- DL manuals

- Quin

- Amplifier

- Q-drive

- Installation & User Manual

Quin Q-drive Installation & User Manual

Summary of Q-drive

Page 1

Installation & users manual quin systems limited q-drive servo amplifier issue 1.5 june 1996 (man430).

Page 2: Copyright Notice

Copyright notice copyright 1996 quin systems limited. All rights reserved. Reproduction of this document, in part or whole, by any means, without the prior written consent of quin systems limited is strictly prohibited. Software version this manual reflects the following software versions. • qdrive....

Page 3: Table Of Contents

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page i table of contents list of figures iii list of tables iv 1. Introduction 1 1.1 q-drive characteristics 2 1.2 emc compliance 3 2. Unpacking and inspection 5 3. Drive specifications 7 3.1 mechanical specification 7 3.2 envi...

Page 4

Q-drive installation manual issue 1.5 page ii copyright © 1996 quin systems ltd. 7. Drive parameters 33 7.1 serial link 33 7.2 getting around the configuration program 33 7.3 page 0 parameters 36 7.4 page 1 parameters 37 7.5 page 2 parameters 39 7.6 page 3 parameters 41 7.7 page 6 parameters 41 7.8 ...

Page 5: List Of Figures

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page iii list of figures figure 1: emc filtering 3 figure 2: fixing centres for the q-drive. 10 figure 3: connections 13 figure 4: p2 upper: resolver connector 16 figure 5: p2 lower: encoder connector 17 figure 6: p10, p11, p12...

Page 6: List of Tables

Q-drive installation manual issue 1.5 page iv copyright © 1996 quin systems ltd. List of tables table 1: drive data 9 table 2: test points 9 table 3: cable sizes 14 table 4: p2 upper, resolver input connections 15 table 5: p2 lower, encoder output connections 17 table 6: p4 rs422 out / rs232 connect...

Page 7: Introduction

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 1 1. Introduction this document is the installation manual for the q-drive servo amplifier, a member of the quin systems ltd. Digital programmable transmission system (pts) range. The q-drive series of servo-amplifiers are...

Page 8: 1.1

Q-drive installation manual issue 1.5 page 2 copyright © 1996 quin systems ltd. 1.1 q-drive characteristics the main characteristics of the q-drive servo-amplifiers are as follows: • digital servo-amplifier with analogue speed command +/- 10v, for brushless motor with resolver. • utilises a 16 bit d...

Page 9: 1.2

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 3 1.2 emc compliance the q-drive amplifier has been tested to and complies with bsen 50081-1 and bsen 50081-2 for radiated emissions. The q-drive also complies with mains borne interference tests when used with a suitable ...

Page 10

Q-drive installation manual issue 1.5 page 4 copyright © 1996 quin systems ltd. This page is intentionally left blank.

Page 11: Unpacking and Inspection

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 5 2. Unpacking and inspection inspect the packaging for external signs of damage if possible before signing the delivery receipt, as this may indicate that the goods have been mishandled in transit. When unpacking the q-dr...

Page 12

Q-drive installation manual issue 1.5 page 6 copyright © 1996 quin systems ltd. This page is intentionally left blank.

Page 13: Drive Specifications

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 7 3. Drive specifications this section gives the overall specifications of the drive, including mechanical details and environmental requirements. 3.1 mechanical specification the dimensions of the q-drive are as follows: ...

Page 14: 3.4

Q-drive installation manual issue 1.5 page 8 copyright © 1996 quin systems ltd. 3.4 electrical specification 3.4.1 general data for all types supply voltage 3 x 220v ac +/- 15% supply frequency 45 to 65 hz operating temperature range 0 to 60° c operating temperature range at full power 0 to 45° c (f...

Page 15

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 9 3.4.2 drive performance specification note: i rms = i peak / 1.41 p =1.73 x i rms x v rms or p= 3 x i rms phase x v rms phase - in star v rms phase = 210v / 1.73 i rms phase = i rms - in delta v rms phase = 210v i rms ph...

Page 16: 3.5

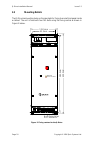

Q-drive installation manual issue 1.5 page 10 copyright © 1996 quin systems ltd. 3.5 mounting details the q-drive has mounting holes on the rear plate for fixing to an electrical panel inside a cabinet. The unit is fixed with four m5 bolts using the fixing centres as shown in figure 2. Below. Figure...

Page 17: 3.6

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 11 3.6 relevant directives this product is designed to be incorporated into a system for the control of machinery, and needs external equipment to enable it to fulfil this function. It must not be relied upon to provide sa...

Page 18

Q-drive installation manual issue 1.5 page 12 copyright © 1996 quin systems ltd. This page is intentionally left blank.

Page 19: Connections

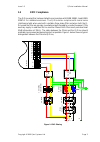

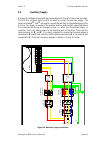

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 13 4. Connections 4.1 general high and low voltage cable connections have been segregated in the q-drive. The positions of the various connectors are shown in figure 3. Figure 3. Connections s' r' s' r' p 7 p7 s u p p l y ...

Page 20

Q-drive installation manual issue 1.5 page 14 copyright © 1996 quin systems ltd. 4.1.1 wiring and connectors the wiring of the q-drive series of servo-amplifiers must be carried out according to the schematics in these instructions. Local wiring regulations must be observed. Special attention should...

Page 21: 4.2

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 15 4.2 low voltage connections details of the low voltage connections which include the encoder, resolver, rs422/ rs232 and discrete signals, are described in the following sections. 4.2.1 p2 upper: resolver the resolver i...

Page 22

Q-drive installation manual issue 1.5 page 16 copyright © 1996 quin systems ltd. Figure 4. P2 upper: resolver connector 4.2.2 p2 lower: encoder the encoder output uses the lower half of connector p2 and is wired as shown in table 5: and figure 5. . The q-drive servo amplifier simulates an incrementa...

Page 23

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 17 figure 5. P2 lower: encoder connector q-drive pin number. Function. Pts d-type pin no. Suggested wire colour. 1. A. 1. Pink. 2. /a. 6. Grey. 3. B. 2. Yellow. 4. /b. 7. Green. 5. Z. 3. Blue. 6. /z. 8. Red. 7. Not used. ....

Page 24

Q-drive installation manual issue 1.5 page 18 copyright © 1996 quin systems ltd. 4.2.3 p4 rs422 out / rs232 the socket p4 is used as the daisy chain out connector in an rs422 multi-drop drive chain or the rs232 port in a single drive application. The rs232 option can only be used if the drive has be...

Page 25

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 19 4.2.5 p10, p11 & p12 these connectors are used for interfacing all other low voltage signals to the drive and are detailed below in table 8: figure 6. Shows the pin 1 & 2 socket of connector p10, p11 & p12 already inser...

Page 26: 4.3

Q-drive installation manual issue 1.5 page 20 copyright © 1996 quin systems ltd. 4.3 high voltage connections 4.3.1 p7, three phase in p7 is a block of three high current screw terminals used to connect the three phase or single phase supply to the q-drive. If a single phase supply is used then conn...

Page 27

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 21 4.3.4 wago spring terminals a group of six wago spring terminals are positioned to the left of the screw terminals. These are used to connect the auxiliary supply and an external fan.The terminals marked r‘ and s‘ are u...

Page 28

Q-drive installation manual issue 1.5 page 22 copyright © 1996 quin systems ltd. This page is intentionally left blank.

Page 29: Electrical Installation

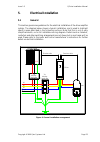

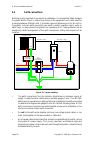

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 23 5. Electrical installation 5.1 general this section gives some guidelines for the electrical installation of the drive amplifier system. The diagram below shows a typical installation, and is used to highlight specific ...

Page 30: 5.2

Q-drive installation manual issue 1.5 page 24 copyright © 1996 quin systems ltd. 5.2 mains supply the q-drive can be powered from one of four sources:- • 220v three phase supply • isolating transformer • auto-transformer. • single phase supply the drives are fitted with surge limiting devices which ...

Page 31: 5.3

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 25 5.3 auxiliary supply a group of six wago spring terminals are positioned to the left of the screw terminals. The first four of these (from the left) are used to connect the auxiliary supply. The terminals marked r‘ and ...

Page 32: 5.4

Q-drive installation manual issue 1.5 page 26 copyright © 1996 quin systems ltd. 5.4 earth connections earthing is very important in any electrical installation. It is an essential safety measure to prevent electric shock in case of any failure of the equipment, and is also used for screening betwee...

Page 33: 5.5

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 27 5.5 connecting the motor to the drive a typical brushless a.C. Motor is connected with two cables; one carries the power to the motor windings, and the other returns signals from a position or speed feedback device such...

Page 34: 5.6

Q-drive installation manual issue 1.5 page 28 copyright © 1996 quin systems ltd. 5.6 connecting the drive to the controller the drive is connected to a quin motion controller using usually two multicore cables and two discrete wire leads: one cable carries the analogue speed demand to the drive, and...

Page 35

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 29 6. Safety - using guards and limits all machines should include comprehensive safety features. This is essential both for normal safety considerations, and to comply with health and safety requirements. It can also prev...

Page 36: 6.1

Q-drive installation manual issue 1.5 page 30 copyright © 1996 quin systems ltd. 6.1 choosing a motor the choice of motor for a particular application depends on several factors. Some of these are given below. • maximum torque required. • continuous torque required (r.M.S.). • maximum motor shaft sp...

Page 37

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 31 in most cases, the inertia and friction can be assumed constant, unless the system has a changing load. In this case the maximum possible load should be used in the calculations. The required velocity profile of the mot...

Page 38: 6.2

Q-drive installation manual issue 1.5 page 32 copyright © 1996 quin systems ltd. 6.2 mounting the motor the motor must be mounted rigidly to the structure of the machine or to a solid floor. If it is not mounted securely, it may vibrate or oscillate when the motor is powered up and the position or v...

Page 39: Drive Parameters

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 33 7. Drive parameters 7.1 serial link the serial link is used to set or monitor drive parameters stored in non-volatile memory using the configuration program. This program allows the user to: • set all user adjustable pa...

Page 40

Q-drive installation manual issue 1.5 page 34 copyright © 1996 quin systems ltd. Run the configuration program by typing; qdrive the initial screen, shown below, appears asking for the password motor to be entered. The program will allow changes to be made only if the password is correct, but will s...

Page 41

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 35 figure 13. Q-drive.Exe: scanning for active drives once a drive has been connected to it, it is possible to change the various parameters available on each page. Moving around and selecting the parameters is done using ...

Page 42: 7.3

Q-drive installation manual issue 1.5 page 36 copyright © 1996 quin systems ltd. Exit program: press to exit the program. New release: for more information on new releases please look at the file readme.Txt . 7.3 page 0 parameters figure 14. Q-drive.Exe: page 0 parameters. 0 proportional gain: (0..1...

Page 43: 7.4

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 37 4 nominal current: (10..64) this parameter sets the continuous current delivered to the motor. This parameter is programmable from 10 to 64 5 pair of motor poles: (1..6) this parameter sets the number of motor pole pair...

Page 44

Q-drive installation manual issue 1.5 page 38 copyright © 1996 quin systems ltd. 9 speed offset:(-127..+127) the setting of the servo-amplifier speed offset is done with this parameter. Which is adjustable between -127 and +127. 10 parameter not used 11 not used on qdrive 12 direction stop: (0..3) t...

Page 45: 7.5

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 39 7.5 page 2 parameters figure 16. Q-drive.Exe: page 2 parameters 16 speed/resolution: (1,2) this parameter selects one of two maximum motor speeds in order to enable the servo-amplifier for the appropriate encoder resolu...

Page 46

Q-drive installation manual issue 1.5 page 40 copyright © 1996 quin systems ltd. 20 enable: hard, trig, soft: (0..2) this parameter defines the way in which the amplifier is enabled. The first setting, “hard”, means that the amplifier can only be enabled using the external contacts available at p12 ...

Page 47: 7.6

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 41 7.6 page 3 parameters figure 17. Q-drive.Exe: page 3 parameters 24 to 53: not used 7.7 page 6 parameters figure 18. Q-drive.Exe: page 6 parameters.

Page 48: 7.8

Q-drive installation manual issue 1.5 page 42 copyright © 1996 quin systems ltd. The parameters on page 6 are read only and as such cannot be changed. 54 resolver position the resolver position is a 12 bit value of the current resolver position within one rotation. 55 revolution counter the revoluti...

Page 49: 7.9

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 43 7.9 page 9 parameters figure 20. Q-drive.Exe: page 9 parameters 74 max peak current (0..127): this parameter defines the maximum peak current that the drive will deliver to the motor 75 max nominal current (0..127): thi...

Page 50: 7.10

Q-drive installation manual issue 1.5 page 44 copyright © 1996 quin systems ltd. 7.10 status & alarm page figure 21. Q-drive.Exe: status display pressing function key from any of the nine pages will bring up the status page as shown above. This page gives a continually updated display of all alarms ...

Page 51

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 45 v battery under voltage the backup battery voltage is too low to reliably maintain the system in the event of a power failure. Vi software watchdog software watchdog has tripped, this usually means that the processor ha...

Page 52

Q-drive installation manual issue 1.5 page 46 copyright © 1996 quin systems ltd. This page is intentionally left blank.

Page 53: Switching On

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 47 8. Switching on preparation of ac brushless servo motors and servo-amplifiers requires a little more attention than that of dc servo-drives. We recommend that switching on for the first time is done according to the fol...

Page 54: 8.3

Q-drive installation manual issue 1.5 page 48 copyright © 1996 quin systems ltd. 8.3 7 segment display on the front panel this display shows the state of the servo-amplifier and motor. The alarm d has the highest priority (following c, 7, 6, 5 etc.). If some alarms take place simultaneously, only th...

Page 55

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 49 8.3.1 checking the electrical rotation sense of the resolver the decimal point of the 7 segment display lights up when the motor shaft is turned clockwise. Figure 23. Electrical rotation sense of the resolver if the dec...

Page 56: 8.4

Q-drive installation manual issue 1.5 page 50 copyright © 1996 quin systems ltd. 8.4 determining the motor phases this operation must only be done when the three-phase motor order is unknown (motor prototype or no documentation). It is necessary to have a dc supply of about 3a. And of sufficient vol...

Page 57: 8.5

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 51 8.5 switch the servo amplifier on with a motor and optimization 8.5.1 preparation before switching the mains voltage on a) disconnect motor from the machine. The 3 phases motor should be again connected to the servo-amp...

Page 58: 8.6

Q-drive installation manual issue 1.5 page 52 copyright © 1996 quin systems ltd. 8.6 compensating the speed controller optimizing the performance of the motor over the whole speed range can be achieved by adjusting the drive amplifiers proportional gain and integral gain parameters. Connect a person...

Page 59

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 53 the motor remaining stationary, find the limits of the range and set the value to the mid point. Press the key to save this value. B) speed compensation the speed factor parameter allows adjustment of the motor speed fr...

Page 60: 8.7

Q-drive installation manual issue 1.5 page 54 copyright © 1996 quin systems ltd. 8.7 trouble shooting the following table shows the most frequent troubles and their causes. No trouble possible cause 1 led “over i” switched on short-circuit between 2 motor terminals 2 display 2 limit of continuous cu...

Page 61: Testing The System

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 55 9. Testing the system 9.1 general this section describes some simple test procedures for some parts of the q-drive systems. These do not comprise a full system test, but may be useful to verify the basic operation of th...

Page 62: 9.4

Q-drive installation manual issue 1.5 page 56 copyright © 1996 quin systems ltd. 9.4 encoder simulator the operation of the encoder simulator can be checked using a control system such as a quin systems pts unit. Connect the encoder output of the drive to the encoder input on a pts system and switch...

Page 63: 10.

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 57 10. Configurations 10.1 general this section gives details of the configuration options on all the drive boards used in the q-drive range of servo amplifiers, although the settings are not normally changed. The amplifie...

Page 64: 10.3

Q-drive installation manual issue 1.5 page 58 copyright © 1996 quin systems ltd. 10.3 amplifier configuration the location of the solder bridges and jumper links used for configuration and the fuse locations is given in figure 26. On page 64 . 10.4 servo-amplifier fuses the following fuses are facto...

Page 65

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 59 for unit types qdv-1-10 and -18, “littlefuse 314" type fuses are used. Dimensions: 6,3 x 32 mm. Supply fuse(fht) all qdv-1 drives use a 20mm fuse warning: blown fuses should only be replaced with the same type and ratin...

Page 66: 10.5

Q-drive installation manual issue 1.5 page 60 copyright © 1996 quin systems ltd. 10.5 backplane configuration the various jumpers available on the q-drive backplane are detailed in table 13: below. Figure 24. On page 61 shows the jumpers in their default positions table 13: backplane configuration j...

Page 67

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 61 figure 24. Backplane configuration 2 d e p4 1 3 4 5 6 7 8 9a b c 1 1 1 rs422/232 j6 j5 p11 p12 s w 1 0 1 f j4 j3 j2 p10 j1 e n c o d e r resolver p3 rs422 p2 upper p2 lower.

Page 68: 10.6

Q-drive installation manual issue 1.5 page 62 copyright © 1996 quin systems ltd. 10.6 backplane fuse the backplane is fitted with a single fuse rated at 500ma fast blow. This fuse is used to protect the auxiliary supply when this option is fitted. It is accessed by removing the front panel and extra...

Page 69: 11.

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 63 11. Options list absolute position the resolver and associated circuits can be permanently powered by an external +/- 12v battery supply. This option is wired onto the q-drive backplane using connectors p11 and p12 grou...

Page 70

Q-drive installation manual issue 1.5 page 64 copyright © 1996 quin systems ltd. Layout of drive amplifier figure 26. Drive amplifier jumper & fuse locations f h t f1 f f r sad r c o s r r e f rsin incabs mo01 vitcrt tri sad imax bo1 bo2 bo3 bo4.

Page 71

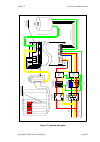

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 65 figure 27. Complete wiring plan 2ø 3 a m p mcb 1ø is ol at in g transformer e ø2 ø3 ø1 pts control system screened motor cable use p3 or p4 to connect to pc com port screened encoder cable connect to pc com port or dumb...

Page 72

Q-drive installation manual issue 1.5 page 66 copyright © 1996 quin systems ltd. This page is intentionally left blank.

Page 73: Index

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 67 index a acceleration 31 alarm battery undervoltage 45 earth defect 44 eeprom fault 44 endswitch 45 heatsink thermostat 45 i2t current limit 45 link motor 45 motor thermostat 45 power fault 45 rdc fault 44 resolver fault...

Page 74

Q-drive installation manual issue 1.5 page 68 copyright © 1996 quin systems ltd. L led’s 47 m machine guards 29 machinery directive 11 mains supply installation 24 maintaining position information 29 max nominal current 43 max peak current 43 maximum current 36 motor connections 27, 28 motor inertia...

Page 75

Issue 1.5 q-drive installation manual copyright © 1996 quin systems ltd. Page 69 w weight 7 width 7 wiring faults 56.