- DL manuals

- Quantec

- Boiler

- 24C

- Installation, commissioning & servicing instructions

Quantec 24C Installation, commissioning & servicing instructions

www.johnsonandstarley.co.uk

sustainable solutions under one roof

H E A T I N G H O T W A T E R V E N T I L A T I O N

INSTALLATION, COMMISSIONING

& SERVICING INSTRUCTIONS

QUANTEC COMBI

ErP

High Efficiency

Combination

Boiler

QuanTec 30C

ErP

- G.C. No. 47-416-12

QuanTec 24C

ErP

- G.C. No. 47-416-13

These instructions are to be left with the User

Publication No. ZZ 1432-6

September 2015

Summary of 24C

Page 1

Www.Johnsonandstarley.Co.Uk sustainable solutions under one roof h e a t i n g h o t w a t e r v e n t i l a t i o n installation, commissioning & servicing instructions quantec combi erp high efficiency combination boiler quantec 30c erp - g.C. No. 47-416-12 quantec 24c erp - g.C. No. 47-416-13 the...

Page 2

Www.Johnsonandstarley.Co.Uk 2 contents the benchmark scheme 2 1 features 3 2 general description 3 3 building standards & regulations 4 4 safety & gas information 4 general safety information handling the unit operating the appliance electrical supply gas supply 5 fiche erp technical data 5 technica...

Page 3

3 sales/spares & replacement help line 01604 762881 1. Features appliance classification: the quantec combi has been tested and ce certified by b.S.I ltd for use with natural gas g20. 2. General description 2.1 the quantec combi appliance is a high efficiency combination boiler, designed to provide ...

Page 4

Www.Johnsonandstarley.Co.Uk 4 3. Building standards & regulations statute law defines that all gas appliances must be installed by competent persons, i.E. Gas safe registered installers. Gas safe membership enquiries tel: 0800 408 5500 in accordance with the gas safety (installation and use) regulat...

Page 5

5 sales/spares & replacement help line 01604 762881 gas leaks do not operate any electrical switches, or use a naked flame turn off the gas supply. Ventilate the area by opening doors and windows. Call the national gas emergency service on 0800 111999 4.2 handling the unit 4.2.1 the weight of this a...

Page 6

Www.Johnsonandstarley.Co.Uk 6 5. Technical data eu regulations no. 811/2013 and no. 812/2013 supplementing directive 2010/30/eu. Table 1. Erp technical data 24c 30c product data symbol value unit condensing boiler - yes yes - low temperature boiler - no no - b11 boiler - no no - cogeneration space h...

Page 7

7 sales/spares & replacement help line 01604 762881 table 2. Technical data 24c 30c maximum weight lift 37kg 38kg gas supply 2h - g20 - 20mbar gas connection 15mm copper injector size 4.2mm 4.75mm domestic hot water flow and return 15mm copper heating flow and return 22mm copper safety valve dischar...

Page 8

Www.Johnsonandstarley.Co.Uk 8 6. Preparation & positioning 6.1 preparation 6.1.1 electrical connections: make sure all the electrical cables are in place. 6.1.2 water connections: important. A minimum length of 1 metre of copper pipe must be fitted to both flow and return connections from the boiler...

Page 9

9 sales/spares & replacement help line 01604 762881 6.1.9 boiler control interlock: central heating system controls should be installed to ensure the boiler is switched off when there is no demand for heating, in compliance with building regulations. 6.1.10 thermostatic radiator valves: central heat...

Page 10

Www.Johnsonandstarley.Co.Uk 10 7. Dimensions & clearances 7.1 dimensions 7.1.1 it is recommended that where the appliance is located in a kitchen, or next to other combustible materials, a gap of 5mm be left on either side and where the flue run is through a void in kitchen units, again a minimum ga...

Page 11

11 sales/spares & replacement help line 01604 762881 8. Heating system 8.1 the installation must comply with all relevant national and local regulations. All components of the system must be suitable for a working pressure of 3 bar and temperature of 110°c. Extra care should be taken in making all c...

Page 12

Www.Johnsonandstarley.Co.Uk 12 ch flow dhw inlet ch return gas inlet dhw outlet plate to plate heat exchanger diverter valve filling loop flow thermistor return thermistor dhw flow restrictor dhw cold inlet filter drain tap dhw thermistor pump automatic air vent low pressure switch pressure relief v...

Page 13

13 sales/spares & replacement help line 01604 762881 figure 7. Carton contents 9.1 wall mounting template use a plumb line to make sure the unit is square. Fix the template to the wall. Mark the positions of the flue and 4 fixing points. 9.1.1 using a 105 mm core drill make the hole through the wall...

Page 14

Www.Johnsonandstarley.Co.Uk 14 figure 9. Flue configurations standard horizontal flue kit offset horizontal rear flue extended horizontal rear flue standard flue kit comprising of: turret horizontal terminal can be fitted to the left or the right. Standard flue kit + 90˚ elbow required extension len...

Page 15

15 sales/spares & replacement help line 01604 762881 p k j i a m m b f g h h n n c d, e q figure 10. Flue terminal positions table 4 terminal position min distance a directly below an opening, air brick, opening window etc 300mm b above an opening, air brick, opening window, etc. 300mm c horizontall...

Page 16

Www.Johnsonandstarley.Co.Uk 16 10.6 type of flue systems 10.6.1 the standard concentric flue system 60/100mm (100mm diameter). 10.6.2 a flexible flue kit (ffk-5) 60/100mm (100mm diameter). For further information contact the sales office at johnson & starley ltd. Telephone 01604 762881. 10.6.3 the a...

Page 17

17 sales/spares & replacement help line 01604 762881 10.10 conventional 60/100mm flue accessory parts no’s table 5. Description colour qty application part no. 1 60/100 standard horizontal flue kit white 1 horizontal 1000-0020070 2 turret white 1 horizontal 1000-0020020 3 800mm horizontal terminal w...

Page 18

Www.Johnsonandstarley.Co.Uk 18 flat roof pitched roof pitched roof pitched roof side view figure 12. Optional roof outlets 10.11 optional roof outlets 10.12 the standard horizontal flue systems the standard horizontal flue kit comprises of: the appliance comes with a wall template. (label ref: 1000-...

Page 19

19 sales/spares & replacement help line 01604 762881 10.13 installation of the standard flue systems important note: before carrying out this procedure ensure seal has not been dislodged from top of the boiler. 1.1 using the template supplied with the boiler, determine the position of the flue. 1.2 ...

Page 20

Www.Johnsonandstarley.Co.Uk 20 11. Condensate drain 11.1 where a new or replacement boiler is being installed, access to an internal “gravity discharge” termination should be one of the main factors considered when determining potential boiler locations, the condensate drainage pipe should be termin...

Page 21

21 sales/spares & replacement help line 01604 762881 12. Electrical warning: this appliance must be earthed. 12.1 drop down control panel: see paragraph 17.5. 12.2 electrical connections 12.2.1 a mains supply of 230vac ~ 50 hz is required. 12.2.2 the fuse rating should be 3a. All external controls a...

Page 22

Www.Johnsonandstarley.Co.Uk 22 13. Wiring diagram figure 22. Wiring diagram col our red rd br own bn white wh grey gy yellow ye pink pk black bk violet vt orange og green/yellow gnye blue bu.

Page 23

23 sales/spares & replacement help line 01604 762881 14. Connections & filling notes. Ensure all boss blanking plugs are removed before connecting hardware. Each valve must be fitted to the correct boss as shown. See figure 25. Ensure each union is fitted with fibre seals provided. On the dhw inlet ...

Page 24

Www.Johnsonandstarley.Co.Uk 24 figure 25. Valves, tail pipes & connections a b c e d f g ch flow condensate drain valve open when in line with flow pressure gauge filling loop cabinet drain dhw outlet gas supply pressure relief valve drain flexible filling loop filter washer dhw inlet ch return ch d...

Page 25

25 sales/spares & replacement help line 01604 762881 15.5 initial lighting 15.5.1 check that the system has been filled and the boiler is not air-locked. Ensure the automatic air vent cap is open. Note: it is important the burner is not operated before the system is fully vented of air. Important: t...

Page 26

Www.Johnsonandstarley.Co.Uk 26 important general checks 15.9 domestic hot water (dhw) mode 15.9.1 fully open all dhw taps in turn and ensure that water flows freely from them. 15.9.2 close all taps except the furthest one from the boiler and check that the boiler is firing at maximum rate. This is f...

Page 27

27 sales/spares & replacement help line 01604 762881 16. Handing over 16.1 hand the user instructions to the householder and explain their responsibilities under the relevant national regulations. 16.2. Explain and demonstrate the lighting and shutting down procedures. 16.3 the operation of the boil...

Page 28

Www.Johnsonandstarley.Co.Uk 28 please note: during routine servicing, and after any maintenance or change of part of the combustion circuit, the following must be checked: • the integrity of the flue system and the flue seals, • the integrity of the boiler combustion circuit and the relevant seals •...

Page 29

29 sales/spares & replacement help line 01604 762881 figure 35. Quantec internal components 17.8 heat exchanger refer to paragraphs 17.5 to 17.7 17.8.1 inspect the inside of the combustion chamber, with a soft brush remove any deposits that may have occurred. Flush with clean water. Do not use any c...

Page 30

Www.Johnsonandstarley.Co.Uk 30 18. Parts replacement 18.1 important: before commencing with any part replacement the appliance should be isolated from the electrical supply and the gas service cock on the appliance closed. 18.1.1 all parts that are removed should be replaced and refitted in reverse ...

Page 31

31 sales/spares & replacement help line 01604 762881 18.7 diverter valve actuator head 18.7.1 refer to paragraph 17.5 18.7.2 remove the electrical connection. 18.7.3 pull out the retaining clip and lift out the diverter head. 18.7.4 fit new actuator head and refit in reverse order. 19.7.5 check oper...

Page 32

Www.Johnsonandstarley.Co.Uk 32 18.14 safety pressure relief valve 18.14.1 drain ch circuit. See paragraph 18.11. 18.14.2 withdraw the clip securing the safety valve. 18.14.3 undo the safety valve union connection. 18.14.4 remove and refit new valve. 18.14.5 refit in reverse order. 18.14.6 refill boi...

Page 33

33 sales/spares & replacement help line 01604 762881 d. Using either ch+ (k1) or ch - (k2) buttons select either 0 or 1. ‘0’ is for the fixed speed standard efficiency pump. ‘1’ is for the pwm high efficiency pump. E. Press and release reset (k4) button to return the display to p 27. F. Exit install...

Page 34

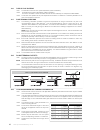

Www.Johnsonandstarley.Co.Uk 34 19. Fault finding flowcharts should a fault occur, the boiler will shut down and these error codes will be displayed. Should a fault occur, the boiler will shut down and these error codes will be displayed. Ignition lockout overheat lockout false flame lockout yes yes ...

Page 35

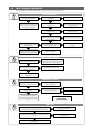

35 sales/spares & replacement help line 01604 762881 sensor stuck lockout return thermistor fault flow/return sensor calibration check valve feed back error eeprom lockout adc lockout flame circuit failure yes yes yes yes yes yes yes yes replace the pcb. Check resistance at 2 different temperatures....

Page 36

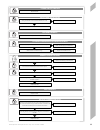

Www.Johnsonandstarley.Co.Uk 36 should a fault occur, the boiler will shut down and these blocking codes will be displayed. Flow thermistor fault yes yes is the wiring securely connected to the low voltage 9 way connector x5 on the pcb? No no securely connect the wiring to the flow thermistor. Fit ne...

Page 37

37 sales/spares & replacement help line 01604 762881 water pressure too high dhw sensor lockout he dhw outlet sensor drift test waiting yes yes yes yes yes yes replace the water pressure sensor. Is the wiring secure to 9 way connector x5 on interface pcb replace the pcb bar 0 1 2 3 service bar 0 1 2...

Page 38

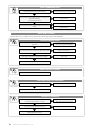

Www.Johnsonandstarley.Co.Uk 38 38 flue temperature senor lockout no display no dhw but ch on yes yes yes yes yes is the wiring secure to 9 way connector x5 on interface pcb replace the pcb replace the pcb no no no no connect the wiring. Supply power to boiler. Connect the wiring from the terminal bl...

Page 39

39 sales/spares & replacement help line 01604 762881 item description model qty part no. G. C. No. 1 pcb assembly 24c 1 1000-0527055 j21-369 30c 1 1000-0527065 j21-370 2 standard pump head 1 1000-0525565 j21-280 3 pump head gasket 1 1000-1508935 j21-281 4 pwm high efficiency pump head 1 1000-0302415...

Page 40

Www.Johnsonandstarley.Co.Uk 40 21 injector (4.75) 24c 1 1000-0711755 j21-359 30c 1 1000-0711135 j21-318 22 ‘o’ ring 1 1000-2501860 j21-235 24 pressure relief valve 1 1000-0023235 j21-269 25 washer 1 1000-3002060 j21-286 26 auto air vent 1 1000-0023275 j21-271 27 ch pressure sensor 1 1000-0525555 j21...

Page 41

41 sales/spares & replacement help line 01604 762881 code of practice for the installation, commissioning and servicing of domestic heating and hot water products benchmark places responsibilities on both manufacturers and installers.* the purpose is to ensure that customers** are provided with the ...

Page 42

*all installations in england and wales must be to local authority building control (labc) either directly or through a competent persons scheme. A building regulations compliance will then be issued to the customer. Www.Centralheating.Co.Uk © heating and hotwater industry council (hhic) this commis...

Page 43

Www.Centralheating.Co.Uk it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service record below, please ensure you have carried out the service as described in the manufac...

Page 44

Johnson & starley ltd rhosili road, brackmills, northampton nn4 7lz sales@johnsonandstarley.Co.Uk marketing@johnsonandstarley.Co.Uk reception/customer service 01604 762881 fax 01604 767408 johnson & starley dravo division industrial h&v sales 01604 707022 sales@johnsonandstarley.Co.Uk www.Dravo.Co.U...