- DL manuals

- Panasonic

- Heat Pump

- WH-MXC16G9E8

- Service manual

Panasonic WH-MXC16G9E8 Service manual

© Panasonic Corporation 2015.

Order No: PAPAMY1506106CE

Mono bloc Unit

WH-MXC16G9E8

Destination

Europe

Turkey

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

Summary of WH-MXC16G9E8

Page 1

© panasonic corporation 2015. Order no: papamy1506106ce mono bloc unit wh-mxc16g9e8 destination europe turkey warning this service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not contain warnings or cautions to advise non...

Page 2: Table Of Contents

2 table of contents 1. Safety precautions ............................................. 3 2. Specifications ..................................................... 5 3. Features ............................................................... 7 4. Location of controls and components ............ 8 4.1 ...

Page 3: 1. Safety Precautions

3 1. Safety precautions read the following “safety precautions” carefully before installation of (mono bloc) air-to-water heatpump system (hereafter referred to as “mono bloc unit”). Electrical works and water installation works must be done by licensed electrician and licensed water system installe...

Page 4

4 warning 18. This equipment is strongly recommended to be installed with residual current device (rcd) on-site according to the respective national wiring rules or country-specific safety measures in terms of residual current. 19. The unit is only for use in a closed water system. Utilization in an...

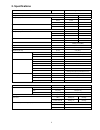

Page 5: 2. Specifications

5 2. Specifications item unit refrigerant system performance test condition en14511 cooling condition (ambient/water) a35w7 - cooling capacity kw 12.20 - btu/h 41600 - kcal/h 10490 - eer w/w 2.56 - kcal/hw 2.20 - heating condition (ambient/water) a7w35 a2w35 heating capacity kw 16.00 16.00 btu/h 546...

Page 6

6 item unit mono bloc unit input power kw cooling: 4.76 heating: 3.74 cooling: - heating: 5.16 maximum input power for mono bloc unit kw 10.27 power supply 1: phase (ø) / max. Current (a) / max. Input power (w) three / 15.5 / 10.27k power supply 2: phase (ø) / max. Current (a) / max. Input power (w)...

Page 7: 3. Features

7 3. Features inverter technology o energy saving high efficiency compact design environment protection o non-ozone depletion substances refrigerant (r410a) easy to use remote control weekly timer setting quality improvement o random auto restart after power failure for safety restart operation o ga...

Page 8

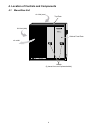

8 4. Location of controls and components 4.1 mono bloc unit air inlet (rear) air outlet air inlet (side) handle (2 pieces front and 2 pieces behind) cabinet front plate top plate.

Page 9

9 4.1.1 main components component name pcb pressure relief valve flow switch pressure gauge water pump rccb bushing cabinet front plate connector name water inlet water outlet cabinet top plate overload protector heater assembly expansion vessel cover air purge valve 1 2 a b 3 4 5 6 7 8 9 10 11 12 1...

Page 10

10 4.1.2 location of control 4.1.2.1 remote control the user interface allows the installer and user to setup, use and maintain the unit. Off/on button this button starts or stops the mode operation function of the unit. Operation led this led indicates the unit is in operation. External thermo cont...

Page 11

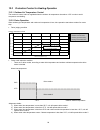

11 4.1.3 to adjust initial settings dealer select menus and determine settings according to the system available in the household. It is recommended that all alterations of settings are done by an authorised dealer or specialist. • after initial installation, you may manually adjust the settings. Th...

Page 12

12 10 booster heater to activate or deactivate the water tank’s booster heater. Note: if no is selected, menu 11 is skipped. Yes 11 booster heater delay timer to delay time for the booster heater to activate while the system is heating up the water tank. 1 hour 20 minutes ~ 1 hour 35 minutes • do no...

Page 13

13 4.1.4 how to use user enjoy quiet operation press . • this operation reduces the noise of mono bloc unit. The operation may cause heating/* 1 cooling ability to decrease. User system status check mode 1 s s e r p . (the display shows status.) 2 s s e r p or to check the selected mode. • dry concr...

Page 14

14 dealer operation/settings to be done only by the authorised dealer/specialist. User operation/settings to be done by the authorised dealer/specialist or user. * 1 the system is locked to operate without cool mode. It can be unlocked only by authorised installers or our authorised service partners...

Page 15

15 user shifting the water temperature desired temperature setting this easily shifts the water outlet temperature if the setting is undesirable. 1 press to enter the water temperature shifting mode. 2 press to change setting. 3 press or to set the desired temperature. (temperature range: -5 °c ~ 5 ...

Page 16

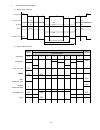

16 user weekly timer setting promotes energy saving by allowing you to set up to 6 programmes in any given day. Indicates the next timer operation programme day to be selected indicates the next timer operation day programme number in a day off timer on timer lights up if timer operation is selected...

Page 17

17 dry concrete function • during construction to dry the concrete under a preset temperature. 1 press and simultaneously and hold for 5 seconds until the display shows “ ”. 2 press . (the display shows “ ”.) 3 press press to select day. Or to set the desired temperature. 4 press to confirm the sele...

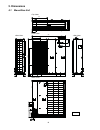

Page 18: 5. Dimensions

18 5. Dimensions 5.1 mono bloc unit (579) 400 356 15 4 1410 61 5 426 .5 175 275 41 3 30 c c 70 27 7 320 152 1283 256 (30) 293 318.5 50 45 45 45 83.5 unit: mm.

Page 19

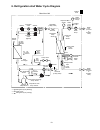

19 6. Refrigeration and water cycle diagram air purge valve mono bloc unit pipe temp. Sensor defrost sensor water inlet temp. Sensor water outlet temp. Sensor pipe temp. Sensor refrigerant temp. Sensor air temp. Sensor bypass exit temp. Sensor eva exit temp. Sensor backup heater outdoor side expansi...

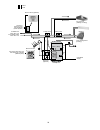

Page 20

20 connect to mono bloc unit main electronic controller (water system) to water inlet mono bloc unit from water outlet mono bloc unit remote control room thermo (optional) fan coil unit (heating / cooling) panel heater unit (heating) floor heating panel (heating) cold water supply connect to mono bl...

Page 21: 7. Block Diagram

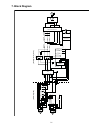

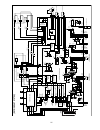

21 7. Block diagram (water system) (refrigerant system) fus e 2 fuse 3 m m sc ms 3~ rect if ic atio nc ircu it rect ifica tio n circ uit re ct ific atio n circ uit rel a y rel a y pt c re act o r r e a c t o r c ap aci t o r ry-p wr 2 ry-h t1 heat er heat er ry-h t2 ry-h ot fu s e 2 01 fu s e 2 02 f...

Page 22

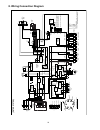

22 8. Wiring connection diagram ww w w w w 1 2 3 1 2 3 te rm in al bo ar d a te rm in al bo ar d te rm in al bo ar d wa te r pu m p opt ional rc cb bl y b b re ac to r tr an sfo rmer ww wb l bl r w 21 21 sw 1 sw 2 y g y/ g bl w w bo br r y g bl g r w po w er su pp ly 1 3-phas e ac 400v 50hz 400v 25 ...

Page 23

23 bl 2 l1- in (b lu ) fg2 01 (gr n) fg2 03 (gr n) fg 202 (g rn) fu se 201 20a 500v fuse 2 t3. 15a l25 0v fuse 3 t6. 3a l2 50v fu se 202 20a 500v fu se 203 20a 500v l2- in (y lw ) l3- in (b lk ) n- in (w ht ) l3-in (bla ck) l-in (whi te) l3-out (ora nge) l2-out (gray ) l3-p 1 (ora nge) l2-p 1 (whi t...

Page 24

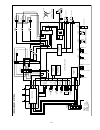

24 9. Electronic circuit diagram ww w w w w 1 2 3 1 2 3 te rm in al bo ar d a te rm in al bo ar d te rm in al bo ar d wa te r pu m p op ti o na l rc cb bl y b b re ac to r tr an sf or m er ww wb l bl r w 21 21 sw 1 sw 2 y g y/g bl w w bo br r y g bl g r w po w er su pp ly 1 3- ph as e ac 400v 50h z ...

Page 25

25 bl 2 l1- in (b lu ) fg2 01 (gr n) fg2 03 (gr n) fg 202 (g rn) fu se 201 20a 500v fuse 2 t3. 15a l 250v fuse 3 t6. 3a l250v fu se 202 20a 500v fu se 203 20a 500v l2- in (y lw ) l3- in (b lk ) n- in (w ht ) l3-in (bla ck) l-in (whi te) l3-out (ora nge ) l2-out (gray ) l3-p1 (oran ge) l2-p1 (whi te)...

Page 26: 10. Printed Circuit Board

26 10. Printed circuit board 10.1 water system 10.1.1 main printed circuit board cn-th1 cn-solar cn-flow cn-thermo g05 data g07 ac1-l3 ac1-n g01 ac1-l1 ac1-l2 g04 cn-olp1 cn-t1 cn-th2 cn-th3 cn-olp2 cn-remote2 cn-pump2 g08 cn-rcv2 cn-v3 g03 cn-pwr cn-v2 cn-ht.

Page 27

27 10.1.2 solar printed circuit board (optional).

Page 28

28 10.2 refrigerant system 10.2.1 main printed circuit board cn-th3 cn-ht2 cn-v1 cn-hot cn-ht1 cn-th2 cn-th1 cn-psw1 cn-ry1 cn-hps cn-ry2 cn-fm1 cn-fm2 cn-dis cn-ev1 cn-ev2.

Page 29

29 10.2.2 noise filter printed circuit board fg202 fg203 n-in l3-in fg201 l1-in l2-in l2-out l1-out l3-out n-out.

Page 30

30 11. Installation instruction mono bloc unit dimension diagram front view bottom view rear view 50 83 . 5 45 45 45 24. 5 27 3 40 0 980 150 28 41 3 27 5 175 320 1283 39 141 0 13 40 20 water outlet pipe water inlet pipe 30 0m m or mo re 300mm or more 10 00 mm or m or e 100mm o r more drain hose conn...

Page 31

31 main components component name pcb pressure relief valve flow switch pressure gauge water pump rccb bushing cabinet front plate connector name water inlet water outlet cabinet top plate overload protector heater assembly expansion vessel cover air purge valve 1 2 a b 3 4 5 6 7 8 9 10 11 12 13 14 ...

Page 32

32 11.1 select the best location install the mono bloc unit in outdoor locations only. Avoid installations in areas where the ambient temperature may drop below -20°c. The mono bloc unit must be installed on a flat, solid surface. A place removed from any heat source or steam which may affect the op...

Page 33

33 11.3 piping installation warning this section is for authorized and licensed electrician / water system installer only. Work behind the front plate secured by screws must only be carried out under supervision of qualified contractor, installation engineer or service person. Please engage a licens...

Page 34

34 drainage piping installation use a drain hose with inner diameter of 15 mm. The hose must be installed in a continuously downward direction and left open to the frost-free atmosphere. If drain hose is long, use a metal support fixture along the way to eliminate the wavy pattern of drain tube. Wat...

Page 35

35 how to guide cable/cord to bushing bind all power supply cords to the u-shaped tube (covered with foam) with band strap (field supply) bind all optional cables and cords with this bands. Bind all power supply cords to the tube (covered with foam) with band strap (field supply) guide all the cable/c...

Page 36

36 8. Tank sensor shall be resistance type, please refer to graph 4.1 for the characteristic and details of sensor. Its cable shall be (2 × min 0.3 mm 2 ), double insulation layer (with insulation strength of min 30v) of pvc-sheathed or polychloroprene sheathed cable. 9. External controller shall be...

Page 37

37 11.4.2 connecting requirement the equipment’s power supply 1 complies with iec/en 61000-3-2. The equipment’s power supply 1 complies with iec/en 61000-3-3 and can be connected to current supply network. The equipment’s power supply 2 complies with iec/en 61000-3-2. The equipment’s power supply 2 ...

Page 38

38 11.4.4 selecting the installation location upper case lower case remote control 30mm or more 30mm or more 30mm or more 120mm or more remote control lower case allow sufficient space around the remote control (1) as shown in the illustration above. Install in a place which is away from direct sunl...

Page 39

39 b. If remote control cable is exposed 1 install the remote control lower case to the wall with the two accessory screws (4). 2 fasten the screws properly until screw head is lower than the rib and reach the base of remote control lower case to ensure they do not damage the pcb inside the remote c...

Page 40

40 11.5 checking and test run procedures warning be sure to switch off all the power supply before performing each of the below action. (1) remove the 5 mounting screws as shown in the illustration. (2) slide the cabinet front plate downward to release the pawls. Then, pull it toward front to remove...

Page 41: 12. Operation and Control

41 12. Operation and control 12.1 basic function inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer mai...

Page 42

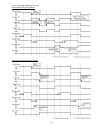

42 heat mode operation time chart on off on off 3 ways valve mode on heatpump thermo off heatpump thermo on on off id water pump backup heater on off backup heater startup timer heater on heater off heater off heater on timer for backup heater to on back from previous off backup heater startup timer...

Page 43

43 12.1.3 cooling operation 12.1.3.1 thermostat control compressor is off when water outlet temperature – internal water setting temperature > -1.5°c for continuously 3 minutes. Compressor is on after waiting for 3 minutes, if the water outlet temperature – water inlet temperature (temperature at th...

Page 44

44 12.1.4 auto mode operation outdoor ambient cool to heat setting temp. Cool mode heat mode heat to cool setting temp. Control details: o to enable the unit to operate either heat or cool mode automatically, heat to cool set temperature and cool to heat set temperature can be set by control panel. ...

Page 45

45 12.1.5 tank mode operation control contents: 3 ways valve direction o 3 ways valve switch to tank side during tank thermo on condition. Switch 3 ways valve to room side when tank achieve tank thermo off temperature and solar turn on condition. Heat pump thermostat characteristic o water set tempe...

Page 46

46 tank mode tank set temp. = 65°c tank side tank thermo off on off on off 3 ways valve id water pump on off booster heater on off heat pump booster heater delay time tank mode (solar priority is not set) on off on off 3 ways valve id water pump on off solar request on off solar 3 way valve on off b...

Page 47

47 12.1.6 heat + tank mode operation setting 1: when heating priority is set by control panel: 1. 3 ways valve control: o 3 ways valve switch to room side during external room thermo on or solar 3 ways valve on or tank thermo off time, and switch to tank side at external room thermo off and solar 3 ...

Page 48

48 characteristic of heat pump thermo on/off under tank side condition water outlet thermo condition o heat pump thermo off temp: 1. Heat pump thermo off temp = 53°c + [+4°c]. 2. Water outlet temperature > heat pump thermo off temp for continuous 90 seconds, heat pump off and water pump continue on....

Page 49

49 heat + tank mode (heating priority set) under solar priority set condition: under solar priority not set condition:.

Page 50

50 setting 2: when heating priority is not set by control panel: when solar priority is set/not set by control panel: 1. 3 ways valve control: o 3 ways valve switch to room side during heating heat-up interval, and switch to tank side during tank heat-up interval. Both modes will switch alternativel...

Page 51

51 characteristic of heat pump thermo on/off under tank side condition water outlet thermo condition o heat pump thermo off temp: 1. Heat pump thermo off temp = 53°c + [+4°c] 2. Water outlet temperature > heat pump thermo off temp for continuous 90 seconds, heat pump off but water pump continue on. ...

Page 52

52 heat + tank mode (heating priority not set) tank set temp. = 60°c on off on off 3 ways valve id water pump on off booster heater on off heat pump interval timer interval timer tank side tank side room side switch to tank side even the heating interval timer not yet completed when tank temperature...

Page 53

53 start with tank mode first room thermo off tank thermo off (end) heat pump thermo off solar request on go in tank interval only after solar off switch to tank heat-up when room thermo off heat pump off at room side when room thermo off and high tank temp. Booster heater off after achieve tank tem...

Page 54

54 heat + tank mode (heating priority not set) under solar priority not set condition: on off room thermo on off on off 3 ways valve on off backup heater on off booster heater water pump on off on off solar valve on off 2 ways valve on off solar request heat pump start with tank mode first tank ther...

Page 55

55 12.1.7 cool + tank mode operation 12.1.7.1 cooling priority set 1. 3 ways valve control: 3 ways valve switch to room side during external room thermo on or tank thermo off time, and switch to tank side at external room thermo off and solar 3 ways valve off. 2. Heat pump operation control:- during...

Page 56

56 characteristic of heat pump thermo on/off under tank side condition a) water outlet thermo condition o heat pump thermo off temp: 1. Heat pump thermo off temp = [53°c] + [+4°c]. 2. Water outlet temperature > heat pump thermo off temp for continuous 3 minutes, heat pump off. O next thermo on temp:...

Page 57

57 12.1.7.2 cooling priority not set 1. 3 ways valve control: 3 ways valve switch to room side during room cooling interval and switch to tank side during tank heat-up interval. Both modes will switch alternately. Tank mode is the initial running mode of this cool + tank mode. 2. Heat pump operation...

Page 58

58 water inlet thermo condition o heat pump thermo off temp: 1) water inlet temperature > [55°c] for continuous 60 seconds, heat pump off. O thermo on temp: 1) thermo on temp = water inlet temperature > [55°c]. C) solar operation condition (only under solar priority set condition) when solar pump on...

Page 59

59 12.1.8 setting water outlet temperature for heat mode the set temperature defines the parameters for the outdoor ambient temperature dependent operation of the unit. Where by the internal water setting temperature is determined automatically depending on the outdoor temperature. The colder outdoo...

Page 60

60 12.1.9 water temperature thermo shift setting switchs are ignored during “pumpdw” = on. Switchs are ignored during “status” = on. “ ▲ ”, “ ▼ ”, ”select” switch are ignored if “setting” = off. “cancel” switch is ignored if “setting” = off & “status” = off. If “set” switch pressed for less than 5se...

Page 61

61 12.2 water pump 12.2.1 water pump control once the indoor unit is on, the water pump will be on immediately and no error judgement for 9 minutes. However, during this 9 minutes operation, if there is any abnormality cause at outdoor or malfunction, the compressor should be off immediately and res...

Page 62

62 12.2.2 a-class pump specification + power for drive dc280-373v - + power for control dc15±10% control signal dc0v-dc6v feedback speed (puls signal) 4puls/rotation - pump 67 5 6 4 2 1 3 vdd gnd vcc fg vsp control signal is analog voltage (dc0v-6v) generated by microcomputer pwm port. Microcomputer...

Page 63

63 12.2.4 water pump speed feedback error basically pump speed feedback is control by micon. When pump speed is below low limit or over high limit for a few seconds, micon detect pump error and system is stopped. Error detection conditions: current pump speed current pump speed > 6000rpm for 10 seco...

Page 64

64 12.5 indoor unit safety 12.5.1 indoor unit safety control 1 when water pump is on, the system will start checking flow switch status (on/off). 2 if the flow switch on for 10 seconds, the system will check on the water inlet temperature for 10 seconds. If the water inlet temperature not exceeds 80...

Page 65

65 12.8 indoor back-up heater control 12.8.1 indoor electric heater control 1 normal heating mode o heater on condition: a. Heater switch is on b. After heatpump thermo on for [30] mins c. After water pump operate [9] mins d. Outdoor air temperature e. When water outlet temperature [-8 ° c] f. [20] ...

Page 66

66 12.9 tank booster heater control 12.9.1 tank booster heater control heating operation condition: tank set temperature + [-7°c] tank set temperature + [+2°c] heater off heater on 1 booster heater turn on condition: o after booster heater delay timer fulfill during heatpump startup time in tank mod...

Page 67

67 12.11 sterilization mode purpose: o to sterilize water tank by setting the required boiling temperature. Control start condition: o tank connection menu is set to yes by control panel. O sterilization menu is set to yes by control panel. O sterilization signal received from control panel by timer...

Page 68

68 12.13 anti freeze control anti freeze protection control menu can be set yes or no by control panel. In heatpump system, there are 3 types of anti freeze control: 1. Expansion tank anti-freeze control expansion tank anti freeze heater on condition: o outdoor ambient temp. Expansion tank anti free...

Page 69

69 12.14 solar operation (optional) 12.14.1 solar operation: 1 external solar heat source signal can be connect to unit for proper control of heat source switching during tank boiling time. 2 control according to preset whether solar priority is set or not. 3 when tank connection is not set at setti...

Page 70

70 solar operation chart in different mode and condition tank mode (solar priority set condition) tank mode (solar priority not set condition).

Page 71

71 heat + tank mode (heating priority not set) (solar priority set condition) tank side 3 way valve room side heatpump on off t1 t2 t2 t3 booster heater solar request solar 3 way valve on off on off on off when solar 3 way valve turn on during tank interval, cancel tank interval immediately and swit...

Page 72

72 heat + tank mode (heating priority set) & cool + tank mode 3 way valve heatpump on off booster heater solar request solar 3 way valve on off on off on off room side on off on off booster heater thermo off booster heater off due to solar 3 way valve on solar priority set solar priority not set sol...

Page 73

73 12.15 external room thermostat control (optional) purpose: 1 better room temperature control to fulfill different temperature request by external room thermostat. Recommended external room thermostat: maker characteristic siemen (rev200) touch panel siemen (raa20) analog connection of external ro...

Page 74

74 12.16 three ways valve control purpose: - 3 ways valve is used to change flow direction of hot water from heat pump between heating side and tank side. Control contents: 1 3 ways valve switch off: o during 3 ways valve switch off time, the hot water will provide heat capacity to heating side. 2 3...

Page 75

75 12.18 external off/on control communication circuit between indoor unit and external controller is as per below. External controller panasonic pcb cn-thermo 17 18 5v 12v_4 r25 1k r23 10k r1 1 4 2 3 zd2 pc1 g2 g2 c30 0.01µ 16v maximum length of communication cable is 20 meter. Control content: ext...

Page 76

76 12.19 holiday mode purpose: promotes energy saving by allowing the user to stop the system during holiday and enables the system to resume at the preset temperature after holiday. Control details: o range of days can be set in holiday mode is from 1 to 999 days. O after days of holiday have been ...

Page 77: 13. Protection Control

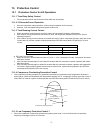

77 13. Protection control 13.1 protection control for all operations 13.1.1 time delay safety control 1 the compressor will not start for three minutes after stop of operation. 13.1.2 30 seconds forced operation 1 once the compressor starts operation, it will not stop its operation for 30 seconds. 2...

Page 78

78 13.1.6 low frequency protection control 2 when all the below conditions comply, the minimum compressor frequency will change to lower frequency. Temperature, t, for: heating cooling outlet water (°c) t t outdoor air (°c) t t indoor heat exchanger (°c) t ≥ 0 t 13.1.7 high pressure sensor control p...

Page 79

79 13.2 heat exchanger (hex) protection control water inlet 10°c 12° free zone (compressor on, heater off) deice (compressor off, heater on) start condition: - when outdoor ambient temperature is less than 10°c. Control details: - heater will turn on and heat pump turn off when water inlet temperatu...

Page 80

80 13.3 protection control for heating operation 13.3.1 outdoor air temperature control the maximum current value is regulated when the outdoor air temperature rises above 14°c in order to avoid compressor overloading. 13.3.2 deice operation when outdoor pipe temperature and outdoor air temperature ...

Page 81

81 deice operation time diagram a. Deice mode 1 control: od fan id pump expansion valve four way valve compressor free free on off off on on free 5 7 6 4 9 8 3 2 1 on on free free max 9 minutes 30 seconds deice 1 b. Deice mode 2 control: od fan od fan main expansion valve bypass expansion valve four...

Page 82

82 13.4 protection control for cooling operation 13.4.1 outdoor air temperature control the compressor operating frequency is regulated in accordance to the outdoor air temperature as shown in the diagram below. This control will begin 1 minute after the compressor starts. Compressor frequency will ...

Page 83: 14. Servicing Mode

83 14. Servicing mode 14.1 remove the cabinet front plate 1. Remove the 5 mounting screws as shown in the illustration. 2. Slide the cabinet front plate downward to release the pawls. Then, pull it toward front to remove it. Cabinet front plate mounting screws mounting screws 14.2 remove the cabinet...

Page 84

84 14.4 proper pump down procedure strictly follow the steps below for proper pump down procedure. Explosion may occur if the steps are not followed as per sequence. 1. Press the “service” switch on remote control to enter service mode. Operate the system in sr : 01 mode for pump down operation. 2. ...

Page 85

85 14.7 how to unlock cool mode 1. Press buttons set and service for 5 seconds. 2. Press select button. 3. Unlock cool mode with ▲/▼. 4. Press set button. 14.8 dry concrete [service mode: 03] if dry concrete has been set, dry concrete status can be activated and monitored by following procedure. 1 p...

Page 86: 15. Maintenance Guide

86 15. Maintenance guide in order to ensure optimal performance of the unit, seasonal inspections on the unit, external filter and field wiring have to be carried out at regular intervals. This maintenance should be carried out by authorized dealer. 1. Water pressure water pressure should not lower ...

Page 87

87 warning be careful not to touch parts other than rccb/elcb test button when the power is supplied to indoor unit. Else, electrical shock may happen. O push the “test” button on the rccb/elcb. The lever would turn down and indicate “0” and indicate green colour if it functions normal. O contact au...

Page 88: 16. Troubleshooting Guide

88 16. Troubleshooting guide 16.1 refrigeration cycle system in order to diagnose malfunctions, make sure that there are no electrical problems before inspecting the refrigeration cycle. Such problems include insufficient insulation, problem with the power source, malfunction of a compressor and a f...

Page 89

89 16.2 relationship between the condition of the mono bloc unit and pressure and electric current condition of the mono bloc unit heating mode cooling mode low pressure high pressure electric current during operation low pressure high pressure electric current during operation water leakage or insu...

Page 90

90 16.3 breakdown self diagnosis function 16.3.1 self diagnosis function (three digits alphanumeric code) when abnormality occur during operation, the system will stop operation, and off/on remote control led will blink and error code will display on the remote control timer display lcd. Even error ...

Page 91

91 16.4 error codes table diagnosis display abnormality/protection control abnormality judgement primary location to verify h00 no abnormality detected — — h12 indoor/outdoor capacity unmatched 90s after power supply indoor/outdoor connection wire indoor/outdoor pcb specification and combination tab...

Page 92

92 diagnosis display abnormality/protection control abnormality judgement primary location to verify f37 indoor water inlet temperature sensor abnormality continue for 5 sec. Water inlet temperature sensor (defective or disconnected) f40 outdoor discharge pipe temperature sensor abnormality continue...

Page 93

93 16.5 self-diagnosis method 16.5.1 connection capability rank abnormality (h12) malfunction decision conditions: during startup operation of cooling and heating, the capability rank of indoor checked by the outdoor is used to determine connection capability rank abnormality. Malfunction caused: 1....

Page 94

94 16.5.2 compressor tank temperature sensor abnormality (h15) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the compressor tank temperature sensor are used to determine sensor error. Malfunction caused: 1. Faulty connector connect...

Page 95

95 16.5.3 water pump abnormality (h20) malfunction decision conditions: during startup and operation of cooling and heating, the rotation speed detected by the ipm of water pump motor during water pump operation is used to determine abnormal water pump (feedback of rotation > 6,000rpm or 1,000rpm). ...

Page 96

96 16.5.4 indoor refrigerant liquid temperature sensor abnormality (h23) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor refrigerant liquid temperature sensor are used to determine sensor error. Malfunction caused: 1. Faul...

Page 97

97 16.5.5 service valve error (h27) malfunction decision conditions: during cooling operation, when:- [a] indoor refrigerant pipe temperature at compressor startup - present indoor refrigerant pipe temperature [b] present high pressure - high pressure at compressor startup **judgment only for first ...

Page 98

98 16.5.6 compressor low pressure protection (h42) malfunction decision conditions: during operation of heating and after 5 minutes compressor on, when outdoor pipe temperature below -29°c or above 26°c is detected by the outdoor pipe temperature sensor. Malfunction caused: 1. Dust accumulation on t...

Page 99

99 16.5.7 water flow switch abnormality (h62) malfunction decision conditions: during operation of cooling and heating, the water flow detected by the indoor water flow switch is used to determine water flow error. Malfunction caused: 1. Faulty water pump. 2. Water leak in system. 3. Faulty connecto...

Page 100

100 16.5.8 outdoor high pressure abnormality (h64) malfunction decision conditions: during operation of cooling and heating, when the outdoor high pressure sensor output signal is 0vdc or 5vdc. Malfunction caused: 1. Faulty connector connection. 2. Faulty sensor. 3. Faulty outdoor unit pcb (main). A...

Page 101

101 16.5.9 deice circulation error (h65) malfunction decision conditions: during deice operation, flow switch detects water flow for 10 seconds during deice. Malfunction caused: 4. Secondary pump. 5. Flow switch faulty. 6. Water pump faulty. 7. Indoor pcb. Abnormality judgment: continue 10 seconds. ...

Page 102

102 16.5.10 indoor backup heater olp abnormality (h70) malfunction decision conditions: during operation of indoor backup heater, when no power supplies to indoor backup heater or olp open circuit. Malfunction caused: 1. Faulty power supply connector connection. 2. Faulty connector connection. 3. Fa...

Page 103

103 16.5.11 tank temperature sensor abnormality (h72) malfunction decision conditions: when tank connection is set to on, the temperatures detected by the tank temperature sensor are used to determine sensor error. Malfunction caused: 1. Faulty connector connection. 2. Faulty sensor. 3. Faulty indoo...

Page 104

104 16.5.12 indoor-control panel communication abnormality (h76) malfunction decision conditions: during standby and operation of cooling and heating, indoor-remote control error occur. Malfunction caused: 1. Faulty connector connection. 2. Faulty remote control 3. Faulty indoor unit pcb (main)..

Page 105

105 16.5.13 indoor/outdoor abnormal communication (h90) malfunction decision conditions: during operation of cooling and heating, the data received from outdoor unit in indoor unit signal transmission is checked whether it is normal. Malfunction caused: 1. Faulty outdoor unit pcb (main). 2. Faulty i...

Page 106

106 16.5.14 tank booster heater olp abnormality (h91) malfunction decision conditions: during operation of tank booster heater, and tank booster heater olp open circuit. Malfunction caused: 1. Faulty connector connection. 2. Faulty tank booster heater overload protector (olp). 3. Faulty indoor unit ...

Page 107

107 16.5.15 unspecified voltage between indoor and outdoor (h95) malfunction decision conditions: the supply power is detected for its requirement by the indoor/outdoor transmission. Malfunction caused: 1. Insufficient power supply. 2. Faulty outdoor unit pcb (noise filter/main)..

Page 108

108 16.5.16 outdoor high pressure protection (h98) malfunction decision conditions: during operation of heating, when pressure 4.0 mpa and above is detected by outdoor high pressure sensor. Malfunction caused: 1. Faulty water pump. 2. Insufficient water flow rate in system. 3. Water leak in system. ...

Page 109

109 16.5.17 indoor freeze-up protection (h99) malfunction decision conditions: during anti-freezing control in cooling operation, when the indoor refrigerant liquid temperature malfunction caused: 1. Faulty water pump. 2. Insufficient water flow rate in system. 3. Water leak in system. 4. 2 way valv...

Page 110

110 16.5.18 outdoor high pressure switch activate (f12) malfunction decision conditions: during operation of cooling and heating, when pressure 4.5mpa and above is detected by outdoor high pressure switch. Malfunction caused: 1. Dust accumulation on the outdoor unit heat exchanger. 2. Air short circ...

Page 111

111 16.5.19 compressor rotation failure (f14) malfunction decision conditions: a compressor rotation failure is detected by checking the compressor running condition through the position detection circuit. Malfunction caused: 1. Compressor terminal disconnect. 2. Faulty outdoor unit pcb (main). 3. F...

Page 112

112 16.5.20 outdoor fan motor (dc motor) mechanism locked (f15) malfunction decision conditions: the rotation speed detected by the hall ic of the fan motor during fan motor operation is used to determine abnormal fan motor (feedback of rotation > 2550rpm or malfunction caused: 1. Operation stop due...

Page 113

113 16.5.21 input over current detection (f16) malfunction decision conditions: during operation of cooling and heating, when outdoor current above 27.9a is detected by the current transformer (ct) in the outdoor unit pcb. Malfunction caused: 1. Excessive refrigerant. 2. Faulty outdoor unit pcb (mai...

Page 114

114 16.5.22 compressor overheating (f20) malfunction decision conditions: during operation of cooling and heating, when temperature above 107°c is detected by the compressor tank temperature sensor. Malfunction caused: 1. Faulty compressor tank temperature sensor. 2. 2/3 way valve closed. 3. Refrige...

Page 115

115 16.5.23 ipm overheating (f22) malfunction decision conditions: during operation of cooling and heating, when temperature 95°c is detected by the outdoor ipm temperature sensor. Malfunction caused: 1. Faulty outdoor unit fan motor. 2. Faulty outdoor unit pcb (main). Abnormality judgment: continue...

Page 116

116 16.5.24 output over current detection (f23) malfunction decision conditions: during operation of cooling and heating, when outdoor dc current is above 54.0a ± 4.0a (for: ud12~16ce) is detected by the ipm dc peak sensing circuitry in the outdoor unit pcb (main). Malfunction caused: 1. Faulty outd...

Page 117

117 16.5.25 refrigeration cycle abnormality (f24) malfunction decision conditions: 1. During operation of cooling and heating, compressor frequency > frated. 2. During operation of cooling and heating, running current: 0.65a 3. During operation of cooling, water inlet temperature - indoor refrigeran...

Page 118

118 16.5.26 four way valve abnormality (f25) malfunction decision conditions: 1. During heating operation, when the indoor pipe temperature of thermostat on indoor unit 2. During cooling operation, when the indoor pipe temperature of thermostat on indoor unit > 45°c. Malfunction caused: 1. Faulty se...

Page 119

119 16.5.27 outdoor high pressure switch abnormal (f27) malfunction decision conditions: during compressor stop, and outdoor high pressure switch is remain opened. Malfunction caused: 1. Faulty connector connection. 2. Faulty switch. 3. Faulty outdoor unit pcb (main). Abnormality judgment: continue ...

Page 120

120 16.5.28 indoor water outlet temperature sensor 2 abnormality (f30) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor water outlet temperature sensor 2 are used to determine sensor error. Malfunction caused: 1. Faulty con...

Page 121

121 16.5.29 outdoor air temperature sensor abnormality (f36) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor air temperature sensor are used to determine sensor error. Malfunction caused: 1. Faulty connector connection. 2...

Page 122

122 16.5.30 indoor water inlet temperature sensor abnormality (f37) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor water inlet temperature sensor are used to determine sensor error. Malfunction caused: 1. Faulty connector...

Page 123

123 16.5.31 outdoor discharge pipe temperature sensor abnormality (f40) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor discharge pipe temperature sensor are used to determine sensor error. Malfunction caused: 1. Faulty c...

Page 124

124 16.5.32 power factor correction (pfc) abnormality (f41) malfunction decision conditions: during operation of cooling and heating, when the pfc protection circuitry in the outdoor unit pcb (main) senses abnormal high dc voltage level. Malfunction caused: 1. Power supply surge. 2. Compressor windi...

Page 125

125 16.5.33 outdoor pipe temperature sensor abnormality (f42) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor pipe temperature sensor are used to determine sensor error. Malfunction caused: 1. Faulty connector connection....

Page 126

126 16.5.34 outdoor defrost temperature sensor abnormality (f43) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the outdoor defrost temperature sensor are used to determine sensor error. Malfunction caused: 1. Faulty connector conne...

Page 127

127 16.5.35 indoor water outlet temperature sensor abnormality (f45) malfunction decision conditions: during startup and operation of cooling and heating, the temperatures detected by the indoor water outlet temperature sensor are used to determine sensor errors. Malfunction caused: 1. Faulty connec...

Page 128

128 16.5.36 outdoor current transformer open circuit (f46) malfunction decision conditions: a current transformer (ct) open circuit is detected by checking the compressor running frequency (≥ rated frequency) and ct detected input current ( malfunction caused: 1. Ct defective. 2. Faulty outdoor unit...

Page 129

129 16.5.37 cooling high pressure overload protection (f95) malfunction decision conditions: during operation of cooling, when pressure 4.0mpa and above is detected by outdoor high pressure sensor. Malfunction caused: 1. Dust accumulation in the outdoor unit heat exchanger. 2. Air short circuit at o...

Page 130

130 17. Disassembly and assembly instructions warning high voltage are generated in the electrical parts area by the capacitor. Ensure that the capacitor has discharged sufficiently before proceeding with repair work. Failure to heed this caution may result in electric shocks. Warning be sure to swi...

Page 131

131 17.3 to remove the cabinet rear plate 17.4 to remove pressure gauge 17.5 to remove rccb.

Page 132

132 17.6 to remove transformer and electronic controller board electronic controller board using screw driver remove screw to remove electronic controller board. Disconnect all connectors of cn-ht(wht), cn-v2(wht), cn-v3(grn), cn-rcv2(wht), cn-olp2(wht), cn-th2(wht), cn-thermo(wht), cn-th3(wht), cn-...

Page 133

133 17.7 to remove pressure relief valve, flow switch and air purge valve pressure relief valve flow switch air purge valve 1. Remove 2 retaining rings. 2. Pull down to remove water hose. 3. Pull outward to remove pressure relief valve. 4. Turn the flow switch anti-clockwise then remove flow switch....

Page 134

134 17.8 to remove water pump water pump 1. Disconnect cn-pump2 connector 2. Remove the screw from the particular plate. 4. Remove 2 retaining rings, then pull out the water pump. 3. Loosen the nut. When reinstall the water pipe, use grease or water at the joining..

Page 135

135 17.9 to remove bottle complete bottle complete 1. Remove the olp teminal cover, then detached lead wire ht1-l2 (orange) and ac2-l3 (black) from the olp terminal. 2. Remove the retaining ring. 3. Loosen 2 nuts. 4. Remove 4 screws to remove the bottle complete. When reinstall the water pipe, use g...

Page 136: 18. Technical Data

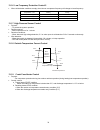

136 18. Technical data 18.1 operation characteristics heating characteristics at different outdoor air temperature condition outdoor air temperature : 7°c (dbt), 6°c (wbt) indoor water inlet temperature : 30°c indoor water outlet temperature : 35°c piping length : 7 m 2.000 3.000 4.000 5.000 6.000 7...

Page 137

137 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 7°c piping length : 7 m 7.000 8.500 10.000 11.500 13.000 14.500 18 21 24 27 30 33 36 39 42 45 outdoor tem...

Page 138

138 cooling characteristics at different outdoor air temperature condition outdoor air temperature : 35°c (dbt), -°c (wbt) indoor water inlet temperature : 12°c indoor water outlet temperature : 18°c piping length : 7 m outdoor temperature (°c) c a pac ity (kw ) outdoor temperature (°c) input p ow e...

Page 139

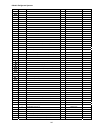

139 18.2 heating capacity table water out (°c) 30 35 40 45 50 55 outdoor air (°c) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) capacity (w) input power (w) -15 16000 6300 16000 6890 16000 7450 16000 8...

Page 140

140 19. Exploded view and replacement parts list 19.1 (refrigerant system) 81 59 60 25 50 52 55 56 55 56 53 57 58 58 54 54 51 61 67 28 66 67 80 76 46 46.

Page 141

141 6 25 68 30 2 4 1 3 62 × 8 75 71 70 13 13 12 10 4 74 5 21 20 26 14 14 24 78 8 7 9 23 13 72 73 11 15.

Page 142

142 44 38 82 29 31 32 22 39 note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 143

143 safety ref. No. Description & name qty. Wh-mxc16g9e8 remark 1 base pan ass’y 1 cwd52k1276 2 compressor 1 5jd650xba22 o 3 bushing - compressor mount 3 cwh50055 4 nut - compressor mount 3 cwh561049 5 crankcase heater 1 cwa341053 6 condenser complete 1 acxb32c0001 7 high pressure sensor cn-hps 1 cw...

Page 144

144 safety ref. No. Description & name qty. Wh-mxc16g9e8 remark 78 sensor - comp. (bypass & eva exit temp) cn-th3 1 cwa50c3165 o 80 sound proof material 1 cwg302598 81 sound proof material 1 cwg302975 82 magnet relays (ry1) 1 k6c2aga00002 o 83 magnet relays (ry2) 1 k6c4e8a00001 o 84 reactor 3 g0c353...

Page 145

145 19.2 (water system) 44 46 50 17 16 34 22 18 3 33 1 45 45 47 2 19 35 49 5 4.

Page 146

146 o/i o/i 40 i/i 41 39 20 21 30 27 36 25 26 28 31 51 32 29 note the above exploded view is for the purpose of parts disassembly and replacement. The non-numbered parts are not kept as standard service parts..

Page 147

147 safety ref. No. Description & name qty. Wh-mxc16g9e8 remark 1 base pan ass’y 1 cwd52k1381 2 hot water coil - complete 1 cwb90c1142 o 3 receiver 1 cwb141073 4 flow switch cn-flow 1 cwb621128 o 5 pump 1 cwb532116 o 16 bottle comp. 1 cwh90c0056 17 heater ass'y 1 cwa34k1049 o 18 sound proof material...