- DL manuals

- QED

- Water Pump

- AP4+

- Operation Manual

QED AP4+ Operation Manual

Leaders in Environmental Compliance Products

OPERATIONS

MANUAL

QED Environmental Systems - P.O. Box 3726 / 2355 Bishop Circle W. Dexter, Michigan 48130-3726

1-800-624-2026 (North America Only) (734) 995-2547 - Tele (734) 995-1170 - Fax info@qedenv.com - E-mail www.qedenv.com

QED Environmental Systems (West) - 1565 Alvarado Street San Leandro, California 94577-2640

1-800-537-1767 (North America Only) (510) 346-0400 - Tele (510) 346-0414 - Fax

DEPENDABLE,

& DELIVERS

DURABLE,

AutoPump Controllerless System

(For 4 inch wells or larger)

+

Au

to

Pump

ATEX Version

602418-02 (doc # 602418 ) (Rev 12/10/12)

Copyright QED Environmental Systems, Dec. 2012

Summary of AP4+

Page 1

Leaders in environmental compliance products operations manual qed environmental systems - p.O. Box 3726 / 2355 bishop circle w. Dexter, michigan 48130-3726 1-800-624-2026 (north america only) (734) 995-2547 - tele (734) 995-1170 - fax info@qedenv.Com - e-mail www.Qedenv.Com qed environmental system...

Page 2

The equipment in this manual is protected under u.S. And foreign patents issued and pending: u.S. Patents: autopump (ap) 5,004,405 "ap" is a registered trademark of "qed environmental systems" "autopump" is a registered trademark of "qed environmental systems" the qed environmental systems logo is a...

Page 3

Pump specifications table of contents introduction _________________________________________________ safety how to contact qed chapter 1: safety ____________________________________________ a partial list of safety procedures fire and explosion protection chapter 3: overview ________________________...

Page 4

Introduction to ensure the best operator safety and system performance, it is strongly recommended that the operators read this entire manual before using the system. This manual reflects our many years of experience and includes comments and suggestions from our sales and service personnel and most...

Page 5

Chapter 1: safety safety has been a prime consideration when designing the autopump system. Safety guidelines are provided in this manual, and the autopump system safety features are listed below. Please do not attempt to circumvent the safety features of this system. We have also listed some possib...

Page 6

Chapter 2 atex certifications, label detail and explanation 3 equipment with an atex label similar to the example in figure 1, is atex certified. Equipment without the label is not atex certified. Figure 1 explains the atex label, figure 2, (following page) shows the label location and appearance. 1...

Page 7

E a m f m f t t t ta = t t x x t c b g c c c c 6 8 8 8 2 2 1 1 1 1 1 1 2 2 4 3 4 5 7 5 oo o o o o ii ii approved e e e s s s a a a a p p r r a ap4+ r a r y r m m m u u u t x b b 6 8 8 8 8 8 9 9 9 9 1 1 1 2 3 3 3 3 4 4 4 4 4 5 5 7 77 7 5 5 5 5 5 5 5 o o o o o o i i q ed , , , , , . . . Top loading bo...

Page 8

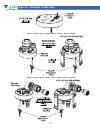

Chapter 3: overview the autopump is very versatile and available in a wide range of lengths, valve arrangements, and materials of construction to meet particular site specifications. Equipment will vary by application and site specifications. (see chapter 3) pump diameter: pressure range: high press...

Page 9

As pump fills, float rises lower float stop check valve unseated allowing liquid into pump pivoting lever tipped downward by descending float upper float stop compressed air flowing into pump as pump empties, float descends lower float stop check valve seated sealing inlet pivoting lever tipped upwa...

Page 10

Ap4+ system provides everything required for pumping fluid from a well. Fluid discharge easy fittings air exhaust cycle counter air supply from compressor note: support harness, rope, and tubing sheath omitted for clarity 7 figure 4 - overview of the ap4+ system pump tubing wellhead 0 0 0 0 0 0 1 1 ...

Page 11

Chapter 4: equipment unpacking during the unpacking procedure, check for the following: the equipment list will vary depending on site specifications, but the following list is a typical configuration • all parts on the packing list have been included in the box • all fitting openings are unobstruct...

Page 12

Chapter 5: installation 1. Cover the pump tubing/hose ends with tape if they are to be pulled through trenches or laid on the ground. This is to prevent debris from entering the lines. 2. Blow out all water and particles from compressed air conduits (including downwell pump air supply lines) and flu...

Page 13

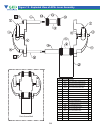

Chapter 5: installation hose bundles 10 hose bundling or the use of jacketed tubing reduces equipment entanglement at the well surface, and aids the removal of the pump from the well. Bundling also assists in positioning the pump and down-well hose assembly against one side of the well casing. Maxim...

Page 14

Figure 6 - examples of well caps 11.

Page 15

Figure 7 - hose bundling 12 tie-wrap detail figure 8 tie-wrap layout thread tie-wraps through support line air exhaust tie-wrap autopump air hose (green) fluid discharge hose (black) air exhaust hose (blue) air exhaust tie-wrap support rope autopump® air hose (green) fluid discharge hose (black) air...

Page 16

Chapter 6: maintenance cleaning pump interior removing the pump’s casing . 1 gently brush off built-up solids from the float, the discharge line, the pump casing and the control rod guide. 1. Remove the bolt at the bottom of the pump which holds the inlet screen in place (bottom loading pumps only)....

Page 19

Figure 10 - exploded view of top loading ap4+ (long & short) note: some parts are available in alternate materials based 16.

Page 20

Figure 11 - exploded view of top loading ap4+ low drawdown note: some parts are available in alternate materials based 17.

Page 21

Figure 12 - exploded view of ap4+ lever assembly parts assembled 18 item no. Part number description qty. 1 1 1 1 1 1 2 1 2 1 2 1 3 303 ss 120 p.Si exhaust poppet-long 303 ss 120 p.Si exhaust poppet-short 303 ss 120 p.Si exhaust poppet-ldd 2 4 120 p.Si intake poppet connector-long 120 p.Si intake po...

Page 22

Figure 13 - exploded view of 1 inch check valve or check ball check valve housing adapter barbed fitting 19.

Page 23

Chapter 7: troubleshooting & repairs problems may occur and usually can be easily resolved by following these instructions. If, after careful reading and service, you cannot resolve the problem, please contact the qed environmental systems (qed) service department at (800) 537-1767. Caution: wear go...

Page 24

Chapter 7: troubleshooting & repairs • if the air exhausts to the atmosphere (outside the well) and a vacuum is drawn on the well, the pump may fail to fill. In order for the pump to fill under these conditions, the pump must be submerged to make up for the pressure difference between the atmosphere...

Page 25

Chapter 7: troubleshooting & repairs returning equipment for service 1. Call the qed service department and obtain a return material authorization (rma) number. Please have available the contact person’s name, company name and address, phone number, fax number, reason for the return, and the names o...

Page 26: Ap4+ B

Specifications - bottom inlet, long 23 ap4+ b description max. Flow o.D. Length 14 gpm (53 lpm) ) m m 1 9 ( n i 6 . 3 51.4 in. (131cm) advantages the autopump heritage 1. The original automatic air- powered well pump, proven worldwide over 23 years 2. The highest flow rates and deepest pumping capab...

Page 27: Ap4 +B

Ap4 +b specifications - bottom inlet, long ap4 + a ut opum p air supply exhaust liquid discharge actuation level 38.4" (98 cm) length with extended screen attached 51.4" (131 cm) inlet o.D. 3.6" (91 mm) application limits (base model) ap4+ autopumps are designed to handle the application ranges desc...

Page 28: Ap4 + B

Ap4 + b specifications - bottom inlet, long 25 1 flow rates may vary with site conditions. Call qed for technical assistance. 2 ft. (60 cm) submergence of pump head 10 ft. (300 cm) submergence of pump head 8 4 0 2 6 12 10 14 16 18 20 6.1 40 12.2 60 18.3 80 24.4 100 30.5 120 36.6 140 42.7 160 48.8 18...

Page 29: Ap4 B

Ap4 b specifications - bottom inlet, long 26 + in well depth 48.8 7 . 2 4 6 . 6 3 5 . 0 3 4 . 4 2 18.3 12.2 6.1 meters 54.9 61 ft. .2 .3 .4 .5 .6 .7 .8 .9 1.1 1.0 1.2 1.3 1.4 1.5 1.6 2.2 1.5 3.0 3.7 5.2 4.5 6.0 7.5 6.7 8.2 9.0 10.5 9.7 11.2 12 . . Liter of air gallon pumped (scf/gal) per (std l/lite...

Page 30: Ap4 B

Specifications - bottom inlet, short 27 ap4 b + max. Flow o.D. Length 13 gpm (49 lpm) ) m m 1 9 ( n i 6 . 3 39.3 in. (100 cm) advantages 1. The original automatic air- powered well pump, proven worldwide over 23 years 2. The highest flow rates and deepest pumping capabilities in the industry 3. Pate...

Page 31: Ap4 B

Ap4 b + specifications - bottom inlet, short ap4 + a ut opum p air supply exhaust liquid discharge actuation level 26.7" (68 cm) length with extended screen attached 39.3" (100 cm) inlet o.D. 3.6" (91 mm) application limits (base model) ap4+ autopumps are designed to handle the application ranges de...

Page 32: Ap4 B

Ap4 b + specifications - bottom inlet, short 29 (equivalent to 1.25-inch o.D.Tubing) 1 inch (25.4 mm) inside diameter discharge hose (equivalent to 1-inch o.D.Tubing) 3/4 inch (19 mm) inside diameter discharge hose flow rates 1 0 0 12.2 40 0 6.1 20 ft. Meters 200 61 180 54.9 80 140 120 100 30.5 60 1...

Page 33: Ap4 B

Ap4 b + 48.8 7 . 2 4 6 . 6 3 5 . 0 3 4 . 4 2 18.3 12.2 6.1 meters 54.9 61 ft. Liter of air gallon pumped (scf/gal) per (std l/liter) liter pumped per standard cubic feet of air approximate standard in well depth in well depth 48.8 7 . 2 4 6 . 6 3 5 . 0 3 4 . 4 2 18.3 12.2 6.1 meters 54.9 61 ft. Lite...

Page 34: Ldap4 B

31 ldap4 b + max. Flow o.D. Length 7.0 gpm (26.5 lpm) 3.6 in (91 mm) 27.5 in. (70 cm) advantages 1. The original automatic air- powered well pump, proven worldwide over 23 years 2. The highest rates and deepest pumping capabilities in the industry in a low drawdown bottom- ll pump 3. Patented, prove...

Page 35: Ldap4 B

Ldap4 b + 32 air supply exhaust liquid discharge actuation level 15.3" (39 cm) length with extended screen attached 27.5" (70 cm) inlet o.D. 3.6" (91 mm) low-drawdown ap4+ autopumps are warranted for one (1) year. Application limits (base model) ap4+ autopumps are designed to handle the application ...

Page 36: Ldap4 B

Ldap4 b 33 + (equivalent to 1.25-inch o.D.Tubing) 1 inch (25.4 mm) inside diameter discharge hose (equivalent to 1-inch o.D.Tubing) 3/4 inch (19 mm) inside diameter discharge hose flow rates 1 10 ft. (300 cm) submergence of pump head 12.2 6.1 1 0 0 20 2 36.6 18.3 24.4 30.5 80 60 40 100 120 gallons m...

Page 37: Ldap4 B

Ldap4 b in well depth .2 1.5 48.8 7 . 2 4 6 . 6 3 5 . 0 3 4 . 4 2 18.3 12.2 6.1 meters 54.9 61 ft. .3 .4 .5 2.2 3.0 3.7 .7 .6 .8 5.2 4.5 6.0 1.0 .9 1.1 7.5 6.7 8.2 1.8 liter of air 13.5 1.5 1.2 1.3 1.4 9.0 9.7 10.5 11.2 gallon pumped 1.6 (scf/gal) per 1.7 (std l/liter) liter pumped 12 per 12.7 stand...

Page 38: Ap4 T

Specifications - top inlet, long 35 ap4 t + max. Flow o.D. Length 10 gpm (38 lpm) 3.6 in (91 mm) 56.7 in. (144 cm) advantages 1. The original automatic air- powered well pump, proven worldwide over 23 years 2. The highest flow rates and deepest pumping capabilities in the industry 3. Patented, prove...

Page 39: Ap4 T

Specifications - top inlet, long 36 ap4 t + xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx application limits (base model) ap4+ autopumps are designed to handle the application ranges described below. For applications outside these ranges, consult qed about ap4+ upgrades. Ma...

Page 40: Ap4 T

Specifications - top inlet, long 37 ap4 t + (equivalent to 1.25-inch o.D.Tubing) 1 inch (25.4 mm) inside diameter discharge hose (equivalent to 1-inch o.D.Tubing) 3/4 inch (19 mm) inside diameter discharge hose flow rates 1 0 0 12.2 40 0 6.1 20 ft. Meters 200 61 180 54.9 80 140 120 100 30.5 60 18.3 ...

Page 41: Ap4 T

In well depth 48.8 7 . 2 4 6 . 6 3 5 . 0 3 4 . 4 2 18.3 12.2 6.1 meters 54.9 61 ft. .2 .3 .4 .5 .6 .7 .8 .9 1.1 1.0 1.2 1.3 1.4 1.5 1.6 2.2 1.5 3.0 3.7 5.2 4.5 6.0 7.5 6.7 8.2 9.0 10.5 9.7 11.2 12 70 psi 5 kg/cm 2 100 psi 7 kg/cm 2 40 psi 3 kg/cm 2 xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxx...

Page 42: Ap4 T

Specifications - top inlet, short 39 ap4 t + max. Flow o.D. Length 9 gpm (34 lpm) 3.6 in (91 mm) 45 in. (110 cm) advantages 1. The original automatic air- powered well pump, proven worldwide over 23 years 2. The highest flow rates and deepest pumping capabilities in the industry 3. Patented, proven ...

Page 43: Ap4 T

Specifications - top inlet, short 40 ap4 t + xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx application limits (base model) ap4+ autopumps are designed to handle the application ranges described below. For applications outside these ranges, consult qed about ap4+ upgrades. M...

Page 44: Ap4 T

Specifications - top inlet, short 41 (equivalent to 1.25-inch o.D.Tubing) 1 inch (25.4 mm) inside diameter discharge hose (equivalent to 1-inch o.D.Tubing) 3/4 inch (19 mm) inside diameter discharge hose flow rates 1 ap4 t + 0 0 12.2 40 0 6.1 20 ft. Meters 200 61 180 54.9 80 140 120 100 30.5 60 18.3...

Page 45: Ap4 T

Xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx 48.8 7 . 2 4 6 . 6 3 5 . 0 3 4 . 4 2 18.3 12.2 6.1 meters 54.9 61 ft. Liter of air gallon pumped (scf/gal) per (std l/liter) liter pumped per standard cubic feet of air approximate standard in well depth in well depth 48.8 7 . 2...

Page 46: Ldap4 T

43 ldap4 t + max. Flow o.D. Length 6.4 gpm (24 lpm) 3.6 in ( 91 mm) 30.75 in. (78 cm) advantages 1. The original automatic air- powered well pump, proven worldwide over 23 years 2. The highest flow rates and deepest pumping capabilities in the industry in a low drawdown top-fill pump 3. Patented, pr...

Page 47: Ldap4 T

44 ldap4 t + air supply exhaust liquid discharge actuation level 27.4" (70 cm) length to t op of fittings 30.75" (78 cm) inlet o.D. 3.6" (91 mm) low-drawdown ap4+ autopumps are warranted for one (1) year. Application limits (base model) ap4+ autopumps are designed to handle the application ranges de...

Page 48: Ldap4 T

45 ldap4 t + (equivalent to 1.25-inch o.D.Tubing) 1 inch (25.4 mm) inside diameter discharge hose (equivalent to 1-inch o.D.Tubing) 3/4 inch (19 mm) inside diameter discharge hose flow rates 1 0 0 18.9 minute 5 48.8 42.7 36.6 12.2 6.1 18.3 24.4 30.5 meters 9 . 4 5 1 6 in well 160 140 120 40 0 20 80 ...

Page 49: Ldap4 T

In well depth .2 1.5 48.8 7 . 2 4 6 . 6 3 5 . 0 3 4 . 4 2 18.3 12.2 6.1 meters 54.9 61 ft. .3 .4 .5 2.2 3.0 3.7 .7 .6 .8 5.2 4.5 6.0 1.0 .9 1.1 7.5 6.7 8.2 1.8 liter of air 13.5 1.5 1.2 1.3 1.4 9.0 9.7 10.5 11.2 gallon pumped 1.6 (scf/gal) per 1.7 (std l/liter) liter pumped 12 per 12.7 standard cubi...

Page 50

Terms, conditions, and warranty five year warranty this limited warranty is in lieu of and excludes all other representations made by advertisements, distributors, agents, or manufacturers sales representatives, and all other warranties, both express and implied. There are no implied warranties of m...

Page 51

Terms, conditions, and warranty subassemblies and other equipment manufactured by others the foregoing warranty does not apply to major subassemblies and other equipment, accessories, and other parts manufactured by others, and such other parts, accessories, and equipment are subject only to the war...

Page 52

Terms, conditions, and warranty 2. Specifying where, when, and from whom the product was purchased. 3. Describing the nature of the defect or malfunction covered by this warranty. 4. After obtaining authorization from qed, sending the malfunctioning component via a rma# (return material authorizatio...

Page 53: Ap4

Ap4 + p m u p ot u a ap4 + p m u p ot u a 4 p a + p m u p ot u a xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx ap4 + a u t opu m p xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx ap4 + a u t opu m p xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxx...

Page 54: Ap4

P.O. Box 3726 ann arbor, michigan 48106-3726 1-800-624-2026 (north america only) (734) 995-2547 - tele (734) 995-1170 - fax info@qedenv.Com - e-mail www.Qedenv.Com 1565 alvarado street san leandro, california 94577-2640 1-800-537-1767 (north america only) (510) 346-0400 - tele (510) 346-0414 - fax a...