- DL manuals

- Quackenbush

- Drill

- 15QNPD-D

- Operation & Service Manual

Quackenbush 15QNPD-D Operation & Service Manual

Summary of 15QNPD-D

Page 1

1 operation & service manual 823111 2/01 15qnpd-d & 15qnpdf-d nutplate drill recoules operation zone industrielle - b.P. 28 avenue maurice chevalier 77831 ozoir-la-ferriere cedex france.

Page 2: Safety Recommendations

2 safety recommendations for your safety and the safety of others, read and understand the safety recommendations and operating instructions be- fore operating any drill motor. Always wear protective equipment: for additional information on eye protection, read the latest edition of ansi z87.1, occu...

Page 3: Safety Recommendations

3 due to the number and variety of tooling applications, the user's meth- ods engineering departments, ect., must consider any hazards that may be associated with each specific ap- plication of this product and provide adequate operator protection from inadvertent contact with any moving components....

Page 4: Table of Contents

4 major tool component nomenclature table of contents safety recommendations 2 & 3 major tool component nomenclature 4 introduction and general information 5 air logic 6 thru 8 disassembly section 9 thru 26 exploded views and parts list 27 thru 38 trouble shooting 39.

Page 5: Depth Control

5 introduction and general information the q-matic nut plate drill motor has been developed for drilling an countersinking the two holes required for attach- ment of nut plate fasteners. Utilizing an air/hydraulic system, and expanding collet grips the work with 240 lbs. Holding force during the com...

Page 6

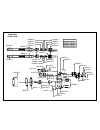

6.

Page 7

7.

Page 8

8.

Page 9: Warning

9 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Pressure foot attachment/disassembly 1. Remove mandrel from lift finger by turning counterclockwise then re...

Page 10

10 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Pressure foot attachment/disassembly — continued 3. Remove pressure foot by loosening clamp screw, then un...

Page 11

11 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Pressure foot attachment/disassembly — continued spindle and backhead disassembly 5. Retract collet lift f...

Page 12

12 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! 2. Remove backhead and spindle assemblies from motor housing. Note: four idler gears are held in position ...

Page 13

13 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! 4. The spindle adjustment screw is removed by screwing the spindle clockwise through the backhead assembly...

Page 14

14 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! 6. Double row ball bearings 863582 are removed from spindle shaft by removing lock nut 623767 and driving ...

Page 15: — Continued

15 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Spindle support plate and spindle cover disassembly — continued 2. Remove two button head screws 622059 fr...

Page 16: Air Motor Assembly Removal

16 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Air motor assembly removal 1. Remove the gear plate 622101 and gear plate spacer 624354 (6,000 & 20,000 rp...

Page 17

17 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! 3. Rear bearing support is removed by tapping the motor housing on cushioned bench top. The rear bearing s...

Page 18

18 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Air motor assembly disassembly 1. Lift front bearing plate 622090 from alignment pin 812164. 2. Unscrew bu...

Page 19

19 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! 3. Air motor assembly components. Feed and clamp cylinder piston disassembly air motor assembly disassembl...

Page 20: Ued

20 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Feed and clamp cylinder piston disassembly — contin- ued 3. Remove retainer ring 622065. Using assembly to...

Page 21

21 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Main air valve assembly removal 1. Set handle in vertical position and remove inlet bushing 622080, then l...

Page 22

22 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Fluid reservoir assembly removal 2. Insert small dowel against reservoir gage 622084 and push fluid reserv...

Page 23: Trigger Assembly Removal

23 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Fluid reservoir assembly removal — continued 1. Remove set screw 622054 from trigger 622073 and pull trigg...

Page 24

24 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Trigger assembly removal — continued 2. Remove snap ring 864271 and pull trigger sleeve and trigger spool ...

Page 25: Mounting Air Booster Pump

25 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Mounting air booster pump 2. Mount optional air booster pump assembly 621482 with three socket head cap sc...

Page 26: Feed Control Valve Removal

26 disconnect air supply before servicing. The clamping and feed mechanisms are exposed.To avoid injury, keep fingers and hands away from these areas when handling or operating tools. Warning ! Mounting air booster pump — continued 1. Using hex wrench, unscrew feed control needle valve part 622026. ...

Page 27

27 clamping assembly 622086-7 622065-1 864737-2 specified by customer specified by customer 625873-5 625873-5 203210-0 specified by customer specified by customer 622143-6 622065-1 622881-1 622072-7 622060-2 614902-5 623811-7 614902-5 622062-8 622127-9 622070-1 622143-6 622143-6 622061-0 624290-3 84...

Page 28

28 name of part foot guard piston retainer ring pressure foot bushing .2500 i.D. Pressure foot bushing .1875 i.D. Lift finger screw front enclosure retainer ring "o"-ring 13/16" x 1-1/16" pressure head retainer ring piston collet piston clamp feed shaft rear bearing plate support "o"-ring 1-3/8" x 1...

Page 29

29 handle assembly add fluid 622064-4 622055-2 812962-9 622063-6 203246-4 622087-5 622059-4 regular model only 622082-6 regular model only specified by customer regular model only 624241-6 622064-4 616302-6 844301-2 622026-3 844306-1 623691-3 622088-3 622054-5 864271-2 622073-5 843434-2 622053-7 621...

Page 30

30 name of part warning label grip sleeve support block bushing shift piston screw pilot valve assembly cover assembly filler check assembly (includes 844303, 844304) needle valve cover assembly screw trigger set screw spindle thrust bushing (included in 622067) support wedge screw spindle cover scr...

Page 31

31 847511-3 622090-9 864236-5 812164-2 864234-0 622089-1 843913-5 600 & 6000 864232-4 20,000 622758-1 847095-7 615641-8 864335-5 to clamping assembly to gear train motor assembly.

Page 32

32 name of part rear bearing retainer screw rotor front bearing plate rear bearing plate 20,000 rpm (left hand rotation) cylinder roll pin rotor collar rear rotor ball bearing front rotor ball bearing rear bearing plate 600 & 6,000 rpm (right hand rotation) rotor blade cylinder motor bearing cap qty...

Page 33

33 623766-3 622057-8 622097-4 623685-5 833774-3 623766-3 622057-8 622097-4 833774-3 623685-5 863582-3 863582-3 623765-5* 623765-5* 863582-3 863582-3 623767-1 623767-1 622093-2 622093-2 622095-8 622095-8 613162-7 622094-1 622094-1 622140-2 622140-2 203245-6 619816-2 619816-2 844799-7 844799-7 622142-...

Page 34

34 name of part caution label (included in 622091)** gear pinion spur retainer ring spindle roll pin* carrier bearing backhead dowel pin (included in 622091)** spindle key* backhead (includes 202903, 619816, 847609) spindle adjustment screw* adjustment knob adjustment drive ring spindle gear* idler ...

Page 35

35 623766-3 622057-8 622097-4 623685-5 623766-3 622057-8 622097-4 623685-5 863582-3 863582-3 623765-5* 623765-5* 863582-3 863582-3 623767-1 623767-1 622093-2 622093-2 622095-8 622095-8 613162-7 613162-7 622094-1 622094-1 622140-2 622140-2 203245-6 619816-2 844799-7 844799-7 622142-8 844799-7 844799-...

Page 36

36 name of part caution label (included in 622091)** spindle roll pin* backhead dowel pin (included in 622091)** spindle key* backhead (includes 202903, 619816, 847609) spindle adjustment screw* adjustment knob adjustment drive ring spindle gear* pinion gear idler gear gear plate adjustment knob spr...

Page 37

37 623766-3 622057-8 622097-4 623685-5 623766-3 622057-8 622097-4 623685-5 863582-3 863582-3 623765-5* 623765-5* 863582-3 863582-3 623767-1 623767-1 622093-2 622093-2 622095-8 622095-8 613162-7 613162-7 622094-1 622094-1 622140-2 622140-2 203245-6 619816-2 844799-7 844799-7 622142-8 622142-8 847609-...

Page 38

38 name of part caution label (included in 623754)** spindle roll pin* spindle key* spindle adjustment screw* adjustment knob adjustment drive ring spindle gear* pinion gear spur idler gear gear plate adjustment knob spring idler gear spacer spindle bearing retainer ring* backhead plug (included in ...

Page 39

39 symptom air motor and/or clamp and feed func- tions do not start when trigger is de- pressed. Air motor does not run when trigger is depressed, but feed and clamp func- tions work properly. Air motor "idles" when trigger is released. Motor runs and the tool clamps workpiece but does not feed. Too...

Page 40

40