- DL manuals

- PlusQuip

- Barcode Reader

- EQP-103

- User Manual

PlusQuip EQP-103 User Manual - 5.3 Live Datastream

√ If the code reader fails to clear the codes, a “Clear Error! Turn

Key on with Engine off!” message displays.

5. Wait a few seconds or press any key to return to

Diagnostic

Menu

.

5.3 Live Datastream

Viewing Data

The

View Data

function allows real time viewing of the vehicle’s

electronic control unit’s PID data, including sensor data, operation of

switches, solenoids and relays.

To view live datastream:

1. Use the UP/DOWN key to select Datastream from

Diagnostic

Menu

screen.

2. Press the ENTER key to confirm.

3. Use the UP/DOWN key to select View Data from

Datastream

screen.

Diagnostic Menu

Read Codes

Clear Codes

Datastream

Freeze Data

I/M Readiness

O2 Monitor Test

EQP-103 User’s Manual

30

Summary of EQP-103

Page 1

Eqp-103 – obdii code reader & reset tool user’s manual this compact, multi-function tool can be used on local and imported vehicles that support the obdii vehicle communication system..

Page 2: 5.. O

Ttaabbllee ooff ccoonntteennttss 1. Ssaaffeettyy iinnffoorrm maattiioonn .............................................................................................................................................. 2 1.1 conventions used ................................................................

Page 3: 1. Safety Information

For your safety, and to prevent damage to the equipment and vehicles, read this manual thoroughly before operating your eqp-103 eobd code reader. The safety messages presented below and throughout this user’s manual are reminders to the operator to exercise extreme care when using this device. Alway...

Page 4

Do not exceed voltage limits between inputs specified in this user’s manual. Always wear ansi approved goggles to protect your eyes from propelled objects as well as hot or caustic liquids. Fuel, oil vapors, hot steam, hot toxic exhaust gases, acid, refrigerant and other debris produced by a malfunc...

Page 5: 2. Using This Manual

2. Using this manual we provide instructions for the usage of your code reader in this manual. Below is a list of conventions we used in the manual. Safety information see safety information on pages 2-3. Bold text bold emphasis is used in procedures to highlight selectable items such as buttons and...

Page 6

Important indicates a situation which, if not avoided, may result in damage to the test equipment or vehicle. Example: important do not soak keypad as water might find its way into the code reader. Note note provides helpful information such as additional explanations, tips, and comments. Example: n...

Page 7: 3. Introduction

3. Introduction the eqp-103 is specially designed to support all 9 obdii service modes, including live data, o2 sensor test and more, on obdii / eobd compliant cars, suvs, light-duty truck and mini-vans sold worldwide since 1996. 3.1 about obdii / eobd what is obd? The first generation of on-board d...

Page 8

Data link connector the data link connector (dlc) is a standard 16-pin interface located under the dashboard on the driver's side of the passenger compartment. If the dlc is not located under the dashboard as stated, a decal describing its location should be attached to the dashboard in the area the...

Page 9

Diagnostic trouble codes (dtcs) diagnostic trouble codes (dtcs) are faults stored by vehicle computers when problems that affect engine performance and emissions are detected. Dtcs are used to help identify the cause of a trouble or troubles with a vehicle, and determine the fault location(s). Dtcs ...

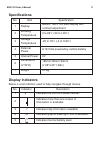

Page 10: Code Reader Controls

3.2 about the code reader code reader controls a. Obd ii port – provides communication for vehicle dlc. B. Lcd display – shows menus, test results and operation tips. C. Up key – moves selection up. Scrolls back and forth through codes retrieved. Press it from home screen to enter the dtc update mod...

Page 11: Accessories Included

E. Hheellpp kkeeyy – accesses the help function. F. Bbaacckk kkeeyy – cancels an action and returns to previous screen or level. Also, press it to enter system setup menu from home screen. G. Eenntteerr kkeeyy – confirms an action or movement and moves to next level. Starts recording live data under...

Page 12: Display Indicators

No. Item specification 1 display backlit, 160 x 105 pixel display with contrast adjustment. 2 working temperature 0 to 60°c (32 to 140°f ) 3 storage temperature -20 to 70°c (-4 to 158°f ) 4 external power 8-18 volts powered by vehicle battery 5 internal power 9v 6 dimensions (l*w*h) 185mm*85mm*35mm ...

Page 13: System Setup

√√ refer to ccooddee rreeaaddeerr ddooeess nnoott ppoowweerr uupp on page 56 of ttrroouubblleesshhoooottiinngg if there are problems. Iinntteerrnnaall bbaatttteerryy to power on the code reader by internal battery: 1. Install 9v battery. 2. Press the ppo ow weerr key to turn on the code reader. √ wh...

Page 14

√ system setup settings remain until change to the existing setups are made. To do system setup: 1. Press the back key to enter system setup from home screen or use the up/down key to select system setup from main menu screen. √ follow on-screen instructions to program the code reader to meet your s...

Page 15

3. Use the up/down key to select desired language. 4. Press the enter key to save language setting and return. Adjusting display contrast to adjust display contrast: 1. Use the up/down key to select contrast from system setup screen. 2. Press the enter key to confirm. 3. Use the up/down key to adjus...

Page 16

4. Press the enter key to save contrast setting and return. Changing measurement unit √ metric is the default measurement unit. To change measurement unit: 1. Use the up/down key to select measurement unit from system setup screen. 2. Press the enter key to confirm. 3. Use the up/down key to select ...

Page 17

4. Press the enter key to save measurement setting and return. Changing auto power-off √ the minimum auto power-off time is 1 minute, and the maximum is 20 minutes. √ the auto power-off function is available only when the code reader is powered by internal battery. To change auto power off time: 1. ...

Page 18

4. Use the enter key to save. Turning on/off beeper √ the beeper is on by default. To turn beeper on/off: 1. Use the up/down key to select beeper from system setup screen. 2. Press the enter key to confirm. 3. Use the up/down key to select desired choice. Auto power-off 01 minute [up] – increase tim...

Page 19

4. Use the enter key to save beeper sound setting. Checking lcd and keypad the tool self-tests function is used to check if the lcd display and the operation of keypad are working correctly. To check lcd 1. Use the up/down key to select tool self-tests from system setup screen. 2. Press the enter ke...

Page 20

4. Use the enter key to confirm and start testing. 5. When completed, use the enter key to return. To check keypad 1. Use the up/down key to select tool self-tests from screen. 2. Press the enter key to confirm. 3. Use the up/down key to select keyboard test from screen. Tool self-tests tool self-te...

Page 21

4. Press any key to start. Key name or scroll direction should show on display when you press a key. √ the only exception is the power key. When you press and hold the key, its name does not display on the screen, but resets the code reader when powered by vehicle battery, or turns off the tool when...

Page 22

2. Press the enter key to view information. Code lookup this function is used to request dtc definitions stored in the code reader. To look up dtcs: 1. Use the up/down key to select code lookup from main menu screen. Tool information s/w ver: v1.00 h/w ver: v1.00 lib ver: v1.0 main menu diagnostics ...

Page 23: 4. Data Review

2. Use the enter key to confirm. 3. Use the up/down key to change highlighted character, press the enter key to confirm and the cursor moves to the next character automatically. 4. Press the enter key to view the dtc definition. 5. To view next or previous dtc, use the up/down key. √ if definition c...

Page 24

2. Press the enter key to confirm. 3. Use the up/down key to scroll to the desired item and press the enter key. √ if no data from last vehicle tested is recorded only module present has information (module id and protocol type) to be reviewed. Main menu diagnostics review data print data code looku...

Page 25: 5. Obdii / Eobd Diagnosis

5. Obdii / eobd diagnosis ddiiaaggnnoossttiicc m meennuu allows you to: • read dtcs. • clear dtcs. • view live datastream. • view freeze data. • view i/m readiness data. • o2 sensor test information. • view on-board monitor test results. • perform component tests. • retrieve vehicle information. • r...

Page 26

√ if vehicle is equipped with more than one computer module (for example a powertrain control module [pcm] and a transmission control module [tcm]), the code reader identifies them by their identification names (id) assigned by manufacturer (i.E. Engine or module $a4). To perform diagnosis: 1. Press...

Page 27

√ if previous recording not to be erased, select no. √ if no data exist in the tool, above prompt is not displayed. Note the code reader keeps one recording only. If data from previous testing is not cleared, information of current test can not be stored. Note review stored data completely before er...

Page 28: 5.1 Reading Dtcs

5.1 reading dtcs the read codes function is used to read dtcs (stored codes), which are used to help identify the cause of a trouble or troubles with a vehicle, and pending codes from the vehicle’s control modules. √ when emission-related or driveability fault occurs the control module illuminates t...

Page 29: Select Other.

√ if no dtcs are present a message stating “no (pending) codes found!” is displayed. √ if any manufacturer specific or enhanced codes detected, a “manufacturer specific codes are found! Press any key to select vehicle make!” message displays prompting you to select vehicle make before viewing dtc(s)...

Page 30

√ this function is performed with koeo. Do not start the engine. To erase codes from vehicle control modules: 1. Use the up/down key to select clear codes from diagnostic menu screen. 2. Press the enter key to confirm. 3. If codes and diagnostic results are to be cleared, use the up/down key to sele...

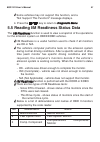

Page 31: 5.3 Live Datastream

√ if the code reader fails to clear the codes, a “clear error! Turn key on with engine off!” message displays. 5. Wait a few seconds or press any key to return to diagnostic menu . 5.3 live datastream viewing data the view data function allows real time viewing of the vehicle’s electronic control un...

Page 32

4. Press the enter key to confirm. √ some vehicles may not support this function. Viewing complete list complete data list displays all supported pids of the vehicle being tested. To view entire data list: 1. Use the up/down key to select complete data list from view data screen. 2. Press the enter ...

Page 33

√ if the “g” icon shows when a pid is selected, press the enter key to view graph. And press the back key to return to live pid screen. 4. Press the back key to return to previous level. Viewing custom data list custom data list allows certain pids from complete data list to be selected. To view cus...

Page 34

2. Press the enter key. 3. Use the up/down key to move up or down, and press the enter key to select or deselect pids to view. Selected parameters are marked with solid squares. √ the number to the right is the order that the pids were selected and will be displayed. √ you are allowed to pick up a m...

Page 35

√ if the g icon displays while a pid is selected press the enter key to view graph. 5. Use the back key to return to view data screen. Changing measurement unit refer to “changing measurement unit” on page 15 of system setup. Recording data the record data function is used to record pids to help dia...

Page 36

To record live data: 1. Use the up/down key to select record data from datastream screen. 2. Press the enter key to confirm. 3. Refer to view data to set up complete data list or customer data list to record. 4. Use the up/down key to pick a trigger mode. 5. Press the enter key to confirm. 6. Use th...

Page 37

√ the asterisk (*) on the screen indicates that a recording currently exist in this memory area. √ if an area with an asterisk (*) was picked, a message prompting to erase data displays. √ if manual trigger is selected, following screen displays: select memory previous recording exists! Erase it and...

Page 38

√ if trigger on dtcs is picked, following screen displays: √ if data is to be erased, select yes; if data is not be erased, pick no to return to select memory screen and pick another one. 7. Press the enter key to start recording or wait for codes to trigger. √ the code reader keeps saving data unti...

Page 39

9. Select yes to view recorded data; pick no or press the back key to return to record data . Playback data the playback data is used to playback recorded pid data. To playback data: 1. Use the up/down key to select playback data from datastream screen. 2. Press the enter key. 3. Use the up/down key...

Page 40

√ if no recording exists, the code reader displays a “no recording found!” message. 4. Press the enter key to playback. 5. Use the up/down key to view pids of each frame; or use the enter key to move back and forth through frames. √ the number to the upper right corner of display indicates the total...

Page 41: 5.4 Viewing Freeze Data

5.4 viewing freeze data the ffrreeeezzee ddaattaa function is used to view freeze frame data, a snapshot of vehicle operating conditions recorded by the on-board computer at the time of an emission-related fault. √√ if codes were cleared, freeze data may not be stored in vehicle memory depending on ...

Page 42

√√ some vehicles may not support this function, and a “not support this function!” message displays. 4. Press the eenntteerr key to return to ddiiaaggnnoossttiicc m meennuu . 5.5 reading i/m readiness status data the ii//m m rreeaaddiinneessss function is used to view a snapshot of the operations fo...

Page 43

4 catalyst mon catalyst monitor 5 htd catalyst heated catalyst monitor 6 evap system mon evaporative system monitor 7 sec air system secondary air system monitor 8 a/c refrig mon air conditioning refrigerant monitor 9 oxygen sens mon oxygen sensor monitor 10 oxygen sens htr oxygen sensor heater moni...

Page 44

√ use the up/down key to select a monitor type and press the enter key to confirm. 3. Depending on readiness test, one of these 2 screens will be present. Or since dtcs cleared mil status off misfire monitor n/a fuel system mon. N/a comp. Component ok catalyst mon n/a htd catalyst n/a this drive cyc...

Page 45: 5.6 O2 Monitor Test

√√ if more than one screen of information is retrieved, use the uupp//ddo ow wnn key to view additional data. √√ some vehicles may not support this function, and a “not supported function!” message displays. 4. Press the bbaacckk key to return to ddiiaaggnnoossttiicc m meennuu . 5.6 o2 monitor test ...

Page 46: 5.7 On-Board Monitor Test

√√ if the vehicle being tested does not support this function, the code reader displays a “not support this function!” message. 4. Press the eenntteerr key to view data of selection. √√ when more than one screen of data is retrieved, use the uupp//ddo ow wnn key to view additional information. 5. Pr...

Page 47

For can vehicles, it receives test data for emission-related powertrain components and systems that are and are not continuously monitored. It is the vehicle manufacturer who is responsible for assigning test and component ids. Nno ottee test results do not necessarily indicate a faulty component or...

Page 48

√ if vehicle being tested does not support this function, the code reader displays a “not support this function!” prompt. 4. Use the enter key to view details of selected test results. √ for non-can vehicles, test screen is illustrated as below: √ for can vehicles, test screen is illustrated as belo...

Page 49: 5.8 Component Test

√√ when more than one screen of data is retrieved, use the uupp//ddo ow wnn key to view additional information. 5. Press the bbaacckk key to return to o onn--bbooaarrdd m moonniittoorr tteesstt . 5.8 component test the ccoom mppoonneenntt tteesstt allows the code reader to control operation of vehic...

Page 50

4. Press the eenntteerr key to start testing, and the code read displays a “command sent!” message. √√ if vehicle being tested does not support this function, the code reader displays a “not support this function!” prompt. 5. Press the bbaacckk key to return to ddiiaaggnnoossttiicc m meennuu. 5.9 re...

Page 51

2. Press the enter key to confirm. 3. Observe on-screen instruction and wait a few seconds or press any key to continue. √ some vehicle may not support this function, and a “not support this function!” message displays. 4. Press the enter key to confirm. 5. Use the up/down key to select an available...

Page 52: 5.10 Modules Present

6. Press the eenntteerr key to view retrieved information. 7. Press the eenntteerr key return. Note not all data is supported by all vehicles. 5.10 modules present the code reader identifies module ids and communication protocols for obd2 modules in the vehicle. To view module ids and communication ...

Page 53: 6. Updating and Printing

2. Press the eenntteerr key to view information. 6. Updating and printing eqp-103 is able to be updated to keep you current with the latest development of diagnosis. Also, it allows you to upload recorded test results to your pc or laptop for analysis and printing. Modules present id protocol $10 is...

Page 54: 6.1 Updating The Code Reader

√ to be able to use the update tool, your pc or laptop must meet the following minimum requirements: • operating system: win98/nt, win me, win2000, win xp, vista or windows 7 • cpu: intel piii or better • ram: 64mb or better • hard disk space: 30mb or better • display: 800*600 pixel, 16 byte true co...

Page 55: 6.2 Printing

2. Press the up key and a “connecting to pc” message shows on eqp-103 screen. 3. Click to start updating. 6.2 printing the pprriinntt ddaattaa function is used to print test results through computer. To print test results: 1. Download and launch pc-link as instructed on page 53 of 6.1 updating the c...

Page 56: 7. Troubleshooting

5. Press the eenntteerr key to confirm. 6. Use the uupp//ddo ow wnn key to select desired data to print. √√ if all recorded data to be printed, use the uupp//ddo ow wnn key to select pprriinntt aallll. 7. Press the eenntteerr key to load data to your computer. 8. Use the bbaacckk key to return to m ...

Page 57: 7.3 Battery Replacement

• verify ignition key is in the on position. • make sure the code reader is correctly attached to vehicle’s data link connector (dlc). • check dlc for cracked or recessed pins, or for any substance that could prevent a good electrical connection. • check eqp-103 obdii connector for bent or broken pi...