- DL manuals

- PleasureCraft Engine Group

- Engine

- 5.0L

- Diagnostic Manual

PleasureCraft Engine Group 5.0L Diagnostic Manual - This Page Left

Summary of 5.0L

Page 1

Mefi 4 / 4b diagnostic manual 5.0/5.7/6.0/8.1l l510005p 11/05.

Page 2: This Page Left

This page left intentionally blank.

Page 3: Contents

Marine electronic fuel injection (mefi 4 / 4b) contents section 1 - general information ........................................................................................................................ Page 1-1 section 2 - ecm and sensors .........................................................

Page 4: This Page Left

This page left intentionally blank.

Page 5: Section 1

5.0/5.7/6.0l/8.1l general information 1 - 1 mefi 4 - pcm marine electronic fuel injection (mefi) section 1 general information contents clearing diagnostic trouble codes (scan) ......Page 5 non-scan diagnosis of driveability concerns (no dtcs set) .................................................Pag...

Page 6: General Description

1 - 2 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm general description visual and physical inspection important: this visual and physical inspection is very important. Perform this inspection carefully and thoroughly. Perform a careful visual and physical inspection when performing any diagnost...

Page 7

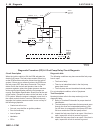

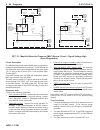

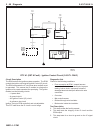

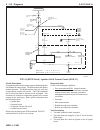

5.0/5.7/6.0l/8.1l general information 1 - 3 mefi 4 - pcm figure 1-1 - marine data link connector (dlc) a b c d e k j h g f a b c d e ms 13554 data link connector (dlc) 6-18-93 times. At the end of the dtc’s, the ecm will simply go back and start over with fl ashing dtc 12. Service mode when the dtc ...

Page 8

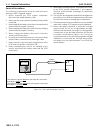

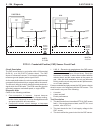

1 - 4 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm xxxxxxxxxxxxxxx defaultxxxxxxxxxxx xxxxxxxxxxxxxxx defaultxxxxxxxxxxx 0 volts 5 volts 6-5-93 ms 13553 v o l t a g e typical sensor range “window” 4.6v 0.7v figure 1-2 - example of sensor normal operation clearing diagnostic trouble codes (non- ...

Page 9

5.0/5.7/6.0l/8.1l general information 1 - 5 mefi 4 - pcm xxxxxxxxxxxxxxx defaultxxxxxxxxxxx xxxxxxxxxxxxxxx defaultxxxxxxxxxxx ------50 -4.2v out of range sensor ------150 -1.7v actual coolant temperature high temp - 0 volts low temp - 5 volts 6-5-93 ms 13552 t e m p e r a t u r e figure 1-3 - examp...

Page 10

1 - 6 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm figure 1-4 - test light amperage draw test dc amps testlight * battery + - if the ammeter indicates less than 3/10 amp(.3a) current flow, the testlight is safe to use. If the ammeter indicates more than 3/10 amp(.3a) current flow, the testlight...

Page 11

5.0/5.7/6.0l/8.1l general information 1 - 7 mefi 4 - pcm voltmeter - voltage position measures magnitude of voltage when connected in parallel to an existing circuit. A digital voltmeter with a 10 megohm input impedance is used because this type of meter will not load down the circuit and result in ...

Page 12

1 - 8 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm j 35689 j 28741-a/bt-8234-a special tools (2 of 3) rt0086 j 34730-2c & j 34730-350/bt 8329 rtk0078 ta 06075 metri-pack terminal remover used for removing 150 series metri-pack “pull-to-seat” terminals from connectors. Refer to wiring harness se...

Page 13

5.0/5.7/6.0l/8.1l general information 1 - 9 mefi 4 - pcm harness test adapter kit used to make electrical test connections in current weather pack, metri-pack and micro-pack style terminals. 20’ diagnostic connector extension cable extension cable to go between the scan tool and the dlc on the engin...

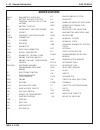

Page 14: Abbreviations

1 - 10 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm baro - barometric pressure bat - battery, battery positive terminal, battery or system voltage b+ - battery positive ckp - crankshaft position sensor ckt - circuit cmp - camshaft position sensor conn - connector cyl - cylinder deg - degrees di...

Page 15: On-Board Service

5.0/5.7/6.0l/8.1l general information 1 - 11 mefi 4 - pcm outer jacket mylar drain wire drain wire 1 remove outer jacket. 2 unwrap aluminum/mylar tape. Do not remove mylar. 1 locate damaged wire. 2 remove insulation as required. 3 splice two wires together using splice clips and rosin core solder. 3...

Page 16

1 - 12 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm rs 22187 figure 1-6 - metri-pack series 150 terminal removal a b 1 4 5 3 2 2 1 1. Metri-pack series 150 female terminal. 2. Locking tang. 3. Tool j35689 or bt-8446. 4. Connector body. 5. Seal. Metri-pack series 150 terminals figure 1-6 some ec...

Page 17

5.0/5.7/6.0l/8.1l general information 1 - 13 mefi 4 - pcm female connector body male connector body 1. Open secondary lock hinge on connector 2. Remove terminal using tool 3. Cut wire immediately behind cable seal 6. Close secondary lock hinge 5. Push terminal into connector until locking tangs enga...

Page 18

1 - 14 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm important • to ensure proper engine operation after repair of connector assembly, wires must be in proper connector location. Before removing index cover, note if there are any wires of the same color. Mark these wires from the location that t...

Page 19

5.0/5.7/6.0l/8.1l general information 1 - 15 mefi 4 - pcm figure 1-8 - micro-pack 100/w series 2 1 3 4 5 6 7 8 9 10111213141516 18 17 1920212223242526272829303132 1 2 tab b tab c 3 4 tab b tab c tab a tab a tab a tab b tab b figure c - strain relief opened figure b - strain relief closed figure a - ...

Page 20: This Page Left

1 - 16 general information 5.0/5.7/6.0/8.1l mefi 4 - pcm this page left intentionally blank.

Page 21: Section 2

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 1 mefi 4 - pcm marine electronic fuel injection (mefi) section 2 engine control module (ecm) and sensors this section will describe the function of the engine control module (ecm) and the sensors. The section explains how voltages reflect the inputs and outputs ...

Page 22: General Description

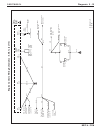

2 - 2 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm typical sensor ecm voltage out signal input 4-24-91 ms 11697 figure 2-1 - three-wire sensors typical sensor ecm sensor signal sensor ground 4-24-91 ms 11698 5v figure 2-2 - two-wire sensors two-wire sensors figure 2-2 shows a schematic representati...

Page 23

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 3 mefi 4 - pcm 4-18-91 ms 11696 v o l t a g e time digital binary signal figure 2-3 - digital voltage signal switch types switched inputs (also known as discretes) to the ecm can cause one bit to change, resulting in information being communicated to the ecm. Sw...

Page 24

2 - 4 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm j2 j1 mefi3004 figure 2-4 - engine control module (ecm) the ecm controls output circuits such as the injectors, iac, relays, etc. By controlling the ground or power feed circuit. Memory there are three types of memory storage within the ecm. They a...

Page 25

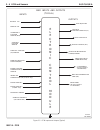

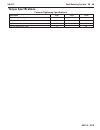

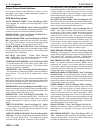

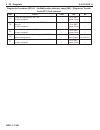

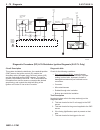

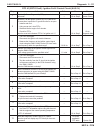

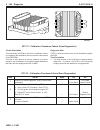

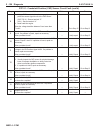

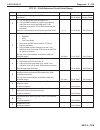

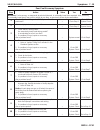

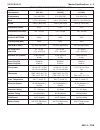

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 5 mefi 4 - pcm ecm inputs and sensor descriptions figure 2-5 lists the data sensors, switches, and other inputs used by the ecm to control its various systems. Although we will not cover them all in great detail, there will be a brief description of each. Input ...

Page 26

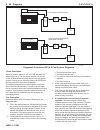

2 - 6 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm figure 2-5 - ecm inputs and outputs (typical) e l e c t r o n i c c o n t r o l m o d u l e mefi inputs and outputs (typical) inputs outputs battery 12v ignition 12v throttle position (tp) sensor manifold absolute pressure(map) engine coolant tempe...

Page 27

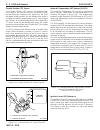

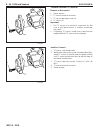

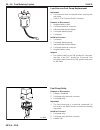

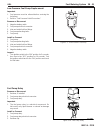

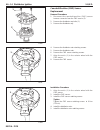

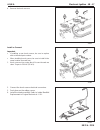

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 7 mefi 4 - pcm figure 2-6 - engine coolant temperature (ect) sensor 1 harness connector 2 locking tab 3 sensor 8-24-94 rs 22189 1 2 3 figure 2-7 - manifold absolute pressure (map) sensor/ intake air temperature (iat) sensor (used on 5.0/5.7l engines) figure 2-8 ...

Page 28

2 - 8 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm intake air temperature (iat) sensor (5.0/5.7l) the intake air temperature (iat) sensor is a thermistor which changes value based on the temperature of air entering the engine (figure 2-12). Low temperature produces a high resistance (100,000 ohms a...

Page 29

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 9 mefi 4 - pcm discrete switch inputs several discrete switch inputs are utilized by the mefi system to identify abnormal conditions that may affect engine operation. Pull-up and pull-down type switches are currently used in conjunction with the ecm to detect cr...

Page 30: Diagnosis

2 - 10 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm diagnosis engine control module (ecm) to read and clear diagnostic trouble codes, use a scan tool or diagnostic trouble code (dtc) tool. Important: use of a scan tool is recommended to clear diagnostic trouble codes from the ecm memory. Diagnostic...

Page 31

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 11 mefi 4 - pcm fuel pump relay replacement removal procedure 1. Turn the ignition off. 2. Remove the retainer. 3. Disconnect the fuel pump relay electrical connector. 4. Remove the fuel pump relay. Important: the fuel pump relay is an electrical component. Do n...

Page 32

2 - 12 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm engine coolant temperature (ect) sensor replacement notice: care must be taken when handling the ect sensor. Damage to the sensor will affect proper operation of the mefi system. Remove or disconnect 1. Turn off the ignition. 2. Drain the cooling ...

Page 33

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 13 mefi 4 - pcm manifold absolute pressure (map) / intake air temperature (iat) sensor replacement (5.0/5.7l) removal procedure 1. Remove the map sensor retaining stud. 2. Remove the map sensor from the intake manifold. 3. Inspect the map sensor seal for wear or...

Page 34

2 - 14 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm manifold absolute pressure (map) sensor replacement (6.0/8.1l) removal procedure 1. Disconnect the manifold absolute pressure (map) sensor electrical connector (1). 684798 2. Remove the map sensor retaining bolt and washer (1). 3. Remove the map s...

Page 35

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 15 mefi 4 - pcm 3. Connect the map sensor electrical connector (1). 684798 1.

Page 36

2 - 16 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm 2 1 ps19190 install or connect 1. Tp sensor over throttle shaft. 2. With throttle valve in the normal closed position (idle), install tp sensor on throttle body assembly, making sure tp sensor pickup lever lines up with the tang on the throttle ac...

Page 37

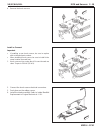

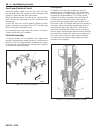

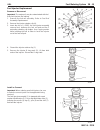

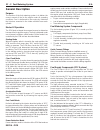

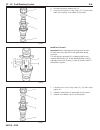

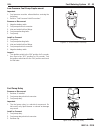

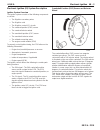

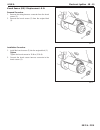

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 17 mefi 4 - pcm 1 o-ring - iac valve 2 iac valve attaching screw a distance of pintle extension b diameter of pintle b a 2 1 rs 22181 ➤ ➤ ➤ ➤ 8-24-94 idle air control (iac) valve remove or disconnect 1. Flame arrestor. 2. Iac electrical connector. 3. Iac valve a...

Page 38

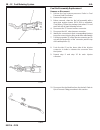

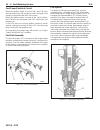

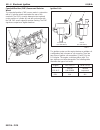

2 - 18 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm 8-24-94 rs 22183 frt 1 knock sensor 2 engine block rs 22182 1 2 knock sensor (ks) (5.0/5.7l) remove or disconnect 1. Negative battery cable. 2. Knock sensor electrical connector. 3. Knock sensor from engine block. Install or connect important • if...

Page 39

5.0/5.7/6.0l/8.1l ecm and sensors 2 - 19 mefi 4 - pcm install or connect important • if installing a new knock sensor, be sure to replace with an identical part number. • when installing knock sensor, be sure to install in the same location removed from. 1. Knock sensors into engine block. Be sure t...

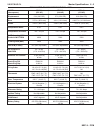

Page 40: Torque Specifi Cations

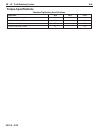

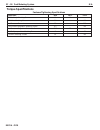

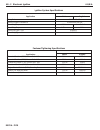

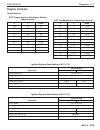

2 - 20 ecm and sensors 5.0/5.7/6.0/8.1l mefi 4 - pcm torque specifi cations fastener tightening specifi cations (5.0/5.7l) application n•m lb ft lb in ecm mounting screws 10-14 88-124 ect sensor 12 108 map/iat sensor attaching stud 5-7 44-62 tp sensor attaching screws 2 18 iac valve attaching screws...

Page 41: Section 3A

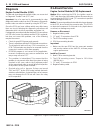

5.0/5.7l fuel metering system 3a - 1 mefi 4 - pcm marine electronic fuel injection (mefi) section 3a fuel metering system - 5.0/5.7l this section describes how the fuel metering system operates, and provides a description of components used on the marine electronic fuel injection equipped engines. T...

Page 42: General Description

3a - 2 fuel metering system 5.0/5.7l mefi 4 - pcm general description purpose the function of the fuel metering system is to deliver the correct amount of fuel to the engine under all operating conditions. Fuel is delivered to the engine by individual fuel injectors mounted in the intake manifold ne...

Page 43

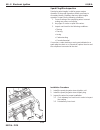

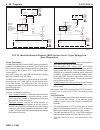

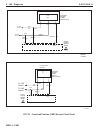

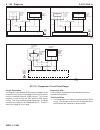

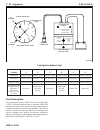

5.0/5.7l fuel metering system 3a - 3 mefi 4 - pcm figure 3-2 - typical fuel control cell (fcc) figure 3-1 - fuel metering system (typical) figure 3-3 - low pressure fuel pump fuel tank pressure regulator fuel filter low- pressure fuel pump fuel control cell fuel rail assembly engine fuel control cel...

Page 44

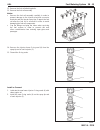

3a - 4 fuel metering system 5.0/5.7l mefi 4 - pcm figure 3-3 - fuel rail assembly figure 3-4 - fuel injector assembly (typical) 9p 0413-sy 1 solenoid assembly 2 spacer and guide assembly 3 core seat 4 ball valve 5 spray tip 6 director plate 7 spray housing 8 core spring 9 solenoid housing 10 solenoi...

Page 45

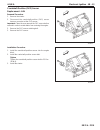

5.0/5.7l fuel metering system 3a - 5 mefi 4 - pcm figure 3-5 - pressure regulator assembly (typical) figure 3-6 - throttle body assembly 1 cover 2 vacuum chamber (vacuum source tube not shown) 3 o - ring seal 4 fuel pressure regulator valve 5 base assembly 6 filter screen (if equipped) 7 diaphragm 8...

Page 46: Diagnosis

3a - 6 fuel metering system 5.0/5.7l mefi 4 - pcm figure 3-8 - flange mounted type iac valve figure 3-7 - iac valve air flow diagram 1 idle air control (iac) valve 2 throttle body assembly 3 throttle valve 4 iac valve pintle a electrical input signal b air inlet rs 22193 a 1 2 4 3 b 8-25-94 1 o-ring...

Page 47

5.0/5.7l fuel metering system 3a - 7 mefi 4 - pcm figure 3-9 - fuel rail and throttle body assemblies 2. Loosen fuel filler cap to relieve any tank vapor pressure. 3. Connect fuel pressure gauge j 34730-1 to fuel pressure connector assembly. Wrap a shop towel around fi tting while connecting the gau...

Page 48

3a - 8 fuel metering system 5.0/5.7l mefi 4 - pcm throttle body assembly the throttle body assembly repair procedures cover component replacement with the unit on the vessel. However, throttle body replacement requires that the complete unit be removed from the engine. Clean important • do not soak ...

Page 49

5.0/5.7l fuel metering system 3a - 9 mefi 4 - pcm quick connect fitting(s) service tools required j 37088-a tool set, fuel line quick-connect separator j 44581 fuel line quick connect separator removal procedure 1. Relieve the fuel system pressure before servicing any fuel system connection. Refer t...

Page 50

3a - 10 fuel metering system 5.0/5.7l mefi 4 - pcm installation procedure 1. Apply a few drops of clean engine oil to the male pipe end. 12784 2. Push both sides of the fi tting together in order to snap the retaining tabs into place. 12786 3. Once installed, pull on both sides of the fi tting in or...

Page 51

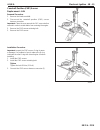

5.0/5.7l fuel metering system 3a - 11 mefi 4 - pcm fuel rail assembly the fuel rails should be removed as an assembly with the injectors attached. Names of component parts will be found on the numbered list that accompanies the disassembled view. Notice: • use care in removing the fuel rail assembly...

Page 52

3a - 12 fuel metering system 5.0/5.7l mefi 4 - pcm fuel rail assembly 1 2 3 4 5 6 7 8 9 legend (1) fuel rail attaching stud (2) fuel pressure connection cap (3) fuel rail assembly (4) fuel injector o-ring (5) fuel injector assembly (6) fuel injector retaining clip (7) fuel pressure regulator (8) fue...

Page 53

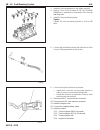

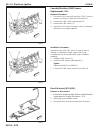

5.0/5.7l fuel metering system 3a - 13 mefi 4 - pcm injector part number location fuel injector and retainer clip fuel injectors notice: use care in removing injectors to prevent damage to the injector electrical connector pins or the injector spray tips. The fuel injector is serviced as a complete a...

Page 54

3a - 14 fuel metering system 5.0/5.7l mefi 4 - pcm fuel pressure regulator assembly important • the fuel pressure regulator is serviced as a complete assembly only. • fuel pressure must be relieved before servicing the fuel system. • refer to “fuel pressure relief procedure.” remove or disconnect 1....

Page 55

5.0/5.7l fuel metering system 3a - 15 mefi 4 - pcm fuel control cell (fcc) replacement - screw on bowl and clamp on bowl important • fuel pressure must be relieved before servicing the fuel pump. • refer to “fuel pressure relief procedure.” remove or disconnect 1. Negative battery cable. 2. Fuel pum...

Page 56

3a - 16 fuel metering system 5.0/5.7l mefi 4 - pcm fuel control cell (fcc) - screw on bowl - element replacement (with engine off) 1. Disconnect the two-wire electrical harness. 2. Hold the 3/4” jam nut located at the bottom of the fcc bowl with a wrench, remove the 3/16” allen plug and drain bowl c...

Page 57

5.0/5.7l fuel metering system 3a - 17 mefi 4 - pcm fuel control cell (fcc) - clamp on bowl - element replacement (with engine off) 1. Disconnect the two-wire electrical harness. 2. Remove the 7/16” plug and drain the bowl contents into a suitable container. Caution: both fuel, which is explosive, an...

Page 58

3a - 18 fuel metering system 5.0/5.7l mefi 4 - pcm low-pressure fuel pump replacement important • fuel pressure must be relieved before servicing the fuel pump. • refer to “fuel pressure relief procedure.” remove or disconnect 1. Negative battery cable. 2. Fuel pump electrical connector. 3. Inlet an...

Page 59: Torque Specifi Cations

5.0/5.7l fuel metering system 3a - 19 mefi 4 - pcm torque specifi cations fastener tightening specifi cations application n•m lb ft lb in throttle body attaching screws 15 11 iac valve attaching screws 3.2 28 fuel pressure connector 13 115 fuel rail attaching screws 10 88.

Page 60: This Page Left

3a - 20 fuel metering system 5.0/5.7l mefi 4 - pcm this page left intentionally blank.

Page 61: Section 3B

6.0l fuel metering system 3b - 1 mefi 4 - pcm marine electronic fuel injection (mefi) section 3b fuel metering system - 6.0l this section describes how the fuel metering system operates, and provides a description of components used on the marine electronic fuel injection equipped engines. The fuel ...

Page 62: General Description

3b - 2 fuel metering system 6.0l mefi 4 - pcm general description purpose the function of the fuel metering system is to deliver the correct amount of fuel to the engine under all operating conditions. Fuel is delivered to the engine by individual fuel injectors mounted in the intake manifold near e...

Page 63

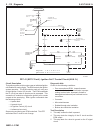

6.0l fuel metering system 3b - 3 mefi 4 - pcm figure 3-2 - fuel control cell (fcc) figure 3-1 - fuel metering system (typical) figure 3-3 - low pressure fuel pump m4054p 2-12-04 fuel tank press. Reg. Fuel filter low- pressure fuel pump fuel control cell fuel rail assembly engine fuel control cell fu...

Page 64

3b - 4 fuel metering system 6.0l mefi 4 - pcm fuel pump electrical circuit when the ignition switch is turned “on,” the ecm turns the fuel pump relay “on” for two seconds causing the fuel pump(s) to pressurize the mefi fuel system. When the ignition switch is turned to the crank position, the ecm tu...

Page 65

6.0l fuel metering system 3b - 5 mefi 4 - pcm figure 3-5 - pressure regulator assembly (typical) figure 3-6 - throttle body assembly (typical) mefi 4335 throttle body assembly the throttle body assembly is attached to the intake manifold air plenum, and is used to control air fl ow into the engine, ...

Page 66: Diagnosis

3b - 6 fuel metering system 6.0l mefi 4 - pcm figure 3-8 - flange mounted type iac valve figure 3-7 - iac valve air flow diagram 1 idle air control (iac) valve 2 throttle body assembly 3 throttle valve 4 iac valve pintle a electrical input signal b air inlet rs 22193 a 1 2 4 3 b 8-25-94 1 o-ring - i...

Page 67

6.0l fuel metering system 3b - 7 mefi 4 - pcm fuel control on-board service the following is general information required when working on the fuel system: • always keep a dry chemical fire extinguisher near the work area. • fuel pipe fittings require new o-rings when assembling. • do not replace fue...

Page 68

3b - 8 fuel metering system 6.0l mefi 4 - pcm throttle body assembly throttle body removal caution: safety glasses must be worn when using compressed air, as flying dirt particles may cause eye injury. • clean all metal parts thoroughly and blow dry with compressed air. Be sure that all fuel and air...

Page 69

6.0l fuel metering system 3b - 9 mefi 4 - pcm quick connect fitting(s) service tools required j 37088-a tool set, fuel line quick-connect separator j 44581 fuel line quick connect separator remove or disconnect 1. Relieve the fuel system pressure before servicing any fuel system connection. Refer to...

Page 70

3b - 10 fuel metering system 6.0l mefi 4 - pcm install or connect 1. Apply a few drops of clean engine oil to the male pipe end. 12784 2. Push both sides of the fi tting together in order to snap the retaining tabs into place. 12786 5. Pull the connection apart. 6. Use a clean shop towel in order to...

Page 71

6.0l fuel metering system 3b - 11 mefi 4 - pcm 3. Once installed, pull on both sides of the fi tting in order to make sure the connection is secure. 12787 1238589 4. Install the retainer on to the quick-connect fi tting..

Page 72

3b - 12 fuel metering system 6.0l mefi 4 - pcm 8. Push the tab (1) on the lower side of the injector connector in order to release the connector from the injector. 9. Repeat step 9 and step 10 for each injector connector. 10. Disconnect the fuel feed line from the fuel rail. Refer to quick connect f...

Page 73

6.0l fuel metering system 3b - 13 mefi 4 - pcm 12. Remove the fuel rail attaching bolts. 13. Remove the fuel rail assembly. Notice: • remove the fuel rail assembly carefully in order to prevent damage to the injector electrical connector terminals and the injector spray tips. Support the fuel rail a...

Page 74

3b - 14 fuel metering system 6.0l mefi 4 - pcm 3. Install the fuel rail assembly to the intake manifold. 4. Apply a 5 mm (0.020 in) band of gm p/n 12345382 threadlock or equivalent to the threads of the fuel rail attaching bolts. 5. Install the fuel rail attaching bolts. Tighten tighten the fuel rai...

Page 75

6.0l fuel metering system 3b - 15 mefi 4 - pcm 4. Discard the injector retainer clip (1). 5. Remove the injector o-ring seals (2), (4) from both ends of the injector. Discard the o-ring seals. Install or connect important: when ordering new fuel injectors, be sure to order the correct injector for t...

Page 76

3b - 16 fuel metering system 6.0l mefi 4 - pcm 1. Lubricate the new o-ring seals (2), (4) with clean engine oil. 2. Install the new injector o-ring seals on the injector. 3. Install a new retainer clip (1) on the injector. 351185 4. Push the fuel injector (5) into the fuel rail injector socket with ...

Page 77

6.0l fuel metering system 3b - 17 mefi 4 - pcm fuel control cell (fcc) replacement - screw on bowl and clamp on bowl important • fuel pressure must be relieved before servicing the fuel pump. • refer to “fuel pressure relief procedure.” remove or disconnect 1. Negative battery cable. 2. Fuel pump el...

Page 78

3b - 18 fuel metering system 6.0l mefi 4 - pcm fuel control cell (fcc) - screw on bowl - element replacement (with engine off) 1. Disconnect the two-wire electrical harness. 2. Hold the 3/4” jam nut located at the bottom of the fcc bowl with a wrench, remove the 3/16” allen plug and drain bowl conte...

Page 79

6.0l fuel metering system 3b - 19 mefi 4 - pcm fuel control cell (fcc) - clamp on bowl - element replacement (with engine off) 1. Disconnect the two-wire electrical harness. 2. Remove the 7/16” plug and drain the bowl contents into a suitable container. Caution: both fuel, which is explosive, and wa...

Page 80

3b - 20 fuel metering system 6.0l mefi 4 - pcm fuel pressure regulator replacement remove or disconnect important • fuel pressure must be relieved before servicing the fuel pump. • refer to “fuel pressure relief procedure.” 1. Remove the fcc bowl. Refer to fuel control cell - element replacement ste...

Page 81

6.0l fuel metering system 3b - 21 mefi 4 - pcm figure 3-3 - low pressure fuel pump low-pressure fuel pump replacement important • fuel pressure must be relieved before servicing the fuel pump. • refer to “fuel pressure relief procedure.” remove or disconnect 1. Negative battery cable. 2. Fuel pump e...

Page 82: Torque Specifi Cations

3b - 22 fuel metering system 6.0l mefi 4 - pcm torque specifi cations fastener tightening specifi cations application n•m lb ft lb in throttle body attaching screws 15 11 iac valve attaching screws 3.2 28 fuel pressure connector 13 115 fuel rail attaching screws 10 89.

Page 83: Section 3C

8.1l fuel metering system 3c - 1 mefi 4 - pcm marine electronic fuel injection (mefi) section 3c fuel metering system - 8.1l this section describes how the fuel metering system operates, and provides a description of components used on the marine electronic fuel injection equipped engines. The fuel ...

Page 84: General Description

3c - 2 fuel metering system 8.1l mefi 4 - pcm general description purpose the function of the fuel metering system is to deliver the correct amount of fuel to the engine under all operating conditions. Fuel is delivered to the engine by individual fuel injectors mounted in the intake manifold near e...

Page 85

8.1l fuel metering system 3c - 3 mefi 4 - pcm figure 3-2 - fuel control cell (fcc) figure 3-1 - fuel metering system (typical) figure 3-3 - low pressure fuel pump fuel tank pressure regulator fuel filter low- pressure fuel pump fuel control cell fuel rail assembly engine fuel control cell fuel syste...

Page 86

3c - 4 fuel metering system 8.1l mefi 4 - pcm fuel pump electrical circuit when the ignition switch is turned “on,” the ecm turns the fuel pump relay “on” for two seconds causing the fuel pump(s) to pressurize the mefi fuel system. When the ignition switch is turned to the crank position, the ecm tu...

Page 87

8.1l fuel metering system 3c - 5 mefi 4 - pcm figure 3-5 - pressure regulator assembly figure 3-6 - throttle body assembly 69059 mefi 4335 throttle body assembly the throttle body assembly is attached to the intake manifold air plenum, and is used to control air fl ow into the engine, thereby contro...

Page 88: Diagnosis

3c - 6 fuel metering system 8.1l mefi 4 - pcm figure 3-8 - flange mounted type iac valve figure 3-7 - iac valve air flow diagram 1 idle air control (iac) valve 2 throttle body assembly 3 throttle valve 4 iac valve pintle a electrical input signal b air inlet rs 22193 a 1 2 4 3 b 8-25-94 1 o-ring - i...

Page 89

8.1l fuel metering system 3c - 7 mefi 4 - pcm fuel control on-board service the following is general information required when working on the fuel system: • always keep a dry chemical fire extinguisher near the work area. • fuel pipe fittings require new o-rings when assembling. • do not replace fue...

Page 90

3c - 8 fuel metering system 8.1l mefi 4 - pcm throttle body assembly throttle body removal caution: safety glasses must be worn when using compressed air, as flying dirt particles may cause eye injury. • clean all metal parts thoroughly and blow dry with compressed air. Be sure that all fuel and air...

Page 91

8.1l fuel metering system 3c - 9 mefi 4 - pcm quick connect fitting(s) service tools required j 37088-a tool set, fuel line quick-connect separator j 44581 fuel line quick connect separator remove or disconnect 1. Relieve the fuel system pressure before servicing any fuel system connection. Refer to...

Page 92

3c - 10 fuel metering system 8.1l mefi 4 - pcm install or connect 1. Apply a few drops of clean engine oil to the male pipe end. 12784 2. Push both sides of the fi tting together in order to snap the retaining tabs into place. 12786 3. Once installed, pull on both sides of the fi tting in order to m...

Page 93

8.1l fuel metering system 3c - 11 mefi 4 - pcm 665445 372749 fuel rail assembly replacement remove or disconnect 1. Relieve the fuel system pressure. Refer to fuel pressure relief procedure. 2. Before removal, clean the fuel rail assembly with a spray type engine cleaner, gm x-30a or equivalent, if ...

Page 94

3c - 12 fuel metering system 8.1l mefi 4 - pcm 8. Push the tab (1) on the lower side of the injector connector in order to release the connector from the injector. 9. Repeat step 9 and step 10 for each injector connector. 10. Disconnect the fuel feed and return from the fuel rail. Refer to quick con...

Page 95

8.1l fuel metering system 3c - 13 mefi 4 - pcm 12. Remove the fuel rail attaching bolts. 13. Remove the fuel rail assembly. 14. Remove the injector lower o-ring seal (4) from the spray tip end of each injector (3). 15. Discard the o-ring seals. Install or connect 1. Lubricate the new lower injector ...

Page 96

3c - 14 fuel metering system 8.1l mefi 4 - pcm 3. Install the fuel rail assembly to the intake manifold. 4. Apply a 5 mm (0.020 in) band of gm p/n 12345382 threadlock or equivalent to the threads of the fuel rail attaching bolts. 5. Install the fuel rail attaching bolts. Tighten tighten the fuel rai...

Page 97

8.1l fuel metering system 3c - 15 mefi 4 - pcm 8. Connect the injector electrical connectors • install each connector on the proper injector in order to ensure correct injector fi ring order. • rotate the injectors as required in order to avoid stretching the wire harness. 9. Reconnect the tp sensor...

Page 98

3c - 16 fuel metering system 8.1l mefi 4 - pcm fuel pressure regulator replacement remove or disconnect 1. Relieve the fuel system pressure. Refer to fuel pressure relief procedure. 2. Disconnect the fuel pressure regulator vacuum line (1). 3. Clean any dirt from the fuel pressure regulator retainer...

Page 99

8.1l fuel metering system 3c - 17 mefi 4 - pcm 665447 705539 8. Connect the fuel pressure regulator vacuum line. 9. Connect the negative battery cable. 10. Inspect for leaks. 10.1. Turn the ignition on for 2 seconds. 10.2. Turn the ignition off for 10 seconds. 10.3. Turn the ignition on. 10.4. Inspe...

Page 100

3c - 18 fuel metering system 8.1l mefi 4 - pcm 4. Discard the injector retainer clip (1). 5. Remove the injector o-ring seals (2), (4) from both ends of the injector. Discard the o-ring seals. Install or connect important: when ordering new fuel injectors, be sure to order the correct injector for t...

Page 101

8.1l fuel metering system 3c - 19 mefi 4 - pcm 4. Push the fuel injector (5) into the fuel rail injector socket with the electrical connector facing outwards. The retainer clip (4) locks on to a fl ange on the fuel rail injector socket. 5. Install the fuel rail assembly. Refer to fuel rail assembly ...

Page 102

3c - 20 fuel metering system 8.1l mefi 4 - pcm fuel control cell (fcc) replacement - screw on bowl and clamp on bowl important • fuel pressure must be relieved before servicing the fuel pump. • refer to “fuel pressure relief procedure.” remove or disconnect 1. Negative battery cable. 2. Fuel pump el...

Page 103

8.1l fuel metering system 3c - 21 mefi 4 - pcm fuel control cell (fcc) - screw on bowl - element replacement (with engine off) 1. Disconnect the two-wire electrical harness. 2. Hold the 3/4” jam nut located at the bottom of the fcc bowl with a wrench, remove the 3/16” allen plug and drain bowl conte...

Page 104

3c - 22 fuel metering system 8.1l mefi 4 - pcm fuel control cell (fcc) - clamp on bowl - element replacement (with engine off) 1. Disconnect the two-wire electrical harness. 2. Remove the 7/16” plug and drain the bowl contents into a suitable container. Caution: both fuel, which is explosive, and wa...

Page 105

8.1l fuel metering system 3c - 23 mefi 4 - pcm figure 3-3 - low pressure fuel pump low-pressure fuel pump replacement important • fuel pressure must be relieved before servicing the fuel pump. • refer to “fuel pressure relief procedure.” remove or disconnect 1. Negative battery cable. 2. Fuel pump e...

Page 106: Torque Specifi Cations

3c - 24 fuel metering system 8.1l mefi 4 - pcm torque specifi cations fastener tightening specifi cations application n•m lb ft lb in throttle body attaching screws 15 11 iac valve attaching screws 3.2 28 fuel pressure connector 13 115 fuel pressure regulator attaching screw 9.5 84 fuel pressure reg...

Page 107: Section 4A

5.0/5.7l distributor ignition 4a - 1 mefi 4 - pcm marine electronic fuel injection (mefi 4) section 4a distributor ignition (di) this section will describe the distributor ignition (di) system used on the 5.0l and the 5.7l engines. The di system uses a single ignition coil and a mechanical distribut...

Page 108

4a - 2 distributor ignition 5.0/5.7l mefi 4 - pcm ignition system specifi cations specifi cations application metric english firing order 1-8-4-3-6-5-7-2 spark plug wire resistance 10,000 ohms per foot spark plug torque 15 n.M 11 lb ft spark plug gap 1.52 mm .060 in spark plug type r030010 fastener ...

Page 109

5.0/5.7l distributor ignition 4a - 3 mefi 4 - pcm distributor ignition (di) system description ignition system overview the ignition system consists of the following components or circuits: • the 8 ignition secondary wires • the ignition coil • the ignition control (ic) circuit • the camshaft positi...

Page 110

4a - 4 distributor ignition 5.0/5.7l mefi 4 - pcm ignition coil m4093 camshaft position (cmp) sensor and reluctor wheel the camshaft position (cmp) sensor works in conjunction with a 1x reluctor wheel mounted inside the distributor housing. The cmp is used to determine the top dead center position o...

Page 111

5.0/5.7l distributor ignition 4a - 5 mefi 4 - pcm noteworthy ignition information there are important considerations to point out when servicing the ignition system. The following noteworthy information will list some of these to help the technician in servicing the ignition system. • the ignition c...

Page 112

4a - 6 distributor ignition 5.0/5.7l mefi 4 - pcm knock sensor (ks) system description purpose to control spark knock (detonation), a knock sensor (ks) system is used. This system is designed to retard spark timing when excessive spark knock is detected in the engine. The ks system allows the engine...

Page 113

5.0/5.7l distributor ignition 4a - 7 mefi 4 - pcm ignition coil replacement removal procedure 1. Disconnect the secondary coil wire at the ignition coil. Refer to spark plug wire replacement. 2. Disconnect the ignition coil harness connector. 3. Remove the ignition coil mounting bolts. 4. Remove the...

Page 114

4a - 8 distributor ignition 5.0/5.7l mefi 4 - pcm spark plug wire inspection spark plug wire integrity is vital for proper engine operation. A thorough inspection will be necessary to accurately identify conditions that may affect engine operation. Inspect for the following conditions: 1. Correct ro...

Page 115

5.0/5.7l distributor ignition 4a - 9 mefi 4 - pcm spark plug replacement removal procedure 1. Remove the spark plug wires. Refer to spark plug wire replacement. 2. Loosen each spark plug one or two turns. 3. Brush or air blast away any dirt from around the spark plugs. 4. Remove the spark plugs one ...

Page 116

4a - 10 distributor ignition 5.0/5.7l mefi 4 - pcm – inspect the spark plug boot for damage. – inspect the spark plug recess area of the cylinder head for moisture, such as oil, coolant or water. A spark plug boot that is saturated causes arcing to ground. • inspect the insulator (2) for cracks. All...

Page 117

5.0/5.7l distributor ignition 4a - 11 mefi 4 - pcm 622527 • inspect for evidence of improper arcing. – measure the gap between the center electrode (4) and the side electrode (3) terminals. An excessively wide electrode gap can prevent correct spark plug operation. – inspect for the correct spark pl...

Page 118

4a - 12 distributor ignition 5.0/5.7l mefi 4 - pcm • deposit fouling - oil, coolant or additives that include substances such as silicone, very white coating, reduces the spark intensity. Most powdery deposits will not effect spark intensity unless they form into a glazing over the electrode. Instal...

Page 119

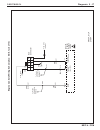

5.0/5.7l distributor ignition 4a - 13 mefi 4 - pcm crankshaft position (ckp) sensor replacement removal procedure 1. Disconnect the crankshaft position (ckp) sensor harness connector at the ckp sensor. 2. Remove the ckp sensor retaining bolt. 3. Remove the ckp sensor. 11485 important: always install...

Page 120

4a - 14 distributor ignition 5.0/5.7l mefi 4 - pcm camshaft position (cmp) sensor replacement removal procedure 1. Disconnect the camshaft position (cmp) sensor harness connector from the cmp sensor (2). 2. Remove the distributor cap bolts (1). 3. Remove the distributor cap. M4089 4. Remove the dist...

Page 121

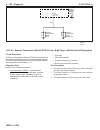

5.0/5.7l distributor ignition 4a - 15 mefi 4 - pcm 678815 rt0086 setting cam retard important: moving the distributor does not adjust ignition timing. Ignition timing is completely computer controlled. However, a parameter called “cam retard” must be within specifi cations or driveability problems w...

Page 122

4a - 16 distributor ignition 5.0/5.7l mefi 4 - pcm 20272 knock sensor (ks) replacement removal procedure 1. Remove the wiring harness connector from the knock sensor (2). 2. Remove the knock sensor (2) from the engine block (1). 20272 installation procedure 1. Install the knock sensor (2) into the e...

Page 123: Section 4B

6.0/8.1l electronic ignition 4b - 1 mefi 4 - pcm marine electronic fuel injection (mefi 4) section 4b electronic ignition this section will describe the electronic ignition (ei) system used on the 6.0l and 8.1l engines. The ei system uses an individual ignition coil for each cylinder. The section ex...

Page 124

4b - 2 electronic ignition 6.0/8.1l mefi 4 - pcm ignition system specifi cations application metric english firing order 1-8-7-2-6-5-4-3 spark plug wire resistance 10,000 ohms per foot spark plug torque 15 n.M 11 lb ft spark plug gap 1.52 mm .060 in spark plug type - 6.0l r030011 spark plug type - 8...

Page 125

6.0/8.1l electronic ignition 4b - 3 mefi 4 - pcm electronic ignition (ei) system description ignition system overview the ignition system consists of the following components or circuits: • the 8 ignition secondary wires • the 8 ignition coils • the 8 ignition control (ic) circuits • the camshaft po...

Page 126

4b - 4 electronic ignition 6.0/8.1l mefi 4 - pcm ignition coils 260177 the ignition system on this engine features a multiple coil confi guration and is known as coil near plug. There are two styles of ignition coil assemblies (1) and (2) for the 8.1l engine. The engine could have either style. The ...

Page 127

6.0/8.1l electronic ignition 4b - 5 mefi 4 - pcm 703554 noteworthy ignition information there are important considerations to point out when servicing the ignition system. The following noteworthy information will list some of these to help the technician in servicing the ignition system. • the igni...

Page 128

4b - 6 electronic ignition 6.0/8.1l mefi 4 - pcm knock sensor (ks) system description purpose to control spark knock (detonation), a knock sensor (ks) system is used. This system is designed to retard spark timing when excessive spark knock is detected in the engine. The ks system allows the engine ...

Page 129

6.0/8.1l electronic ignition 4b - 7 mefi 4 - pcm ignition coil(s) replacement removal procedure 1. Disconnect the spark plug wires at the ignition coils. Refer to spark plug wire replacement. 2. Disconnect the ignition coil harness connector. 3. Remove the ignition coil mounting bolts. 4. Remove the...

Page 130

4b - 8 electronic ignition 6.0/8.1l mefi 4 - pcm spark plug wire inspection spark plug wire integrity is vital for proper engine operation. A thorough inspection will be necessary to accurately identify conditions that may affect engine operation. Inspect for the following conditions: 1. Correct rou...

Page 131

6.0/8.1l electronic ignition 4b - 9 mefi 4 - pcm spark plug replacement removal procedure 1. Remove the spark plug wires. Refer to spark plug wire replacement. 2. Loosen each spark plug one or two turns. 3. Brush or air blast away any dirt from around the spark plugs. 4. Remove the spark plugs one a...

Page 132

4b - 10 electronic ignition 6.0/8.1l mefi 4 - pcm – inspect the spark plug boot for damage. – inspect the spark plug recess area of the cylinder head for moisture, such as oil, coolant or water. A spark plug boot that is saturated causes arcing to ground. • inspect the insulator (2) for cracks. All ...

Page 133

6.0/8.1l electronic ignition 4b - 11 mefi 4 - pcm 622527 • inspect for evidence of improper arcing. – measure the gap between the center electrode (4) and the side electrode (3) terminals. An excessively wide electrode gap can prevent correct spark plug operation. – inspect for the correct spark plu...

Page 134

4b - 12 electronic ignition 6.0/8.1l mefi 4 - pcm • deposit fouling - oil, coolant or additives that include substances such as silicone, very white coating, reduces the spark intensity. Most powdery deposits will not effect spark intensity unless they form into a glazing over the electrode. Install...

Page 135

6.0/8.1l electronic ignition 4b - 13 mefi 4 - pcm crankshaft position (ckp) sensor replacement - 6.0l removal procedure 1. Remove the starter. 2. Disconnect the crankshaft position (ckp) sensor harness connector at the ckp sensor. Important: clean the area around the ckp sensor before removal in ord...

Page 136

4b - 14 electronic ignition 6.0/8.1l mefi 4 - pcm crankshaft position (ckp) sensor replacement - 8.1l removal procedure 1. Disconnect the crankshaft position (ckp) sensor harness connector at the ckp sensor. 674728 important: use penetrating oil, and allow the oil to soak around the ckp sensor prior...

Page 137

6.0/8.1l electronic ignition 4b - 15 mefi 4 - pcm camshaft position (cmp) sensor replacement - 6.0l removal procedure 1. Remove the intake manifold. 2. Disconnect the camshaft position (cmp) sensor harness connector. Important: clean the area around the ckp sensor before removal in order to avoid de...

Page 138

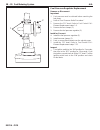

4b - 16 electronic ignition 6.0/8.1l mefi 4 - pcm camshaft position (cmp) sensor replacement - 8.1l removal procedure 1. Disconnect the camshaft position (cmp) sensor harness connector (3) from the cmp sensor (1). 2. Remove the cmp sensor retaining bolt (2). 3. Remove the cmp sensor (1). 4. Inspect ...

Page 139

6.0/8.1l electronic ignition 4b - 17 mefi 4 - pcm install or connect important • if installing a new knock sensor, be sure to replace with an identical part number. • when installing knock sensor, be sure to install in the same location removed from. 1. Knock sensors into engine block. Be sure threa...

Page 140

4b - 18 electronic ignition 6.0/8.1l mefi 4 - pcm installation procedure 1. Install the knock sensor (2) into the engine block. Tighten tighten the knock sensor to 20 n.M (15 lb ft). 2. Connect the knock sensor harness connector (1) to the knock sensor (2). 678815 knock sensor (ks) 1 replacement - 8...

Page 141

6.0/8.1l electronic ignition 4b - 19 mefi 4 - pcm 20272 knock sensor (ks) 2 replacement - 8.1l removal procedure 1. Remove the wiring harness connector from the knock sensor (2). 2. Remove the knock sensor (2) from the engine block (1). 20272 installation procedure 1. Install the knock sensor (2) in...

Page 142: This Page Left

4b - 20 electronic ignition 6.0/8.1l mefi 4 - pcm this page left intentionally blank.

Page 143: Section 5

5.0/5.7/6.0/8.1l diagnosis 5 - 1 mefi 4 - pcm marine electronic fuel injection (mefi 4/4b) section 5 diagnosis this section will be used to perform diagnostic procedures on the marine electronic fuel injection (mefi 4/4b) equipped engines. It describes the system circuits and diagnostic procedures u...

Page 144: Diagnosis

5 - 2 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm diagnosis the diagnostic procedures and functional checks in this manual are designed to locate a faulty circuit or component through logic based on the process of elimination. The procedures are prepared with the requirement that the system functioned c...

Page 145: Engine Controls

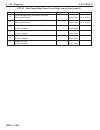

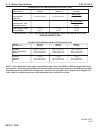

5.0/5.7/6.0/8.1l diagnosis 5 - 3 mefi 4 - pcm ignition system specifi cations (6.0 / 8.1l) specifi cations application metric english firing order 1-8-7-2-6-5-4-3 spark plug wire resistance 10,000 ohms per foot spark plug torque 15 n.M 11 lb ft spark plug gap 1.52 mm .060 in spark plug type (8.1l) r03...

Page 146

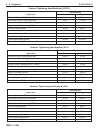

5 - 4 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm fastener tightening specifi cations (8.1l) specifi cations application metric english camshaft position (cmp) sensor bolt 12 n.M 106 lb in crankshaft position (ckp) sensor bolt 12 n.M 106 lb in engine control module (ecm) mounting screws 10-14 n.M 88-124 l...

Page 147

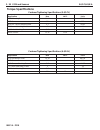

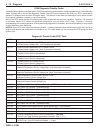

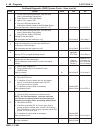

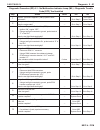

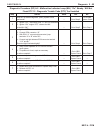

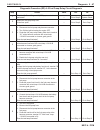

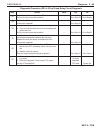

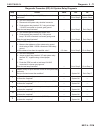

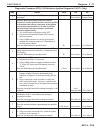

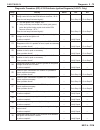

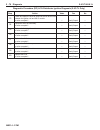

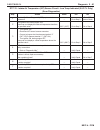

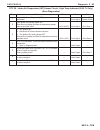

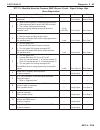

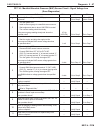

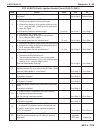

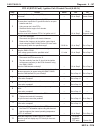

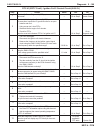

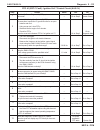

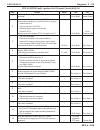

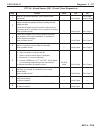

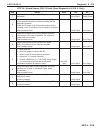

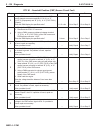

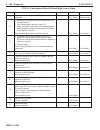

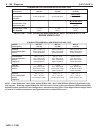

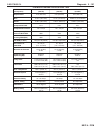

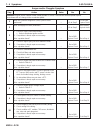

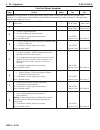

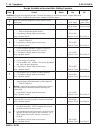

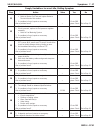

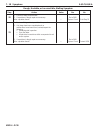

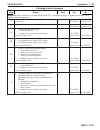

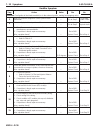

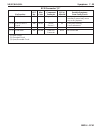

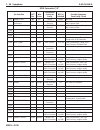

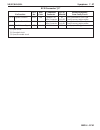

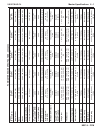

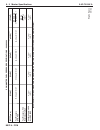

5.0/5.7/6.0/8.1l diagnosis 5 - 5 mefi 4 - pcm engine scan tool data list the engine scan tool data list contains all engine related parameters that are available on the scan tool. Use the engine scan tool data list only after the following is determined: • on-board diagnostic system check is complet...

Page 148

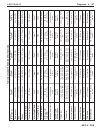

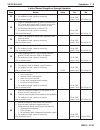

5 - 6 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 6.0l mpi.

Page 149

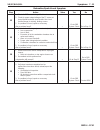

5.0/5.7/6.0/8.1l diagnosis 5 - 7 mefi 4 - pcm 8.1l mpi.

Page 150

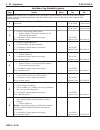

5 - 8 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine diacom data defi nitions the engine diacom data definitions contain a brief description of all engine related parameters available on the pcm preferred screen. Ecm data descriptions total trouble codes - scan tool range 0-999- this indicates the nu...

Page 151

5.0/5.7/6.0/8.1l diagnosis 5 - 9 mefi 4 - pcm warning buzzer output - scan tool displays “on” or “off” - indicates the ecm commanded state of the buzzer. The buzzer may be commanded “on” for various conditions. Max engine rpm logged - scan tool displays 0- 9999 rpm - the ecm keeps a log of the maxim...

Page 152

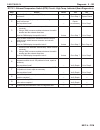

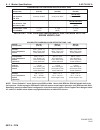

5 - 10 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm diagnostic trouble codes the malfunction indicator lamp (mil) will be “on” if the malfunction exists under the conditions listed below. If the malfunction clears, the lamp will go out and the diagnostic trouble code (dtc) will be stored in the ecm. ...

Page 153

5.0/5.7/6.0/8.1l diagnosis 5 - 11 mefi 4 - pcm diagnostic trouble code (dtc) table (cont’d) dtc description dtc 81 crankshaft position (ckp) sensor circuit fault. Crank signal fault. (hard or no start, backfi re, no power) dtc 81 camshaft position (cmp) sensor circuit fault. Cam signal fault. (no sym...

Page 154

5 - 12 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm clearing diagnostic trouble codes - non scan 1. Install diagnostic trouble code (dtc) tool. 2. Ignition “on,” engine “off.” 3. Switch dtc tool to “service mode” or “on.” 4. Move the throttle from 0% (idle) to 100% (wot) and back to 0%. 5. Switch dtc too...

Page 155

5.0/5.7/6.0/8.1l diagnosis 5 - 13 mefi 4 - pcm fuel system specifi cations use regular unleaded gasoline rated at 87 octane or higher. It is recommended that the gasoline meet specifi cations which were developed by the american automobile manufacturers association for better vehicle performance and e...

Page 156

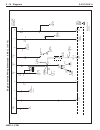

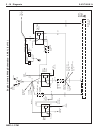

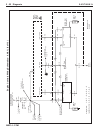

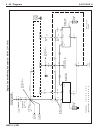

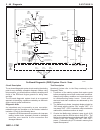

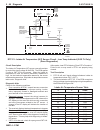

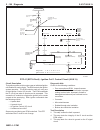

5 - 14 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (1 of 13) serial data 10-pin boat harness connector m4001_8.1lp 2-10-04 10 j2 malfunction indicator lamp (mil) battery feed 27 j1 j2 j1 buzzer 8 1 blk gry gry tan tan/ blk ppl/ wht red/ wht yel/ red lt blu br...

Page 157

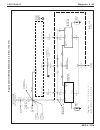

5.0/5.7/6.0/8.1l diagnosis 5 - 15 mefi 4 - pcm engine controls w iring schematics - 6.0/8.1l (2 of 13) engine control module (ecm) ecm ground ecm ground ecm ground blk 450 blk blk blk blk blk blk blk blk blk lt grn gry gry grn/ yel grn/ yel pnk/blk blk 450 blk 450 m4002_8.1lp 2-10-04 s111 s112 s117 ...

Page 158

5 - 16 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (3 of 13) 1 battery feed engine control module (ecm) orn 440 s122 orn 440 red/ wht 2 ppl/ wht red/wht pnk 439 mefi system relay 19 j2 j1 6 ppl 902 pnk 439 blk 150 fuse block gry 120 gry pnk/blk grn/ye l grn/ ...

Page 159

5.0/5.7/6.0/8.1l diagnosis 5 - 17 mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (4 of 13) engine control module (ecm) brn/wht 419 blk/ wht 451 orn 440 dlc connector fgh j k ed c b a from s120 (b+) to pin #10 (10-pin boat harness) from s116 (ignition) from s112 (ground) 10 j2 27 2 j1 orn/...

Page 160

5 - 18 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (5 of 13) 8 7 2 j2 3 gry 416e lt grn 432 blk 814 blk 814 blk 814 yel 410 b a c manifold absolute pressure (map) sensor engine coolant temperature (ect) sensor throttle position(tp) sensor engine control modul...

Page 161

5.0/5.7/6.0/8.1l diagnosis 5 - 19 mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (6 of 13) cmp sensor signal depspower ckp sensor signal depslo camshaft position (cmp) sensor engine control module (ecm) m4006_8.1l 2-10-04 solid state 17 18 16 32 j2 a a c c b b crankshaft position (ckp) se...

Page 162

5 - 20 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (7 of 13) b fuel injector driver a fuel injector driver b engine control module (ecm) pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 inj/ecm fuse 20a a ac e g k j hd f b 26 fuel injec...

Page 163

5.0/5.7/6.0/8.1l diagnosis 5 - 21 mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (8 of 13) fuel injecto r harness connector m4008_8.1l 12-21-01 fuel injector driver b 11 j1 fuel injector driver a 26 dk blu dk blu dk blu dk blu dk blu 467 dk grn dk grn dk grn dk grn dk grn 468 pnk pnk ac e...

Page 164

5 - 22 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (9 of 13) 12 ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control a ignition control h spark plug spark plug ignition coil (cylinder #1) firing order: 1 - 8 - 7 - 2 -...

Page 165

5.0/5.7/6.0/8.1l diagnosis 5 - 23 mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (10 of 13) 30 ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control f ignition control c spark plug spark plug ignition coil (cylinder #5) firing order: 1 - 8 - 7 - 2 ...

Page 166

5 - 24 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (1 1 of 13) 28 ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control d ignition control g spark plug spark plug ignition coil (cylinder #2) firing order: 1 - 8 - 7 - 2...

Page 167

5.0/5.7/6.0/8.1l diagnosis 5 - 25 mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (12 of 13) 15 ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control e ignition control b spark plug spark plug ignition coil (cylinder #6) firing order: 1 - 8 - 7 - 2 ...

Page 168

5 - 26 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 6.0/8.1l (13 of 13) m4013_8.1lp 2-10-04 ignition control h 12 ignition control a cylinder #1 cylinder #3 cylinder #5 cylinder #7 cylinder #2 cylinder #4 cylinder #6 cylinder #8 31 blk red 2127 dk grn 2125 lt blu 2123 ...

Page 169: This Page Was

5.0/5.7/6.0/8.1l diagnosis 5 - 27 mefi 4 - pcm this page was intentionally left blank.

Page 170

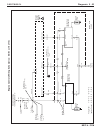

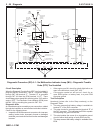

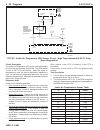

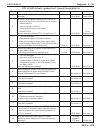

5 - 28 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 5.0/5.7l (1 of 9) serial data 10-pin boat harness connector m4001_5.7lp 2-10-04 10 j2 malfunction indicator lamp (mil) 27 j1 j1 buzzer 8 blk gry gry tan tan/ blk ppl/ wht red/ wht red/ wht red/ wht yel/ red yel/ red r...

Page 171

5.0/5.7/6.0/8.1l diagnosis 5 - 29 mefi 4 - pcm engine controls w iring schematics- 5.0/5.7l (2 of 9) engine control module (ecm) ecm ground ecm ground ecm ground blk 450 blk blk blk blk blk gry gry grn/ yel grn/ yel pnk/blk blk 450 blk 450 m4002_5.7p 2-10-04 s113 s117 s119 s116 13 28 29 b a 1 2 gene...

Page 172

5 - 30 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 5.0/5.7l (3 of 9) 1 battery feed engine control module (ecm) orn 440 s122 orn 440 red/ wht 2 red/ wht 2 red/wht red/wht pnk 439 mefi system relay 19 j2 j1 6 ppl 902 pnk 439 blk 150 fuse block gry 120 grn/yel grn/yel s...

Page 173

5.0/5.7/6.0/8.1l diagnosis 5 - 31 mefi 4 - pcm engine controls w iring schematics- 5.0/5.7l (4 of 9) engine control module (ecm) brn/wht 419 blk/ wht 451 orn 440 dlc connector fgh j k ed c b a from s120 (b+) to pin #10 (10-pin boat harness) from s116 (ignition) from s113 (ground) 10 j2 27 2 j1 orn/ ...

Page 174

5 - 32 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 5.0/5.7l (5 of 9) 8 21 2 7 j2 3 gry 416e lt grn 432 blk 814 blk 814 blk 814 yel 410 4 1 3 manifold a bsolute pressure (map)/intake a ir temperature (iat) sensor engine coolant temperature (ect) sensor throttle positio...

Page 175

5.0/5.7/6.0/8.1l diagnosis 5 - 33 mefi 4 - pcm engine controls w iring schematics- 5.0/5.7l (6 of 9) cmp sensor signal ic control ignition voltage ignition control signal coil driver ground depspower ckp sensor signal depslo camshaft position (cmp) sensor spark plugs coil wire ignition coil distribu...

Page 176

5 - 34 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine controls w iring schematics- 5.0/5.7l (7 of 9) b fuel injector driver a fuel injector driver b engine control module (ecm) pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 pnk 439 inj/ecm fuse 20a a 26 fuel injector cylinder #2 b a fuel in...

Page 177: This Page Was

5.0/5.7/6.0/8.1l diagnosis 5 - 35 mefi 4 - pcm this page was intentionally left blank.

Page 178

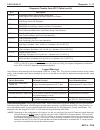

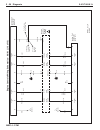

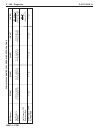

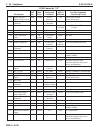

5 - 36 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm connector pinout identifi cation (1 of 2) (5.0/5.7l) 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 j-1 ecm 32 way connector ecm pin ckt(wire) ckt (wire) circuit description number number color j1-1 j1-2 451 bl...

Page 179

5.0/5.7/6.0/8.1l diagnosis 5 - 37 mefi 4 - pcm ecm connector pinout identifi cation (2 of 2) (5.0/5.7l) 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 j-2 ecm 32 way connector ecm pin ckt(wire) ckt (wire) circuit description number number color j2-1 440 orn bat...

Page 180

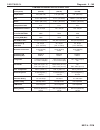

5 - 38 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm connector pinout identifi cation (1 of 2) (6.0/8.1l) 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 j-1 ecm 32 way connector ecm pin ckt(wire) ckt (wire) circuit description number number color j1-1 468 lt blu/...

Page 181

5.0/5.7/6.0/8.1l diagnosis 5 - 39 mefi 4 - pcm j-2 ecm 32 way connector ecm pin ckt(wire) ckt (wire) circuit description number number color j2-1 440 orn battery feed j2-2 416 gry 5 volt reference j2-3 814 blk sensor ground j2-4 j2-5 j2-6 j2-7 410 yel ect sensor signal j2-8 432 lt grn map sensor sig...

Page 182

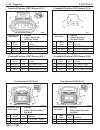

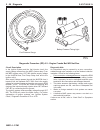

5 - 40 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm wire circuit pin color no. Function a red 631 depspower (12v ref) b yel/blk 1868 depslo (low ref) c brn/wht 633 cmp sensor signal 366117 connector part information • 15324165 • 3-way f metri-pack 150 series sealed 684840 connector part information • 121...

Page 183

5.0/5.7/6.0/8.1l diagnosis 5 - 41 mefi 4 - pcm 684833 fuel injector #5 (6.0/8.1l) 684833 fuel injector #6 (6.0/8.1l) connector part information • 12129140 • 2-way f metri-pack 280.1 p2s (blk) connector part information • 12129140 • 2-way f metri-pack 280.1 p2s (blk) wire circuit pin color no. Functi...

Page 184

5 - 42 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 684833 fuel injector #7 (6.0/8.1l) 684833 fuel injector #8 (6.0/8.1l) connector part information • 12129140 • 2-way f metri-pack 280.1 p2s (blk) connector part information • 12129140 • 2-way f metri-pack 280.1 p2s (blk) wire circuit pin color no. Functi...

Page 185

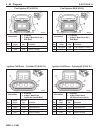

5.0/5.7/6.0/8.1l diagnosis 5 - 43 mefi 4 - pcm wire circuit pin color no. Function a blk 151 ground b brn 2129 low reference c ppl 2125 ic 5 control d pnk 39 ignition voltage 684854 connector part information • 12162144 • 4-way f metri-pack 150 series sealed (blk) ignition coil/driver - cylinder #5 ...

Page 186

5 - 44 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 684790 ignition coils - 1,3,5,7 (inline connector-8.1l) wire circuit pin color no. Function a blk 151 ground b brn 2129 low reference c ppl 2126 ic 6 control d pnk 39 ignition voltage 684854 connector part information • 12162144 • 4-way f metri-pack 150...

Page 187

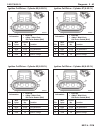

5.0/5.7/6.0/8.1l diagnosis 5 - 45 mefi 4 - pcm 35437 knock sensor, lh - odd (6.0/8.1l) 684840 manifold absolute pressure (map) sensor (6.0/8.1l) wire circuit pin color no. Function a dk blu 467 ks 1 signal connector part information • 15355362 • 1-way f metri-pack 150 series sealed (nat) 35437 knock...

Page 188

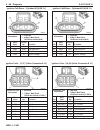

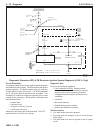

5 - 46 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 1 battery feed engine control module (ecm) orn 440 s122 orn 440 red/ wht 2 red/ wht 2 red/wht red/wht pnk 439 mefi system relay 19 ppl 902 pnk 439 blk 150 s121 ignition feed s120 ecm/bat fuse 20a e f s107 not used from s107 30 86 85 87a 87 from pin #5 1...

Page 189

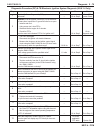

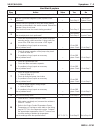

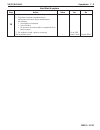

5.0/5.7/6.0/8.1l diagnosis 5 - 47 mefi 4 - pcm important: • do not perform this diagnostic if there is not a drivability concern, unless another procedure directs you to that diagnostic. • before you proceed with diagnosis, search for applicable service bulletins. • before you proceed with diagnosis...

Page 190

5 - 48 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm on-board diagnostic (obd) system check - scan (cont’d) step action value yes no 1. On the diacom screen select the ‘tests’ tab, and select “activate base timing mode.” 2. Select diacom, ‘ecm data’ display. 5 3. Ignition “on,” engine “off.” 4. Link to th...

Page 191: This Page Was

5.0/5.7/6.0/8.1l diagnosis 5 - 49 mefi 4 - pcm this page was intentionally left blank.

Page 192

5 - 50 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 1 battery feed engine control module (ecm) orn 440 s122 orn 440 red/ wht 2 red/ wht 2 red/wht red/wht pnk 439 mefi system relay 19 ppl 902 pnk 439 blk 150 s121 ignition feed s120 ecm/bat fuse 20a e f s107 not used from s107 30 86 85 87a 87 from pin #5 1...

Page 193

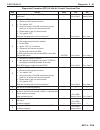

5.0/5.7/6.0/8.1l diagnosis 5 - 51 mefi 4 - pcm 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 2 attempt to start the engine. Does the engine start? — go to step 3 go to step 6 1. Remove diagnostic trouble code (dtc) tool. 2. Ignition “on,” engine ...

Page 194

5 - 52 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 13 locate and repair open in ckt 419. Go to obd is action complete? — system check —- locate and repair short to ground in ckt 440, then replace 14 the fuse. Go to obd is action complete? — system check — locate and repair open in ckt 440. Go to obd 15 ...

Page 195: This Page Was

5.0/5.7/6.0/8.1l diagnosis 5 - 53 mefi 4 - pcm this page was intentionally left blank.

Page 196

5 - 54 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 1 battery feed engine control module (ecm) orn 440 s122 orn 440 red/ wht 2 red/ wht 2 red/wht red/wht pnk 439 mefi system relay 19 ppl 902 pnk 439 blk 150 s121 ignition feed s120 ecm/bat fuse 20a e f s107 not used from s107 30 86 85 87a 87 from pin #5 1...

Page 197

5.0/5.7/6.0/8.1l diagnosis 5 - 55 mefi 4 - pcm 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Ignition “off,” disconnect ecm “j1” and “j2”connectors. 2 2. Ignition “on,” engine “off,” observe the mil. Is the mil “on?” — go to step 5 go to step ...

Page 198

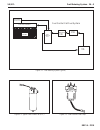

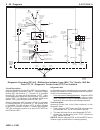

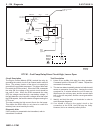

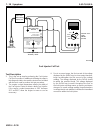

5 - 56 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm m4051 9-18-02 10 0 20 30 40 50 60 70 80 90 100 150 fuel pressure gauge battery powered timing light diagnostic procedure (dp) a-3 - engine cranks but will not run diagnostic aids an intermittent may be caused by a poor connection, rubbed through wire in...

Page 199

5.0/5.7/6.0/8.1l diagnosis 5 - 57 mefi 4 - pcm 1 was the “on-board diagnostic”(obd) system check go to obd performed? — go to step 2 system check important: refer to the applicable dtc diagnostic 2 procedure if any of the following dtc’s are set: 41 or 81. Turn the ignition “on,” engine “off.” do th...

Page 200

5 - 58 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm step action value yes no diagnostic procedure (dp) a-3 - engine cranks but will not run perform the following additional inspections: • inspect that the throttle angle is at 0% at a closed throttle. If the throttle angle is not at 0%, refer to dtc 21 th...

Page 201: This Page Was

5.0/5.7/6.0/8.1l diagnosis 5 - 59 mefi 4 - pcm this page was intentionally left blank.

Page 202

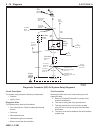

5 - 60 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm m4054p 2-12-04 fuel tank pressure regulator fuel filter low- pressure fuel pump fuel control cell fuel rail assembly engine fuel control cell fuel system fuel tank press. Reg. Fuel filter low- pressure fuel pump fuel control cell fuel rail assembly engi...

Page 203

5.0/5.7/6.0/8.1l diagnosis 5 - 61 mefi 4 - pcm 12. A rich condition may result from the fuel pressure being above the required value. See the master specifi cation sheet found at the end of this section. Drivability conditions associated with rich conditions can include hard starting followed by blac...

Page 204

5 - 62 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm diagnostic procedure (dp) a-4 fuel system diagnosis (cont’d) step action value yes no important: the fuel pressure may vary slightly when the fuel pump stops running. After the fuel pump stops 3 running, the fuel pressure should stabilize and remain con...

Page 205

5.0/5.7/6.0/8.1l diagnosis 5 - 63 mefi 4 - pcm diagnostic procedure (dp) a-4 fuel system diagnosis (cont’d) step action value yes no 1. Relieve the fuel pressure. Refer to fuel pressure relief procedure. 2. Disconnect the fuel feed pipe and the fuel return pipe from the fuel rail. 3. Install the j 3...

Page 206

5 - 64 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm diagnostic procedure (dp) a-4 fuel system diagnosis step action value yes no 1. Relieve the fuel pressure. Refer to fuel pressure relief procedure. 2. Disconnect the fuel return pipe from the fuel rail. 3. Install the j 37287 fuel pipe shut-off adapter ...

Page 207: This Page Was

5.0/5.7/6.0/8.1l diagnosis 5 - 65 mefi 4 - pcm this page was intentionally left blank.

Page 208

5 - 66 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine control module (ecm) j1 6 pnk 439 fuse block gry 120 gry pnk/blk grn/yel grn/yel fuel pump relay control s116 s117 s118 to dlc connector term. "c" from s107 (b+) from s122 (ignition) 87a 87 s119 1 2 not used fuel pump relay fuse 20a low pressure ...

Page 209

5.0/5.7/6.0/8.1l diagnosis 5 - 67 mefi 4 - pcm diagnostic procedure (dp) a-5 fuel pump relay circuit diagnosis step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 2 check the fuel pump relay fuse. Is the fuse open? — go to step...

Page 210

5 - 68 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm step action value yes no probe the battery feed circuit for the fuel pump relay at the 10 harness connector with a test lamp j 34142-b connected to b+. Does the test lamp illuminate? — go to step 20 go to step 21 1. Turn off the ignition. 2. Disconnect ...

Page 211

5.0/5.7/6.0/8.1l diagnosis 5 - 69 mefi 4 - pcm step action value yes no 22 inspect for a poor connection at the ecm. Did you fi nd and correct the condition? — go to step 26 go to step 23 23 replace the ecm. Is the action complete? — go to step 26 — 1. Inspect the fuel pump harness for a short to gro...

Page 212

5 - 70 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 1 battery feed engine control module (ecm) orn 440 s122 orn 440 red/ wht 2 ppl/ wht red/wht pnk 439 mefi system relay 19 j2 ppl 902 blk 150 ignition feed to dlc connector term. "f" s120 ecm/bat fuse 20a e f s107 not used 30 86 85 87a 87 fuse block m4057...

Page 213

5.0/5.7/6.0/8.1l diagnosis 5 - 71 mefi 4 - pcm step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Turn off the ignition. 2. Disconnect the system relay electrical connector. 2 3. Probe system relay terminal “30,” using a te...

Page 214

5 - 72 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm cmp sensor signal ic control ignition voltage ignition timing signal coil driver ground depspower ckp sensor signal depslo camshaft position (cmp) sensor spark plugs coil wire ignition coil distributor ignition control module (icm) high voltage switch (...

Page 215

5.0/5.7/6.0/8.1l diagnosis 5 - 73 mefi 4 - pcm diagnostic procedure (dp) a-7a distributor ignition diagnosis (5.0/5.7l only) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check caution: before proceeding, remove all injector co...

Page 216

5 - 74 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm diagnostic procedure (dp) a-7a distributor ignition diagnosis (5.0/5.7l only) step action value yes no 1. Turn the ignition “off.” 9 2. Using a test lamp connected to b+, probe the ignition coil driver circuit, terminal “c.” does the test lamp illuminat...

Page 217

5.0/5.7/6.0/8.1l diagnosis 5 - 75 mefi 4 - pcm step action value yes no using a test lamp connected to b+, probe the ignition 18 timing control circuit at the ecm harness connector, “j2-31.” does the test lamp illuminate brightly? — go to step 30 go to step 19 1. Turn the ignition “on,” engine “off....

Page 218

5 - 76 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm diagnostic procedure (dp) a-7a distributor ignition diagnosis (5.0/5.7l only) step action value yes no locate and repair the short to ground in the coil driver circuit 33 between the ignition coil and the ic module. Is action complete? — verify repair —...

Page 219: This Page Was

5.0/5.7/6.0/8.1l diagnosis 5 - 77 mefi 4 - pcm this page was intentionally left blank.

Page 220

5 - 78 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm diagnostic procedure (dp) a-7b electronic ignition system diagnosis (6.0/8.1l only) ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control e spark plug ignition coil (cylinder #6) firing order: 1 - 8 - 7 - 2 - 6 -...

Page 221

5.0/5.7/6.0/8.1l diagnosis 5 - 79 mefi 4 - pcm diagnostic procedure (dp) a-7b electronic ignition system diagnosis (6.0/8.1l only) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) ...

Page 222

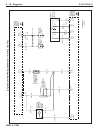

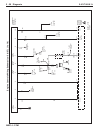

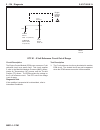

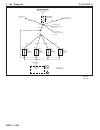

5 - 80 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm engine control module (ecm) m4059 9-18-02 coil b coil a stepper motor m b a c d 30 15 31 16 j1 grn/wht 443 grn/ blk 444 blu/ wht 442 blu/blk 441 idle air control (iac) valve iac coil b high iac coil b low iac coil a low iac coil a high diagnostic proced...

Page 223

5.0/5.7/6.0/8.1l diagnosis 5 - 81 mefi 4 - pcm diagnostic procedure (dp) a-8 idle air control functional test step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Ignition “off” for 10 seconds. 2. Disconnect iac harness conne...

Page 224

5 - 82 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 7 j2 3 blk 814 blk 814 yel 410 engine coolant temperature (ect) sensor engine control module (ecm) sensor ground ect sensor signal engine control module (ecm) b a s123 j2 m4060 9-18-02 from map sensor from tp sensor • if dtc 33 is also set, check for op...

Page 225

5.0/5.7/6.0/8.1l diagnosis 5 - 83 mefi 4 - pcm step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check turn ignition on, leaving engine off. 2 does scan tool display a coolant temperature less than the specifi ed value? -30°c (-22°f...

Page 226

5 - 84 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm • check harness routing for a potential short to ground in ckt 410. After repairs, clear dtc’s following “clear dtc’s procedure.” failure to do so may result in dtc’s not properly being cleared. Test description 2. Dtc 15 will set if signal voltage indi...

Page 227

5.0/5.7/6.0/8.1l diagnosis 5 - 85 mefi 4 - pcm step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check turn ignition on, leaving engine off. 2 does scan tool display a coolant temperature greater than the specifi ed value? 130°c (26...

Page 228

5 - 86 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 2 3 gry 416e blk 814 blk 814 throttle position(tp) sensor engine control module (ecm) sensor ground engine control module (ecm) s125 s123 tp sensor signal dk blu 417 23 j2 j2 m4061 11-20-02 c b a gry 416 5 volt reference from ect sensor from map sensor ...

Page 229

5.0/5.7/6.0/8.1l diagnosis 5 - 87 mefi 4 - pcm dtc 21 - throttle position (tp) sensor circuit - signal voltage high (scan diagnostics) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Throttle closed. 2 2. Turn ignition o...

Page 230

5 - 88 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 2 3 gry 416e blk 814 blk 814 throttle position(tp) sensor engine control module (ecm) sensor ground engine control module (ecm) s125 s123 tp sensor signal dk blu 417 23 j2 j2 m4061 11-20-02 c b a gry 416 5 volt reference from ect sensor from map sensor ...

Page 231

5.0/5.7/6.0/8.1l diagnosis 5 - 89 mefi 4 - pcm dtc 22 - throttle position (tp) sensor circuit - signal voltage low (scan diagnostics) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Throttle closed. 2 2. Turn ignition on...

Page 232

5 - 90 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 8 21 2 j2 3 gry 416e lt grn 432 blk 814 blk 814 blk 814 4 1 3 manifold absolute pressure (map)/intake air temperature (iat) sensor (5.0/5.7l) engine control module (ecm) map sensor signal sensor ground engine control module (ecm) 2 s125 s123 ppl 472 j2 ...

Page 233

5.0/5.7/6.0/8.1l diagnosis 5 - 91 mefi 4 - pcm dtc 23 - intake air temperature (iat) sensor circuit - low temp indicated (5.0/5.7l only) (scan diagnostics) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check turn ignition on, l...

Page 234

5 - 92 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm 8 21 2 j2 3 gry 416e lt grn 432 blk 814 blk 814 blk 814 4 1 3 manifold absolute pressure (map)/intake air temperature (iat) sensor (5.0/5.7l) engine control module (ecm) map sensor signal sensor ground engine control module (ecm) 2 s125 s123 ppl 472 j2 ...

Page 235

5.0/5.7/6.0/8.1l diagnosis 5 - 93 mefi 4 - pcm dtc 25 - intake air temperature (iat) sensor circuit - high temp indicated (5.0/5.7l only) (scan diagnostics) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check turn ignition on, ...

Page 236

5 - 94 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm dtc 33 - manifold absolute pressure (map) sensor circuit - signal voltage high (scan diagnostics) • if the idle is rough or unstable, refer to symptoms for items which may cause an unstable idle. • with the ignition “on,” engine “off,” the manifold pres...

Page 237

5.0/5.7/6.0/8.1l diagnosis 5 - 95 mefi 4 - pcm dtc 33 - manifold absolute pressure (map) sensor circuit - signal voltage high (scan diagnostics) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Install a vacuum gauge to a...

Page 238

5 - 96 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm dtc 34 - manifold absolute pressure (map) sensor circuit - signal voltage low (scan diagnostics) • if the idle is rough or unstable, refer to symptoms for items which may cause an unstable idle. • with the ignition “on,” engine “off,” the manifold press...

Page 239

5.0/5.7/6.0/8.1l diagnosis 5 - 97 mefi 4 - pcm dtc 34 - manifold absolute pressure (map) sensor circuit - signal voltage low (scan diagnostics) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Turn the ignition off. 2. In...

Page 240

5 - 98 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ic control ignition voltage ignition control signal coil driver ground spark plugs coil wire ignition coil distributor ignition control module (icm) high voltage switch (distributor) 31 j2 a a c c d b mounted on ignition coil b gry 2121 blk pnk pnk brn ...

Page 241

5.0/5.7/6.0/8.1l diagnosis 5 - 99 mefi 4 - pcm dtc 41 (est a fault) - ignition control circuit (5.0/5.7l only) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check 1. Turn ignition “on,” engine “off.” 2. Disconnect the ignition ...

Page 242

5 - 100 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control a spark plug ignition coil (cylinder #1) firing order: 1 - 8 - 7 - 2 - 6 - 5 - 4 - 3 ignition control: a - b - c - d - e - f - g - h ignition coils (cylinder...

Page 243

5.0/5.7/6.0/8.1l diagnosis 5 - 101 mefi 4 - pcm dtc 41 (est a fault) - ignition coil 1 control circuit (6.0/8.1l) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) dtcs are set at t...

Page 244

5 - 102 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control d spark plug ignition coil (cylinder #2) firing order: 1 - 8 - 7 - 2 - 6 - 5 - 4 - 3 ignition control: a - b - c - d - e - f - g - h ignition coils (cylinder...

Page 245

5.0/5.7/6.0/8.1l diagnosis 5 - 103 mefi 4 - pcm dtc 41 (est d fault) - ignition coil 2 control circuit (6.0/8.1l) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) dtcs are set at t...

Page 246

5 - 104 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control h spark plug ignition coil (cylinder #3) firing order: 1 - 8 - 7 - 2 - 6 - 5 - 4 - 3 ignition control: a - b - c - d - e - f - g - h ignition coils (cylinder...

Page 247

5.0/5.7/6.0/8.1l diagnosis 5 - 105 mefi 4 - pcm dtc 41 (est h fault) - ignition coil 3 control circuit (6.0/8.1l) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) dtcs are set at t...

Page 248

5 - 106 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control g spark plug ignition coil (cylinder #4) firing order: 1 - 8 - 7 - 2 - 6 - 5 - 4 - 3 ignition control: a - b - c - d - e - f - g - h ignition coils (cylinder...

Page 249

5.0/5.7/6.0/8.1l diagnosis 5 - 107 mefi 4 - pcm dtc 41 (est g fault) - ignition coil 4 control circuit (6.0/8.1l) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) dtcs are set at t...

Page 250

5 - 108 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control f spark plug ignition coil (cylinder #5) firing order: 1 - 8 - 7 - 2 - 6 - 5 - 4 - 3 ignition control: a - b - c - d - e - f - g - h ignition coils (cylinder...

Page 251

5.0/5.7/6.0/8.1l diagnosis 5 - 109 mefi 4 - pcm dtc 41 (est f fault) - ignition coil 5 control circuit (6.0/8.1l) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) dtcs are set at t...

Page 252

5 - 110 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control e spark plug ignition coil (cylinder #6) firing order: 1 - 8 - 7 - 2 - 6 - 5 - 4 - 3 ignition control: a - b - c - d - e - f - g - h ignition coils (cylinder...

Page 253

5.0/5.7/6.0/8.1l diagnosis 5 - 111 mefi 4 - pcm dtc 41 (est e fault) - ignition coil 6 control circuit (6.0/8.1l) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) dtcs are set at t...

Page 254

5 - 112 diagnosis 5.0/5.7/6.0/8.1l mefi 4 - pcm ecm ground ignition feed to fuse block term. "a" from system relay term. "87" ignition control c spark plug ignition coil (cylinder #7) firing order: 1 - 8 - 7 - 2 - 6 - 5 - 4 - 3 ignition control: a - b - c - d - e - f - g - h ignition coils (cylinder...

Page 255

5.0/5.7/6.0/8.1l diagnosis 5 - 113 mefi 4 - pcm dtc 41 (est c fault) - ignition coil 7 control circuit (6.0/8.1l) step action value yes no 1 was the “on-board diagnostic” (obd) system check go to obd performed? — go to step 2 system check important: if all the ignition control (ic) dtcs are set at t...

Page 256