- DL manuals

- Qsonica

- Computer Hardware

- SONICATOR S-4000

- Operation Manual

Qsonica SONICATOR S-4000 Operation Manual

Summary of SONICATOR S-4000

Page 1

Sonicator ultrasonic processor part no. S-4000 operation manual 53 church hill road newtown, ct 06470 203.426.0101 tel 203.426.7026 fax info@sonicator.Com www.Sonicator.Com.

Page 2

2 table of contents section page no. 1. Warnings 4 2. Specifications 5-6 3. Principles of operation 7 4. Description of components 8-10 5. Preparation for use (getting started) 11-14 6. Operating instructions 15-24 7. Accessories 25-26 8. Sound reducing enclosure 27-29 9. Techniques for optimizing r...

Page 3

3 please read the manual in its entirety. The new digital sonicator offers several new and innovative features. This manual provides the necessary instruction and guidance to help ensure the successful operation of this device..

Page 4

4 1. Warnings your new ultrasonic liquid processor has been designed, built and tested to assure maximum operator safety. However, no design can completely protect against improper use that may lead to bodily injury and/or property damage. For total safety and equipment protection, read the instruct...

Page 5

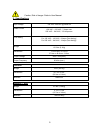

5 caution, risk of danger. Refer to user manual. 2. Specifications input voltage 100 vac -240 vac @ 50/60 hz rated current 100 vac – 120 vac, 7 amps max. 220 vac – 240 vac, 3.5 amps max. Fuse rating for 100 vac – 120 vac, 8 amps (fast acting)* for 220 vac – 240 vac, 4 amps (fast acting)* weight 13.5...

Page 6

6 environmental pollution degree 2 installation category ii operating limits shipping/storage temperature: 39 - 95 o f (4 - 35 o c)** relative humidity 20 - 90% (non condensing) temperature: 35 -120 o f (2 - 49 o c) relative humidity 10 - 95% (non condensing) ambient pressure extremes: 40,000 ft. Re...

Page 7

7 3. Principles of operation the ultrasonic electronic generator transforms ac line power to a 20 khz signal that drives a piezoelectric converter/transducer. This electrical signal is converted by the transducer to a mechanical vibration due to the characteristics of the internal piezoelectric crys...

Page 8

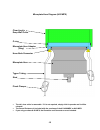

8 4. Description of major components generator the generator supplies a 20 khz electrical signal to the converter. The s-4000’s advanced digital signal processing tracks frequency changes in the probe-converter assembly caused by load and temperature changes, and maintains maximum electrical efficie...

Page 9

9 the # s-4000 includes a standard ½” diameter tapped horn (#200). Generator converter ½” horn with replaceable tip converter cable.

Page 10

10 s-4000 rear panel on/off switch power cord connector converter cable connector usb connector temperature probe connector footswitch jack cooling fan.

Page 11

11 5. Preparation for use (getting started) to safeguard the fuse against failure, always switch the power supply off before connecting or disconnecting the power cord. The power cord supplied by qsonica must be used. If it does not match your wall outlet, use the appropriate universal adapter for y...

Page 12

12 attaching and detaching horns horn removal horn tightening tip removal tip tightening microtip ™ removal microtip ™ tightening wrench set note: when tightening a microtip™ the tip must not be in contact with the worksurface. Always have the tip extending off the end of the table or worksurface..

Page 13

13 ½” horn microtips ™ connect either end of the coaxial high frequency cable to the rear of the generator and the other end to the receptacle on the converter. Push the connectors in and turn the chrome rings clockwise ¼ turn to secure the connectors. If a foot switch or timer switch is used, plug ...

Page 14

14 if you will be using a microtip ™ or extender, remove the flat tip on the end of the horn, then attach the microtip ™ or extender in its place. Horns and probe tips wear after normal usage. Using a severely worn tip can damage internal components. Replace tips when they become pitted. See the mai...

Page 15

15 6. Operating instructions your new ultrasonic liquid processor has been designed with a color ¼ vga lcd user interface with touch screen capabilities. All program and run functions are controlled through the touch screen panel. 1. Answer the microtip ™ question, yes or no. See page 13 and 25 for ...

Page 16

16 operating instructions (continued) this is the opening screen that momentarily appears after sonicator is switched on. The following screen then appears: when using a microtip ™ , the yes button must be selected. Warning : improper selection will result in tip damage or poor sonication. Damage ca...

Page 17

17 this screen allows the user to select manual mode, program menu, options screen or diagnostic test mode. Manual mode – this mode allows the user to manually start and stop sonication at any amplitude setting between 1-100%. Program menu – this mode allows the user to create a program, select or r...

Page 18

18 the following screen displays the manual mode . A . Amplitude (intensity) setting - output amplitude may be set between 1-100%. B . Power displayed in watts. C . Energy displayed in joules. D . Elapsed time – total time of active sonication. E . Temperature probe measurement (note: if “opn” appea...

Page 19

19 program menu the unit can be programmed to sonicate at specific, user-selected time intervals including pulse mode. Select/modify a program – create, select or modify up to 10 different programs. Select/modify sequence 1 & 2 – select a sequence of programs for the unit to run in succession. A max...

Page 20

20 programming screen how to create a program the sonicator has the ability to save up to 10 programs. 1. Select a program number from the keypad, the program number will appear above the amplitude box. For each of the following steps : after touching a field, the background will change to yellow in...

Page 21

21 how to run a saved program from the program screen (see image at top of previous page), touch the program number on the right side of the screen and the selected program settings will appear. Follow steps 9 and 10 from the previous page. This run screen is an example of a sample program in progre...

Page 22

22 sequencing after selecting sequence 1 or 2 from the program menu, the following screen will appear: sequence programming screen after creating multiple programs, a sequence of those programs may be selected. Select the program number and the amount of time desired between programs. Save the setti...

Page 23

23 the following option screen can be accessed from either menu screen. The option menu enables the selection of temperature units , footswitch operational modes and display contrast . Option screen temperature units – a temperature probe (# tp4000) is required for use of this option. The temperatur...

Page 24

24 help screens the s-4000 is equipped with fault detection circuits that protect the generator from overloads due to defective converter / probe assemblies. Several help screens may appear depending on the type of fault detected. Below are two examples. Further details are included in the troublesh...

Page 25

25 7. Accessories a variety of horns are available to process different sample sizes. Please visit www.Sonicator.Com to review tables detailing each horn option and their specific processing volume. Direct sonication (inserting a probe directly into your vessel) is the most popular way to sonicate a...

Page 26

26 96 tip horn dual horn with flocell ™ ¾” solid probes please refer section 9, techniques for optimizing results section for further assistance with direct probe sonication. Indirect sonication eliminates the need for a probe to come in contact with your sample. This technique is often described as...

Page 27

27 8. Sound enclosure instructions the sound enclosure provides personal protection from the noise generated by ultrasonics. The enclosure reduces sound levels by approximately 25% when compared to sonication done in an open setting. For example, the standard ½” horn produces 90 db and when used ins...

Page 28

28 b. Cup horns after the legs are attached, rotate the enclosure 180 0 so it is standing on the legs. Insert the converter cable up through the hole in the bottom of the box before attaching it to the converter and cup horn. Slowly lower the assembly into the holder making sure the cable is not cri...

Page 29

29 c. Dual horns prior to operation, the horn and converter must be properly tightened (using the appropriate wrench set) before being inserted into the sound enclosure. Remove collar and insert covertor as shown. Attach collar around converter and secure screws. Proper setup of dual horn is shown..

Page 30

30 9. Techniques for optimizing results probe depth immerse the probe tip 1.5 times the tip diameter into the solution, without touching the bottom. For example, the ½” horn should be immersed ¾” below the liquid surface. Immersion depth can be less for larger horns and may have to be more for small...

Page 31

31 10. Maintenance sonicators create high intensity vibration which puts stress on the converter and horn assembly. Regular maintenance is needed to ensure optimum results. Warning: it is recommended to follow the general maintenance procedure on a regular basis. Never hand tightening tips or horns;...

Page 32

32 high voltage is present in the cable and will pose a shock hazard. Do not touch the converter assembly until the power switch is off and the unit is unplugged. Should the sonicator display an error screen, follow the directions on the screen to remedy the fault. See section 11, troubleshooting fo...

Page 33

33 clean threaded stud clean threading in converter. Do not allow liquid to drip into convertor. Allow parts to dry tighten stud to horn.

Page 34

34 cleaning horn stud cleaning horn threading.

Page 35

35 cleaning replaceable tip threading after all connection points have been cleaned, use compressed air (if possible) to ensure all debris has been blown out of the holes. Let the parts air dry. Re-attach all components tightly. Cleaning instructions the generator and converter may be cleaned using ...

Page 36

36 a prolonged period, cause the tip to erode, and decrease the efficiency of the sonication process without showing up on the power monitor. The smoother and more polished the tip, the more power will be transmitted into the liquid. Any erosion of the probe tip will increase the rate of future eros...

Page 37

37 11. Troubleshooting the s-4000 is equipped with fault detection circuits that protect the generator from overloads due to defective converter / probe assemblies. In the event of a failure, two types of error screens, similar to the ones shown below, will appear. If system error e1 through e4 appe...

Page 38

38 alcohol and properly re-assembling tightly together using the appropriate wrenches. Note: if the display freezes, switch off main power, wait 5 seconds and switch back on. Note: if you touch start and sonication does not occur, switch off main power, wait 5 seconds and switch back on. If these st...

Page 39

39 12. Warranty qsonica warrants each product manufactured by it to be free from defects in material and workmanship under normal use and service for 2 years. Qsonica’s obligation under this warranty is limited to the repair or replacement at its sole option of any product or part thereof, which has...

Page 40

40 13. Return of equipment all requests for repairs and replacement parts should be directed to the customer service department at qsonica following the outlined procedure below. 1. Go to www.Sonicator.Com and click on the contact us section. Follow the troubleshooting procedures. If troubleshooting...

Page 41

41 14. Instructions for specialty horns cup horn instructions 1. Ensure rubber splash shield is securely placed under the cup. 2. Install and hand tighten the cup horn onto the converter. Then tighten the horn with the pin spanner wrenches. 3. The sound enclosure holds the cup horn securely. See sou...

Page 42

42 processing. Three different sizes are available. Most laboratory grade plastic or borosilicate glass vessels that will fit into the cup are suitable for sonication. Polystyrene and polycarbonate are the best transmitters of acoustic energy. Polypropylene and polyethylene are softer and may be les...

Page 43

43.

Page 44

44 microplate horn instructions the microplate horn is a large, 6” diameter horn capable of processing a variety of sample sizes. An entire microtiter plate or several microtubes can be sonicated at one time. A liquid media, such as water or glycol, is used to transmit the ultrasonic energy from the...

Page 45

45 tighten the horn. Figure 2 shows how to loosen the horn. After the horn has been tightened, check the alignment of the plastic collars. Ensure the plastic collars are lined up properly on the o-rings and not installed on an angle. If the collars are not on correctly, the horn may leak water. Figu...

Page 46

46 note: the tubing can be connected to a device, such as a peristaltic pump to re-circulate cold water through the horn reservoir, this is described below. This tubing is commercially available and you will need to purchase longer pieces of tubing for this process. How to fill the horn reservoir fo...

Page 47

47 operation ensure that there are no air bubbles under your samples. As with any sonicator application, the amplitude setting is subjective and may vary with each user’s particular application. Most users have found their best results while running the mph at or above amplitude setting 5. It is rec...

Page 48

48 microplate horn diagram (#431mpx) clear acrylic deep well collar o-ring microplate horn adapter (grey) hose barb connector microplate horn tygon tubing stud pinch clamps • the tall, clear collar is removable. If it is not required, simply slide it upwards and it will be released. • the sound encl...

Page 49

49 suggested microplates, pumps and chillers and where to buy them: microtiter plates 96 shallow-well microplate: • 96-well full skirt pcr plate, 2ml, part #285096. Manufacturer: e&k scientific (1-800-934-8114) • hard shell™ skirted microplate, 96-well, part # hsp-9601. Manufacturer: mj research (1-...

Page 50

50 800a flocell™ instructions the 800a allows you to see the liquid level inside the unit. The material of the body tube is polycarbonate and is resistant to most dilute acids and bases, oils, aliphatic hydrocarbons, ethers and alcohols. It may be attacked by strong alkalis, aromatic or halogenated ...

Page 51

51 800b flocell ™ instructions the material of the body tube is stainless steel and is resistant to most dilute acids and bases, oils, aliphatic hydrocarbons, ethers and alcohols. Strong acids are not recommended. Do not exceed 100 psi pressure. Set-up instructions 1. Three ¼” npt hose fittings and ...

Page 52

52 800c flocell ™ instructions the material of the body tube is stainless steel and is resistant to most dilute acids and bases, oils, aliphatic hydrocarbons, ethers and alcohols. Strong acids are not recommended. Do not exceed 100 psi pressure. Set-up instructions 1. Clean flocell ™ and all metal p...

Page 53

53.

Page 54

54 dual horns the dual horn is made up of three parts. The dual horn (part # 351) and two solid 3/4” extenders (part # 355). These parts must be attached and tightened with the appropriate wrench set to ensure proper connection so the horn resonates at the proper frequency. As with all horns, there ...

Page 55

55 if using a sound enclosure, please refer to the sound enclosure section of the manual for assistance with properly mounting the dual horn. The ¾” extender horns are tested in pairs at the factory to ensure balanced operation and consistent output when used together. It is highly recommended to re...