- DL manuals

- Prozeda

- Controller

- Primos 250 SR

- Installation And Operating Instructions Manual

Prozeda Primos 250 SR Installation And Operating Instructions Manual - 10.2

Restore factory settings

41

10.2

Setting the energy output measurements

The "Basic settings" menu allows you to set the following parameters:

•

P:12: Measurement principle for energy output measurement

•

P:15: Flow rate for the "Flow indicator" measurement principle

•

P:16: Energy output measurement: Glycol type

•

P:17: Energy output measurement: Glycol concentration.

11

Restore factory settings

ATTENTION

Risk of loss of current settings due to incorrect restoration of the factory

settings.

Before restoring the factory settings, make sure that you no longer

require the current settings.

If necessary, save the current settings to a microSD card before

restoring the factory settings.

The factory settings are the parameters that were preset ex works.

In order to restore the factory settings, select the value "1" in the "P: 35:" menu item in the

"Basic settings" menu.

The factory settings will be restored.

12

Networking the controller with other devices

The RS-485 interface (ProBus and ProBusX) allows you to connect the controller to other

devices in a network. By networking (with the conexio 600 or conexio 200 web module) you

can use the following additional functions via a PC, tablet PC, smartphone etc.:

•

Viewing the controller's data on another device (monitoring)

•

Operating the controller from another device (remote control)

The manufacturer can provide further details.

Summary of Primos 250 SR

Page 1

Controller unit for solar thermal systems primos 250 sr installation and operating instructions english version of original german installation and operating instructions version: 1.2 july 2016.

Page 2: Terminology

Terminology in order to facilitate the use of the assembly and operating instructions, the following terminology will be used: • these installation and operating instructions will hereinafter be designated as "instructions". • the primos 250 sr controller will hereinafter be designated as "controlle...

Page 3: Target Group

This manual is designed to help you use the controller properly, safely and economically. Target group this manual is addressed to all persons who carry out any of the following tasks: • installing the controller • connecting the controller • putting the controller into operation • setting the contr...

Page 4: Danger

Style conventions used in the text specific style conventions are assigned to different elements in the manual. This makes it easy to recognise the type of text concerned: standard text, "menu", "menu item", "button designations", • lists and actions. Notes accompanied by this symbol contain informa...

Page 5: Table Of Contents

Table of contents 1 safety ........................................................................................................................ 7 1.1 proper use ..........................................................................................................................................

Page 6

10 measuring energy output ...................................................................................... 40 10.1 flow indicator...................................................................................................................................... 40 10.2 setting the energy ou...

Page 7: Safety

Safety 7 1 safety this chapter contains information on: • the proper use of the controller and • the safe use of the controller. Read this chapter through carefully before you install, connect or operate the controller. 1.1 proper use the controller is used for monitoring and controlling a solar the...

Page 8: Preventing Risks Of Fire

Safety 8 preventing risks of fatal injury from electric shocks • make sure that all regulations applicable at the point of use are complied with. • always make sure that the controller is disconnected from the power supply before carrying out any work on it. • make sure that the connections of the p...

Page 9: 2.1

Description of the controller 9 • use only sensor connection boxes supplied by the manufacturer. 2 description of the controller the controller is used for monitoring and controlling a solar thermal system. The controller allows the system to be configured in accordance with the local situation at t...

Page 10: Installing The Controller

Installing the controller 10 3 installing the controller danger risk of fatal injuries due to explosions or fire. Never use the controller in areas where there is a risk of explosion. Install the controller on a non-flammable subsurface. Danger risk of fatal electric shock when working on the opened...

Page 11: 3.1

Installing the controller 11 3.1 removing the terminal cover undo the locking screw (1). To remove the terminal cover (2), pull it off as shown here..

Page 12: 3.2

Connecting the controller 12 3.2 fastening the controller if you wish to lead cables and lines through the back of the controller, you need to do this before you fasten it. Attention risk of damage to the controller housing due to screws tightened too firmly. Tighten the screws only as firmly as nec...

Page 13: Connecting The Controller

Connecting the controller 13 4 connecting the controller danger risk of fatal electric shock when working on the opened controller. Make sure that the controller is disconnected from the mains voltage before removing the terminal cover. Make sure that the power supply has been secured to prevent it ...

Page 14

Connecting the controller 14 the following illustration shows the elements of the controller that are important for connection: pos. Description 1 terminals for extra-low voltage area 2 fuse 3 terminals for 230 v area 4 terminals for protective conductor 5 terminals for relay contact 6 cut-out apert...

Page 15: 4.2

Connecting the controller 15 4.2 connecting the controller to the power supply when making the mains connection, you must ensure that the mains supply can be disconnected at any time. If you make a permanent mains connection, proceed as follows: install a switch outside the controller. If you make t...

Page 16: 4.4

Connecting the controller 16 4.4 assignment of the terminals to the system components the connections in the following table are options that may be used in all hydraulic layouts: terminal use s4 / s4 temperature sensor for the collector return for the "energy output measurement" function b a rs-485...

Page 17

Connecting the controller 17 terminal assignment for hydraulic layout 110.00 terminal use r1 / n / pe solar circuit pump, 230 v connection. Power control for high-efficiency pump on he1/m1 s1 / s1 temperature sensor for collector s2 / s2 temperature sensor for storage tank (s4 / s4) temperature sens...

Page 18

Connecting the controller 18 terminal assignment for hydraulic layout 000.00 in layout 000.00 you can use all outputs as multi-function controllers. In this case you must define at least one of the three switching outputs r1or r0 as a multi-function controller. Terminal use r1 / n / pe multi-functio...

Page 19: Operating The Controller

Operating the controller 19 5 operating the controller this chapter provides you with an overview of the controller's display elements and operating elements. This is followed by explanations of all the basic actions. 5.1 description of the display elements the main menu is located in the top part o...

Page 20

Operating the controller 20 when you have selected a menu, the applicable menu symbol (1) will be displayed. The bottom section of the screen displays the value (3) complete with a corresponding addition (2) and a measurement value symbol (7). Below these, status information and messages may be disp...

Page 21: 5.2

Operating the controller 21 5.2 using the operating buttons the operating buttons allow you to navigate in the menus and make changes to values. The following table explains the functions of the operating buttons: operating buttons function display the previous menu item. Increase the displayed valu...

Page 22: Menus

Displaying and changing the values in the menus 22 changing values to activate the displayed menu item, select . The value flashes. To increase the value, select . To reduce the value, select . To cancel the entry, select . The value stops flashing. The value that is currently set will be displayed....

Page 23

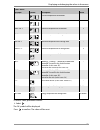

Displaying and changing the values in the menus 23 „info“ menu example symbol description reset 75 °c current temperature of collector – min. 12 °c minimum temperature of collector × max. 105 °c maximum temperature of collector × 52 °c current temperature of storage tank min. 40 °c minimum temperatu...

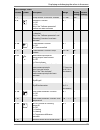

Page 24: 6.2

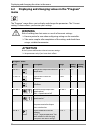

Displaying and changing the values in the menus 24 6.2 displaying and changing values in the "program" menu the "program" menu allows you to display and change the parameters. The "current settings" column allows you to enter your settings. Warning risk of scalding from hot water as a result of inco...

Page 25

Displaying and changing the values in the menus 25 „program“ menu value symbol description range factory setting current setting menu. 13:21 current time 00:00–23:59 12:00 23:03:11 current date the following eight menu items apply to multi-function controllers r1 and r4. If a hydraulic layout has be...

Page 26

Displaying and changing the values in the menus 26 „program“ menu value symbol description range factory setting current setting stop 20:00 4 time window 4: stop for the "tube collector" and "drain-back" functions. Only if the time controller has been activated for these functions in the "basic sett...

Page 27: 6.3

Displaying and changing the values in the menus 27 6.3 controlling switching outputs in the "manual mode" menu the "manual mode" menu allows the controller's switching outputs to be turned on and off for test purposes. To enable the controller to run in automatic mode again, you have to exit manual ...

Page 28

Displaying and changing the values in the menus 28 there are two operating modes: • user mode • editing mode. In user mode you can display values in this menu, but you cannot make any changes to them. If user mode is activated, the menu symbol is displayed in the form of a "locked" symbol. In editin...

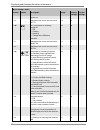

Page 29

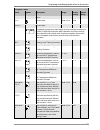

Displaying and changing the values in the menus 29 „basic settings“ menu position symbol description range factory settings current settings p: 7: pump runtime "drain-back" function 15–360 s 180 s p: 8: "recooling" function 0 = off 1 = on only if the "collector protection" function has been activate...

Page 30

Displaying and changing the values in the menus 30 „basic settings“ menu position symbol description range factory settings current settings for mfc r1 p: 23: selection of the sensor for the sink for mfc r1 1–4 4 p: 30: mfc r4 function at switching output r0 0 = off 1 = cooling 2 = heating 3 = tempe...

Page 31: 7.1

Setting the control functions 31 „basic settings“ menu position symbol description range factory settings current settings 1 = probus, for working with conexio 600 the change will not take effect until after the controller is restarted. * position 16: glycol types selection meaning selection meaning...

Page 32: 7.2

Setting the control functions 32 switched on when a certain specific target temperature has been reached in the collector. The "program" menu allows you to set the following parameter: • target temperature for the collector. 7.2 setting the pump control system you can connect standard pumps and high...

Page 33

Setting the control functions 33 controlling he pumps with analog signals in the case of the pump control system complete with analog signal, the controller sends a 0–10 v analog signal to terminals he1 and he2. Definitions for the output voltage (u): • pump off: 0.5 v • speed control: linear charac...

Page 34: 7.3

Setting the control functions 34 inverted in the case of the pump control system with an inverted pwm signal, the nominal speed of the pump (0–100 %) corresponds to the pwm signal (100-0 %). The following diagram shows the power curve for the pump control system with an inverted pwm signal at a mini...

Page 35: 8.1

Setting multi-function controllers (mfc) 35 8 setting multi-function controllers (mfc) depending on the hydraulic layout, switching outputs r0, r1, r2 and r3 can be used as multi-function controllers (mfc). These can be set irrespective of the basic functions of the controller. You can assign the fo...

Page 36: 8.3

Setting multi-function controllers (mfc) 36 temperature rises above the upper limit of the preset temperature range (hysteresis), the switching output of the multi-function controller switches off. The "basic settings" menu allows you to set the following parameters: • p:30: mfc r4 function at switc...

Page 37: 9.1

Setting protective functions 37 9 setting protective functions in order to protect the solar power system against frost and overheating, the controller is equipped with the following protective functions: • "collector protection" function • "storage tank protection" function • "system protection" fu...

Page 38: 9.4

Setting protective functions 38 when the temperature falls below the system protection temperature, the system will be in the "collector protection" function again. When the temperature falls below the collector protection temperature, the system will be in normal operating mode. 9.4 setting the "re...

Page 39: Time-Controlled

Measuring energy output 39 the control type is selected in the menu "basic settings" with the following value: • p:5: "collector protection" function − "drain-back" time-controlled function time-controlled you can set a time window and a pump runtime. In the time window the solar circuit pump is swi...

Page 40: Measuring Energy Output

Measuring energy output 40 10 measuring energy output the controller can calculate and display the energy output of the solar power system. To do so, it requires the following values: • flow rate • temperature difference between the collector and collector return flow temperatures • glycol type and ...

Page 41: 10.2

Restore factory settings 41 10.2 setting the energy output measurements the "basic settings" menu allows you to set the following parameters: • p:12: measurement principle for energy output measurement • p:15: flow rate for the "flow indicator" measurement principle • p:16: energy output measurement...

Page 42: Faults

Faults 42 13 faults attention risk of damage to the system if faults are remedied incorrectly. Make sure that faults are only ever remedied by specialist personnel. There are two categories of system faults: • faults that are detected by the controller and trigger a fault message • faults that are n...

Page 43

Faults 43 the table below shows the faults with fault messages: fault message possible cause action ! Flashing a sensor line is interrupted. Here s2 make sure that the sensor lines are intact. A sensor is faulty. Check the sensor resistance. If necessary, replace the sensor. ! Flashing a short circu...

Page 44: 13.2

Faults 44 13.2 faults without fault message the table below shows the faults without fault messages: fault possible cause action no indication on the display. There is no mains voltage. Switch on the controller or connect the controller to the mains voltage. Make sure that the main fuse for the main...

Page 45

Technical data 45 fault possible cause action the pump symbol rotates without the pump actually running. The connection to the pump has been interrupted. Make sure that the cable connection to the pump is intact. The pump has seized up. Make sure that the pump is running. There is no voltage at the ...

Page 46: Technical Data

Technical data 46 14 technical data autonomous electronic temperature difference controller, continuous operation housing material 100% recyclable abs housing dimensions l x w x d in mm 176 × 162 × 44 protection class ip30 according to din 40050, en 60529 operating voltage ac 230 voltage, 50 hz, –10...

Page 47: Resistance Table

Resistance table 47 15 resistance table with reference to the table below check the functioning of the temperature sensors using a resistance meter: temperature in °c / resistance in ohms –10 °c 0 °c 10 °c 20 °c 40 °c 60 °c 80 °c 100 °c 960 Ω 1000 Ω 1039 Ω 1078 Ω 1155 Ω 1232 Ω 1309 Ω 1385 Ω 16 acces...

Page 48

Disposing of the controller 48 17 disposing of the controller the environmentally-friendly disposal of electronic assemblies, recyclable materials and other unit components is regulated by national and regional laws. Contact the competent local authority for detailed information on disposal. Dispose...

Page 52: Address Of Manufacturer

These instructions were prepared by a technical documentation office certified by doccert- system. Address of manufacturer prozeda gmbh in der büg 5 d-91330 eggolsheim telephone: +49(0)9191/6166-0 telefax: +49(0)9191/ 6166-22 email: kontakt@prozeda.De www.Prozeda.De.