- DL manuals

- Quick

- Toy

- Outdo 600 Pro

- Assembly And Maintenance Manual

Quick Outdo 600 Pro Assembly And Maintenance Manual

Summary of Outdo 600 Pro

Page 1

Sport/pro helicopter first edition assembly and maintenance manual www.Quickheli.Com page 1 of 60

Page 2: Table of Contents

Table of contents introduction 3 customer service 4 features 5 pre-assembly information 6 required tools 7 hardware and optional accessories 8 other requirements 10 section 1- upper frame 12 section 2: main frame 23 section 3: driving system 30 section 4: tail assembly 32 section 5: control systems ...

Page 3: Introduction

Page 3 of 60 introduction congratulation and thank you for the purchase of great product! It is our sole desire for you to enjoy the quality workmanship and performance of any of our electric li-po powered helicopters. We believe we have the latest designs and technology incorporated into our model ...

Page 4: Customer Service

Page 4 of 60 customer service quickworldwide 201 south 3 rd . St. & 309 n. Coopersburg, pa 18036 phone: (610)-282-4811 fax: (610)-282-4816 websites: http://www.Hhiheli.Com http://www.Quickheli.Com http://www.Giantscaleplanes.Com e-mail: hhi@fast.Net office hours: mon – fri: 8:30 – 6:00 sat: 8:30 – 1...

Page 5: Features

Features quick outdo-600 1. Frame construction: quick outdo 600 frames are made of the highest quality black g-10 frames or carbon fiber. These frames are not only rigid but will provide excellent vibration absorption. 2. Constant tail rotor drive system: provides full tail authority during engine o...

Page 6: Pre-Assembly Information

Pre-assembly information warning: the radio-controlled model helicopter contained in this kit is not a toy. Rather, it is a sophisticated piece of equipment. This product is not recommended for use by children without adult supervision. Radio controlled models such as this are capable of causing bot...

Page 7: Required Tools

Required tools page 7 of 60

Page 8: Radio Mounting Accessories

Hardware & optional accessories glues and thread lock compounds radio mounting accessories page 8 of 60

Page 9

Other hardware & optional accessories 3mm flybar stiffeners hhi 402 60 size skid stops hhi 200 available in colors servo arm set landing gear dampeners hhi 2004 base load antenna hhi 53** available in blue, gold, purple and in 40, 50, and 72 mhz page 9 of 60

Page 10: Finishing Caps

Finishing caps • adds color and style • distributes force across larger surface area 3mm 4mm (20 pcs in a package) (8 pcs in a package) black hhim11100b --- without blue hhim11103 hhim11108 gold hhim11101 hhim11106 green hhim11100g --- purple hhim11100 hhim11105 with red hhim11100r --- silver hhim11...

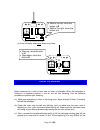

Page 11: Other Requirements

Other requirements radios: any radio that supports ems/ccpm mixing will work fine. Hobbies & helis & its distributors carry various lines of helicopter radios. Servos : any sport servo will offer acceptable performance. However, because servos operate all critical functions of the helicopter, they c...

Page 12: Assembly

Assembly section 1: upper frame bag 1 • i n your kit, parts are bagged according to each major assembly and are labeled “bag 1, bag 2, etc.” you will note that the heading for each assembly indicates which bag correlates with each assembly. • for a good installation, only open up the bag that you ne...

Page 13

1-1 elevator shaft bearings no. Part no. Description qty 1 qf551c upper frame (from frame bag) 2 2 brg05104f 5x10x4flanged bearing 2 note: the bearing flange mates against the inside of the frame page 13 of 60

Page 14

1-2 left aileron & rudder servo subassembly no. Part no. Description qty 1 1-1 l. Upper frame subasssembly 1 2 ***** servo 2 3 hhi2.5m14 m2.5x14 cap head bolt 8 4 hhi2.5mln m2.5 locknut 8 note: if the servos come with anti-vibrating rubber, insert them on the servos first. We recommend using the ser...

Page 15

1-3 right aileron & elevator servo subassembly no. Part no. Description qty 1 1-1 r. Upper frame subassembly 1 2 ***** servo 2 3 hhi2.5m14 m2.5x14 cap head bolt 8 4 hhi2.5mln m2.5 locknut 8 1-4 inner elevator control arm subassembly (4 no part no. Description qty 1 qc557 inner elevator control arm 1...

Page 16

1-5 tail transmission subassembly no part no. Description qty 1 qd551b counter gear 1 2 qd551a counter gear shaft 1 3 qd551c counter gear lock pin 1 4 qpm4clip m4 e-clip 2 5 qd553 counter gear bearing block 2 6 qd575 pulley gear plate 1 7 qd554a pulley gear block pin 1 8 qd504 pulley gear 1 -install...

Page 17

1-6 upper frame installation 1-6-a elevator control arm-right side no. Part no. Description qty 1 1-3 r. A&e arm subassembly 1 2 1-4 inner el. Ctrl. Arm subassembly 1 3 qc552 outer elevator control arm 1 4 hhi3m05ss m3x5 set screw 1 5 hhi3m4ps m3x4 pivot ball stud 5 6 qf567 m3x5x3 spacer 1 7 qc524r ...

Page 18

1-6-b anti-rotation guide assembly (sport model) no. Part no. Description qty 1 1-6-a right upper frame (up to step 1-6-a) 1 2 qf673 washout anti-rot. Guide 1 3 qf567 m3x5x3 spacer 2 4 hhi3m45c m3x45 cap head bolt 2 page 18 of 60

Page 19

1-6-b anti-rotation guide assembly (pro model) no. Part no. Description qty 1 1-6-a right upper frame (up to step 1-6-a) 1 2 qf318 washout anti-rot. Guide base 1 3 qf317 washout anti-rot. Guide a (from frame bag) 1 4 qf567 m3x5x3 spacer 2 5 hhi3m10c m3x10 cap head bolt 2 6 hhi3m06c m3x6 cap head bol...

Page 20

1-6-c main shaft bearing blocks no. Part no. Description qty 1 1-6-b right upper frame (up to step 1-6-b) 1 2 qf559 main shaft bearing block 2 3 hhi3m08c m3x8 cap head bolt 4 note: for the lower bearing block, the flange should face down. For the upper one, the flange should face up. Page 20 of 60

Page 21

1-6-d frame cross members, pinion gear bearing block & tail transmission no. Part no. Description qty 1 1-6-c right upper frame (up to step 1-6-c) 1 2 1-5 tail transmission subassembly 1 3 qf501 32mm cross member 4 4 qf559 pinion gear bearing block* 1 5 hhi3m08c m3x8 cap head bolt 10 *pinion gear be...

Page 22

1-6-e upper frame installation no. Part no. Description qty 1 1-6-d right upper frame (up to step 1-6-d) 1 2 1-2 left upper frame subassembly 1 3 qf567 m3x5x3 spacer 3 4 qc524l left aileron control lever 1 5 hhi3m4ps m3x4 pivot ball stud 3 6 hhi3m08c m3x8 cap head bolt 14 7 hhi3m12c m3x12 cap head b...

Page 23

Section 2: main frame bag 2 2-1 lower frame assembly no. Part no. Description qty no part no. Description qty 1 qfe55 8c lower frame(from frame bag) 2 7 qf569 60mm cross member 3 2 qf356c* radio tray (from frame bag) 1 8 hhi3m08c m3x8 cap head bolt 6 3 qf357 gyro plate (from frame bag) 1 9 hhi3m10c ...

Page 24

For pro version, mount the radio tray on three half round cross members using six m3x6 philip screws (no. 11) first. The six holes in the radio tray maybe counter sunk for nicer finish. Page 24 of 60

Page 25

For both models, use the double side tape to attach the rear esc mounting tray on two half round cross members installed underneath the gryro plate. 2-2 motor mount assembly no. Part no. Description qty no. Part no. Description qty 1 ***** motor 1 6 qfe569 bulkhead (from frame bag) 1 2 qde568 motor ...

Page 26

• for axi, use the motor mounting plate, seven m4x8 cap head bolts, and seven m4 washers. If you use axi with model 4130/**, you have to make a cut on the motor mount to make room for the motor wires to come out. Page 26 of 60

Page 27

2-3 main frame installation no. Part no. Description qty no. Part no. Description qty 1 1 upper frame assembly 1 5 hhi3m20c m3x20 cap head bolt 6 2 2-1 lower frame assembly 1 6 qf501 32mm cross member 3 3 2-2 motor mount assembly 1 7 qfl307 rear one-piece cross 2 4 hhi3m8 m3x8 cap head bolt 10 page ...

Page 28

2-4 landing gear subassembly no. Part no. Description qty no. Part no. Description qty 1 hhi4042 landing gear strut 2 4 qd354 m2.5x6 phillip screw 4 2 hhi4042 landing gear skid 2 5 ***** ca glue 1 3 qd561 landing gear end cap 4 6 hhi3m12c m3x12 cap head bolt 4 7 hhi03mln m3 locknut 4 • drill 4 holes...

Page 29

• install the main frames onto the landing gear assembly and secure them with four m3x12 cap head bolts. Page 29 of 60

Page 30

Section 3: driving system bag 3 3-1 main gear subassembly no. Part no. Description qty no. Part no. Description qty 1 qd355 lower main gear 88t 1 4 qd354* auto-rotation clutch 1 2 qd502 upper main gear 97t 1 5 hhi3m06c m3x6 cap head bolt 4 3 qd559 lower main gear hub 1 6 hhi3m06p m3x6 philip screw 4...

Page 31

3-2 driving system assembly no. Part description qty no. Part no. Description qty 1 3-1 main gear subassembly 1 5 hhi3m22c m3x22 cap head bolt 1 2 2 main frame assembly 1 6 hhi03mln m3 locknut 1 3 qd556 main shaft 1 7 hhi3m05ss m3x5 set screw 4 4 qd357 main shaft collar 1 • slide the main gear subas...

Page 32

Section 4: tail assembly bag 4 4-1 tail pulley gear subassembly no. Part no. Description qty 1 qt513 tail output shaft 1 2 qt520b tail gear lock pin 1 3 qt556 tail pulley gear 1 4 qt520a tail gear side plate 1 4-2 tail rotor subassembly no. Part no. Description qty no. Part no. Description qty 1 qt5...

Page 33

First, to prevent the boom end from rotating, drill a 2.5mm hole in the side of the boom end, then secure with a m2.5x6 cap head bolt. Install the bearings into the tail case side plates. The flange should be inside. Page 33 of 60

Page 34

4-3 tail rotor installation no. Part no. Description qty no. Part no. Description qty 1 qt365 dual bearing tail rotor 1 9 qt360 horizontal fin mount 1 2 hhi3m22c m3x22 cap head bolt 2 10 qt360a vertical fin mount a 1 3 hhi6305 tail blade 2 11 qt360b vertical fin mount b 1 4 qt365b tail blade spacer ...

Page 35

After installing all the parts as shown above, slide this subassembly on the output shaft then secure it with one m3x5 set screw. Page 35 of 60

Page 36

4-4 installation of the tail & frame no. Part no. Description qty no. Part no. Description qty 1 4-3 tail assembly 1 6 hhi3m08c m3x8 cap head bolt 2 2 hhi4062r boom support (in box) 2 7 hhi3m10c m3x10 cap head bolt 2 3 hhi4062a* boom support end 4 8 hhi3m45c m3x45 cap head bolt 4 4 qt558 tail boom c...

Page 37

Section 5: control systems bag 5 5-1 washplate assembly 5-2 washout assembly no. Part no. Description qty no. Part no. Description qty 1 qc352 washout base 1 5 hhi3m05ss m3x5 set screw 2 2 qc105 washout arm 2 6 hhi3m8ps m3x8pivot ball stud 2 3 qc358 washout link 2 7 hhi3m12c m3x12 cap head bolt 2 4 ...

Page 38

5-3 control system installation no. Part no. Description qty 1 4-1 swashplate assembly 1 2 4-2 washout assembly 1 3 3-3 helicopter (up to step 3) 1 4 qc651 double pin washout anti-rotation base 1 5 qc651 washout anti-rot guide pin 2 6 hhi3m05ss m3x5 set screw 4 7 qc301 swash anti-rotation pin 1 note...

Page 39

Section 6: rotor head bag 6 6-1 main rotor hub assembly no. Part no. Description qty no. Part no. Description qty 1 qh558 main blade grip * 2 9 hhi3m5x3 m3x5x3 spacer 2 2 qh554 pitch arm** 2 10 qhl353 head spindle spacer 2 3 qhl351 center hub 1 11 qh556 thrust bearing spacer 2 4 qh352 hiller arm 2 1...

Page 40

6-2 flybar & seesaw assembly no. Part no. Description qty no. Part no. Description qty 1 qh357 seesaw 1 8 qh643 4mm standard flybar (in box) 1 2 qh323 seesaw collar 2 9 hhi3m05ss m3x5 set screw 2 3 hhi3m8c m3x8 cap head bolt 2 10 qh649 4mm fly-bar paddle 2 4 hhi3m8ps m3x8 pivot ball stud 2 11 qp150p...

Page 41

6-3 rotor head installation no. Part no. Description qty 1 6-2 fly-bar seesaw assembly 1 2 5-3 helicopter (up to step 4) 1 3 hhi3m20c m3x20 cap head bolt 1 4 hhi03mln m3 locknut 1 install the head assembly into the main shaft, and then secure it by one m3x20 cap head bolt and one m3 locknut. Page 41...

Page 42

Section 7: linkage bag 7 7-1 rudder push rod installation no. Part no. Description qty 1 hhi4073c* rudder push rod (in box) 1 2 hhi4073a* rudder push rod end 2 3 hhi2903** pushrod guide clamp-on 1 4 hhi2900l*** rudder pushrod guide 3 5 hhi2900i*** rudder pushrod guide insert 3 6 qp124 shim ball 1 7 ...

Page 43

The length of the rudder rod measured from center to center should be around 713 mm. 7-2 linkage assembly no. Part no. Description qty 1 qp150p 2.3 long ball end 26 2 hhir23035 2.3x35mm rod 2 3 hhir23040 2.3x40mm rod 3 4 hhir23045 2.3x45mm rod 2 5 hhir23070 2.3x70mm rod 2 6 hhir23090 2.3x90mm rod 2 ...

Page 44: Coding The Rod Assembly:

Coding the rod assembly: all the linkage should be assembled with dimensions measured center to center and coded as following: no. Code rod description center to center qty 1 a 2.3x35mm rod 51.5 mm 2 2 b 2.3x40mm rod 64 mm 3 3 c 2.3x45mm rod 66.5 mm 2 4 d 2.3x70mm rod 94.5 mm 2 5 e 2.3x90mm rod 110 ...

Page 45

Page 45 of 60

Page 46

Section 8: settings bag 8 8-1 main blade installation no. Part no. Description qty 1 6-2 helicopter (up to step 6) 1 2 ***** main blade 2 3 ***** main blade spacer 4 4 hhi4m30c m4x30 cap head bolt 2 5 hhi04mln m4 locknut 2 8-2 setting up radio no. Part no. Description qty 1 7-1 helicopter (up to ste...

Page 47

Before setting up the radio, you have to install the receiver, gyro, speed controller, and batteries for your helicopter. See your radio, receiver, speed controller, and gyro manuals for how to hook up. Instead of giving you the exact length of each linkage rod we will explain to you what you are tr...

Page 48

Step 1:first set your radio up so that all servos are moving in the right direction and adjust all travel values to 100%. If you have a radio with swash mixing values set those to 50% (pitch, aileron and elevator). Now center both radio sticks (including “throttle”) and center all trim and sub-trim ...

Page 49

Washout arm and the flybar connection point. Turn your radio and receiver back on and center both sticks. Now adjust the length of the flybar linkage so the washout arms are level (horizontal), see picture 1. Also make sure your flybar arms and flybar-paddles are level (horizontal), when adjusting t...

Page 50

Picture 5, tail center picture 6, tail positive thrust picture 7, tail negative thrust picture 8, tail page 50 of 60

Page 51

Pitch travel setup collective position normal flying aerobatic up (100%) +10 o +10 o center (50%) +5 o +0 o down (0%) -3 o -10 o throttle curve setup fuel electric (non governor mode) collective position normal flying aerobatic normal flying aerobatic up (100%) 100% 100% 85% 85% center (50%) 70% 60%...

Page 52

Most setups, but a powerful motor or a light helicopter might need more. For rpm adjustment during anything other than full stick deflection you should use the throttle. A short recap, adjust throttle to adjust rpm during anything other than full collective. At full collective adjust the pitch. See ...

Page 53: Fre-Flight Checks

Fre-flight checks • the rotor flybar and shaft must be straight. • the flybar and control paddles must tilt in the proper direction and operates smoothly throughout the whole range. • check the swashplate to make sure it move smoothly and clean. • when control input are given to tilt the swashplate,...

Page 54: Warnings

Warnings • do not operate helicopters in rainy, windy, or snowy condition. • operate helicopter in a safe zone away from crowds, traffic, or distractions. • use the proper batteries to prevent damage to the motor and equipment. • make sure all the batteries are fully and properly charged. • make sur...

Page 55: Adjustments

Adjustments tracking adjustment:the tips of the main rotor blades should follow the same path when they rotate. We call the main rotor blades are in track. (a) rev up the motor until the helicopter becomes light on its landing gear. Raise throttle gently and gradually (b) if the main rotor blades ar...

Page 56: How To Hover

(c) if the helicopter nose goes down or up, then: how to hover basic maneuver for a pilot is learn how to hover a helicopter. When the helicopter is floating in a stationary position in the air, we call that hovering. Use the following procedure to practice your hovering: (a) make sure everything is...

Page 57

Pilot to keep the helicopter from moving. It will also be difficult to know if the helicopter is in trim or not for a beginner. Keep going on the practice close to ground you will develop your skills. (d) keep practicing lifting your helicopter no more than 8 inches (20cm) from the ground until you ...

Page 58: How To Fly Forward

How to fly forward once you have mastered hovering fight: (a) let’s begin the exercise of changing positions by practice moving the helicopter to the left or right slowly from 60 inches (1.5 m) above the ground. Hovering at 60 inches page 58 of 60

Page 59

(b) once you have been comfortable with all the movements and controls in the previous step, start using some tail rotor control to make the helicopter point slightly to the left or right as you fly it to the left or right. Keep practicing the figure-eight path as shown below, you will master all ba...

Page 60: After Flight Checks

After flight checks after each flight, the helicopter should be thoroughly inspected: (a) unplug the batteries. (b) check every bolt, nut, and screw to make sure none has loosened due to vibration. (c) check every rotating and movable part like head rotor, swashplate, tail rotor,…to ensure they stil...