- DL manuals

- Protherm

- Boiler

- 23 MOV

- Installation manual

Protherm 23 MOV Installation manual - Contents

- 2 -

CONTENTS

Ú D R Ž B A

Search and trouble-shooting

12

Diagnosing faults

12.1

...................................................................... 25

Fault codes

12.2

............................................................................... 25

Gas conversion

13

Settings

13.1

.................................................................................... 26

Discharging water

14

Heating system

14.1

....................................................................... 27

Servising

15

Function check

15.1

........................................................................ 27

Replacement parts

16

Spare parts

17

Techni

18 cal

parameters

Summary of 23 MOV

Page 1

23 mtv v.19 23 mov v.19 wall-hang non-condensing boiler power 8,5 - 23,3 kw flow heating hw gepard v e r s i o n installation manual en.

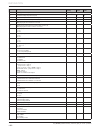

Page 2: Contents

- 1 - contents introduction manual 1 product documentation 1.1 .............................................................. 3 relevant documents 1.2 .................................................................. 3 explanation of symbols 1.3 ........................................................

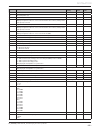

Page 3: Contents

- 2 - contents Ú d r Ž b a search and trouble-shooting 12 diagnosing faults 12.1 ...................................................................... 25 fault codes 12.2 ............................................................................... 25 gas conversion 13 settings 13.1 ................

Page 4

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 3 - introduction introduction manual 1 product documentation 1.1 instructions are included with the device and after the installation must be handed to the user in accordance with applicable regulations. Study the handbook carefully t...

Page 5

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 4 - introduction and the european directive 89/336/eec on electromagnetic compatibility. The appliance is also approved according to the european norms en 677, en 625, en 60335-01, en 50165, en 55014, en 61000-3-2 and en 61000-3-3. In...

Page 6

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 5 - introduction hydraulic scheme 2.5 23 mov 2.5.1 1 a b c d e 1 2 3 4 5 6 7 8 9 10 20 19 17 18 16 14 13 12 15 11 legend 1 safety valve 2 gas valve 3 hw exchanger 4 discharge valve 5 burner 6 ignition electrodes 7 ntc ch water intake ...

Page 7

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 6 - introduction 23 mtv 2.5.2 1 2 3 4 5 6 7 8 9 10 11 a b c d e 21 20 18 19 17 15 14 13 16 12 legend 1 safety valve 2 gas valve 3 hw exchanger 4 discharge valve 5 burner 6 ignition electrodes 7 ntc ch water intake temperature sensor 8...

Page 8

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 7 - introduction safety instructions and regulations 3 safety instructions 3.1 when gas pressure exceeds the limit specifi ed input device, the device may not start. E incorrect installation can cause electric shock or damage to equip...

Page 9

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 8 - instalation installation location of equipment 4 location 4.1 instructions 4.1.1 before you choose a location for placement of equipment, carefully consult safety warnings and instructions in the user manual and installation guide...

Page 10

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 9 - instalation dimensions 5.3 gepard 23 mov 5.3.1 311 410 742 179 205 Ø125 gepard 23 mtv 5.3.2 311 410 Ø39 742 184 205 82 65 116 65 82 205 26 160 134.

Page 11

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 10 - instalation mounting the boiler 5.4 when mounting the boiler on the wall, proceed in accordance with the installation design conditions (e.G. Wall load bearing properties, chimney inlet, pipe inlet and outlet connections). The mo...

Page 12

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 11 - instalation hydraulic connection 6 the boiler connection terminals may not be placed under undue pressure from the piping system for the ch circuit, the hw circuit or from the gas intake. This assumes a precise observance of the ...

Page 13

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 12 - instalation air and exhaust lines 7 1 3 4 2 5 6 legend 1 chimney - 110 mm pre 12 kw, 125 mm pre 25 kw 2 over-fl ow safety device 3 draught diverter 4 heat exchanger 5 combustion chamber 6 burner - 13 blades.

Page 14

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 13 - instalation 1 3 4 2 5 6 legenda 1 fan 2 air pressure switch 3 draught diverter 4 heat exchanger 5 combustion chamber 6 burner - 13 blades.

Page 15

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 14 - instalation regulations 7.1 the type mov is designed for combustion gases to be removed and discharged into a chimney (through a chimney inlet) with a minimum stabilised thrust of 2 pa. The boiler is connected to the chimney inle...

Page 16

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 15 - instalation double chimney never has terminal elements — the same as with pipes that vent into open areas! Both components of the route — external (air) and internal (exhaust gas) — must safely feed into the relevant chimney duct...

Page 17

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 16 - instalation piping gradient 7.2.8 the layout of the piping must permit a down-gradient of the exhaust piping towards the boiler at a nominal gradient of 3 percent. A device for drawing off condensate must be placed on the piping ...

Page 18

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 17 - instalation connecting the boiler to the electricity 8 supply e incorrect installation can cause electric shock or damage to equipment. Electrical connection device can be performed only by a qualifi ed technician. The device mus...

Page 19

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 18 - instalation bmu 8.2 1 legend 1 removable connector for 24v & ebus room thermostats & outdoor sensor.

Page 20

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 19 - instalation boiler wiring diagram 8.3 1 10 2 11 3 12 4 13 5 14 6 15 7 16 8 17 9 18 10 5 9 4 8 3 7 2 6 1 1 2 3 4 10 9 8 7 6 5 4 3 2 1 19 20 18 17 16 15 14 13 12 11 m d t t ntc ebus 24 v x2 x30 x90 x32 x40 x51 x31 x25 x21 x13 230 v...

Page 21

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 20 - instalation external accessories 8.4 for regulating the boiler from a room regulator, only a regulator that has a no-voltage input, i.E. That does not send any external voltage into the boiler, may be used. Load carrying capacity...

Page 22

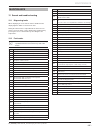

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 21 - instalation code parameter description p.01 forcing the adjustable power burner when heating the appliance functions at power adjustable from pmin. To 100% by using buttons + or - on the right side after successful ignition. P.02...

Page 23

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 22 - instalation code description manufacturing setting minimum value maximum value 00 heating part load, adjustable values in kw following power range 01 central heating pump overrun (min) 5 2 60 02 maximum off period after central h...

Page 24

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 23 - instalation code description manufacturing setting minimum value maximum value 36 dhw waterfl ow sensor (l/min) 40 flow temperature (°c) 41 return temperature (°c) 43 heating curve displayed only when outdoor t° sensor connected ...

Page 25

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 24 - instalation code description manufacturing setting minimum value maximum value 96 reset adjustable parameters to the factory settings 0 0 1 re-check and restart 10.3 after installing equipment, equipment check. • start the instal...

Page 26

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 25 - maintenance maintenance search and trouble-shooting 12 diagnosing faults 12.1 when displaying an error code the letter f will fl ash on the display together with the relevant error code. During the normal course of operation of t...

Page 27

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 26 - maintenance gas conversion 13 the panther boilers are in their basic versions designed to use natural gas as fuel. The modifi cations required to switch to a different fuel must be carried out by an authorised technician with a v...

Page 28

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 27 - maintenance discharging water 14 the outlet valve is designated primarily for lowering the water pressure in the boiler during repairs. Only a partial discharge of water from the boiler is possible through this outlet. A complete...

Page 29

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 28 - maintenance replacement parts 16 burner 16.1 fan 16.2.

Page 30

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 29 - maintenance air pressure switch 16.3.

Page 31

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 30 - maintenance over - fl ow safety device 16.4 return heating ntc sensor 16.5 flow heating ntc sensor 16.6.

Page 32

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 31 - maintenance pressure sensor 16.7 ignition transformator 16.8.

Page 33

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 32 - maintenance plate to plate exchanger 16.9.

Page 34

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 33 - maintenance gas valve 16.10

Page 35

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 34 - maintenance dhw fl ow sensor 16.11.

Page 36

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 35 - maintenance expansion vessel 16.12.

Page 37

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 36 - maintenance spare parts 17 to ensure safe operation and long life product, you must use only original parts from the manufacturer. I this product has the ce marking of conformity. Use only new original parts from the manufacturer...

Page 38

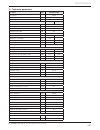

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 37 - maintenance techniccal parameters 18 description units gepard 23 mov gas category ii2h3p distribution b11bs ignition electronic power / fuel natural gas propane maximum thermal consumption kw 25,8 minimum thermal consumption kw 1...

Page 39

P2_gepard_installer manual_ work basis_en_02 - 03/10 - protherm - 38 - maintenance description units gepard 23 mtv gas category ii2h3p distribution c12, c32, c42, c52, c82, b22 ignition electronic power / fuel natural gas propane maximum thermal consumption kw 25,0 minimum thermal consumption kw 10,...

Page 41

Www.Protherm.Eu p2_gep ard_installer manual_ work basis_en_02 - 03/10 insert the bar code protherm spol. S r.O. Pplk. Pľjušťa 45 909 01 skalica tel.: 034 6966 101 fax: 034 6966 111.