- DL manuals

- Quietside

- Air Conditioner

- QSFMO-D2

- Service Manual

Quietside QSFMO-D2 Service Manual

Summary of QSFMO-D2

Page 1

Service manual model: qsfmo-d2 qsfmo-t3 qsfmo-q4 (refrigerant : r410a).

Page 2: 1. Summary

1 technical.Information service manual 1. Summary part Ⅰ : technical information outdoor unit qsfmo-t3 qsfmo-q4 qsfmo-d2.

Page 3: 2. Specifications

2 technical.Information service manual 2. Specifications the.Above.Data.Is.Subject.To.Change.Without.Notice;.Please.Refer.To.The.Nameplate.Of.The.Unit. .Model.Of.Outdoor.Unit.. Qsfmo-d2 qsfmo-t3 qsfmo-q4 .Product.Code.. Cb228w01600_k90639 cb228w01700_k90639 cb228w01800_k90639 .Compressor.Manufacture...

Page 4: 3. Outline Dimension Diagram

3 technical.Information service manual 3. Outline dimension diagram 35.1 37.2 27. 6 15.6 13.4 22.0 14. 5 35.4 32.1 23.5 14.9 12.4 13.5 21.7 unit:inch (1)qsfmo-d2 (2)qsfmo-t3..Qsfmo-q4 unit:inch.

Page 5

4 technical.Information service manual 4. Refrigerant system diagram outdoor indoor d1 c 1 b 1 a 1 filter a heat exchanger gas -liquid separator inverter compresso r discharge silencer discharge temperature sensor sp 4-way valve outdoor heat exchanger fan high pressure switch b heat exchanger c heat...

Page 6: 5. Electrical Part

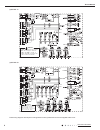

5 technical.Information service manual 5. Electrical part 5.1 wiring diagram symbol symbol.Color. Symbol symbol.Color. Symbol name wh white gn green cap jumper.Cap ye yellow bn brown comp compressor rd red bu blue grounding.Wire yegn yellow/green bk black / / vt violet og orange / / ● indoor unit ●i...

Page 7

6 technical.Information service manual these.Wiring.Diagrams.Are.Subject.To.Change.Without.Notice;.Please.Refer.To.The.One.Supplied.With.The.Unit. (3)qsfmo-q4 (2)qsfmo-t3 3ohdvhgrqwwrxfkdq\whuplqdo zkhqwkhyrowdjhriwhuplqdo 3'&dqg1'&dw$3lv kljkhuwkdq9wrsuhyhqwwkh ulvnrihohfwulfdovkrfn :$51,1* / 1 / 1...

Page 8

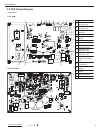

7 technical.Information service manual 5.2 pcb printed diagram 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 1 compressor interface 2 unit a liquid valve and gas valve 3 unit b liquid valve and gas valve 4 compressor overload protector 5 temperature sensor 6 compressor electric heater 7 outdoor fan 8 4-...

Page 9

8 technical.Information service manual ● top view (2)qsfmo-t3.Qsfmo-q4 13 1 2 3 4 5 6 7 8 9 10 11 12 14 15 16 17 18 19 20 21 22 1 compressor interface 2 3 4 5 6 temperature sensor interface 7 interface of compressor overload protector 8 interface of chassis electric heater 9 interface of compressor ...

Page 10: 6. Function and Control

9 technical.Information service manual 6. Function and control 1 basic functions of the system 1.1 cooling mode 1.1.1 cooling conditions and process: if the compressor is in stop status and start the unit for cooling operation, when one of the indoor units reaches the cooling operation condition, th...

Page 11

10 technical.Information service manual 1.3.3 outdoor fan control in heating mode the outdoor fan starts before 5s of the starting of compressor and then it will run in high speed for 40s; the fan shall run at every speed for at least 80s; when the compressor stops, the outdoor fan stops after 1min....

Page 12

11 technical.Information service manual 2.4 communication malfunction detection of the quantity of installed indoor units: after 3min of energizing, if the outdoor unit does not receive the communication data of certain indoor unit, the outdoor unit will judge that indoor unit is not installed and w...

Page 13: 9. Maintenance

22 installation.And.Maintenance service manual 9. Maintenance 9.1 precautions before performing inspection or repair there.Are.High-capacity.Electrolytic.Capacitors.On.The.Outdoor.Mainboard..Thus,.Even.The.Power.Is.Cut.Off,.There.Is.High.Voltage. Inside.The.Capacitors.And.It.Needs.More.Than.20min.To...

Page 14

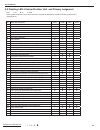

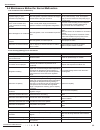

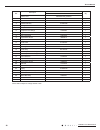

23 installation.And.Maintenance service manual 9.2 flashing led of indoor/outdoor unit and primary judgement note: ○ : off ● : on Ƽ : blink when several malfunctions occur at the same time, they will be displayed in circulation and every malfunction is displayed for 5s. No malfunction description le...

Page 15

24 installation.And.Maintenance service manual 18k: 24/30k: 43 communication failure with unit a ● Ƽ ● ● 44 communication failure with unit b Ƽ Ƽ ● ● 45 communication failure with unit c ○ ○ Ƽ ● 46 communication failure with unit d ● ○ Ƽ ● 47 unit a freeze protection Ƽ ○ Ƽ ● 48 unit b freeze protect...

Page 16

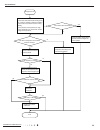

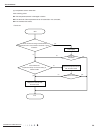

25 installation.And.Maintenance service manual energize the unit if the above cases are existed? Yes no no no no no yes yes yes yes test the isolation impedance between the three phases of the compressor and thecopper pipe malfunction is eliminated end if the wire of compressor is connected well and...

Page 17

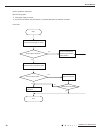

26 installation.And.Maintenance service manual (2) pfc protection malfunction main checking points: ● ● if the power supply is normal; check if the connection wire of induction is connected well and if the induction is broken; flow chart: start check if the power supply is normal power supply is abn...

Page 18

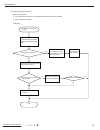

27 installation.And.Maintenance service manual (3) capacity charging malfunction main checking points: ● ● if the mainboard is broken; if the wiring of the induction is connected well and if the induction is broken; flow chart: energize the unit and wait for 1min test the voltage between the two end...

Page 19

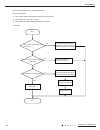

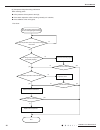

28 installation.And.Maintenance service manual (4) anti-high temperature and overload malfunction main checking points: ● ● if the outdoor fan is running normally; if the outdoor ambient temperature is within the normal range; ● if the indoor and outdoor radiation environment is good; flow chart: st...

Page 20

29 installation.And.Maintenance service manual start check whether the wiring terminal between temperature sensor and controller is loosened or poorly contacted? Yes yes yes yes insert the temperature sensor tightly no no no no eliminate the malfunction check whether the temperature senspr is normal...

Page 21

30 installation.And.Maintenance service manual (6) start failure malfunction main checking points: ƽ ƽ if the stop duration of the compressor is sufficient; if the connection wire of the compressor is connected properly; ƽ if the compressor is broken; flow chart: ƽ if the refrigerant charging amount...

Page 22

31 installation.And.Maintenance service manual (7) communication malfunction main checking points: ƽ ƽ if the indoor mainboard or outdoor main board is broken; if the connection wire between the indoor unit and outdoor unit is connected well, if the wires inside the unit is connected well; flow char...

Page 23

32 installation.And.Maintenance service manual eliminate the malfunction eliminate the malfunction eliminate the malfunction eliminate the malfunction end no no no no no no no no yes yes yes yes yes yes yes yes yes all the indoor units appear communication malfunction de-energize,check the connectio...

Page 24

33 installation.And.Maintenance service manual (8) compressor overload, diacharge protection malfunction main checking points: ƽ ƽ if there is refrigerant leakage; if the eletric expansion valve is connected well or it is broken; ƽ if the overload protector is broken; flow chart: eliminate the malfu...

Page 25

34 installation.And.Maintenance service manual (9) compressor desynchronizing malfunction main checking points: ƽ ƽ if the eletric expansion valve is working normally or it is broken; if the pressure of the system is too high; ƽ if the radiation of the unit is good; flow chart: eliminate the malfunc...

Page 26

35 installation.And.Maintenance service manual possible.Causes. Discriminating.Method.(air.Conditioner.Status) troubleshooting. Set.Temperature.Is.Improper observe.The.Set.Temperature.On.Remote.Controller..Adjust.The.Set.Temperature rotation.Speed.Of.The.Idu.Fan. Motor.Is.Set.Too.Low small.Wind.Blow...

Page 27

36 installation.And.Maintenance service manual 7. Abnormal sound and vibration possible.Causes. Discriminating.Method.(air.Conditioner.Status) troubleshooting. When.Turn.On.Or.Turn.Off.The.Unit,. The.Panel.And.Other.Parts.Will. Expand.And.There's.Abnormal. Sound. There's.The.Sound.Of."papa" normal.P...

Page 28

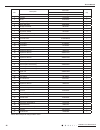

37 installation.And.Maintenance service manual 10. Exploded view and parts’ list (1)qsfmo-d2 1 2 3 4 6 7 11 12 13 14 19 20 22 23 24 26 27 17 25 18 8 21 10 9 5 16 15.

Page 29

38 installation.And.Maintenance service manual above.Data.Is.Subject.To.Change.Without.Notice. No. Description part.Code qty qsfmo-d2 product.Code cb228w01600_k90639 1 front.Grill .01473065 1 2 cabinet .0143303402p 1 3 chassis.Sub-assy .01205168p 1 4 drainage.Joint .26113009 1 5 compressor.Gasket .7...

Page 30

39 installation.And.Maintenance service manual (2)qsfmo-t3 1 2 3 4 5 8 9 6 10 11 12 13 14 20 23 24 26 29 30 31 32 33 34 35 37 36 39 40 17 16 25 28 15 38 19 21 22 7 18 27.

Page 31

40 installation.And.Maintenance service manual no. Description part.Code qty qsfmo-t3 product.Code cb228w01700_k90639 1 front.Grill .01473049 1 2 cabinet .01433047p 1 3 drainage.Plug 06123401 3 4 chassis.Sub-assy .02803068p 1 5 drainage.Connecter .06123401 1 6 compressor.And.Fittings .00105036 1 7 c...

Page 32

41 installation.And.Maintenance service manual (3)qsfmo-q4 1 2 3 4 5 8 9 6 10 11 12 13 14 23 24 25 28 30 31 32 33 34 35 36 38 37 18 17 26 29 16 15 39 40 41 7 19 21 22 20 27.

Page 33

42 installation.And.Maintenance service manual no. Description part.Code qty qsfmo-q4 product.Code cb228w01800_k90639 1 front.Grill .01473049 1 2 cabinet .01433047p 1 3 drainage.Plug 06123401 3 4 chassis.Sub-assy .02803068p 1 5 drainage.Connecter .06123401 1 6 compressor.And.Fittings .00105036 1 7 c...

Page 34: 11. Removal Procedure

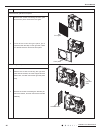

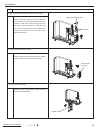

43 installation.And.Maintenance service manual 11. Removal procedure 11.1 removal procedure(qsfmo-d2) steps procedure 1..Remove.Top.Cover.And.Handle before.Disassembly. Handle top.Panel 1 2 twist. Off. The. Screws. Used. For. Fixing. The. Top. Cover,. Pull.The.Top.Cover.Upward.To.Remove.It. 3 twist....

Page 35

44 installation.And.Maintenance service manual steps procedure remove. The. Screws. Connecting. The. Front. Grille. And.The.Front.Panel..Remove.The.Front.Grille. Twist. Off. The. Screws. Fixing. The. Panel,. Pull. It. Upward,loosen.The.Clasp.On.The.Right.Side,.Rotate. It.To.The.Left.And.Then.Remove....

Page 36

45 installation.And.Maintenance service manual steps procedure remove.The.Screws.Fixing.The.Electric.Box.Sub-assy;. Loosen.The.Wire.Bundle;.Pull.Out.The.Wiring.Terminals. And.Then.Pull.The.Electric.Box.Upwards.To.Remove.It. 5.Remove.Electric.Box.Assy electric.Box remove. The. Nuts. Fixing. The. Blad...

Page 37

46 installation.And.Maintenance service manual steps procedure 8..Remove.4-way.Valve 6..Remove.Soundproof.Sponge 7..Remove.Reactor tear.Up.The.Soundproof.Sponge.Carefully. Soundproof. Sponge discharge. The. Refrigerant. Completely;unsolder. The. Pipelines. Connecting. The. Compressor. And. The. Cond...

Page 38

47 installation.And.Maintenance service manual steps procedure 9..Remove.Electronic.Expansion.Valve.And.Cut-off.Valve 10..Remove.Valve.Support.Sub-assy remove. Electronic. Expansion. Valve. And. Cut-off. Valve. Unsolder. The. Spot. Weld. Between. Electronic. Expansion. Valve. And. Cut-off. Valve. As...

Page 39

48 installation.And.Maintenance service manual 12...Remove.Compressor steps procedure twist.Off.The.Three.Foot.Nuts.On.Compressor.And.Then remove.The.Compressor. Dissemble.The.Chassis.Sub-assy.And.Condenser sub-assy. 13..Remove.Condenser.Sub-assy compressor remove. The. Screws. Connecting. The. Supp...

Page 40

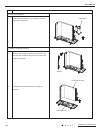

49 installation.And.Maintenance service manual 11.2 removal procedure(qsfmo-t3/qsfmo-q4) steps procedure remove.The.Screws.Fixing.Big.Handle.And.Right.Side plate.To.Remove.The.Big.Handle. 1.Remove.Big.Handle.And.Wire.Connection.Cover before.Disassembly remove.The.Screws.Fixing.Wire.Connection.Cover ...

Page 41

50 installation.And.Maintenance service manual steps procedure remove.The.Screws.Fixing.Top.Cover,.Panel.And.Left.& right.Side.Plate,.To.Remove.Top.Cover. Remove.The.Screws.Fixing.Grille.And.Panel,.To.Remove. The.Grille.On.The.Panel. Remove.The.Screws.Fixing.Panel,.Chassis.And.Motor support,.To.Remo...

Page 42

51 installation.And.Maintenance service manual steps procedure remove.The.Screws.Fixing.Right.Side.Plate,.Valve support.And.Guard.Grille,.To.Remove.The.Right.Side plate. Remove.The.Screws.Fixing.Guard.Grille.And.Left.Side plate.To.Remove.Guard.Grille. Remove.The.Screws.Fixing.Chassis.And.Condenser s...

Page 43

52 installation.And.Maintenance service manual steps procedure remove.The.Screws.Fixing.Support.And.Chassis,.To remove.The.Condenser.Support. Remove.The.Screw.Nuts.Fixing.Fan.Blade.With.Spanner,. To.Remove.The.Fan.Blade. Remove.The.Tapping.Screws.Fixing.Motor,.Pull.Out.The pin.Of.Leading.Wire.For.Mo...

Page 44

53 installation.And.Maintenance service manual steps procedure remove.The.Tapping.Screws.Fixing.Isolation.Sheet, loosen.The.Wire.Binds,.Pull.Out.The.Terminal,.Lift.To remove.The.Electric.Box.Sub-assy. Remove.The.Screws.Fixing.Pfc.Electrical.Inductance and.Isolation.Sheet,.To.Remove.The.Pfc.Electrica...

Page 45

54 installation.And.Maintenance service manual steps procedure welding.Cut.The.Welding.Point.Jointing.The.Suction pipe.Sub-assy,.Compressor.And.Liquid.Receiver,.To remove.The.Suction.Pipe.Sub-assy. Remove.The.Screws.Fixing.Isolation.Sheet.And.Liquid receiver.And.Lift.To.Remove.The.Liquid.Receiver. R...

Page 46

55 installation.And.Maintenance service manual steps procedure remove.The.Screw.Nuts.Fixing.Compressor.Foots.And chassis.With.Spanner,.As.Well.As.The.Foot.Cushion,.To remove.The.Compressor. Remove.The.Screws.Fixing.Valve.Support.Assy.And chassis.Sub-assy,.To.Remove.The.Valve.Support.Assy. Welding.Cu...

Page 47

56 installation.And.Maintenance service manual (1) (2) terminal of compressor overload protection terminal of temperature sensor terminal of 4-way valve terminal of outdoor fan terminal of compressor wire pfc induction wire grounding wire circlip retainer high and low pressure switch remove the nut ...

Page 48

57 installation.And.Maintenance service manual screws screws screws screws screws screws screws electric box assy electric box cover clasp(left) clasp(right) remove.The.2.Screws.Fixing.The.Electric.Box. Assy.And.Then.Lift.The.Electric.Box.Assy.Upwards. To.Remove.It. D e f g push. The. Electric. Box....

Page 49

58 installation.And.Maintenance service manual sticking stripe soundproof sponge 7.Remove.The.Isolation.Plate.And.Reactor remove.The.2.Screws.Connecting.The.Isolation. Plate.And.Condenser.Side.Plate;.Remove.The. 3.Screws.Connecting.The.Isolation.Plate.And. Chassis,.And.Then.Remove.The.Isolation.Plat...

Page 50

59 installation.And.Maintenance service manual screw 8.Valve.Support.Sub-assy valve.Support. Sub-assy unsolder.The.Welding.Joint.Connecting.The.Valve. With. Capillary. And. Condenser;. Unsolder. The. Welding.Joint.Connecting.The.Gas.Valve.And.Air- return.Pipe;.Remove.The.2.Bolts.Fixing.The.Gas. Valv...

Page 51

60 installation.And.Maintenance service manual compressor foot.Nuts remove.The.2.Screws.Fixing.The.Condenser.And. Chassis,.And.Then.Lift.The.Condenser.Upwards.To. Remove.It. 12.Remove.Compressor remove.The.3.Foot.Nuts.Fixing.Compressor.And. Then.Lift.The.Compressor.Upwards.To.Remove.The. Compressor....

Page 52

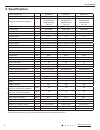

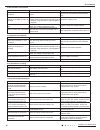

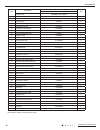

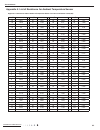

63 installation.And.Maintenance service manual appendix 4: list of resistance for ambient temperature sensor appendix 1: resistance table of ambient temperature sensor for indoor and outdoor units(15k) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) temp( o c) resistanc...

Page 53

64 installation.And.Maintenance service manual appendix 1: resistance table of ambient temperature sensor for indoor and outdoor units(20k) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) -19 181.4 20 25.01 59 5.13 98 1.427 -18 171.4 21 23.9 60...

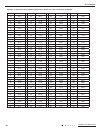

Page 54

65 installation.And.Maintenance service manual appendix 1: resistance table of ambient temperature sensor for indoor and outdoor units(50k) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) temp( o c) resistance(kΩ) -29 853.5 10 98 49 18.34 88 4.75 -28 799.8 11 93.42 50 1...

Page 55

Jf00301856.