional data dimension : inch refrigerant liquid line (3/8") flare connection refrigerant gas line (5/8") flare connection drain hose od 45/64 drain and wiring port (3-5/32) indoor unit : wall mounted type 1 sm830203-01̲pac-i̲us-letter.Indb40 40 sm830203-01̲pac-i̲us-le...

Page 47

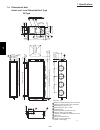

1-41 1. Specifications 1-4 dimensional data indoor unit : ceiling type 26 type drain connection drain connection for left side refrigerant liquid line (3/8") flare connection refrigerant gas line (5/8") flare connection hole for rear side refrigerant tubing hole for through-the-wall refrigerant tubi...

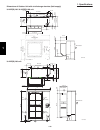

Page 48

1-42 1. Specifications 1-4 dimensional data indoor unit : ceiling type 36, 42 type drain connection drain connection for left side refrigerant liquid line (3/8") flare connection refrigerant gas line (5/8") flare connection hole for rear side refrigerant tubing hole for through-the-wall refrigerant ...

Page 49

1-43 1. Specifications 1-4 dimensional data indoor unit : low silhouette duct type 26 type refrigerant liquid line (3/8") flare connection refrigerant gas line (5/8") flare connection upper drain port (o.D. 1-1/4) bottom drain port (o.D. 1-1/32) suspension lug power supply inlet (conduit size 1/2") ...

Page 50

1-44 1. Specifications 1-4 dimensional data indoor unit : low silhouette duct type 36 type refrigerant liquid line (3/8") flare connection refrigerant gas line (5/8") flare connection upper drain port (o.D. 1-1/4) bottom drain port (o.D. 1-1/32) suspension lug power supply inlet (conduit size 1/2") ...

Page 51

1-45 1. Specifications 23/32 1-7/32 f g h g f 11/32 e d b (o.D.) a (hole) c-ø1/8 (hole) 1/4 (hole) 12-1/32 10-1/4 (o.D.) 29/32 7-7/8 1-25/32 5/16 1-25/32 31/32 13/32 2118_u_i 2-ø1/8 13/32 31/32 8-9/32 31/32 a b c* * ø 1/8 number of holes d e f g h i 26 type 39-9/32 37-7/8 5 7-3/32 5 × 7-3/32 = 35-7/...

Page 52

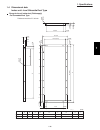

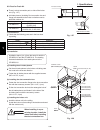

1-46 1. Specifications 1-4 dimensional data (b) outdoor unit: u-26pe1u6, u-26ps1u6 u-36pe1u6, u-36ps1u6 1 sm830203-01̲pac-i̲us-letter.Indb46 46 sm830203-01̲pac-i̲us-letter.Indb46 46 2012/01/19 22:39:25 2012/01/19 22:39:25.

Page 53

1-47 1. Specifications 1-4 dimensional data (b) outdoor unit: u-42pe1u6, u-42ps1u6 1 sm830203-01̲pac-i̲us-letter.Indb47 47 sm830203-01̲pac-i̲us-letter.Indb47 47 2012/01/19 22:39:25 2012/01/19 22:39:25.

Page 54

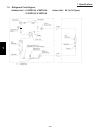

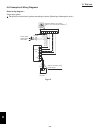

1-48 1. Specifications 1-5 refrigerant flow diagram outdoor unit : u-26pe1u6, u-26ps1u6 indoor unit : 26, 30, 36 types u-36pe1u6, u-36ps1u6 sm830203-00̲pac-i̲us-letter.Indb48 48 2011/11/09 20:22:21 1 sm830203-01̲pac-i̲us-letter.Indb48 48 sm830203-01̲pac-i̲us-letter.Indb48 48 2012/01/19 22:39:25 2012...

Page 55

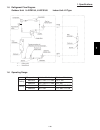

1-49 1. Specifications 1-5 refrigerant flow diagram outdoor unit: u-42pe1u6, u-42ps1u6 indoor unit: 42 type 1-6 operating range temperature indoor air intake outdoor air intake cooling maximum 90 °f db / 77 °f wb 115 °f db minimum 64 °f db / 57 °f wb 14 °f db heating maximum 86 °f db 64 °f wb / 75 °...

Page 56

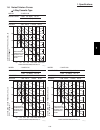

1-50 1. Specifications 1-7 capacity correction graph according to temperature condition u-26pe1u6, u-26ps1u6 u-36pe1u6, u-36ps1u6 u-42pe1u6, u-42ps1u6 1 sm830203-01̲pac-i̲us-letter.Indb50 50 sm830203-01̲pac-i̲us-letter.Indb50 50 2012/01/19 22:39:26 2012/01/19 22:39:26.

Page 57

1-51 1. Specifications 1-8 noise criterion curves 4-way cassette type model : s-26pu1u6 sound level : high 38 db(a), nc 31 low 31 db(a), nc 23 condition : center, under the unit 4.9 ft. Source : 208 - 230 v, 1 phase, 60 hz model : s-42pu1u6 sound level : high 45 db(a), nc 38 low 34 db(a), nc 27 cond...

Page 58

1-52 1. Specifications 1-8 noise criterion curves wall mounted type source : 208 - 230 v, 1 phase, 60 hz condition : distance 3.3 ft., under the unit 3.3 ft. S-26pk1u6 1 sm830203-01̲pac-i̲us-letter.Indb52 52 sm830203-01̲pac-i̲us-letter.Indb52 52 2012/01/19 22:39:26 2012/01/19 22:39:26.

Page 59

1-53 1. Specifications 1-8 noise criterion curves ceiling type model : s-26pt1u6 sound level : high 40 db(a), nc 34 low 36 db(a), nc 26 condition : distance 3.3 ft., under the unit 3.3 ft. Source : 208 - 230 v, 1 phase, 60 hz 60 50 40 30 20 10 octave band sound pressure level, db (0 db = 0.0002 bar)...

Page 60

1-54 1. Specifications 1-8 noise criterion curves low silhouette duct type model : s-26pf1u6 sound level : high 34 db(a), nc 22 / low 27 db(a), nc 18 condition : under the unit 4.9 ft. Source : 208 - 230 v, 1 phase, 60 hz 1761_u_i 60 50 40 30 20 10 approximate threshold of hearing for continuous noi...

Page 61

1-55 1. Specifications 1-8 noise criterion curves outdoor units remarks: 1. Value obtained in the actual place where the unit is installed may be slightly higher than the values shown in this graph because of the conditions of operation, the structure of the building, the background noise and other ...

Page 62

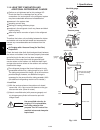

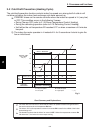

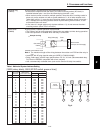

1-56 1. Specifications 1-9 increasing the fan speed jumper cable jumper cable electrical component box (at shipment) (jumper cable installed) 2159_m_i fan motor socket fan motor 900 air flow (cfm) external static pressure 0 50 0 0.1 0.2 0.3 0.4 0.5 150 700 500 300 limit line l 100 1982_u_i h hh (pa)...

Page 63

1-57 1. Specifications 1-10 air throw distance chart 4-way cassette type 0 3 7 10 13 17 20 0 3 7 10 13 horizontal distance (ft.) axis air velocity (ft./sec) ver tical dist ance (ft.) axis air velocity 2111_x_i model: 26 type model: 36, 42 type : louver angle 20˚ in cooling mode : louver angle 60˚ in...

Page 64

1-58 1. Specifications 1-10 air throw distance chart wall mounted type cooling - - - - - heating fan speed high high room air temp. 80 °f 70 °f flap angle 0 °, 22.5°, 45° 45 °, 67.5° axis air velocity (ft./sec.) vertical distance (ft.) horizontal distance (ft.) 10 13 5 0 model: 26 type 1 sm830203-01...

Page 65

1-59 1. Specifications 1-10 air throw distance chart ceiling type model: 26 type 0 3 7 10 13 17 20 23 26 29 33 0 3 7 10 13 17 horizontal distance (ft.) axis air velocity (ft./sec) ver tical dist ance (ft.) 2115_t_i axis air velocity model: 36 type 2116_t_i axis air velocity 0 3 7 10 13 17 20 23 26 2...

Page 66

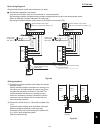

1-60 1. Specifications 1-11. Electrical wiring general precautions on wiring (1) as shown on its nameplate, then carry out the wiring closely following the wiring diagram. (2) before wiring, confirm the rated voltage of the unit provide a power outlet to be used exclusively for each unit, and a powe...

Page 67

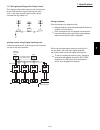

1-61 1. Specifications inter-unit power wiring power wiring inter-unit control wiring 8p terminal board outdoor unit indoor unit u1 u2 1 2 g l1 l2 wiring system diagrams basic wiring diagram for standard control note disconnect switch may be needed by the national/local code. Always comply with nati...

Page 68

1-62 1. Specifications warning loose wiring may cause the terminal to overheat or result in unit malfunction. A fire hazard may also exist. Therefore, ensure that all wiring is tightly connected. How to connect wiring to the terminal for stranded wiring (1) cut the wire end with a wire cutter or wir...

Page 69

1-63 1. Specifications 1-12. Installation instructions 1. Tubing size outdoor unit single type refrigerant tubing between the indoor and outdoor units should be kept as short as possible. The length of the refrigerant tubes between the indoor and outdoor units are limited by the elevation difference...

Page 70

1-64 1. Specifications caution 1. This unit requires no additional refrigerant charge up to 100 ft. Tubing length. In case of more than 100 ft., additional refrigerant charge is required. Refer to table 1-3. 2. In case of multi type installation, indoor units should be installed within the same room...

Page 71

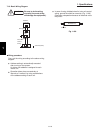

1-65 1. Specifications 3. Selecting the installation site 3-1. Outdoor unit avoid: heat sources, exhaust fans, etc. (fig. 1-3) damp, humid or uneven locations do: choose a place as cool as possible. Choose a place that is well ventilated and outside air temperature does not exceed maximum 115°f cons...

Page 72

1-66 1. Specifications 3-2. Air-discharge chamber for top discharge be sure to install an air discharge chamber in the field when: it is difficult to keep a space of min. 20" between the air discharge outlet and an obstacle. The air discharge outlet is facing a sidewalk and discharged hot air may bo...

Page 73

1-67 1. Specifications 3-5. Dimensions of wind ducting reference diagram for air-discharge chamber (fi eld supply) for u-26pe(s)1u6 / u-36pe(s)1u6 unit ① air discharge chamber ② air discharge chamber (base) for u-42pe(s)1u6 unit ① unit front, air discharge chamber ② unit left side, air discharge cha...

Page 74

1-68 1. Specifications dimensions of outdoor unit with air-discharge chamber (fi eld supply) u-26pe(s)1u6 / u-36pe(s)1u6 unit u-42pe(s)1u6 unit 13-3/8 2-17/32 21-13/16 1/2 6-11/16 25-31/32 4-5/16 2 / 1 2 / 1 14-31/32 15-15/16 19/32 2 3/ 5 2 2 3/ 5 2 13/32 wind direction wind directio n wind directio...

Page 75

1-69 1. Specifications reference diagram for air-discharge chamber (fi eld supply) u-26pe(s)1u6 / u-36pe(s)1u6 / u-42pe(s)1u6 required space around outdoor unit if the air discharge chamber is used, the space shown below must be secured around the outdoor unit. If the unit is used without the requir...

Page 76

1-70 1. Specifications 3-6. Dimensions of snow ducting reference diagram for snow-proof vents (fi eld supply) for u-26pe(s)1u6 / u-36pe(s)1u6 unit ① unit top, snow-proof vent ② unit left side ③ unit right side ④ unit reverse side ⑤ unit reverse side ⑥ unit sides, reinforcement brackets for snow-proo...

Page 77

1-71 1. Specifications dimensions of outdoor unit with snow-proof vents (fi eld supply) u-26pe(s)1u6 / u-36pe(s)1u6 unit u-42pe(s)1u6 unit 11-57/64 16-47/64 15-15/16 14-61/64 2 5/64 19/3 2 25/32 30-5/64 25-25/64 7-3/64 3/4 30-45/64 37-1/64 wind direction wind direction wind direction wind direction ...

Page 78

1-72 1. Specifications reference diagram for snow-proof vents – 1 space requirements for setting – (1) u-26pe(s)1u6 / u-36pe(s)1u6 / u-42pe(s)1u6 ] t i n u f o t n o r f e h t o t e l c a t s b o [ ] t i n u f o r a e r e h t o t e l c a t s b o [ : n e p o s i p o t : n e p o s i p o t top is block...

Page 79

1-73 1. Specifications reference diagram for snow-proof vents – 2 space requirements for setting – (2) u-26pe(s)1u6 / u-36pe(s)1u6 / u-42pe(s)1u6 [obstacles to the front and rear of unit] the top and both sides must remain open. Either the obstacle to the front or the obstacle to the rear must be no...

Page 80

1-74 1. Specifications 4. How to install the outdoor unit 4-1. Installing the outdoor unit use concrete or a similar material to create the base, and ensure good drainage. Ordinarily, ensure a base height of 2". Or more. If a drain pipe is used, or for use in cold-weather regions, ensure a height of...

Page 81

1-75 1. Specifications 5. Selecting the installation site 5-1. Indoor unit avoid: areas where leakage of flammable gas may be expected. Places where large amounts of oil mist exist. Direct sunlight. Locations near inverter lamps which may affect the performance of the unit. Locations near heat sourc...

Page 82

1-76 1. Specifications 6. How to install the indoor unit 4-way cassette type (u1 type) 6-1. Suspending the indoor unit this unit uses a drain pump. Use a level gauge to check that the unit is level. 6-2. Preparation for suspending (1) fix the suspension bolts securely in the ceiling using the method...

Page 83

1-77 1. Specifications 6-3. Placing the unit inside the ceiling (1) when placing the unit inside the ceiling, determine the pitch of the suspension bolts using the supplied full-scale installation diagram. (fig. 1-15) the size of the opening for the indoor unit can be confirmed by attaching the full...

Page 84

1-78 1. Specifications 6-4. Installing the drain piping (1) prepare standard hard pvc pipe for the drain and use the supplied drain hose and hose band to pre- vent water leaks. The pvc pipe must be purchased separately. The transparent part allows you to check drainage. (fig. 1-17) (2) after checkin...

Page 85

1-79 1. Specifications 6-5. Checking the drainage after wiring and piping are completed, use the follow- ing procedure to check that the water will drain smooth- ly. For this, prepare a bucket and wiping cloth to catch and wipe up spilled water. (1) take off the tube cover and through the opening, s...

Page 86

1-80 1. Specifications ceiling panel 6-6. Before installing the ceiling panel (1) remove the air-intake grille and air filter from the ceiling panel. (figs. 1-24 and 1-25) (a) remove the 2 screws on the latch of the air- intake grille. (fig. 1-24) (b) press on the 2 latches of the air-intake grille ...

Page 87

1-81 1. Specifications 6-7. Installing the ceiling panel (1) lift the ceiling panel and position it to align the panel hook with the panel catch of the indoor unit. Note the ceiling panel must be mounted in the correct direction. Note that the 2 catches of the panel differ in size. Confirm that the ...

Page 88

1-82 1. Specifications 6-9. Duct for fresh air there is a duct connection part on side of the indoor unit. (fig. 1-27) (1) accessories check that the following parts are in the box when unpacking. (2) installation fit the duct connection box into the rectangular hole of air-intake plenum with the ac...

Page 89

1-83 1. Specifications (d) installing the ceiling panel attach the ceiling panel to the air-intake plenum. Drawing the panel downwards sets the panel in position temporarily with the panel catch (at 2 locations). Remove the socket cover of the air-intake plenum and pass the 8p sockets through it. (f...

Page 90

1-84 1. Specifications wall mounted type (k1 type) 6-10. Removing the wall fixture from the unit remove the set screws and take off the rear panel. (fig. 1-30) note tubing can be extended in 3 directions as shown in fig. 1-31. Select the direction that provides the shortest run to the outside unit. ...

Page 91

1-85 1. Specifications 6-12. Installing the rear panel on the wall be sure to confirm that the wall is strong enough to suspend the unit. See either item a) or b) below depending on the wall type. A) if wooden wall (1) attach the rear panel to the wall with the 10 screws pro- vided. (fig. 1-36) if y...

Page 92

1-86 1. Specifications 6-13. Removing the grille to install the indoor unit basically, these models can be installed and wired without removing the grille. If access to any internal part is needed, follow the steps given below: how to remove the grille (1) set the 2 flaps in the horizontal position....

Page 93

1-87 1. Specifications 6-15. Wiring instructions general precautions on wiring (1) before wiring, confirm the rated voltage of the unit as shown on its nameplate, then carry out the wiring closely following the wiring diagram. (2) provide a power outlet to be used exclusively for each unit. A power ...

Page 94

1-88 1. Specifications 6-17. Shaping the tubing (1) shape the refrigerant tubing so that it can easily go into the hole. (fig. 1-45) (2) push the wiring, refrigerant tubing and drain hose through the hole in the wall. Adjust the indoor unit so it is securely seated on the wall fixture. (3) carefully...

Page 95

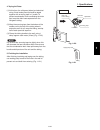

1-89 1. Specifications ceiling type (t1 type) 6-19. Suspending the indoor unit (1) place the full-scale diagram (supplied) on the ceiling at the spot where you want to install the indoor unit. Use a pencil to mark the drill holes. (fig. 1-50). Note since the diagram is made of paper, it may shrink o...

Page 96

1-90 1. Specifications (5) before suspending the indoor unit, remove the 2 screws on the latch of the air-intake grilles, open the grilles, and remove them by pushing the claws of the hinges as shown in fig. 1-54. Then remove both side panels sliding them along the unit toward the front after removi...

Page 97

1-91 1. Specifications ceiling surface . X or p p a h c ni 1 suspension bolt washer (supplied) nut (field supply) fig. 1-58 fig. 1-59 fig. 1-60 (7) suspend the indoor unit as follows. (a) mount a washer and two hexagonal nuts on each suspension bolt as shown in fig. 1-58. (b) lift the indoor unit wi...

Page 98

1-92 1. Specifications 6-20. Duct for fresh air there is a duct connection port (knock-out hole) at the right-rear on the panel top of the indoor unit for drawing in fresh air. If it is necessary to draw in fresh air, remove the cover by knocking it out and connect the duct to the indoor unit throug...

Page 99

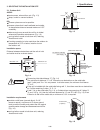

1-93 1. Specifications low silhouette ducted type (f1 type) 6-22. Required minimum space for installation and service this air conditioner is usually installed above the ceiling so that the indoor unit and ducts are not visible. Only the air intake and air outlet ports are visible from below. The mi...

Page 100

1-94 1. Specifications 6-23. Suspending the indoor unit depending on the ceiling type: • insert suspension bolts as shown in fig. 1-69 or • use existing ceiling supports or construct a suitable support as shown in fig. 1-70. (1) when placing the unit inside the ceiling, determine the pitch of the su...

Page 101

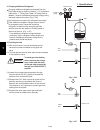

1-95 1. Specifications fig. 1-73 shows an example of installation. 6-24. Installing the drain piping (1) prepare standard hard pvc pipe for the drain and use the supplied hose band to prevent water leaks. The pvc pipe must be purchased separately. When doing this, leave a gap between the drain socke...

Page 102

1-96 1. Specifications caution do not install an air bleeder tube as this may cause water to spray from the drain pipe outlet. (fig. 1-76) if it is necessary to increase the height of the drain pipe, the section directly after the connection port can be raised a maximum of 19-11/16". Do not raise it...

Page 103

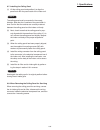

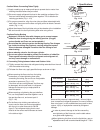

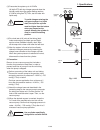

1-97 1. Specifications 6-26. Increasing the fan speed if external static pressure is too great (due to long extension of ducts, for example), the air flow volume may drop too low at each air outlet. This problem may be solved by increasing the fan speed using the following procedure: (1) remove 4 sc...

Page 104

1-98 1. Specifications 6-27. When installing the indoor unit confirm that the indoor unit should be installed in a horizontal position. Use the level gauge or vinyl tube and check every four corner of the unit is in horizontal. If the air outlet duct flange is positioned with downward gradient, ther...

Page 105

1-99 1. Specifications supplement on drain piping checkpoint after installation after installation of indoor and outdoor units, panels and electrical wiring, check the following items. K r a m e r k c e h c m o t p m y s t n i o p k c e h c 1 make sure whether indoor and outdoor units are correctly ...

Page 106

1-100 1. Specifications 7. How to install the wireless remote controller important when using this air conditioner with the wireless remote controller it may sometimes be impossible to change the operation modes while other indoor unit is running. When this happens, a double beep tone sounds, the (o...

Page 107

1-101 1. Specifications 7-2. Room temperature sensor setting the room temperature sensors are built into the indoor unit and the wireless remote controller. Either of these room temperature sensors can operate. The system is shipped from the factory set to the indoor unit sensor. To switch to the re...

Page 108

1-102 1. Specifications 4-way cassette type (u1 type) 7-5. Indicator section installation remove the ceiling panel and indicator cover and install the indicator section. (1) remove the ceiling panel. (2) remove the corner cover behind the mark section. (3 screws) (3) remove the mark section inside t...

Page 109

1-103 1. Specifications ceiling type (t1 type) 7-7. Indicator section installation remove the side panel to install the indicator section. (fig. 1-91) (1) remove the side panel. Open the air intake grille, remove the screw at one place and then remove the side panel by sliding it toward the front (a...

Page 110

1-104 1. Specifications 7-9. Electrical wiring 7-10-1. How to use the test run setting (u1, t1 types) (1) set dip switch [ds] no. 1 on the wireless receiver unit pcb from off to the on position. (2) press the on/off operation button on the wireless remote controller. (3) make a test run using the ai...

Page 111

1-105 1. Specifications 7-11. Misoperation alarm indicators alarm indicator lamps on the indoor unit indicate the error cause if the air conditioner fails to operate upon being switched on. The possible alarm indications are given in table 1-9. Fig. 1-95 shows the location of the alarm lamps on the ...

Page 112

1-106 1. Specifications caution if the signal receiving unit is installed near a rapid-start or inverter type fluorescent lamp (neither one uses glow lamps), it may be impossible to receive signals from the wireless remote controller. To avoid signal interference from fluorescent lamps, install the ...

Page 113

1-107 1. Specifications when using the signal receiving unit on a wall with the front exposed, choose a wall surface that the signal receiving unit can be mounted on. (1) insert a fl athead screwdriver into the slot on the lower side of the signal receiving unit and pry off the back case. (2) the wi...

Page 114

1-108 1. Specifications 7-13. Electrical wiring caution be sure to do the wiring correctly (incorrect wiring will damage the equipment). Recommended wire diameter and allowable length for signal receiving unit wiring and its branch wiring: awg #18, max 1,300 ft. 7-14. Test run switch (1) remove the ...

Page 115

1-109 1. Specifications 7-15. Misoperation alarm indicators a blinking lamp for other than the signal receiving unit fi lter shows that a problem has occurred in the unit, so make an inspection. (refer to servicing information in the service manual, etc.) also, if wired remote controller and dedicat...

Page 116

1-110 1. Specifications 7-16. Basic wiring diagram caution be sure to do the wiring correctly (incorrect wiring will damage the equipment). Wiring procedure carry out the wiring according to the above wiring diagram. Address setting is automatically executed after turning on the system. An indoor un...

Page 117

1-111 1. Specifications 7-17. Wiring system diagram for group control this diagram shows when several units (maximum of 8) are controlled by a signal receiving unit (main unit). In this case, a signal receiving unit can be connected at any indoor unit. Group control using 2 signal receiving units it...

Page 118

1-112 1. Specifications 7-18. Wiring system diagram for multiple remote controllers to operate 1 indoor unit with 2 signal receiving units set at different locations. Caution carry out the wiring correctly (incorrect wiring will damage the equipment). When installing multiple remote controllers this...

Page 119

1-113 1. Specifications 7-19. Test run procedure wall mounted type (k1 type) 7-20. Check items before the test run (1) turn on the remote power switch at least 12 hours before the test run in order to charge the crankcase heater. (2) fully open the service valves on the gas-tube and liquid-tube side...

Page 120

1-114 1. Specifications 7-21. Preparing for the test run 7-21-1. Changing the room temperature sensor room temperature sensors are installed inside the indoor unit and the wireless remote controller. Either room temperature sensor can be used. When “unit sensor” is indicated on the wireless remote c...

Page 121

1-115 1. Specifications 7-22. Precautions request that the customer be present at the time the test run is performed. Explain the operating instructions to the customer, and then have the customer actually operate the system. Be sure to pass the manual and warranty certifi cate to the customer. Veri...

Page 122

1-116 1. Specifications 7-23. When setting indoor unit control pcb switch for wall mounted indoor unit when using both the wired and wireless remote controller, refer to the procedure below. If this setting is not made correctly an alarm will occur. (the operation lamp on the display blinks.) this s...

Page 123

1-117 1. Specifications 7-24. Dia gnosis t a b le wired remote cause e 0 1 e 0 2 e 0 9 e 1 4 e 0 4 e 0 6 e 1 5 e 1 6 e 2 0 p 0 5 l 0 2 p 0 9 dis pla yed l 0 7 displa ye d indoor unit 1:1 connection (single type) nothing is displa ye d nothing is displa ye d displa yed displa yed oper ating lamp is b...

Page 124

1-118 1. Specifications 1-13. How to process tubing 8. How to install the timer wired remote controller the liquid tubing side is connected by a flare nut, and refer to the instraction manual attaehed to the timer remote controller. The gas tubing side is connected by brazing. 1. Connecting the refr...

Page 125

1-119 1. Specifications caution before connecting tubes tightly (1) apply a sealing cap or water-proof tape to prevent dust or water from entering the tubes before they are used. (2) be sure to apply refrigerant lubricant to the matching surfaces of the fl are and union before connecting them togeth...

Page 126

1-120 1. Specifications do not use a spanner to tighten the valve stem caps. Doing so may damage the valves. Depending on the installation conditions, applying excessive torque may cause the nuts to crack. Precautions for packed valve operation if the packed valve is left for a long time with the va...

Page 127

1-121 1. Specifications 4. Taping the tubes (1) at this time, the refrigerant tubes (and electrical wiring if local codes permit) should be taped together with armoring tape in 1 bundle. To prevent condensation from overfl owing the drain pan, keep the drain hose separate from the refrigerant tubing...

Page 128

1-122 1. Specifications 1-14. Leak test, evacuation and additional refrigerant charge perform an air-tightness test for this package a/c. Check that there is no leakage from any of the connections. Air and moisture in the refrigerant system may have undesirable effects as indicated below. Pressure i...

Page 129

1-123 1. Specifications (3) pressurize the system up to 4.15 mpa (42 kgf/cm 2 g) with dry nitrogen gas and close the cylinder valve when the gauge reading reaches 4.15 mpa (42 kgf/cm 2 g). Then, test for leaks with liquid soap. Caution to avoid nitrogen entering the refrigerant system in a liquid st...

Page 130

1-124 1. Specifications caution to avoid gas from leaking when removing the charge hose, make sure the stem of the gas tube is turned all the way out (“back seat”) position. 3. Charging additional refrigerant charging additional refrigerant (calculated from the liquid tube length as shown in section...

Page 131: 2. Processes and Functions

2-1 room temperature control .......................................................................................... 2-2 2-2 cold draft prevention (heating cycle) ........................................................................ 2-4 2-3 automatic fan speed (indoor unit) ......................

Page 132

2-2 2. Processes and functions fig. 1 (thermo. Off) (thermo. On) room temp. Thermo. On 5 minutes more than 5 minutes 3 minutes set temp compressor outdoor fan (h or m) indoor fan f f o f f o f f o f f o 1 1. Refer to 2-4 outdoor fan speed control more than 3 minutes more than 5 minutes n o n o n o n...

Page 133

2-3 2. Processes and functions fig. 2 thermo. On thermo. On +2 °f f f o f f o 2 1. Refer to 2-4 outdoor fan speed control off set speed n o n o n o on (reversing cycle) on temp. Operation remote control sensor (only for wireless remote controller) body sensor off off set speed set speed 3 seconds on...

Page 134

2-4 2. Processes and functions fig. 3 92 88 81 77 50 set fan speed auto or h m l ll ll/off ll l l l ll ll/off ll l m m ll ll/off ll l m h max. 6 minutes “standby” indicator indoor unit coil temp. E2 ( °f) ll= very low speed l= low speed m= medium speed h= high speed “standby” appears 1135_ths_i char...

Page 135

2-5 2. Processes and functions fig. 4 indoor fan speed l h m m h 1923_m_s room temp. (deg) set temp. +3 +2 +1 h m : high : middle l : low chart explanations and notes when the fan speed changes, it keeps the speed step for at least 3 minutes, even if the temperature changes to another speed step dur...

Page 136

2-6 2. Processes and functions 124 142 2-4 control functions electronic control valve control opening of the electronic control valve is controlled so that the appropriate operating conditions are maintained, based on the signal from each sensor (discharge temperature [td], intake temperature [ts], ...

Page 137

2-7 2. Processes and functions 36 (36, 48 types) overcurrent protection control (1) if the overcurrent protection circuit detects abnormal current, the compressor is stopped. (error count = 1.) the compressor then restarts after 3 minutes. (2) if compressor start/stop is repeated 4 times (error coun...

Page 138

2-8 2. Processes and functions 1 • • • • • 2 3 defrost control defrost sequence heating operation (25-minute mask) frost detection defrost start (reverse cycle defrost) defrost in progress defrost cancel start-up operation operating frequency: 61.8 hz outdoor unit fan: off electronic control valve: ...

Page 139

2-9 2. Processes and functions fan motor plug (cn004) eeprom ic mdc heat exchanger temperature (c2) sensor heat exchanger temperature (c1) sensor suction temperature (ts) sensor outdoor air temperature (to) sensor compressor discharge temperature (td) sensor refrigerant recovery switch (s005) quiet ...

Page 140

2-10 2. Processes and functions push-button switch (black): automatic address setting switch • if the system address switch (s002: set to 0 at time of shipment) setting is other than "0" (central control), press this switch once to automatically set the addresses at all indoor units which are in the...

Page 141

2-11 2. Processes and functions 3p plug (black): terminal plug for the communications line • at the time of shipment from the factory, the short-circuiting socket (2p, black) is installed between pins 1 and 2 on the terminal plug (terminal = yes). • when central control is used for multiple systems,...

Page 142

Sm830203-01̲pac-i̲us-letter.Indb12 12 sm830203-01̲pac-i̲us-letter.Indb12 12 2012/01/26 14:25:11 2012/01/26 14:25:11.

Page 143: 3. Electrical Data

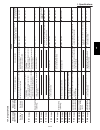

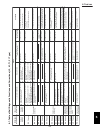

3-1 3-2 indoor units................................................................................................................... 3-2 outdoor units.............................................................................................................. 3 -10 3. Electrical data 3-1 sm83020...

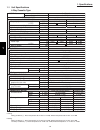

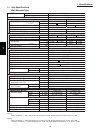

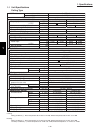

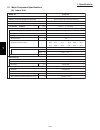

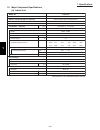

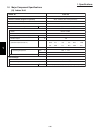

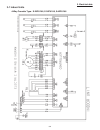

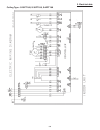

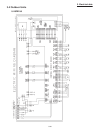

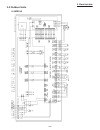

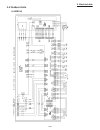

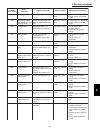

Page 144

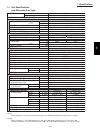

3-2 3. Electrical data 3-1 indoor units 4-way cassette type : s-26pu1u6, s-36pu1u6, s-42pu1u6 sm830203-00̲pac-i̲us-letter.Indb2 2 sm830203-00̲pac-i̲us-letter.Indb2 2 2011/11/09 20:22:52 2011/11/09 20:22:52.

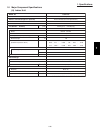

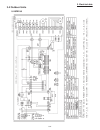

Page 145

3-3 3. Electrical data 4-way cassette type : s-26pu1u6, s-36pu1u6, s-42pu1u6 sm830203-00̲pac-i̲us-letter.Indb3 3 sm830203-00̲pac-i̲us-letter.Indb3 3 2011/11/09 20:22:53 2011/11/09 20:22:53.

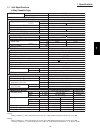

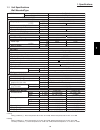

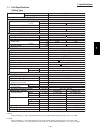

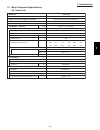

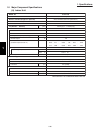

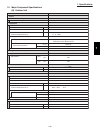

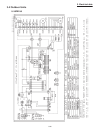

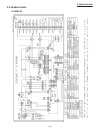

Page 146

3-4 3. Electrical data wall mounted type : s-26pk1u6 sm830203-00̲pac-i̲us-letter.Indb4 4 sm830203-00̲pac-i̲us-letter.Indb4 4 2011/11/09 20:22:53 2011/11/09 20:22:53.

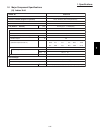

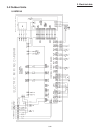

Page 147

3-5 3. Electrical data wall mounted type : s-26pk1u6 sm830203-00̲pac-i̲us-letter.Indb5 5 sm830203-00̲pac-i̲us-letter.Indb5 5 2011/11/09 20:22:54 2011/11/09 20:22:54.

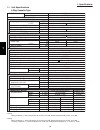

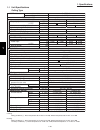

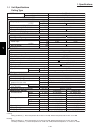

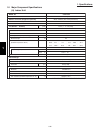

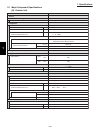

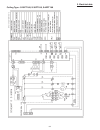

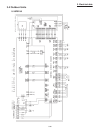

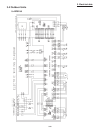

Page 148

3-6 3. Electrical data ceiling type : s-26pt1u6, s-36pt1u6, s-42pt1u6 sm830203-00̲pac-i̲us-letter.Indb6 6 sm830203-00̲pac-i̲us-letter.Indb6 6 2011/11/09 20:22:54 2011/11/09 20:22:54.

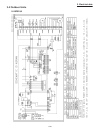

Page 149

3-7 3. Electrical data ceiling type : s-26pt1u6, s-36pt1u6, s-42pt1u6 sm830203-00̲pac-i̲us-letter.Indb7 7 sm830203-00̲pac-i̲us-letter.Indb7 7 2011/11/09 20:22:54 2011/11/09 20:22:54.

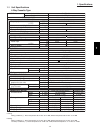

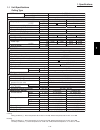

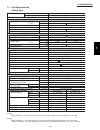

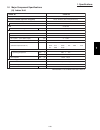

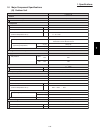

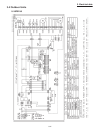

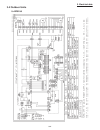

Page 150

3-8 3. Electrical data low silhouette ducted type : s-26pf1u6, s-36pf1u6 sm830203-00̲pac-i̲us-letter.Indb8 8 sm830203-00̲pac-i̲us-letter.Indb8 8 2011/11/09 20:22:55 2011/11/09 20:22:55.

Page 151

3-9 3. Electrical data low silhouette ducted type : s-26pf1u6, s-36pf1u6 sm830203-00̲pac-i̲us-letter.Indb9 9 sm830203-00̲pac-i̲us-letter.Indb9 9 2011/11/09 20:22:55 2011/11/09 20:22:55.

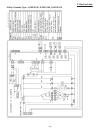

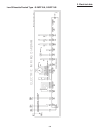

Page 152

3-10 3. Electrical data 3-2 outdoor units u-26pe1u6 sm830203-00̲pac-i̲us-letter.Indb10 10 sm830203-00̲pac-i̲us-letter.Indb10 10 2011/11/09 20:22:55 2011/11/09 20:22:55.

Page 153

3-11 3. Electrical data 3-2 outdoor units u-26pe1u6 sm830203-00̲pac-i̲us-letter.Indb11 11 sm830203-00̲pac-i̲us-letter.Indb11 11 2011/11/09 20:22:55 2011/11/09 20:22:55.

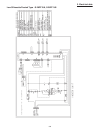

Page 154

3-12 3. Electrical data 3-2 outdoor units u-26ps1u6 sm830203-00̲pac-i̲us-letter.Indb12 12 sm830203-00̲pac-i̲us-letter.Indb12 12 2011/11/09 20:22:56 2011/11/09 20:22:56.

Page 155

3-13 3. Electrical data 3-2 outdoor units u-26ps1u6 sm830203-00̲pac-i̲us-letter.Indb13 13 sm830203-00̲pac-i̲us-letter.Indb13 13 2011/11/09 20:22:56 2011/11/09 20:22:56.

Page 156

3-14 3. Electrical data 3-2 outdoor units u-36pe1u6 sm830203-00̲pac-i̲us-letter.Indb14 14 sm830203-00̲pac-i̲us-letter.Indb14 14 2011/11/09 20:22:56 2011/11/09 20:22:56.

Page 157

3-15 3. Electrical data 3-2 outdoor units u-36pe1u6 sm830203-00̲pac-i̲us-letter.Indb15 15 sm830203-00̲pac-i̲us-letter.Indb15 15 2011/11/09 20:22:56 2011/11/09 20:22:56.

Page 158

3-16 3. Electrical data 3-2 outdoor units u-36ps1u6 sm830203-00̲pac-i̲us-letter.Indb16 16 sm830203-00̲pac-i̲us-letter.Indb16 16 2011/11/09 20:22:57 2011/11/09 20:22:57.

Page 159

3-17 3. Electrical data 3-2 outdoor units u-36ps1u6 sm830203-00̲pac-i̲us-letter.Indb17 17 sm830203-00̲pac-i̲us-letter.Indb17 17 2011/11/09 20:22:57 2011/11/09 20:22:57.

Page 160

3-18 3. Electrical data 3-2 outdoor units u-42pe1u6 sm830203-00̲pac-i̲us-letter.Indb18 18 sm830203-00̲pac-i̲us-letter.Indb18 18 2011/11/09 20:22:58 2011/11/09 20:22:58.

Page 161

3-19 3. Electrical data 3-2 outdoor units u-42pe1u6 sm830203-00̲pac-i̲us-letter.Indb19 19 sm830203-00̲pac-i̲us-letter.Indb19 19 2011/11/09 20:22:58 2011/11/09 20:22:58.

Page 162

3-20 3. Electrical data 3-2 outdoor units u-42ps1u6 sm830203-00̲pac-i̲us-letter.Indb20 20 sm830203-00̲pac-i̲us-letter.Indb20 20 2011/11/09 20:22:59 2011/11/09 20:22:59.

Page 163

3-21 3. Electrical data 3-2 outdoor units u-42ps1u6 sm830203-00̲pac-i̲us-letter.Indb21 21 sm830203-00̲pac-i̲us-letter.Indb21 21 2011/11/09 20:22:59 2011/11/09 20:22:59.

Page 164

Sm830203-00̲pac-i̲us-letter.Indb22 22 sm830203-00̲pac-i̲us-letter.Indb22 22 2011/11/09 20:22:59 2011/11/09 20:22:59.

Page 165: 4. Service Procedures

4-1. Meaning of alarm messages ......................................................................................... 4-2 4-2. Symptoms and parts to inspect ................................................................................... 4-5 4-3. Details of alarm messages ........................

Page 166

4-2 4. Service procedures remote controller is detecting error signal from indoor unit e01 e02 e10 e11 e14 e03 e08 e09 e04 e05 e06 e07 e15 e12 e16 e20 e17 e18 e31 l01 l02 l03 l04 l07 l08 l09 l10 l11 l13 indoor unit is detecting error signal from remote controller (and system controller) error in rec...

Page 167

4-3 4. Service procedures p09 p01 p10 p03 p04 p05 p15 p19 p20 p22 p26 p29 p31 h01 f01 f02 f10 f04 f06 f07 f08 f12 f29 ceiling panel connection failure indoor protection fan protective thermostat float switch discharge temperature trouble high pressure switch or compressor motor thermal protector is ...

Page 168

4-4 4. Service procedures (2) led indicator messages on outdoor control pcb power on sequence 1. No communication from indoor units in system 2. Communication received from 1 or more indoor units in system 3. Regular communication ok (capacity and unit quantity match) if it is not possible to advanc...

Page 169

4-5 4. Service procedures 4-2. Symptoms and parts to inspect judgment condition clear condition p03 p05 p04 p15 p19 p20 p22 p26 remote controller alarm display alarm contents judgment and correction abnormal discharge temperature • discharge temp. Detected at or above the specified value. Stops when...

Page 170

4-6 4. Service procedures judgment condition clear condition p29 f04 f06 alarm contents judgment and correction recovery at restart recovery at restart recovery at restart recovery at restart recovery at restart current detection circuit trouble • ac current value is high even when compressor is sto...

Page 171

4-7 4. Service procedures judgment condition clear condition f31 l02 l04 l07 l10 l13 e07 e06 e14 e15 e16 e20 e31 h01 remote controller alarm display alarm contents judgment and correction automatic recovery eeprom trouble reading/writing failure recovery at power reset 1. Check eeprom (ic007). 2. Ch...

Page 172

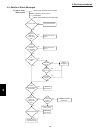

4-8 4. Service procedures no no no no no no no no no yes yes yes yes yes yes yes yes yes [alarm “p29”] (mdc trouble) (1) input power detection circuit trouble compressor does not run. Breakdown motor current detection circuit trouble is power ok? Correct power line. Is current detection circuit wiri...

Page 173

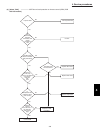

4-9 4. Service procedures no no no no no no no yes yes yes yes yes yes yes replace outdoor unit control pcb. (2) [alarm “p26”] hic pcb trouble) igbt short-circuit protection on inverter control (ipdu) pcb is power ok? Correct power line. Are circuit wiring, connector connections, and reactor connect...

Page 174

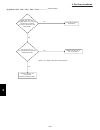

4-10 4. Service procedures hic + between terminals resistance hic + hic + hic + hic – hic – hic – hic – u v w u v w resistance 200 k Ω or more 300 k Ω or more 300 k Ω or more 300 k Ω or more 200 k Ω or more 200 k Ω or more 200 k Ω or more no yes replace outdoor unit control pcb. (3) [alarm “e31”] (c...

Page 175

4-11 4. Service procedures no no no no yes yes yes yes (4) [alarm "p22"] outdoor unit fan motor drive circuit trouble are connectors cn003 and cn004 connected correctly to the outdoor unit control pcb? Correct the connector connections. Disconnect connectors cn003 and cn004 from outdoor unit control...

Page 176

4-12 4. Service procedures no no yes yes check the outdoor unit control pcb. Replace if pcb has failed. Sensor trouble (5) [alarms “f04,” “f06,” “f07,” “f08,” “f12”] are connectors cn020, 021, 022, 023, and 024 (td, to, c1, c2, and ts sensors) connected correctly to the outdoor unit control pcb? Cor...

Page 177

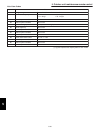

4-13 4. Service procedures sensor installation sensor sensor type sensor sensor type s s e r d d a s s e r d d a n o i t a c o l 00 room temp. 05 – (temp. Used for control)* 01 remote controller temp. 06 discharge temp. Indoor unit 02 indoor intake temp. 07 – 03 indoor heat exchanger temp. (e1 ) 08 ...

Page 178

4-14 4. Service procedures check pin short-circuit the cooling check pin (or heating check pin) on the outdoor unit control pcb to perform the control described below. 1. Thermistor checks the checks listed below are performed for 1 second each, in order from the top down. The results are displayed ...

Page 179

5-1. Overview ......................................................................................................................... 5-2 5-2. Functions ....................................................................................................................... 5-2 5-3. Normal display o...

Page 180

5-2 5. Outdoor unit maintenance remote control 5-1. Overview what is the outdoor unit maintenance remote controller? Beginning with the dc-inv series of outdoor units, nonvolatile memory (eeprom) is used in the outdoor unit pcb. In this way, the setting switches that were located on earlier pcbs hav...

Page 181

5-3 5. Outdoor unit maintenance remote control remote controller assy special service checker wiring relay connector (2p, white) pcb connector (3p, blue) rc (3p, blue) outdoor unit pcb 5-3. Normal display operations and functions normal display functions • connect the special service checker wiring ...

Page 182

5-4 5. Outdoor unit maintenance remote control display (functions) • use the temperature setting and buttons to change the item code. S k r a m e r s t n e t n o c y a l p s i d e d o c m e t i 00 (1) s u t a t s l a i t i n i t a l a m r o n n e h w f f o : ) e d o c ( s t n e t n o c m r a l a t i...

Page 183

5-5 5. Outdoor unit maintenance remote control *2: 7-segment, 4-digit display for remote controller timer display the connected unit nos. Are displayed as shown below, using the 7-segment 4-digit ( ) display and the colon. — — — — — — — — 1 7 1 2 1 7 2 8 1 3 1 3 8 9 1 4 1 4 9 5 10 15 20 6 1 1 1 6 21...

Page 184

5-6 5. Outdoor unit maintenance remote control 5-4. Monitoring operations: display of indoor unit and outdoor unit sensor temperatures (1) press and hold the button and button simultaneously for 4 seconds or longer to switch to temperature monitor mode. During temperature monitoring, “service monito...

Page 185

5-7 5. Outdoor unit maintenance remote control 5-5. Monitoring the outdoor unit alarm history: display of outdoor unit alarm history * displays outdoor unit alarms only. Does not display indoor unit alarms. * check the indoor unit alarm histories separately using the indoor unit remote controllers o...

Page 186

5-8 5. Outdoor unit maintenance remote control list of item codes r e t e m a r a p e d o c m e t i 01 control system schedule 02 control system schedule 03 control system schedule 04 snowfall sensor operation 0 = no sensor, control performed 1 = no sensor, control not performed do not set do not se...

Page 187

5-9 5. Outdoor unit maintenance remote control setting mode 2 (1) press and hold the button, button, and button simultaneously for 4 seconds or longer. (2) use the temperature setting and buttons to change the item code. The item codes and setting data are shown in the table below. (3) use the timer...

Page 188

5-10 5. Outdoor unit maintenance remote control r e t e m a r a p e d o c m e t i 80 refrigerant type 407 = r407c 22 = r22 410 = r410a 81 outdoor unit capacity* 0 = disabled 80 : 26 type 112 : 36 typ 140 : 42 type do not set do not set do not set 82 control system schedule 83 control system schedule...

Page 189: 6. Test Run

6-1. Preparing for test run ............................................................................................... 6-2. Caution........................................................................................................................ 6-3. Test run procedure ......................

Page 190

6-2 6. Test run 6. Test run 6-1. Preparing for test run before attempting to start the air conditioner, check the following: (1) all loose matter is removed from the cabinet espe- cially steel filings, bits of wire, and clips. (2) the control wiring is correctly connected and all electrical connecti...

Page 191

6-3 6. Test run u1, k1, t1, f1 type 6-2. Caution this unit may be used in a single-type refrigerant system where 1 outdoor unit is connected to 1 indoor unit. The indoor and outdoor unit control pcbs utilize a semiconductor memory element (eeprom). The settings required for operation were made at th...

Page 192

6-4 6. Test run 6-4. Items to check before the test run (1) (2) turn the breaker on at least 12 hours in advance in order to energize the crank case heater. Fully open the closed valves on the liquid tube and gas tube sides. 6-5. Test run using the remote controller (1) press and hold the remote con...

Page 193

6-5 6. Test run wired remote contr o ller di spla y cause correction nothing is displa yed nothing is displa yed e 0 1 dis pla ye d e 0 2 displa yed e 0 9 displa yed e 1 4 displa ye d e 0 4 displa yed e 0 6 di spla yed e 1 5 displa yed e 1 6 displa yed e 2 0 di spla yed p 0 5 displa yed l 0 2 displa...

Page 194

6-6 6. Test run 6-8. Examples of wiring diagrams basic wiring diagram 1 single-type system be careful to avoid miswiring when connecting the wires. (miswiring will damage the units.) 1 2 1 2 0 l2 u1 rc u2 l1 u2 u1 g 1 2 system address rotary switch (set to “0” at the time of shipment.) outdoor unit ...

Page 195

6-7 6. Test run 1 2 1 2 l2 u1 rc u2 l1 u2 u1 g 1 2 1 2 l2 u1 rc u2 l1 u2 u1 g 1 2 system address rotary switch (set to “ 0 ” at the time of shipment.) outdoor unit indoor unit wired remote controller wht blk (optional) remote controller wiring (field supply) system address rotary switch (set to “ 0 ...

Page 196

6-8 6. Test run setting the outdoor unit system addresses for basic wiring diagram 2 (set the system addresses: 1, 2, 3...) on 1 2 0 system address rotary switch (set to “0” at time of shipment) system address rotary switch system address dipswitch off on 10s 20s 3 – 5hp outdoorunit control pcb fig....

Page 197

6-9 6. Test run indicating (marking) the indoor and outdoor unit combination number indicate (mark) the number after automatic address setting is completed. (1) so that the combination of each indoor unit can be easily checked when multiple units are installed, ensure that the indoor and outdoor uni...

Page 198

201201 sm830203-01̲pac-i̲us-letter.Indb1 1 sm830203-01̲pac-i̲us-letter.Indb1 1 2012/01/27 13:49:35 2012/01/27 13:49:35.