Summary of MICRO-Router MOF

Page 1

Proxxontools.Com micro-router mof manual.

Page 2

Notes 2.

Page 3

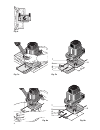

3 8 8 fig. 1 fig. 2 fig. 5 fig. 4 fig. 3.

Page 4

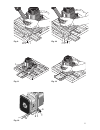

4 0 10 20 30 fig. 6 fig. 7a fig. 7b fig. 8b fig. 8a.

Page 5

3 2 1 fig. 11 fig. 13 5 0 10 20 30 0 10 20 30 0 10 20 30 fig. 9 fig. 10 fig. 12.

Page 6

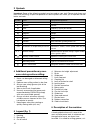

Operating instructions mof surface mill contents: 1 general safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 2 specific safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3 symbols ...

Page 7

Dear customer, in order to be able to operate router safely and correctly, please carefully read the fol- lowing safety and operating instructions pri- or to use. The use of these instructions makes it easier to get familiar with the device, prevents mal- functions caused by improper operation, and ...

Page 8

Diately. Damaged cords increase the risk of electric shock. 8. When operating a power tool outside, use an outdoor extension cord marked "w-a" or "w." these cords are rated for outdoor use and reduce the risk of electric shock. Personal safety 9. Stay alert, watch what you are doing and use common s...

Page 9

Use this tool unsafely or incorrectly, you can suffer serious personal injury. 1. Hold on the power tool by insulated gripping surfaces when performing an operations where the cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will make ex- posed metal parts of the to...

Page 10

4 additional precautionary mea- sures during surface milling: 1. Never use damaged or deformed milling cutters. 2. Replace worn milling cutters in due time 3. Always wear safety glasses (risk of the tool breaking) 4. Wear a dust mask if applicable. 5. Use only accessories and spare parts recommended...

Page 11

Ting tapers, rabbet milling, profile milling, etc. The many, many possibilities often be- come apparent only after working with the mill cutter. A variety of materials such as wood, synthetics, acryl, mdf, gypsum board, etc. Can be processed. We supply corresponding and sensible accessories for you ...

Page 12

These mill cutters (with a shank diameter of 1/8” or 3.2 mm) are attuned to the use of your machine and guarantee excellent re- sults. 7.2 insertion and replacement of the mill cutter router bit (fig. 2): warning! Please make sure the plug has been pulled out when replacing the mill cutter! In all c...

Page 13

1. Clamp in the desired cutter (see chapter 7.2., „insertion and replacement of the mill cutter router bit“) 2. Pull out lock-on lever 1; the spring pre- load presses the foot into its lowest posi- tion. 3. Press milling-cutter head 2 into the guides against the spring force to a posi- tion correspo...

Page 14

• for practical purposes, one should use one limit stop for each type of milling work. There are different possibilities for this, so only the most practical are ex- plained here: 7.5.2 milling with limit stops 7.5.2.1 milling with parallel limit stops (limit stop is included in the scope of deliv- ...

Page 15

To do this, clamp it to the work piece using, for example, c-clamps. In this way, the con- tours of the template can be „traced“ with the mof foot-edge and the desired milled groove can be made. However, just as described in the previous point, in this procedure it is better to take the clearance be...

Page 16

Description item no: straight no 29 024 straight no 29 026 straight no 29 028 core box no 29 030 v-groove 90° no 29 032 plunge no 29 034 piloted round over no 29 036 rabbeting no 29 038 beading no 29 040 piloted cove no 29 042 9 accessories warning! Use only accessories that are recommended by the m...