- DL manuals

- QuickTec

- Boiler

- EKCO.L2

- User Manual

QuickTec EKCO.L2 User Manual

Summary of EKCO.L2

Page 1

Electric central heating flow boiler quicktec gmbh · bardelebenweg 25 · 14089 berlin · germany tel: +49 (0) 30 / 577 01 88 40 · fax: +49 (0) 30 / 577 01 88 49 · e-mail: mail@quick-tec.Com · quick-tec.Com.

Page 2

Used product can’t be treated as general communal waste. Disassembled appliance has to be delivered to the collection point of electrical and electronic equipment for recycling. Appropriate utilisation of used product prevents potential negative environmental influences that may occur as a result of...

Page 3: Safety Instructions

3 gb-031ab/f. Safety instructions 1. Read and strictly follow the installation and operating instructions to ensure a long life and reliable boiler operation. 2. An efficient electrical installation which has been completed in accordance with the binding norms of electric installation. 3. A wet cent...

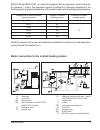

Page 4: Installation

4 return inlet flow outlet installation 1. Hang the boiler up in a vertical position on fixing screws with the inlet and outlet pipes to the bottom, maintaining clearances from the walls and the ceiling. 2. Connect the boiler to the central heating system equipped with a cut-off valves. 3. Fill the ...

Page 5

5 gb-031ab/f. 1 1 ekco.Ln2...P boiler connection to the central heating system ekco.Ln2 and ekco.Ln2...P model are equipped with an expansion vessel (capacity: 6l, pressure: 1,5 bar). The expansion vessel is sufficient for following capacities of the heating system at given temperatures of the mediu...

Page 6

6 room thermostat (rp entry) – when the voltage free contact gets opened the boiler will stop heating. The entry is responsible for boiler control depending on the room temperature. (room thermostat connection details – page 4, sub clause 7). We-019/01 cylinder water temperature sensor (tzas entry-r...

Page 7

7 gb-031ab/f. Dhw cylinder thermostat (tzas entry- refers to ekco.Ln2 and ekco.L2 model) – kospel suggests to use the vczmh6000e valve with the vc6013zz00 servo-motor. The three-way valve control is performed by applying 230v on the brown wire or the black wire (blue is the neutral wire). Voltage on...

Page 8: Start Up

8 start up led 1 2 3 4 5 led 1. Disconnect the na contacts or detach temperature regulator from the boiler. 2. Check if the appropriate system installation pressure is reached (see the „technical data” section). By using or buttons whilst the control panel is off, the pressure value will be displaye...

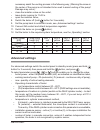

Page 9: Advanced Settings

9 gb-031ab/f. Advanced settings for advanced settings switch the control panel to standby mode (press and hold button for 3 seconds) then press and hold the ,button, and press . To select parameter press , or buttons enable you to change the value: - boiler power - enter the power amount (kw) as ind...

Page 10: Control Panel

10 control panel a - pressure [bar] b - flow [l/min] c - power [kw] d - temperature [0°c] e - digital display f - indicator of medium temperature setting (for dhw cylinder) g - indicator of room thermostat and heating activity (for central heating) h - indicator of pump and flow activity i,j - inact...

Page 11

11 gb-031ab/f. Winter mode (ch) when the control panel is switched to „winter mode” the icon is on. In this time the control panel is in the main view display, the icons show current working mode of boiler. The digital display shows the temperature of medium (for central heating). You can check out ...

Page 12

12 the temp. Can be set between 20 – 85°c. A controller will switch over to the main view, if you don’t use a buttons for 1 min. To automatically switch to the main view press (when you are in medium temp. Setting view). To ensure smooth and economic boiler operation, the temperature of the medium (...

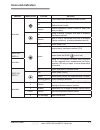

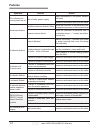

Page 13: Icons and Indicators

13 gb-031ab/f. Model indicator status details all models on room thermostat allows the boiler to heat off the required temperature has been reached (boiler doesn’t heat), flickers master appliance doesn’t allow to heat (na entry is open), on pump is active, a proper flow rate of medium has been reac...

Page 14: Failures

14 failures refers to ekco.Ln2 and ekco.L2 boiler only symptom reason action the indicators on control panel are off lack of boiler power supply check parameters of the power network and fuses contact an authorised service or the seller a indicator flickers insufficient pressure (below 0,5bar) switc...

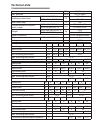

Page 15: Technical Data

Technical data max. Pressure mpa 0,3 (3 bar) min. Pressure mpa 0,05 (0,5 bar) outflowing water temp. Ekco.Ln2; ekco.L2 °c 20 ÷ 85 ekco.Ln2..P; ekco.L2...P 20 ÷ 60 max. Water temp. °c 100 overall dimensions (height x width x depth ekco.Ln2; ekco.Ln2...P mm 710 x 418 x 252 ekco.L2; ekco.L2...P 710 x 4...

Page 16

Quicktec gmbh · bardelebenweg 25 · 14089 berlin · germany tel: +49 (0) 30 / 577 01 88 40 · fax: +49 (0) 30 / 577 01 88 49 · e-mail: mail@quick-tec.Com · quick-tec.Com.