- DL manuals

- Quadra-Fire

- Stove

- DV-40

- Installation, Operation, Venting And Maintenance Instructions

Quadra-Fire DV-40 Installation, Operation, Venting And Maintenance Instructions

Page 1

WARNING

If the information in this manual is not followed exactly a fire or explosion may result, causing

property damage, personal injury or death.

North America’s Best

CONGRATULATIONS! You are now the proud owner of one of the finest gas stoves on the market - the QUADRA-FIRE.

DV-40 STEP TOP DIRECT VENT FREESTANDING GAS STOVE (DV-40 STEP)

INSTALLATION, OPERATION, VENTING AND MAINTENANCE INSTRUCTIONS

SAVE THESE INSTRUCTIONS

401 N. Wynne Street

Colville, WA 99114

www.aladdinhearth.com

aladdin@aladdinhearth.com

Revised (8/98)

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS

•

Extinguish any open flame.

•

Open windows.

•

Do not try to light any appliance.

•

Do not touch any electric switch.

•

Do not use any telephone in your building.

•

Immediately call your gas supplier from a neighbor’s phone.

•

Follow the gas supplier’s instructions.

•

If you cannot reach your gas supplier, call the fire department.

•

Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

This appliance may be installed in an aftermarket permanently located, manufactured (mobile)

home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance

is not convertible for use with other gases, unless a certified kit is used.

Revised 04/19/1998 Part #250-4320 & #842-3220

Summary of DV-40

Page 1

Page 1 warning if the information in this manual is not followed exactly a fire or explosion may result, causing property damage, personal injury or death. North america’s best congratulations! You are now the proud owner of one of the finest gas stoves on the market - the quadra-fire. Dv-40 step to...

Page 2: Table of Contents

Page 2 table of contents page safety label ............................................................................................................................................. 3 safety notices .....................................................................................................

Page 3: Dv-40 Step Safety Label

Page 3 dv-40 step safety label (found on pull-out on back of stove).

Page 4: Safety Notices

Page 4 safety notices this stove should be installed only by a qualified installer. It is approved for installation in a bedroom. Bedroom installation in canada requires that stove be hooked to a thermostat. The stove must be electrically grounded in accordance with local codes, or the latest editio...

Page 5: Specifications

Page 5 specifications natural gas propane manifold pressure 3.5” wc 10.0” wc minimum inlet gas supply pressure 4.5” wc 11 0” wc maximum inlet gas supply pressure 7.0” wc 14.0” wc btu input rating (high) 40,000 btuh 40,000 btuh btu output rating (high)* 34,000 btuh 34,000 btuh btu input rating (low) ...

Page 6: Dimensions

Page 6 dimensions 1 2 5 /16 " [3 13 m m ] 2 4 5 /8" [6 2 5m m ] 2 4 7 /8" [6 3 2m m ] 2 0 5 /8" [5 2 4m m ] 6 1 /8 " [15 6 m m ] 1 2 9 /16 " [3 19 m m ] 2 1 1 /2" [5 4 6m m ] 2 3 3 /16 " [5 89 m m ] 2 0 9 /16 " [5 22 m m ] 6 1 /8 " [15 6 m m ] 1 2 9 /16 " [3 19 m m ] 2 1 1 /2" [5 4 6m m ] 2 3 3 /16 ...

Page 7: Unpacking The Stove

Page 7 unpacking the stove 1. Unbolt pallet using a 7/16” wrench to remove the four bolts from the underside of the pallet. 2. Between the firebox bottom and pallet is an accessories box containing logs, nuggets, touch-up paint, an allen key, and instructions for installation of legs or pedestal. 1....

Page 8

Page 8 dv40 step pedestal installation instructions 1. Remove log box located between stove and pallet 2. Remove door from unit. 3. Remove pallet mounting bolts from underneath pallet and remove stove from pallet 4. With front door removed lay unit down on it’s front for easy access to bottom.(fig. ...

Page 9: Thermostat Installation

Page 9 thermostat connection thermostat installation if desired, a thermostat may be installed to regulate the quadra-fire dv-40 step. It is important to use a thermostat designed for millivolt operation. Do not connect this stove to a thermostat serving any other appliance. Bedroom installation in ...

Page 10: Planning Your Installation

Page 10 planning your installation there are four types of direct vent system installations approved for use with the dv40 step. It is very important to maintain a balance between the combustion air intake and the flue gas exhaust venting system. The types of installation are: horizontal termination...

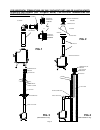

Page 11: Fig. 4

Page 11 fig. 4 fig. 1 fig. 2 fig. 3 termination cap part # 991 top adapter part # 985k flashing 4” flex liner direct vent pipe retro connector termination cap part # 991 4” flex pipe retro connector direct vent pipe existing metal chimney system (usa installations only) (usa installations only) for ...

Page 12: Simpson Dura-Vent Parts List

Page 12 simpson dura-vent parts list simpson dura-vent offers a complete line of component parts for installation in both horizontal and vertical applications. Many items are offered in decorative black, as well as a galvanized finish. The galvanized pipe and fittings are used for concealed location...

Page 13

Page 13 simpson dura-vent parts list ( cont .) basic kits the standard termination kit (kit 0970a) includes the following: 990b 1 each 90° black elbow 940 1 each round ceiling support/wall thimble 985 1 each high wind horizontal termination cap note: the above kit is not a complete termination syste...

Page 14: Clearances To Combustibles

Page 14 clearances to combustibles minimum clearances to combustible materials from stove body: a left & right of stove (one wall) 9” (225mm) b back wall (to pipe) 8” (200mm) c top of unit (from stove top) 24” (600mm) d corner clearance* 1” (25mm) e alcove (each side) 12” (300mm) (max. Depth) 36” (9...

Page 15: How To Use Vent Graph

Page 15 how to use vent graph 1. Measure the distance from the top of stove to the center of the 90° elbow. On the graph below, draw a horizontal line from that measurement on the vertical axis across until it intersects with the slanted line. 2. From the point of this intersection, draw a vertical ...

Page 16: Venting Instructions

Page 16 venting instructions please note: in order to comply with applicable codes and product warranties, only simpson dura- vent venting components may be used. Do not use field-fabricated venting components. The quadra-fire dv40 step is approved to be vented either through the side wall or vertic...

Page 17: Venting

Page 17 venting note: this stove is a direct vent heater. All combustion air must come directly from the outside of the building. The vent pipe for this unit consists of an inner and an outer pipe. The inner pipe carries the stove exhaust out of the system, and the outer pipe brings fresh combustion...

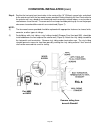

Page 18: Fig. 5

Page 18 fig. 5 female locking lugs male locking lugs horizontal installation note: restrictor strap is required if horizontal venting configuration has 10’ or greater of vertical rise and not more than one 90 degree elbow. Step 1. Set the gas stove in its desired location. Check to determine if wall...

Page 19: Horizontal Installation (

Page 19 horizontal installation ( cont .) step 3. With the adapter and pipe attached to the stove, slide the stove into its correct location, maintaining minimum clearance to combustibles, and mark the wall for a 10” x 10” (254mm x 254mm) square hole. The center of the square hole should line up wit...

Page 20: Horizontal Installation (

Page 20 horizontal installation ( cont .) step 4. Position the horizontal vent termination in the center of the 10” (254mm) square hole, and attach to the exterior wall with the four wood screws provided. Before attaching the vent termination to the exterior wall, run a bead of non-hardening mastic ...

Page 21: Horizontal Installation (

Page 21 horizontal installation ( cont .) step 5. Before connecting the horizontal run of vent pipe to the vent termination, slide the black decorative wall thimble cover over the vent pipe. Step 6. Slide the stove and vent assembly towards the wall, carefully inserting the vent pipe into the vent c...

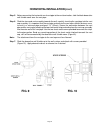

Page 22: Vertical Terminations

Page 22 vertical terminations using gs series pipe step 1. Check the installation instructions for required 2 inch clearances (air space) to combustibles when passing through ceilings, walls, roofs, enclosures, attic rafters, or other nearby combustible surfaces. (see page 24, fig. 16) do not pack a...

Page 23: Vertical Terminations (

Page 23 vertical terminations ( cont .) using gs series pipe (cont.) step 4. Assemble the desired lengths of gs pipe and elbows necessary to reach from the stove up through the round support box. Insure that all pipe and elbow connections are in their fully twist- locked position. Be sure to seal th...

Page 24: Vertical Terminations (

Page 24 vertical terminations ( cont .) using gs series pipe (cont.) step 7. Continue to assemble pipe sections until the height of the vent cap (h) (figure 15) meets the minimum code requirements described in code requirements as outlined in the current can/ cga-bl49 installation codes (in canada),...

Page 25: Vertical Terminations (

Page 25 vertical terminations ( cont .) cathedral ceiling installation step 1. Follow installation steps 1 and 2 under vertical termination section. Step 2. Using the plumb-bob, mark the centerline of the venting system on the ceiling, and drill a small hole through the ceiling and roof at this poin...

Page 26: Vertical Terminations (

Page 26 vertical terminations ( cont .) installation into a class a metal chimney note: have the existing installation inspected by a qualified chimney sweep or professional installer prior to converting to direct vent. The existing chimney system must be in serviceable condition and functionally so...

Page 27: Vertical Terminations (

Page 27 vertical terminations ( cont .) installation into an existing masonry chimney step 1. Before cutting any holes, assemble the desired sections of direct vent pipe to determine the center of the masonry penetration. Step 3. Secure the flashing (sdv #705c) to the top of the masonry chimney usin...

Page 28: Vertical Terminations (

Page 28 vertical terminations ( cont .) installation into an existing masonry chimney (cont.) fig. 24 step 7. If additional lengths of flex liner are needed to span the chimney height, use a flex coupler to connect the pieces of flex liner together. Connect the flex to the coupler by using four shee...

Page 29: Vertical Terminations (

Page 29 vertical terminations ( cont .) step 9. Attach the flex to the retro connector. Use three sheet metal screws to attach the flex liner to the connector (figure 26). Mount the retro connector to the masonry wall using masonry bolts. Redrill larger holes on connector as needed. Be careful to in...

Page 30: Gas Line Connection

Page 30 caution in some areas, gas line pressure may be more than 1/2 psig (14”wc). If you believe that this might be the case in your locality, contact your gas supplier or local utility company. Line pressure greater than 1/2 psig will damage the stove valve. You must install a regulator upstream ...

Page 31: High Altitude Operation

Page 31 high altitude operation in canada, this unit is approved from 0 to 4500 feet above sea level. Installation of this stove at altitudes above 4500 feet is subject to field test of the individual installation and approval by the local authority having jurisdiction. In the united states, input r...

Page 32: Gas

Page 32 caution: disconnect any electrical cords and turn off gas supply to unit before proceeding. Valve regulator tower 1. Turn control knob to the off position and shut off the gas supply to the valve. 2. Using a torx t20, or slotted screwdriver, remove the three pressure regulator mounting screw...

Page 33: , (

Page 33 burner orifice replacement 5. Remove the right top log bracket using a phillips screwdriver (screws are accessed through rectangular hole in bracket.) see fig. 4, pg. 37 (labeled “peg in right log bracket”) 6. Remove the right and left side log retaining brackets (one per side). (top of log ...

Page 34

Page 34 conversion instructions (cont.) pilot tower orifice replacement 13. Loosen (ccw rotation) and remove pilot target hex fitting with a 7/16” end wrench as shown in figure a. Fig. A 14. Remove the currently installed orifice with a pair of needlenose pliers or other means as shown in figure b. ...

Page 35: Log Installation

Page 35 log installation warning ! Proper installation of this log set and nuggets are critical to the safety, performance, and aesthetics of this appliance. Follow each step accurately. Conversion instructions, (cont.) lighting and pressure testing 24. Apply gas to system and re-light appliance acc...

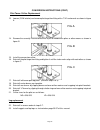

Page 36: Figure 1

Page 36 figure 1 place peg holes in log #23 over pegs in center burner pan. If damage has occurred to right or left base log, and replacement is necessary, removal is illustrated in conversion instruction steps 5-7. Figure 3 figure 2 do not allow nuggets on backside of this plate. Do not allow long ...

Page 37: Caution !

Page 37 log installation, continued figure 4 right top log #24. Peg hole peg in right log bracket notch for right top log finished log set caution ! Light appliance with door open to insure there is no hesitation or delay of flame transfer through nugget bed. If ignition is noisy or delayed momentar...

Page 38: First Fire

Page 38 first fire note: never operate this stove with the door open. Before first firing the stove, read the owner’s manual to familiarize yourself with the stove’s features, controls, and cautions for operation. Remove all labels from glass before operating this stove for the first time. Plug powe...

Page 39: Lighting Instructions

Page 39 lighting instructions (located on pull-up at left rear of stove).

Page 40: Pressure Testing

Page 40 o u t p u t s id e t e s t va lv e in p u t s id e t e s t va lv e pressure testing this appliance must be disconnected from the gas supply piping system if any testing is done to the system that exceeds the test pressure of 1/2 psig. If the test pressure is less than or equal to 1/2 psig, t...

Page 41: Maintenance

Page 41 maintenance cleaning and inspection of venting system at least once yearly, preferably before the heating season, have the insert and venting system cleaned and inspected by a qualified service person. This will insure proper and safe operation throughout the year. Cleaning the burner tubes ...

Page 42

Page 42 blower cleaning and/or replacement cleaning is recommended at least once yearly or as needed. 1. Disconnect power and turn off gas supply. 2. Unplug blower at molex connector (see “a” below). 3. Remove two screws on back plate of blower compartment. 4. Slide blower compartment away from stov...

Page 43: Schematics

Page 43 schematics orange=o black=b w h i t e = w red=r green=g o b.

Page 44: Snap Disc Replacement

Page 44 snap disc replacement 1. Disconnect power from unit and turn off gas supply. 2. Remove four screws as shown in figure below and take off rear heatshield. 3. Remove all wires attached to snap disc. 4. Remove set screws holding snap disc in place. 5. Replace in reverse order. Rear heat shield ...

Page 45: Accessories

Page 45 accessories these may be ordered through your quadra-fire dealer. 812-2880 thermostat, manual 811-0520 thermostat, programable 844-0100 thermostatic remote control replacement parts 842-3200 baffle 842-3230 black door with gold trim ring 842-3210 blower assembly, 160 cfm 842-0380 blower cord...

Page 46

Page 46 pilot replacement instructions 1) if log set is installed, remove the top logs, center log, ember nuggets and left base log. If log set is not installed remove only left base log. 2) remove six #8/32 screws that hold the center burner pan in place. Lift burner pan out of firebox and set asid...

Page 47: Flame Troubleshooting

Page 47 flame troubleshooting note: it is important to understand that the flame and glow in this appliance was designed to resemble a matured wood flame. The amount of charcoal nuggets and glowing ember limit the amount of flame height attainable. This appliance will not have the typical tall yello...

Page 48

Page 48 flame troubleshooting, cont. 2. If vertically vented, a restrictor strap is required to reduce the volume of combustion air, which in turn will raise the flame height. 3. If vented vertically with a horizontal run included; determine if the rise to run is close to the venting graft maximum, ...

Page 49: Pilot Troubleshooting

Page 49 pilot troubleshooting a. Pilot won’t light 1. Make sure valve setting is in the pilot position. 2. Check for spark at igniter. A. If no spark: 1. Check the wiring between the piezo and the igniter. Wire may be looped and be sparking to stove body. If so, move wiring. Check tightness of piezo...

Page 50

Page 50 thermopile (millivolt generator) thermocouple pilot hood pilot assembly showing flame properly adjusted. Flames.

Page 51

Gas stove limited lifetime warranty aladdin hearth products, warrants this gas heating appliance to the original purchaser for the lifetime of the appliance, to be free from defects in material and workmanship. This warranty gives you specific legal rights; you may have other rights which may vary f...