- DL manuals

- Panasonic

- Air Conditioner

- WH-ADC0309H3E

- Service Manual

Panasonic WH-ADC0309H3E Service Manual

© Panasonic Corporation 2016.

Order No: PAPAMY1607068CE

Air-to-Water Hydromodule + Tank

Indoor Unit

Outdoor Unit

WH-ADC0309H3E5

WH-UD03HE5-1

WH-UD05HE5-1

WH-UD07HE5-1

WH-UD09HE5-1

Destination

Europe

Turkey

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by

in the Schematic

Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced

with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of

manufacturer.

!

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

Summary of WH-ADC0309H3E

Page 1

© panasonic corporation 2016. Order no: papamy1607068ce air-to-water hydromodule + tank indoor unit outdoor unit wh-adc0309h3e5 wh-ud03he5-1 wh-ud05he5-1 wh-ud07he5-1 wh-ud09he5-1 destination europe turkey important safety notice there are special components used in this equipment which are importan...

Page 2: Table Of Contents

2 table of contents 1. Safety precautions ............................................. 4 2. Specifications ..................................................... 6 2.1 wh-adc0309h3e5 wh-ud03he5-1 .......... 6 2.2 wh-adc0309h3e5 wh-ud05he5-1 .......... 9 2.3 wh-adc0309h3e5 wh-ud07he5-1 ........ 12 2....

Page 3

3 18.4 to remove rccb ..................................... 200 18.5 to remove electronic controller ............... 200 18.6 to remove flow switch and air purge valve .......................................................... 201 18.7 to remove water pump ........................... 201 18.8 to rem...

Page 4: 1. Safety Precautions

4 caution warning warning 1. Safety precautions read the following “safety precautions” carefully before installation of air-to-water hydromodule + tank (here after referred to as “tank unit”). Electrical works and water installation works must be done by licensed electrician and licensed water syst...

Page 5

5 caution warning 19. During pump down operation, stop the compressor before remove the refrigeration piping. Removal of refrigerant piping while compressor is operating and valves are opened will cause suck-in of air, abnormal high pressure in refrigerant cycle and result in explosion, injury etc. ...

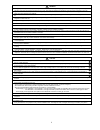

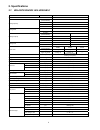

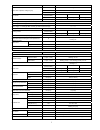

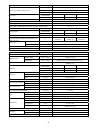

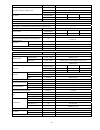

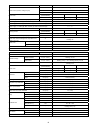

Page 6: 2. Specifications

6 2. Specifications 2.1 wh-adc0309h3e5 wh-ud03he5-1 item unit outdoor unit performance test condition en 14511 cooling capacity condition (ambient/water) a35w7 kw 3.20 btu/h 10900 kcal/h 2750 cooling eer w/w 3.08 kcal/hw 2.64 heating capacity condition (ambient/water) a7w35 a2w35 kw 3.20 3.20 btu/h ...

Page 7

7 item unit outdoor unit power source (phase, voltage, cycle) ø single v 230 hz 50 input power condition (ambient/water) a35w7 a7w35 a2w35 kw cooling: 1.04 heating: 0.64 heating: 0.90 maximum input power for heatpump system kw 2.59 power supply 1 : phase (Ø) / max. Current (a) / max. Input power (w)...

Page 8

8 item unit indoor unit expansion vessel volume i 10 mwp bar 3 capacity of integrated electric heater / olp temp kw / °c 3.00 / 80 tank volume (spec / nett) l 200 / 185 max. Tank water set temperature °c 65 tank coil surface m 2 1.8 maximum working pressure heat / cool bar 3.0 tank circuit bar 8.0 o...

Page 9

9 2.2 wh-adc0309h3e5 wh-ud05he5-1 item unit outdoor unit performance test condition en 14511 cooling capacity condition (ambient/water) a35w7 kw 4.50 btu/h 15300 kcal/h 3870 cooling eer w/w 2.69 kcal/hw 2.32 heating capacity condition (ambient/water) a7w35 a2w35 kw 5.00 4.20 btu/h 17100 14300 kcal/h...

Page 10

10 item unit outdoor unit power source (phase, voltage, cycle) ø single v 230 hz 50 input power condition (ambient/water) a35w7 a7w35 a2w35 kw cooling: 1.67 heating: 1.08 heating: 1.35 maximum input power for heatpump system kw 2.59 power supply 1 : phase (Ø) / max. Current (a) / max. Input power (w...

Page 11

11 item unit indoor unit protection device a residual current circuit breaker (30) expansion vessel volume i 10 mwp bar 3 capacity of integrated electric heater / olp temp kw / °c 3.00 / 80 tank volume (spec / nett) l 200 / 185 max. Tank water set temperature °c 65 tank coil surface m 2 1.8 maximum ...

Page 12

12 2.3 wh-adc0309h3e5 wh-ud07he5-1 item unit outdoor unit performance test condition en 14511 cooling capacity condition (ambient/water) a35w7 kw 6.00 btu/h 20500 kcal/h 5160 cooling eer w/w 2.63 kcal/hw 2.26 heating capacity condition (ambient/water) a7w35 a2w35 kw 7.00 6.55 btu/h 23900 22300 kcal/...

Page 13

13 item unit outdoor unit power source (phase, voltage, cycle) ø single v 230 hz 50 input power condition (ambient/water) a35w7 a7w35 a2w35 kw cooling: 2.28 heating: 1.57 heating: 1.96 maximum input power for heatpump system kw 4.59 power supply 1 : phase (Ø) / max. Current (a) / max. Input power (w...

Page 14

14 item unit indoor unit protection device a residual current circuit breaker (30) expansion vessel volume i 10 mwp bar 3 capacity of integrated electric heater / olp temp kw / °c 3.00 / 80 tank volume (spec / nett) l 200 / 185 max. Tank water set temperature °c 65 tank coil surface m 2 1.8 maximum ...

Page 15

15 2.4 wh-adc0309h3e5 wh-ud09he5-1 item unit outdoor unit performance test condition en 14511 cooling capacity condition (ambient/water) a35w7 kw 7.00 btu/h 23900 kcal/h 6020 cooling eer w/w 2.43 kcal/hw 2.09 heating capacity condition (ambient/water) a7w35 a2w35 kw 9.00 6.70 btu/h 30700 22800 kcal/...

Page 16

16 item unit outdoor unit power source (phase, voltage, cycle) ø single v 230 hz 50 input power condition (ambient/water) a35w7 a7w35 a2w35 kw cooling: 2.88 heating: 2.18 heating: 2.14 maximum input power for heatpump system kw 5.01 power supply 1 : phase (Ø) / max. Current (a) / max. Input power (w...

Page 17

17 item unit indoor unit protection device a residual current circuit breaker (30) expansion vessel volume i 10 mwp bar 3 capacity of integrated electric heater / olp temp kw / °c 3.00 / 80 tank volume (spec / nett) l 200 / 185 max. Tank water set temperature °c 65 tank coil surface m 2 1.8 maximum ...

Page 18: 3. Features

18 3. Features inverter technology o energy saving high efficiency environment protection o non-ozone depletion substances refrigerant (r410a) long installation piping o long piping up to 30 meter with height difference 20 meter o flexible 4-way piping for outdoor unit easy to use control panel o au...

Page 19

19 4. Location of controls and components 4.1 indoor unit 4.1.1 remote controller buttons and display 4 5 6 3 2 1 buttons / indicator 1 quick menu button (for more details, refer to the separate quick menu guide.) 2 back button returns to the previous screen 3 lcd display 4 main menu button for func...

Page 20

20 3 temperature of each zone 4 time and day 5 water tank temperature 6 outdoor temperature 7 sensor type/set temperature type icons water temperature → compensation curve water temperature → direct pool only room thermostat → external room thermostat → internal display 1 mode selection auto • depen...

Page 21

21 4.1.2 initialization before starting to install the various menu settings, please initiate the remote controller by selecting the language of operation and installing the date and time correctly. It is recommended that the installer conducts the following initialization of the remote controller. ...

Page 22

22 4.1.3 quick menu 4.1.4 menus (for user) after the initial settings have been completed, you can select a quick menu from the following options and edit the setting. 1 press to display the quick menu. Force dhw powerful quiet force heater weekly timer force defrost error reset r/c lock 2 use to se...

Page 23

23 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 1.2 holiday timer to save energy, a holiday period may be set to either turn off the system or lower the temperature during the period. Off on holiday start and end. Date and time off or lowered temperature • weekly timer...

Page 24

24 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 2 system check 2.1 energy monitor present or historical chart of energy consumption, generation or cop. Present select and retrieve historical chart select and retrieve • cop= coef fi cient of performance. • for historica...

Page 25

25 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 3.3 backlight sets the duration of screen backlight. 1 min 3.4 backlight intensity sets screen backlight brightness. 4 3.5 clock format sets the type of clock display. 24h 3.6 date & time sets the present date and time. Y...

Page 26

26 4.1.5 menus (for installer) y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 5 installer setup system setup 5.1 optional pcb connectivity to connect to the external pcb required for servicing. No • if the external pcb is connected (optional), the system will have follow...

Page 27

27 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 5.6 base pan heater to select whether or not optional base pan heater is connected. R e t a e h n a p e s a b e h t - a e p y t * activates only during deice operation. * type b -the base pan heater activates when outdoor...

Page 28

28 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m control pattern advanced parallel heat yes • buffer tank is activated only after selecting “yes”. -8 °c set the temperature threshold to start the bivalent heat source. 0:30 delay timer to start the bivalent heat source (...

Page 29

29 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 5.10 solar connection • the optional pcb connectivity must be selected yes to enable the function. • if the optional pcb connectivity is not selected, the function will not appear on the display. No yes buffer tank select...

Page 30

30 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 5.13 sg ready no yes 120 % capacity (1) & (2) of buffer tank and dhw tank (in %) 5.14 external compressor sw no 5.15 circulation liquid to select whether to circulate water or glycol in the system. Water 5.16 heat-cool sw...

Page 31

31 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m water temp. For heating on compensation curve x axis: -5 °c, 15 °c y axis: 55 °c, 35 °c input the 4 temperature points (2 on horizontal x axis, 2 on vertical y axis). • temperature range: x axis: -15 °c ~ 15 °c, y axis: s...

Page 32

32 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 6.2 * 1, * 2 cool to set various water & ambient temperatures for cooling. Water temperatures for cooling on and t for cooling on. Water temp. For cooling on compensation curve cooling on temperatures in compensation curv...

Page 33

33 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 6.3 auto automatic switch from heat to cool or cool to heat. Outdoor temperatures for switching from heat to cool or cool to heat. Outdoor temp. For (heat to cool) / outdoor temp. For (cool to heat) outdoor temp. For (hea...

Page 34

34 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m sterilization monday sterilization may be set for 1 or more days of the week. Sun / mon / tue / wed / thu / fri / sat sterilization: time 12:00 time of the selected day(s) of the week to sterilize the tank 0:00 ~ 23:59 st...

Page 35

35 y a l p s i d / s n o it p o g n it t e s g n it t e s tl u a f e d u n e m 7.3 dry concrete to dry the concrete ( fl oor, walls, etc.) during construction. Do not use this menu for any other purposes and in period other than during construction edit to set the temperature of dry concrete. On / e...

Page 36

36 4.1.6 main components 1 remote controller 2 water pump 3 control board cover 4 main pcb 5-1 single phase rccb/elcb (main power) single phase rccb/elcb (backup heater) water filter set 7 6 heater assembly 8 3-way valve (not visible) 9 overload protector (not visible) 0 expansion vessel (not visibl...

Page 37

37 4.2 outdoor unit ud03_05he5-1 ud07_09he5-1 air inlet (rear) air inlet (side) air outlet air inlet (rear) air inlet (side) air outlet.

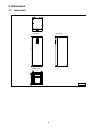

Page 38: 5. Dimensions

38 5. Dimensions 5.1 indoor unit unit: mm 70 10 80 61 2 60 478 60 36 598 717.

Page 39

39 5.2 outdoor unit 5.2.1 wh-ud03he5-1 wh-ud05he5-1 space necessary for installation anchor bolt pitch 355 x 260 100 cm 10 cm unit: mm 823.4 68.5 37 622 (2 3) 69 61 298 540 (124) 21.9 160 53.4 32 97 167 33 0 10 cm.

Page 40

40 5.2.2 wh-ud07he5-1 wh-ud09he5-1 unit: mm 391 900 253 110 320 218 318.5 355 181 795 41 0 0 2 6 ) 0 4 1 ( 175 140 300 260 17 6 24 (10) (3 0 ) dd (30) (1 0 ) 320 20 (1 5 ) 40 400

Page 41

41 6. Refrigeration and water cycle diagram model piping size rated length (m) max elevation (m) min. Piping length (m) max. Piping length (m) additional refrigerant (g/m) tank unit outdoor unit gas liquid adc0309* ud03*e5* / ud05*e5 Ø12.70 mm (1/2") Ø6.35 mm (1/4") 5 5 3 15 20 ud07*e5* / ud09*e5* Ø...

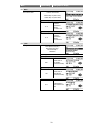

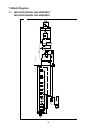

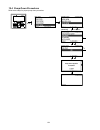

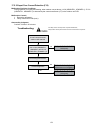

Page 42: 7. Block Diagram

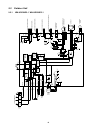

42 7. Block diagram 7.1 wh-adc0309h3e5 wh-ud03he5-1 wh-adc0309h3e5 wh-ud05he5-1 indoor uni t o ut door un it 1 2 3 ss r 2 0 7 mi x in g va lv e zo ne 2 mi x in g va lv e zo n e 1 so lar wa t e r pu m p p ool wa t e r pu m p wa t e r pu m p zo n e 2 wa t e r pum p zo ne 1 ss r2 0 5 ss r2 03 ss r2 02 ...

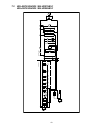

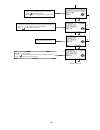

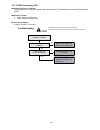

Page 43

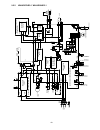

43 7.2 wh-adc0309h3e5 wh-ud07he5-1 wh-adc0309h3e5 wh-ud09he5-1 indoo r unit o ut doo r unit 1 2 3 ms 3~ nois ef ilte r sc re a c t o r rel a y f u se2 fu s e 1 cap aci tor circui t pf cc ircui t recti fic at io nci rcuit re ct ifica tio nc ir cu it m basep anh ea ter ry-h t2 ry-h ot 4-w ay sv alv e ...

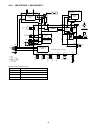

Page 44

44 8. Wiring connection diagram 8.1 indoor unit cn 2 cn 1 cn -p w r4 (blk) 5 3 1 1 w w w w w w w w bl w b r 1 1 4 2 2 3 1 1 1 2 2 3 cn -p wr 3 (grn) cn -pw r2 04 (y lw ) cn-p wr2 02 (ylw ) cn-c omm (ylw ) dc n (blu) dc p (r ed ) cn -c nt (wht) cn -p w r2 (b lu ) ry-v 2 ry-v 3 roo m the rm o 1 1 1 cn...

Page 45

45 8.2 outdoor unit 8.2.1 wh-ud03he5-1 wh-ud05he5-1 resistance of compressor windings model wh-ud03he5-1 / wh-ud05he5-1 connection 5rd132xbe21 u - v 1.897 Ω v - w 1.882 Ω u - w 1.907 Ω note: resistance at 20°c of ambient temperature. Remarks ; black : (blk) blue : (blu) white : (wht) red : (red) yel...

Page 46

46 8.2.2 wh-ud07he5-1 wh-ud09he5-1 resistance of compressor windings model wh-ud07he5-1 / wh-ud09he5-1 connection 5kd240xcc21 u - v 0.551 Ω u - w 0.561 Ω v - w 0.542 Ω note: resistance at 20°c of ambient temperature. W 1 rectification 1 ms 3 y b r r r (optional) 1 (blue) circuit 3 di sc ha rge tem p...

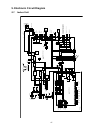

Page 47

47 9. Electronic circuit diagram 9.1 indoor unit cn 2 cn1 cn -pw r 4 (b lk ) 5 3 1 1 w w w w w w w w bl w b r 1 1 4 2 3 1 1 1 1 2 2 3 3 cn -p w r 3 (grn) cn -p wr (b lk ) cn -pw r2 04 (y lw ) cn -pw r 20 2 (y lw ) cn -co m m (y lw ) ac n (w ht) ac l (b lk ) dc n (b lu) dc p (re d) cn -cn t (w ht) cn...

Page 48

48 9.2 outdoor unit 9.2.1 wh-ud03he5-1 wh-ud05he5-1 ms 3~ ms 3~ fa n mo to r base pan he at er optio nal blu 1 1 10 14 16 ic 19 3 w u v 5 5 blu or g or g 3 1 2 1 gr n gr n wh t bl k re d da ta (r ed ) ac -w ht (w ht ) fg 1( grn) fg 2 (g rn) ac -b lk (b lk ) fu se 10 3 (20a 250v ) ra t2 (g ry ) ra t1...

Page 49

49 9.2.2 wh-ud07he5-1 wh-ud09he5-1 w 1 recti fi cati on 1 ms 3 y b r r r (optiona l) 1 (b lue) ci rc ui t 3 discharge temp.S ensor (thermistor) (w hite) 6 1 cn- ev (m ai n exp an si on va lve ) rea cto r elec tro m ag neti c coil r w 2 3 (whi te ) 2 compres sor bl termi na l t3.15a l250v fuse 2 ci r...

Page 50: 10. Printed Circuit Board

50 10. Printed circuit board 10.1 indoor unit 10.1.1 main printed circuit board g02 cn-olp1 cn-pwr3 data cn-pwr2 cn-flwsen cn-pwr4 ac1-n g01 ac1-l3 cn-th2 cn-th1 cn-th3 cn-cnt cn6 cn5 cn4 cn3.

Page 51

51 10.1.2 sub printed circuit board (optional) cn-pwr202 cn207 cn204 cn-pwr204 cn205 cn-comm cn210 cn206.

Page 52

52 10.2 outdoor unit 10.2.1 main printed circuit board wh-ud03he5-1 wh-ud05he5-1 10.2.1.1 cn-tank cn-th3 cn-dis cn-th1 cn-mtr1 cn-stm cn-hot cn-hps power transistor (ipm) current transformer (ct).

Page 53

53 wh-ud07he5-1 wh-ud09he5-1 10.2.1.2 power transistor (ipm) cn-fm1 current transformer (ct) cn-ev cn-th1 cn-dis cn-hps cn-th2 cn-tank cn-psw1.

Page 54

54 10.2.1.2.1 noise filter printed circuit board 10.2.1.2.2 capacitor printed circuit board fg1 fg2 cn-wht cn-acl cn-acn cn-blk ac-blk ac-c dcn-in dcp-in dcn-out.

Page 55

55 11. Installation instruction field supply accessories (optional) no. Part model specifications maker i 2-way valve kit *cooling model electromotoric actuator sfa21/18 ac230v siemens 2-port valve vvi46/25 siemens ii room thermostat wired paw-a2w-rtwired ac230v - wireless paw-a2w-rtwireless iii mix...

Page 56

56 5 finish by sealing the sleeve with putty or caulking compound at the final stage. 11.1.3 piping installation typical piping installation 11.1.3.1 access to internal components 11.1.3.2 warning this section is for authorized and licensed electrician/water system installer only. Work behind the fr...

Page 57

57 11.1.3.3.1 cutting and flaring the piping 1 please cut using pipe cutter and then remove the burrs. 2 remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3 please make flare after inserting the...

Page 58

58 a pressure reducing valve (field supply) with below specification is strongly advised to be installed along the line of the tube connector i of tank unit. Refer typical piping installation section to locate both of these valves. Recommended pressure reducing valve specifications: o set pressure: ...

Page 59

59 5) please note that the system’s pressure may rise slightly if the test is carried out on mid day, due to temperature rise. The inverse may happen when there is temperature drop at night. However, this variation will be minimal. 6) waiting time depends on the size of the system. Larger systems ma...

Page 60

60 11.1.4 connect the cable to tank unit warning this section is for authorized and licensed electrician only. Work behind the control board cover secured by screws must only be carried out under supervision of qualified contractor, installation engineer or service person. Fixing of power supply cab...

Page 61

61 wire stripping and connecting requirement 11.1.4.2 connecting requirement 11.1.4.3 for tank unit with ud03he5-1/ud05he5-1 the equipment’s power supply 1 complies with iec/en 61000-3-2. The equipment’s power supply 1 complies with iec/en 61000-3-3 and can be connected to current supply network. Th...

Page 62

62 2 set the pressure relief valve level “down”. 3 start filling water (with pressure more than 0.1 mpa (1 bar)) to the space heating / cooling circuit via tube connector g . Stop filling water if the free water flow through pressure relief valve drainage . 4 turn on the tank unit and make sure wate...

Page 63

63 remote controller wiring 11.1.7.2 remote controller cable shall be (2 x min 0.3 mm 2 ), of double insulation pvc-sheathed or rubber sheathed cable. Total cable length shall be 50 m or less. Be careful not to connect cables to other terminals of tank unit (e.G. Power source wiring terminal). Malfu...

Page 64

64 replace the remote controller 11.1.7.5 cover replace the existing remote controller cover with remote controller cover to close the hole left after remove the remote controller. 1 release the remote controller cover’s hooks from behind the front plate. 2 press from front to fix the remote control...

Page 65

65 maintenance for safety relief 11.1.9.2 valve it is strongly recommended to operate the valve by turn the knob counter clockwise to ensure free water flow through discharge pipe at regular intervals to ensure it is not blocked and to remove lime deposit. Proper pump down procedure 11.1.9.3 warning...

Page 66

66 11.2 outdoor unit attached accessories optional accessory 11.2.1 select the best location if an awning is built over the unit to prevent direct sunlight or rain, be careful that heat radiation from the condenser is not obstructed. Avoid installations in areas where the ambient temperature may dro...

Page 67

67 model a b c d e f ud03*e5* and ud05*e5* 540 160 20 330 430 46 ud07*e5* and ud09*e5* 620 140 15 355 450 44 (unit : mm) after selecting the best location, start installation according to installation diagram. 1 fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm). 2 ...

Page 68

68 11.2.4 evacuation of the equipment when installing an air-to-water heat pump, be sure to evacuate the air inside the unit and pipes in the following procedure. 1 connect a charging hose with a push pin to the low side of a charging set and the service port of the 3-way valve. O be sure to connect...

Page 69

69 wire stripping and connecting requirement 11.2.5.1 11.2.6 pipe insulation 1 please carry out insulation at pipe connection portion as mentioned in indoor/outdoor unit installation diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2 if drain hose or conne...

Page 70

70 11.3 appendix 11.3.1 variation of system this section introduces variation of various systems using air-to-water heatpump and actual setting method. Introduce application related to temperature setting. 11.3.1.1 11.3.1.1.1 temperature setting variation for heating connect floor heating or radiato...

Page 71

71 connect floor heating or radiator directly to tank unit. Remote controller is installed on tank unit. Install separate external room thermistor (specified by panasonic) in the room where floor heating is installed. This is an application that uses external room thermistor. Examples of installatio...

Page 72

72 connect floor heating or radiator to 2 circuits through buffer tank as shown in figure. Install pumps and thermistors (specified by panasonic) on both circuits. Install mixing valve in the circuit with lower temperature among the 2 circuits. (generally, if install floor heating and radiator circu...

Page 73

73 this is an application that connects to the swimming pool only. Connects pool heat exchanger directly to tank unit without using buffer tank. Install pool pump and pool sensor (specified by panasonic) at secondary side of the pool heat exchanger. Remove remote controller from tank unit and instal...

Page 74

74 this is an application that connects the buffer tank to the tank unit before connecting to the solar water heater to heat up the tank. Buffer tank’s temperature is detected by buffer tank thermistor (specified by panasonic). Solar panel’s temperature is detected by solar thermistor (specified by ...

Page 75

75 11.3.2 how to fix cable connecting with external device (optional) 11.3.2.1 all connections shall follow to the local national wiring standard. It is strongly recommended to use manufacturer-recommended parts and accessories for installation. For connection to main pcb 1 two-way valve shall be sp...

Page 76

76 10 demand signal cable shall be (2 x min 0.3 mm 2 ), double insulation layer of pvc-sheathed or rubber- sheathed cable. 11 sg signal cable shall be (3 x min 0.3 mm 2 ), double insulation layer of pvc-sheathed or rubber-sheathed cable. 12 heat/cool switch cable shall be (2 x min 0.3 mm 2 ), double...

Page 77

77 connection of the main pcb 11.3.2.3 signal inputs optional thermostat l n =ac230v, heat, cool=thermostat heat, cool terminal ❈ it does not function when using the optional pcb external control dry contact open=not operate, short=operate (system setup necessary) able to turn on/off the operation b...

Page 78

78 signal inputs optional thermostat l n =ac230v, heat, cool=thermostat heat, cool terminal sg signal dry contact vcc-bit1, vcc-bit2 open/short (system setup necessary) switching sw (please connect to the 2 contacts controller) heat/cool sw dry contact open=heat, short=cool (system setup necessary) ...

Page 79

79 temperature (°c) resistance (kΩ) 40 3.615 35 4.375 30 5.326 25 6.523 20 8.044 15 9.980 10 12.443 5 15.604 0 19.70 -5 25.05 -10 32.10 -15 41.45 -20 53.92 -25 70.53 -30 93.05 -35 124.24 -40 167.82 for optional pump. Power supply: ac230v/50hz, recommended part: yonos 25/6: made by wilo for optional ...

Page 80

80 on the wall near the tank unit, attach the adaptor by screwing screws through the holes in the back cover. Pull the cn-cnt cable through the hole in the bottom of the adaptor and re-attach the front cover to the back cover. Use the included cord clamp to fix the cn-cnt cable to the wall. Pull the...

Page 81

81 11.3.3 system installation remote controller outline 11.3.3.1 24 40˚c 10:34am,mon 18˚c 5 6 4 3 2 1 ˚c name function 1: function icon display set function/status holiday mode demand control weekly timer room heater quiet mode tank heater remote controller room thermostat solar powerful mode boiler...

Page 82

82 first time of power on (start of installation) initialization 12:00, mon initializing. When power is on, firstly initialization screen appears (10 sec) « 17:26, wed start when initialization screen ends, it turns to normal screen. « language 12:00, wed english francais deutsch italiano select con...

Page 83

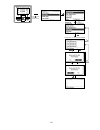

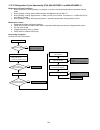

83 installer setup 11.3.3.2 1 system setup optional pcb connectivity yes/no 2 only when the selection for optional pcb is yes zone & sensor 1 zone/2 zone zone settings 3 heater capacity capacity select 4 anti freezing 5 only when the selection for optional pcb is yes buffer tank connection 6 base pa...

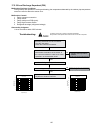

Page 84

84 17 operation setup heat water temp. For heating on compensation curve compensation curve setup cooling model only 18 direct direct temp. Setup outdoor temp. For heating off heating off temp. Setup 19 t for heating on t for heating setup 20 outdoor temp. For heater on o/d temp for heater on setup ...

Page 85

85 system setup 11.3.3.3 1. Optional pcb connectivity initial setting: no system setup 17:26, wed confirm confirm confirm confirm confirm optional pcb connectivity zone & sensor heater capacity anti freezing select if function below is necessary, please purchase and install optional pcb. Please sele...

Page 86

86 6. Base pan heater initial setting: no system setup 17:26, wed confirm confirm confirm tank connection buffer tank connection tank heater base pan heater select select whether base pan heater is installed or not. If set yes, select to use either heater a or b. A: turn on heater when heating with ...

Page 87

87 9. External sw initial setting: no system setup 17:26, wed confirm confirm confirm confirm base pan heater alternative outdoor sensor bivalent connection external sw select able to turn on/off the operation by external switch. 10. Solar connection initial setting: no system setup 17:26, wed alter...

Page 88

88 13. Sg ready initial setting: no system setup 17 confirm confirm confirm confirm :26, wed solar connection external error signal demand control sg ready select switch operation of heat pump by open-short of 2 terminals. Setting belows are possible sg signal working pattern vcc-bit1 vcc-bit2 open ...

Page 89

89 operation setup 11.3.3.4 17. Water temp. For heating on initial setting: compensation curve 35°c -5°c 15°c 55°c hot water temperature compensation curve outdoor temperature decide temperature of 4 points as shown in diagram set target water temperature to operate heating operation. Compensation c...

Page 90

90 23. Outdoor temp. For (heat to cool) initial setting: 15°c 15° c heat cool outdoor temp. Rising set outdoor temp that switches from heating to cooling by auto setting. Setting range is 5°c ~ 25°c timing of judgement is every 1 hour 24. Outdoor temp. For (cool to heat) initial setting: 10°c 10° c ...

Page 91

91 service setup 11.3.3.5 29. Pump maximum speed initial setting: depend on model service setup 17:26, wed flow rate max. Duty operation 88:8 l/min 0xce air purge select normally setting is not necessary. Please adjust when need to reduce the pump sound etc. Besides that, it has air purge function. ...

Page 92

92 11.4 service and maintenance custom menu when connect cn-cnt connector with computer please use optional usb cable to connect with cn-cnt connector. After connected, it requests for driver. If pc is under windows vista or later version, it automatically installs the driver under internet environm...

Page 93: 12. Operation and Control

93 12. Operation and control 12.1 basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer mai...

Page 94

94 12.1.4 target water temperature setting target water temperature control of standard system (optional pcb not 12.1.4.1 connected) there are 2 types of temperature control selection which are compensation and direct. Temperature control type selection by installer: 1 compensation : wlo, whi, odlo,...

Page 95

95 outdoor ambient is updated every 30 minutes when operation on. Setting water outlet temperature always follow w (lo) or w (hi) whenever is higher if outdoor ambient sensor or indoor communication error happen. However, when powerful mode is requested by remote control during heating mode, the hig...

Page 96

96 12.1.6 target zone water temperature control purpose:- to control zone mixing and zone pump according to the zone sensor temperature target zone 1 water temperature setting control 12.1.6.1 start condition o heating zone 1 is on by remote control or timer or auto mode or o cooling zone 1 is on by...

Page 97

97 target zone 2 water temperature setting control 12.1.6.2 start condition o heating zone 2 is on by remote control or timer or auto mode or o cooling zone 2 is on by remote control or timer or auto mode. Cancel condition o heating zone 2 is off by remote control or timer or auto mode and o cooling...

Page 98

98 * there will be no zone sensor connected to zone 1 (no zone sensor error), mixing valve and zone pump will not operate. During extension system (optional pcb connected) * there will be no zone sensor connected to zone 1 (no zone sensor error), mixing valve and zone pump will not operate. During e...

Page 99

99 12.1.7 auto mode operation control details: o to enable the unit to operate either heat or cool mode automatically, heat to cool set temperature and cool to heat set temperature can be set by control panel. O automatic operation is judged based on control panel setting temperature and outdoor amb...

Page 100

100 case 2: tank heater off or external heater is select o when heat pump off due to water thermos & tank temperature > tank water set temperature for continuously 20 seconds. Or o tank temperature > tank set temperature + 1°c for continuously 20 seconds. O tank thermo on case 1: tank heater on (int...

Page 101

101 conditon 2 : tank heater off (internal tank heater) if tank temperature achieve tank thermo off, heat pump turn off, water pump turn off, room heater off and 3 ways valve switch to room side. When tank temperature achieve heat pump on condition, water pump on, heat pump on and room heater turn o...

Page 102

102 3 room heater control: o during heating heat-up interval follow normal room heater control operation. 4 tank heater control: o during heating heat-up interval internal tank heater will not function under heating heat-up interval. O during tank heat-up interval internal tank heater will turn on a...

Page 103

103 5 2 ways valve is close. 6 indoor water pump control: o indoor water pump always turn on if room heat pump thermo on or tank thermo on. 12.1.12 outdoor fan motor operation outdoor fan motor is adjusted according to operation condition. It starts when compressor starts operation and it stops 30 s...

Page 104

104 1) p-q graph for different pump hex duty p-q (wh-adc0309h3e5) 12.2.2 zone water pump control purpose: water pump install at each zone to circulate the water inside each zone during buffer tank connection selected “yes” or 2 zone systems. Content: ac type water pump install for this zone water pu...

Page 105

105 pool water pump stop condition o pool zone: zone room request off or o pool function is cancel * zone 1 & zone 2 water pump need to turn off when antifreeze deice pump stop control activate and turn on back after the antifreeze deice pump stop control end under setting of "no" buffer tank connec...

Page 106

106 12.3 indoor unit safety 12.3.1 indoor unit safety control 1 when water pump is on, the system will start checking flow switch status (on/off). 2 if the flow switch on for 10 seconds, the system will check on the water inlet temperature for 10 seconds. If the water inlet temperature not exceeds 8...

Page 107

107 12.6 indoor back-up heater control 12.6.1 indoor electric heater control 1 normal heating mode o heater on condition: a. Heater switch is on b. After heatpump thermo on for [30] mins c. After water pump operate [9] mins d. Outdoor air temperature e. When water outlet temperature [-4 ° c] f. [20]...

Page 108

108 12.7 tank heater control 12.7.1 tank heater remote control setting 1 tank heater selection: external: - booster heater use to heat up tank when select external internal: - backup heater use to heat up tank when select internal * when select external tank heater, heater delay on timer need to set...

Page 109

109 12.8 base pan heater control (optional) to enable the base pan heater function, control panel initial setting has to be manually adjusted by activating base pan heater menu. There are 2 optional start condition can be selected, type a or type b. Control details: 1 type a: (default auto mode) sta...

Page 110

110 stop condition: force heater request off or operation off request or mode change request or power reset or error of above list happens during force heater operation. Control contents: when force heater mode start condition fulfilled, turn on water pump and turn on room heater follow below contro...

Page 111

111 end condition o off/on button is pressed. O powerful function is off by remote control. 12.11 quiet operation quiet mode is use to reduce the noise of outdoor unit by reducing the frequency or fan speed. Quiet level there are 3 level (level 1, level 2, level 3) to set by quick menu function on r...

Page 112

112 12.13 outdoor ambient thermo off control purpose: o stop provides heating to room side during high outdoor ambient condition. Control content: o heating outdoor ambient thermos off control only applicable when heat pump operate in heat mode. (this control will not activate when running in tank s...

Page 113

113 12.15 force dhw mode purpose: when user want to use hot water now, user can press this force dwh mode under the quick menu to operate tank only mode to boil up the tank temperature. Remocon setting: force dhw function can be activate under quick menu. Control content: when press the force dhw fu...

Page 114

114 12.17 anti freeze control anti freeze protection control menu can be set yes or no by control panel. In heatpump system, there are 3 types of anti freeze control: 1. Expansion tank anti-freeze control expansion tank anti freeze heater on condition: o outdoor ambient temp. Expansion tank anti fre...

Page 115

115 12.18 solar operation (optional) 12.18.1 solar operation: solar function: this function allow user to control the solar pump to operate depend on the solar sensor reading compare to the tank installed. Solar pump will circulate the hot water energy store at solar panel to heat up the dhw tank or...

Page 116

116 12.18.2 solar operation control solar function can only be activate if the solar function selection “yes” from remote control. To achieve hot water from solar panel, indoor need to control the solar pump and circulate hot water from solar panel. Under normal case: o solar pump start condition: s...

Page 117

117 parallel mode o parallel mode allows heat pump and boiler on at the same time. Boiler operates as an additional heating capacity when low heat pump capacity at low ambient condition. Control detail: during operation on at heat mode or tank mode or heat + tank mode o boiler signal turns on when: ...

Page 118

118 start condition: o water outlet ≥ 85°c continues for 5 minutes. O water inlet ≥ 85°c continues for 5 minutes. O zone1 water temp ≥ 75°c continues for 5 minutes. O zone2 water temp ≥ 75°c continues for 5 minutes. Contents: after start condition fulfilled, set boiler prohibit flag = 1 cancel condi...

Page 119

119 control content: external room thermostat control activate only when remote thermostat connection select yes by indoor control panel. When indoor running heat mode, refer thermo on/off from heating line feedback. And when indoor running cool mode, refer thermo on/off from cooling line feedback. ...

Page 120

120 12.23 external off/on control communication circuit between indoor unit and external controller is as per below. Maximum length of communication cable is 50 meter. Control content: external control switch control panel off/on control panel power led system status on on on on on off off off off o...

Page 121

121 12.24 external compressor switch (optional pcb) external compressor switch port can have two purpose of control as below: heat source on/off function (dip switch pin 3 on pcb "off") heater on/off function (dip switch pin 3 on pcb "on") heat source on/off function purpose: heat pump on/off functi...

Page 122

122 operation on/off will depend on remocon request. When heat mode is running with contact open, user change this setting to contact close, indoor will this signal to remocon judge and change mode to cool and send back to indoor. And it is same as from cool mode change to heat mode. * this switch h...

Page 123

123 if buffer selection is “yes” room side new target buffer tank temperature = current target buffer tank temperature * remote control setting (" capacity 1) % * max min regulation is follow target buffer tank temperature control specification ** no change of target zone water temperature, only set...

Page 124

124 control content: if start condition is fulfilled, indoor will receive the voltage signal from optional pcb. Indoor will send the rate value to outdoor unit. Outdoor will change the current limit according to the percentage receive from indoor unit. 12.28 holiday mode purpose: promotes energy sav...

Page 125

125 13. Protection control (wh-ud03he5-1 wh-ud05he5-1) 13.1 protection control for all operations 13.1.1 time delay safety control 1 the compressor will not start for three minutes after stop of operation. 13.1.2 30 seconds forced operation 1 once the compressor starts operation, it will not stop it...

Page 126

126 13.1.5 high pressure sensor control purpose: - to protect the system operation. Detection period: - after compressor on for 1 minute. Detection conditions: - when abnormal high voltage detection, 5 v or when open circuit detection 0v for 5 seconds continuously. After detection: - when abnormalit...

Page 127

127 13.2 protection control for heating operation 13.2.1 outdoor air temperature control the maximum current value is regulated when the outdoor air temperature rises above 14°c in order to avoid compressor overloading. 13.2.2 deice operation when outdoor pipe temperature and outdoor air temperature...

Page 128

1 1 .3 protection control for cooling operation 1 .3.1 outdoor air temperature control the compressor operating frequency is regulated in accordance to the outdoor air temperature as shown in the diagram below. This control will begin 1 minute after the compressor starts. Compressor frequency will a...

Page 129

129 14. Protection control (wh-ud07he5-1 wh-ud09he5-1) 14.1 protection control for all operations 14.1.1 time delay safety control 1 the compressor will not start for three minutes after stop of operation. 14.1.2 30 seconds forced operation 1 once the compressor starts operation, it will not stop it...

Page 130

130 14.1.5 high pressure sensor control purpose: - to protect the system operation. Detection period: - after compressor on for 1 minute. Detection conditions: - when abnormal high voltage detection, 5 v or when open circuit detection 0v for 5 seconds continuously. After detection: - when abnormalit...

Page 131

131 14.2 protection control for heating operation 14.2.1 outdoor air temperature control the maximum current value is regulated when the outdoor air temperature rises above 14°c in order to avoid compressor overloading. 14.2.2 deice operation when outdoor pipe temperature and outdoor air temperature...

Page 132

132 14.3 protection control for cooling operation 14.3.1 outdoor air temperature control the compressor operating frequency is regulated in accordance to the outdoor air temperature as shown in the diagram below. This control will begin 1 minute after the compressor starts. Compressor frequency will...

Page 133: 15. Servicing Guide

133 15. Servicing guide 15.1 how to take out front plate open and close front plate 1 remove the 2 mounting screws of bottom front plate. 2 slide it upwards to unhook the bottom front plate hook. 3 reverse above steps 1~2 for close it. 15.2 test run 1 before test run, make sure below items have been...

Page 134

134 15.4 pump down procedures refer below steps for proper pump down procedure. [screen 4] press sw & scroll to “pump down” press.

Page 135

135 15.5 how to adjust pump speed note: 1. Whenever at [screen 5], if press sw to off, pump operation should be turned off. 2. Whenever at [screen 6], if press sw to off, pump operation should be turned off. Press & scroll to “installer setup” [screen 4] - range (0.1~99.9)l/min - press or sw to sele...

Page 136

136 15.6 how to unlock cool mode operation must be off display latest status retrieved from eeprom press ( + + ) sw’s continuously for 5secs.

Page 137

137 15.7 eeprom factory default data setup procedure will stop & eeprom default data setup process will start. - once eeprom default data setup process is complete, initialization process will re-start from beginning. - press ( , , , ) simultaneously for 5secs continuously, initialization process du...

Page 138

138 15.8 dry concrete setup 11 : 00am,mon [screen 4] [screen n e e r c s [ ] 5 6] once ‘on’ is confirm, stage 1 setup will start every day stage will increment with its respective setup next page press & scroll to “installer setup”.

Page 139

139 - press or button to select no. Of stages. - press to store latest status. - press button, display will return to [screen 6]. Return to [screen 6] - if suppose to select 10 stages, then setup will start from stage 1/10. - press or button to select set temperature. - press button to store latest ...

Page 140: 16. Maintenance Guide

140 16. Maintenance guide in order to ensure safety and optimal performance of the tank unit, seasonal inspections on the tank unit, functional check of rccb/elcb, field wiring and piping have to be carried out at regular intervals. This maintenance should be carried out by authorized dealer. Contac...

Page 141

141 warning 4 air purge valve air purge valve must be installed at all high points in a closed water circuit system. An automatic air purge valve is provided inside the indoor unit. To automatically purge the air from the system, turn the plug on the air outlet anticlockwise by one complete turn fro...

Page 142

142 9 maintenance for anode bar to protect the tank body an anode bar is placed inside the tank. The anode bar will corrode, depending on the water quality. When diameter is approximate 8 mm the anode must be replaced. Examine it once in a year. A. Turn off power supply. B. Close water supply valve....

Page 143

143 16.1.4 specifications specifications of fresh water was heat transfer medium in brazed heat 16.1.4.1 exchanger parameter quality limits for tap water on the secondary side temperature below 60°c ph 7 to 9 alkalinity 60mg/l ₃ conductivity hardness [ca ⁺ , mg ⁺ ] / [hco ₃⁻ ] > 0.5 chloride sulphat...

Page 144: 17. Troubleshooting Guide

144 17. Troubleshooting guide 17.1 refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a ...

Page 145

145 17.2 relationship between the condition of the air-to-water heatpump indoor and outdoor units and pressure and electric current condition of the air-to- water heatpump indoor and outdoor units heating mode cooling mode low pressure high pressure electric current during operation low pressure hig...

Page 146

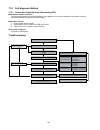

146 17.3 breakdown self diagnosis function 17.3.1 self diagnosis function (three digits alphanumeric code) when abnormality occur during operation, the system will stop operation, and off/on control panel led will blink and error code will display on the control panel. Even error code is reset by tu...

Page 147

147 press button and select “system check” display last 4 error retrieved from eeprom [screen 4] press sw to select “error history”.

Page 148

148 17.4 error codes table diagnosis display abnormality/protection control abnormality judgement primary location to verify h00 no abnormality detected — — h12 indoor/outdoor capacity unmatched 90s after power supply indoor/outdoor connection wire indoor/outdoor pcb specification and combination ta...

Page 149

149 diagnosis display abnormality/protection control abnormality judgement primary location to verify f20 outdoor compressor overheating protection 4 times occurrence within 30 minutes compressor tank temperature sensor clogged expansion valve or strainer insufficient refrigerant outdoor pcb compres...

Page 150

150 17.5 self-diagnosis method 17.5.1 connection capability rank abnormality (h12) malfunction decision conditions: during startup operation of cooling and heating, the capability rank of indoor checked by the outdoor is used to determine connection capability rank abnormality. Malfunction caused: 1...

Page 151

151 17.5.2 compressor tank temperature sensor abnormality (h15) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the compressor tank temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty connector connect...

Page 152

152 17.5.3 water pump abnormality (h20) malfunction decision conditions: during startup and operation of cooling and heating, the rotation speed detected by the ipm of water pump motor during water pump operation is used to determine abnormal water pump (feedback of rotation > 6,000rpm or 1,000rpm)....

Page 153

153 17.5.4 indoor refrigerant liquid temperature sensor abnormality (h23) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor refrigerant liquid temperature sensor are used to determine sensor error. Malfunction caused: 1 faul...

Page 154

154 17.5.5 service valve error (h27) malfunction decision conditions: during cooling operation, when:- [a] indoor refrigerant pipe temperature at compressor startup - present indoor refrigerant pipe temperature [b] present high pressure - high pressure at compressor startup 2 **judgment only for fir...

Page 155

155 17.5.6 abnormal solar sensor (h28) malfunction caused: 1 faulty connector connection. 2 faulty solar sensor. 3 faulty indoor sub pcb. Abnormality judgment: continue for 5 seconds. For safety reason and to prevent component breakdown, always switch off the power before remove and connect the comp...

Page 156

156 17.5.7 abnormal swimming pool sensor (h31) malfunction caused: 1 faulty connector connection. 2 faulty swimming pool sensor. 3 faulty indoor sub pcb. Abnormality judgment: continue for 5 seconds. For safety reason and to prevent component breakdown, always switch off the power before remove and ...

Page 157

157 17.5.8 abnormal buffer tank sensor (h36) malfunction caused: 1 faulty connector connection. 2 faulty buffer tank sensor. 3 faulty indoor sub pcb. Abnormality judgment: continue for 5 seconds. For safety reason and to prevent component breakdown, always switch off the power before remove and conn...

Page 158

158 17.5.9 brand code not matching (h38) malfunction caused: 1 indoor and outdoor brand code not match. For safety reason and to prevent component breakdown, always switch off the power before remove and connect the component. Caution yes ● use only panasonic units. ● change to panasonic unit. No br...

Page 159

159 17.5.10 compressor low pressure protection (h42) malfunction decision conditions: during operation of heating and after 5 minutes compressor on, when outdoor pipe temperature below -29°c or above 26°c is detected by the outdoor pipe temperature sensor. Malfunction caused: 1 dust accumulation on ...

Page 160

160 17.5.11 abnormal zone 1 sensor (h43) malfunction caused: 1 faulty connector connection. 2 faulty buffer tank sensor. 3 faulty indoor sub pcb. Abnormality judgment: continue for 5 seconds. For safety reason and to prevent component breakdown, always switch off the power before remove and connect ...

Page 161

161 17.5.12 abnormal zone 2 sensor (h44) malfunction caused: 1 faulty connector connection. 2 faulty buffer tank sensor. 3 faulty indoor sub pcb. Abnormality judgment: continue for 5 seconds. For safety reason and to prevent component breakdown, always switch off the power before remove and connect ...

Page 162

162 17.5.13 water flow switch abnormality (h62) malfunction decision conditions: during operation of cooling and heating, the water flow detected by the indoor water flow switch is used to determine water flow error. Malfunction caused: 1 faulty water pump. 2 water leak in system. 3 faulty connector...

Page 163

163 17.5.14 outdoor high pressure abnormality (h64) malfunction decision conditions: during operation of cooling and heating, when the outdoor high pressure sensor output signal is 0 vdc or 5 vdc. Malfunction caused: 1 faulty connector connection. 2 faulty sensor. 3 faulty outdoor unit pcb (main). A...

Page 164

164 17.5.15 deice circulation error (h65) malfunction decision conditions: during startup and operation of deice (mode 2), the water flow (> 10l/min) detected by the water flow switch is used to determine deice circulation error. Malfunction caused: 1 water flow in air-to-water heatpump indoor unit ...

Page 165

165 17.5.16 abnormal external thermistor 1 (h67) malfunction caused: 1 faulty connector connection. 2 faulty room temperature zone 1 sensor. 3 faulty indoor sub pcb. Abnormality judgment: continue for 5 seconds. For safety reason and to prevent component breakdown, always switch off the power before...

Page 166

166 17.5.17 abnormal external thermistor 2 (h68) malfunction caused: 1 faulty connector connection. 2 faulty room temperature zone 2 sensor. 3 faulty indoor sub pcb. Abnormality judgment: continue for 5 seconds. For safety reason and to prevent component breakdown, always switch off the power before...

Page 167

167 17.5.18 indoor backup heater olp abnormality (h70) malfunction decision conditions: during operation of indoor backup heater, when no power supplies to indoor backup heater or olp open circuit. Malfunction caused: 1 faulty power supply connector connection. 2 faulty connector connection. 3 fault...

Page 168

168 17.5.19 tank temperature sensor abnormality (h72) malfunction decision conditions: when tank connection is set to on, the temperatures detected by the tank temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty connector connection. 2 faulty sensor. 3 faulty indoor u...

Page 169

169 17.5.20 pcb communication error (h74) malfunction decision conditions: when external pcb connection is select “yes” and no communication with external pcb micon for 10 seconds and above. Malfunction caused: 1 faulty connector connection. 2 faulty indoor pcb. 3 faulty indoor sub pcb. Abnormality ...

Page 170

170 17.5.21 indoor-control panel communication abnormality (h76) malfunction decision conditions: during standby and operation of cooling and heating, indoor-control panel error occur. Malfunction caused: 1 faulty connector connection. 2 faulty control panel. 3 faulty indoor unit pcb (main). Trouble...

Page 171

171 17.5.22 indoor/outdoor abnormal communication (h90) malfunction decision conditions: during operation of cooling and heating, the data received from outdoor unit in indoor unit signal transmission is checked whether it is normal. Malfunction caused: 1 faulty outdoor unit pcb (main). 2 faulty ind...

Page 172

172 17.5.23 tank booster heater olp abnormality (h91) malfunction decision conditions: during operation of tank booster heater, and tank booster heater olp open circuit. Malfunction caused: 1 faulty connector connection. 2 faulty tank booster heater overload protector (olp). 3 faulty indoor unit pcb...

Page 173

173 17.5.24 unspecified voltage between indoor and outdoor (h95) malfunction decision conditions: the supply power is detected for its requirement by the indoor/outdoor transmission. Malfunction caused: 1 insufficient power supply. 2 faulty outdoor unit pcb (noise filter/main). Troubleshooting: for ...

Page 174

174 17.5.25 outdoor high pressure protection (h98) malfunction decision conditions: during operation of heating, when pressure 4.0 mpa and above is detected by outdoor high pressure sensor. Malfunction caused: 1 faulty water pump. 2 insufficient water flow rate in system. 3 water leak in system. 4 2...

Page 175

175 17.5.26 indoor freeze-up protection (h99) malfunction decision conditions: during anti-freezing control in cooling operation, when the indoor refrigerant liquid temperature malfunction caused: 1 faulty water pump. 2 insufficient water flow rate in system. 3 water leak in system. 4 2 way valve pa...

Page 176

176 17.5.27 outdoor high pressure switch activate (f12) malfunction decision conditions: during operation of cooling and heating, when pressure 4.5 mpa and above is detected by outdoor high pressure switch. Malfunction caused: 1 dust accumulation on the outdoor unit heat exchanger. 2 air short circu...

Page 177

177 17.5.28 compressor rotation failure (f14) malfunction decision conditions: a compressor rotation failure is detected by checking the compressor running condition through the position detection circuit. Malfunction caused: 1 compressor terminal disconnect. 2 faulty outdoor unit pcb (main). 3 faul...

Page 178

178 17.5.29 outdoor fan motor (dc motor) mechanism locked (f15) malfunction decision conditions: the rotation speed detected by the hall ic of the fan motor during fan motor operation is used to determine abnormal fan motor (feedback of rotation > 2550 rpm or malfunction caused: 1 operation stop due...

Page 179

179 17.5.30 input over current detection (f16) malfunction decision conditions: during operation of cooling and heating, when outdoor current above 14.8 a (ud03he5-1, ud05he5-1), 27.9 a (ud07he5-1, ud09he5-1) is detected by the current transformer (ct) in the outdoor unit pcb. Malfunction caused: 1 ...

Page 180

180 17.5.31 compressor overheating (f20) malfunction decision conditions: during operation of cooling and heating, when temperature above 107°c (ud03he5-1, ud05he5-1), 112°c (ud07he5-1, ud09he5-1) is detected by the compressor tank temperature sensor. Malfunction caused: 1 faulty compressor tank tem...

Page 181

181 17.5.32 ipm overheating (f22) malfunction decision conditions: during operation of cooling and heating, when temperature 95°c is detected by the outdoor ipm temperature sensor. Malfunction caused: 1 faulty outdoor unit fan motor. 2 faulty outdoor unit pcb (main). Abnormality judgment: continue 3...

Page 182

182 17.5.33 output over current detection (f23) malfunction decision conditions: during operation of cooling and heating, when outdoor dc current is above 21.1 a (ud03he5-1, ud05he5-1) 50.0 a (ud07he5-1, ud09he5-1) is detected by the ipm dc peak sensing circuitry in the outdoor unit pcb (main). Malf...

Page 183

183 17.5.34 refrigeration cycle abnormality (f24) (wh-ud03he5-1 and wh-ud05he5-1) malfunction decision conditions: 1 during operation of cooling and heating, compressor frequency > frated. 2 during operation of cooling and heating, running current: 0.65 a 3 during operation of cooling, water inlet t...

Page 184

184 17.5.35 refrigeration cycle abnormality (f24) (wh-ud07he5-1 and wh-ud09he5-1) malfunction decision conditions: 1 during compressor running (heating / cooling) for more than 10 minutes except deice, pumpdown and test mode. 2 during heating / cooling, water outlet and water inlet difference is les...

Page 185

185 17.5.36 four way valve abnormality (f25) malfunction decision conditions: 1 during heating operation, when the indoor pipe temperature of thermostat on indoor unit 2 during cooling operation, when the indoor pipe temperature of thermostat on indoor unit > 45°c. Malfunction caused: 1 faulty senso...

Page 186

186 17.5.37 outdoor high pressure switch abnormal (f27) malfunction decision conditions: during compressor stop, and outdoor high pressure switch is remain opened. Malfunction caused: 1 faulty connector connection. 2 faulty switch. 3 faulty outdoor unit pcb (main). Abnormality judgment: continue for...

Page 187

187 17.5.38 low discharge superheat (f29) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor pipe temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty connector connection. 2 faulty sensor. 3 f...

Page 188

188 17.5.39 indoor water outlet temperature sensor 2 abnormality (f30) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor water outlet temperature sensor 2 are used to determine sensor error. Malfunction caused: 1 faulty conn...

Page 189

189 17.5.40 outdoor air temperature sensor abnormality (f36) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor air temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty connector connection. 2 ...

Page 190

190 17.5.41 indoor water inlet temperature sensor abnormality (f37) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor water inlet temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty connector ...

Page 191

191 17.5.42 outdoor discharge pipe temperature sensor abnormality (f40) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor discharge pipe temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty co...

Page 192

192 17.5.43 power factor correction (pfc) abnormality (f41) malfunction decision conditions: during operation of cooling and heating, when the pfc protection circuitry in the outdoor unit pcb (main) senses abnormal high dc voltage level. Malfunction caused: 1 power supply surge. 2 compressor winding...

Page 193

193 17.5.44 outdoor pipe temperature sensor abnormality (f42) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor pipe temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty connector connection. ...

Page 194

194 17.5.45 outdoor defrost temperature sensor abnormality (f43) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor defrost temperature sensor are used to determine sensor error. Malfunction caused: 1 faulty connector connec...

Page 195

195 17.5.46 indoor water outlet temperature sensor abnormality (f45) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor water outlet temperature sensor are used to determine sensor errors. Malfunction caused: 1 faulty connect...

Page 196

196 17.5.47 outdoor current transformer open circuit (f46) malfunction decision conditions: a current transformer (ct) open circuit is detected by checking the compressor running frequency ( rated frequency) and ct detected input current ( malfunction caused: 1 ct defective. 2 faulty outdoor unit pc...

Page 197

197 17.5.48 cooling high pressure overload protection (f95) malfunction decision conditions: during operation of cooling, when pressure 4.0 mpa and above is detected by outdoor high pressure sensor. Malfunction caused: 1 dust accumulation in the outdoor unit heat exchanger. 2 air short circuit at ou...

Page 198

198 warning 18. Disassembly and assembly instructions high voltage are generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. 18.1 to remove front p...

Page 199

199 18.2 to remove pressure gauge 18.3 to remove remote control 3. Use spanner to release nut of pressure gauge. 1. Remove 3 screws to remove the particular plate. 2. Remove 4 screws to remove the connecting bar. 1. Remove the top case from the bottom case. Bottom case flat-blade screwdriver insert ...

Page 200

200 18.4 to remove rccb 18.5 to remove electronic controller 1. Remove 6 screws to remove the control board cover. Control board cover 3. Remove screw to remove the rccb. 2. Disconnect lead wires (black and white) from the rccb. Rccb 2. Disconnect all connectors from main pcb, cn-flwsn, cn-pump1, cn...

Page 201

201 18.6 to remove flow switch and air purge valve when reinstall flow switch, ensure the arrow on the flow switch is parallel with the pipe shaft and is facing in the direction of flow. During reinstall air purge valve. 18.7 to remove water pump 6. Remove 2 retaining rings, then remove the flow sen...

Page 202

202 18.8 to remove bottle complete 18.9 to remove water filter 3. Disconnect 2 pipe connection. 4. Remove 2 screws from bracket. 2. Remove air purge valve. 1. Disconnect the connector cn_olp1 from the electronic controller and detached the lead wire ht1-l3 (red) and ac2-l3 (black). 1. Set 2 valve fo...

Page 203: 19. Technical Data

203 19. Technical data 19.1 operation characteristics 19.1.1 wh-adc0309h3e5 wh-ud03he5-1 heating characteristics at different outdoor air temperature condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : ...

Page 204

204 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m outdoor temperature (°c) ca pac ity ( kw ) outdoor temperature (°c) input p o wer...

Page 205

205 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 19°c indoor water outlet temperature : 4°c piping length : 7 m outdoor temperature (°c) c apa ci ty ( kw ) outdoor temperature (°c) input p o we...

Page 206

206 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 23°c indoor water outlet temperature : 18°c piping length : 7 m outdoor temperature (°c) cap a ci ty ( kw ) outdoor temperature (°c) in pu t p o...

Page 207

207 heating characteristics at different piping length condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m piping length (m) piping length (m) input p o we r ( kw ) piping length (m) capa ci ty (k w...

Page 208

208 cooling characteristics at different piping length condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m piping length (m) capac ity ( kw ) piping length (m) in pu t p ow e r ( kw ) 0.900 0.940 0....

Page 209

209 19.1.2 wh-adc0309h3e5 wh-ud05he5-1 heating characteristics at different outdoor air temperature condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m outdoor temperature (°c) outdoor temperature (...

Page 210

210 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m outdoor temperature (°c) cap a ci ty ( kw ) outdoor temperature (°c) in p u t p o...

Page 211

211 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 19°c indoor water outlet temperature : 14°c piping length : 7 m outdoor temperature (°c) cap a ci ty ( kw ) outdoor temperature (°c) in p u t p ...

Page 212

212 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 23°c indoor water outlet temperature : 18°c piping length : 7 m outdoor temperature (°c) ca pac ity ( kw ) outdoor temperature (°c) inp u t po w...

Page 213

213 heating characteristics at different piping length condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m piping length (m) piping length (m) in pu t p owe r ( kw ) piping length (m) cap a ci ty (k...

Page 214

214 cooling characteristics at different piping length condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m piping length (m) capac ity ( kw ) piping length (m) in pu t p ow e r ( kw ) 1.60 0 1.62 0 ...

Page 215

215 19.1.3 wh-adc0309h3e5 wh-ud07he5-1 heating characteristics at different outdoor air temperature condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m outdoor temperature (°c) outdoor temperature (...

Page 216

216 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m outdoor temperature (°c) cap a ci ty ( kw ) outdoor temperature (°c) in pu t p ow...

Page 217

217 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 19°c indoor water outlet temperature : 14°c piping length : 7 m outdoor temperature (°c) c apa ci ty ( kw ) outdoor temperature (°c) in put p ow...

Page 218

218 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 23°c indoor water outlet temperature : 18°c piping length : 7 m outdoor temperature (°c) cap a ci ty ( kw ) outdoor temperature (°c) in pu t p o...

Page 219

219 heating characteristics at different piping length condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m piping length (m) piping length (m) inp ut p ow er ( kw ) piping length (m) c a pac ity (k ...

Page 220

220 cooling characteristics at different piping length condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m piping length (m) cap a ci ty ( kw ) piping length (m) inpu t p o w er ( kw ) 2.000 2.100 2...

Page 221

221 19.1.4 wh-adc0309h3e5 wh-ud09he5-1 heating characteristics at different outdoor air temperature condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m outdoor temperature (°c) outdoor temperature (...

Page 222

222 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m outdoor temperature (°c) ca pa ci ty ( kw ) outdoor temperature (°c) in put p ow ...

Page 223

223 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 19°c indoor water outlet temperature : 14°c piping length : 7 m outdoor temperature (°c) c apa ci ty ( kw ) outdoor temperature (°c) inpu t p ow...

Page 224

224 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 23°c indoor water outlet temperature : 18°c piping length : 7 m outdoor temperature (°c) c apa ci ty ( kw ) outdoor temperature (°c) in put p ow...

Page 225

225 heating characteristics at different piping length condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m piping length (m) piping length (m) inp u t p ower ( kw ) piping length (m) c a pac ity (k ...

Page 226

226 cooling characteristics at different piping length condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m piping length (m) capac ity ( kw ) piping length (m) input p ow e r ( kw ) 2.60 0 2.70 0 2....

Page 227

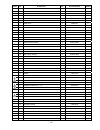

227 19.2 heating capacity table 19.2.1 wh-adc0309h3e5 wh-ud03he5-1 water out (°c) 30 35 40 45 50 55 outdoor air (°c) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) -15 3200 ...

Page 228

228 19.3 cooling capacity table 19.3.1 wh-adc0309h3e5 wh-ud03he5-1 water out (°c) 7 14 18 outdoor air (°c) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) 18 2400 420 4400 730 3700 490 25 3200 730 4100 860 3500 590 35 3200 1040 3900 1070 3300 740 43 2900 1200 3...

Page 229

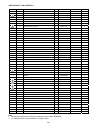

229 20. Exploded view and replacement parts list 20.1 indoor unit note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. O/i o/i i/i i/i o/i o/i o/i 52 53 55 56 40 57 54 43 32 35 33 37 38 39 36 31 28 30 29...

Page 230

230 note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 17 15 9 20 18 16 26 27 8 13 14 11 4 19 24 23 5 3 2 50 7 6 22.

Page 231

231 safety ref. No. Description qty. Wh-adc0309h3e5 remark 1 chassis-complete 1 acxd50c00250 2 drain valve 1 cwb65c1026 o 3 pressure and temp relief valve (tank) 1 acxb62-00110 o 4 sensor co. (tank temp cn-th2) 1 cwa50c3257 o 5 filter complete 1 cwb51c1021 6 base pan (heater) 1 acxd52-00260 7 purge ...

Page 232

232 safety ref. No. Description qty. Wh-adc0309h3e5 remark 53 operating instruction 1 acxf55-03310 54 operating instruction 1 acxf55-03320 55 operating instruction 1 acxf55-03330 56 operating instruction 1 acxf55-03340 57 installation instruction 1 acxf60-03330 note: all parts are supplied from papa...

Page 233

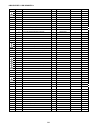

233 20.2 outdoor unit 20.2.1 wh-ud03he5-1 wh-ud05he5-1 note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 48 23 17 47 22 1 19 30 38 2 3 26 27 4 21 24 37 18 20 33 35 39 44 48 42 14 34 32 42 31 40 13 43 ...

Page 234

234 safety ref. No. Description & name qty. Wh-ud03he5-1 wh-ud05he5-1 remark 1 chassis ass'y 1 cwd52k1317 ← 2 anti - vibration bushing 3 cwh50077 ← 3 compressor 1 5rd132xbe21 ← o 4 nut - compressor mount 3 cwh561096 ← 5 crankcase heater 1 cwa341044 ← 6 sound proof material 1 cwg302762 ← 7 bracket fa...

Page 235

235 20.2.2 wh-ud07he5-1 wh-ud09he5-1 note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 41 19 36 40 44 37 38 34 35 33 22 44 42 32 16 39 28 47 1 51 52 44 46 43.

Page 236

236 note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 15 14 3 7 17 10 12 18 19 45 48 8 21 20 49 11 31 30 5 5 6 6 5 29 2 6 13 4 9 1.

Page 237

237 note: the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts. 50 23 27 25 26 24.

Page 238

238 safety ref. No. Description & name qty. Wh-ud07he5-1 wh-ud09he5-1 remark 1 base pan ass’y 1 cwd52k1294 ← 2 compressor 1 5kd240xcc21 ← o 3 crankcase heater 1 cwa341043 ← 4 bushing - compressor mount 3 cwh50055 ← 5 nut-compressor mount 3 cwh561049 ← 6 gasket for terminal cover 3 cwb811017 ← 7 cond...

Page 239

239 safety ref. No. Description & name qty. Wh-ud07he5-1 wh-ud09he5-1 remark 51 accessory - complete 1 cwh82c1839 ← 52 accessory co. (drain elbow) 1 cwg87c900 ← note: all parts are supplied from papamy, malaysia (vendor code: 00029488). “o” marked parts are recommended to be kept in stock. [papamy] ...