- DL manuals

- R.P.S. Corporation

- Floor Machine

- MAGNUM series

- Service Manual

R.P.S. Corporation MAGNUM series Service Manual

Summary of MAGNUM series

Page 1

Service manual r.P.S. Corporation phone: 1-800-634-4060 p.O. Box 241 fax: 1-866-632-6961 racine, wisconsin version 1.0 ma gnum series r.P.S. Corporation phone: 1-800-450-9824 p.O. Box 241 fax: 1-866-632-6961 racine, wisconsin 53401 www.Tomcatequip.Com operator and parts manual m o d e l m a g n u m.

Page 2

Caution! Ii to reduce the chance of personal injury and/or property damage, the following instructions must be careful observed: proper service and repair are important to the safety of the service technician and the safe reliable operation of all cleaning equipment. If part replacement is necessary...

Page 3

Foreword iii factory cat/tomcat service manuals are intended for use by professional, qualified technicians. Attempting repairs or service without the appropriate training, tools, and equip- ment could cause injury to you or others and damage to your piece of equipment that may cause it not to operat...

Page 4

Safety iv safety message your safety and the safety of others is very important and operating this unit safely is an important responsibility. To help you make informed decisions about safety, we have provided opera- tion procedures and other safety information in this manual. This information infor...

Page 5

Safety v safety precautions • hazardous voltage. Shock, burns or electrocution can result. Always disconnect the batteries before servicing machine. • batteries emit hydrogen gases, explosion or fire can result. Keep sparks and open flame away! • charge unit in a well ventilated area and keep battery ...

Page 7

Magnum service manual v1.0 toc toc - i table of contents contents maintenance 1-1 maintenance schedule .......................................................1-1 lubrication ......................................................................................1-1 machine parts 2-1 control descriptio...

Page 8

Magnum service manual v1.0 toc toc - ii table of contents solution system 6-1 dispensing solution .............................................................6-1 adjusting solution flow ...........................................................6-2 draining solution tank ..............................

Page 9

Magnum service manual v1.0 toc toc - iii table of contents battery safety 11-1 danger of exploding batteries ........................................... 11-1 safe charging .............................................................................. 11-1 handling battery acid .........................

Page 10

Magnum service manual v1.0 toc toc - iv table of contents computer control system 13-1 controller overview ........................................................ 13-1 inputs ...............................................................................................13-1 outputs ...................

Page 11

Specifications spec-1 machine length 58 3/4 in. (149cm) machine height 40 1/4 in. (102cm) machine chassis width 24.1/2 in. (62 cm) machine current consumption (average) 55 amps brush motor: up to 70 amps vacuum motor: up to 30 amps transport drive: up to 70 amps solution tank capacity 30 gallons (11...

Page 12

Specifications spec-2 magnum-26c magnum-26d magnum-30c magnum-30d magnum-34c magnum-34d machine width with squeegee 32 3/4 in. 32 3/4 in. 36 3/4 in. 36 3/4 in. 43 3/4 in. 43 3/4 in. 83 cm 83 cm 93 cm 93 cm 111 cm 111 cm scrub brush size (qty. 2) 22 x 5.5 in. 13 in. 28 x 5.5 in. 15 in. 32 in. X 5.5 i...

Page 13

Magnum service manual v1.0 1 1-1 maintenance maintenance maintenance schedule attention! Make sure machine is turned off and the batteries are disconnected before performing any repairs or service on the machine! Your machine is equipped with four brush-type motors that require periodic inspection t...

Page 14

Magnum service manual v1.0 1 1-2 maintenance ...

Page 15

Magnum service manual v1.0 1 1-3 maintenance ...

Page 16

Magnum service manual v1.0 1 1-4 maintenance blank this page was intentionally left blank.

Page 17

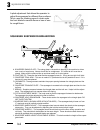

Magnum service manual v1.0 2 2-1 machine introduction machine parts page 7 figure 1. Machine controls and features 1 2 3 4 5 6 7 8 14 13 12 11 10 9 16 17 18 24 31 25 29 28 23 30 26 27 32 33 34 39 35 36 37 38 40 20 22 21 figure 3. Figure 2. Figure 4a. Figure 4b. 19 15 9. Squeegee lift lever 10. Spray...

Page 18

Magnum service manual v1.0 2 2-2 machine introduction page 7 figure 1. Machine controls and features 1 2 3 4 5 6 7 8 14 13 12 11 10 9 16 17 18 24 31 25 29 28 23 30 26 27 32 33 34 39 35 36 37 38 40 20 22 21 figure 3. Figure 2. Figure 4a. Figure 4b. 19 15 page 7 figure 1. Machine controls and features...

Page 19

Magnum service manual v1.0 2 2-3 machine introduction 1. Main power switch: turns the machine on and off. 2. Forward/reverse switch (red): makes the machine move backwards when depressed. 3. Speed control knob: controls the speed of the traction drive. 4. Lcd screen: lists status, functions and sett...

Page 20

Magnum service manual v1.0 2 2-4 machine introduction blank this page was intentionally left blank.

Page 21

Magnum service manual v1.0 3 3-1 squeegee system squeegee system the magnum’s squeegee system is designed to work with the recovery system to pick up water and dirt from the floor using air flow created by the vacuum motor. The front blade of the squeegee tool is designed with notches that allow the a...

Page 22

Magnum service manual v1.0 3 3-2 squeegee system a pitch adjustment that allows the operator to adjust the squeegee for different floor surfaces. This is used for creating more of a leak under the front blade for smooth floors or less of one for rough floors. squeegee suspension...

Page 23

Magnum service manual v1.0 3 3-3 squeegee system squeegee blades squeegee blades are wear items. The back blade wears fastest on the edge that contacts the floor (lower front edge). This blade can ideally be turned four times. It is important to have a sharp squeegee edge on the floor; otherwise the s...

Page 24

Magnum service manual v1.0 3 3-4 squeegee system replacing blades we stock individual blades or blade kits that include a blade set and new set of squeegee wheels. We recommend changing wheels when you change blades as they are wear items and they are critical to the proper operation of the squeegee...

Page 25

Magnum service manual v1.0 3 3-5 squeegee system squeegee adjustment a squeegee needs to be adjusted to the type of surface that it is operating on. This means the adjustments that pick up well on rough concrete will probably not work well on glass- smooth vinyl tile or ceramic tile. The reverse wou...

Page 26

Magnum service manual v1.0 3 3-6 squeegee system ...

Page 27

Magnum service manual v1.0 3 3-7 squeegee system the squeegee assemble has adjustable squeegee wheels. The adjustment for this is a 5/16 fine thread bolt and lock nut. It was designed this way to keep non-service person- nel from adjusting it. The squeegee wheels wear with use and periodic adjustment...

Page 28

Magnum service manual v1.0 3 3-8 squeegee system ...

Page 29

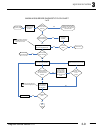

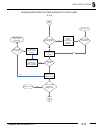

Magnum service manual v1.0 3 3-9 squeegee system squeegee does not pick up water check for good suction and air flow at the squeegee hose. Is there good suction and flow? Go to recovery system diagnosis operate the machine and verify the customers complaint is there a problem with the machine? Verif...

Page 30

Magnum service manual v1.0 3 3-10 squeegee system from previous page are there missing parts? Check to make sure the spacers, washers and springs are all there and in working order. Verify the measurement where the front of the triangle plate bolts to the towbar. There should be exactly 7/8" clearan...

Page 31

Magnum service manual v1.0 4 4-1 squeegee lift system squeegee lift system the squeegee lift system on the magnum was designed with simplicity in mind. It has very straight forward operation and minimal parts to assure consistent and highly reliable opera- tion. To operate move the squeegee lift lev...

Page 32

Magnum service manual v1.0 4 4-2 squeegee lift system blank this page was intentionally left blank.

Page 33

Magnum service manual v1.0 5 5-1 recovery system recovery system the recovery system of the magnum series is powered by a 24 volt 550 watt vacuum motor. The recovery tank is designed with a large lid to facilitate 100% access for complete clean- ing out the recovery tank when use of the machine is fi...

Page 34

Magnum service manual v1.0 5 5-2 recovery system to clean the vacuum float: remove the white retaining clamp from the screen. Pull the vac screen / float ball assembly off the vac box. Rinse with hot water. Scrub with a brush if necessary dry thoroughly. Replace vac screen / float ball assembly onto va...

Page 35

Magnum service manual v1.0 5 5-3 recovery system vacuum motor the vacuum motor used on the magnum series scrubbers is a high efficiency, shunt would motor. The motor runs a approximately 12, 000 rpm. The motor is rated at 550 watts and has 72” of water lift. Although the motor has service parts avail...

Page 36

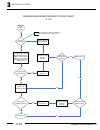

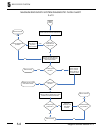

Magnum service manual v1.0 5 5-4 recovery system machine is not picking up water. Is the vacuum switch turned on? Did this remedy the problem? Instruct customer on how to operate their machine does the vacuum motor run? Go to vacuum motor diagnosis section no yes no bill customer is the recovery tan...

Page 37

Magnum service manual v1.0 5 5-5 recovery system is squeegee clogged? Clean the squeegee. Inspect the blades and wheels. Replace parts as necessary. Install squeege back on the machine and test operation. Did this remedy the problem? Instruct customer on proper machine maintenance check vacuum lift ...

Page 38

Magnum service manual v1.0 5 5-6 recovery system check inside the hose for obstructions were any obstructions or clogs found? Clean out obstructions or clogs and retest machine. Did this remedy the problem? Bill the customer remove the float cage and measure the vacuum at the float screen bracket is...

Page 39

Magnum service manual v1.0 5 5-7 recovery system blank this page was intentionally left blank.

Page 40

Magnum service manual v1.0 6 6-1 solution system solution system the solution system on the magnum series consists of main body of the machine which is also the solution tank, the fill opening, sight gauge/drain, filter, potentiometer, controller, and solution solenoid valve. The solution is turned on...

Page 41

Magnum service manual v1.0 6 6-2 solution system solution system electrical circuit the electrical circuit of the magnum series is divided into two parts. The input circuit and the output circuit. The input circuit consists of the controller, the scrub switch and the solution potentiometer. The cont...

Page 42

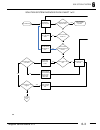

Magnum service manual v1.0 6 6-3 solution system no solution flow is there water in the tank does water flow out of the filter? Remove the solution filter screen test machine / verify complaint does the machine dispense water? Fill solution tank with water no yes is the solution screen clogged? Solu...

Page 43

Magnum service manual v1.0 6 6-4 solution system use a voltmeter to test for voltage across the deltrol valve terminals when the green handle bar button is depressed. Make sure to measure for at least 10 seconds. Do you have either a pulsing or steady 24 volts? Check the screw on the back of the del...

Page 44

Magnum service manual v1.0 7 7-1 brush drive system brush drive system the brush drive system on the magnum series comes in two versions. The disc type and the cylindrical type. Each one has its own merits although they do the same thing which is turn the scrub brush or scrub pad. Cylindrical the cy...

Page 45

Magnum service manual v1.0 7 7-2 brush drive system setting brush pressure the scrub deck pressure is adjusted continuously while scrubbing. Using the brush pres- sure switch on the control panel you set the desired scrubbing pressure. The desired brush pressure is shown on a bar graph on the lcd di...

Page 46

Magnum service manual v1.0 7 7-3 brush drive system installing & removing brushes disc machines with the machine turned on, turn off the brush deck switch. Turn machine power off. Open the two latches on the jaws and swing them aside. Rotate each brush until both tabs of the spring clip are accessib...

Page 47

Magnum service manual v1.0 7 7-4 brush drive system blank this page intentionally left blank.

Page 48

Magnum service manual v1.0 8 8-1 brush lift system brush lift system the active brush lift system on the magnum series consists of an actuator, down pres- sure springs, scrub switch and the controller. The brush deck is raised and lowered by the brush deck actuator which is driven by the controller....

Page 49

Magnum service manual v1.0 8 8-2 brush lift system down pressure down pressure is regulated by the controller on the machine as. The desired brush pres- sure is selected by using the brush pressure switch on the control panel. The brush pres- sure selection is read out on the lcd display in the form...

Page 50

Magnum service manual v1.0 8 8-3 brush lift system if the brush head lifts too high when it is in the full-raised position it may not have enough travel to extend low enough to reach into recesses in the floor. If the machine exhibits this condition, lower the overall brush height by backing out the ...

Page 51

Magnum service manual v1.0 8 8-4 brush lift system blank this page was intentionally left blank.

Page 52

Magnum service manual v1.0 9 9-1 traction drive system traction drive system the magnum series of scrubbers is powered by and electric transaxle system. The trans- axle is self contained and bolts to the bottom of the frame. The trans-axle is equipped with a 1/2 horsepower motor that transfers power...

Page 53

Magnum service manual v1.0 9 9-2 traction drive system blank this page intentionally left blank.

Page 54

Magnum service manual v1.0 10 10-1 chassis system chassis system the chassis system on the magnum series is built on a heavy duty 7 gauge powder coated full frame. The frame gives the machine great strength and durability. Everything is fas- tened to the frame using stainless steel hardware allowing...

Page 55

Magnum service manual v1.0 10 10-2 chassis system blank this page was intentionally left blank.

Page 56

Magnum service manual v1.0 11 11-1 battery system battery safety danger of exploding batteries batteries contain sulfuric acid and produce explosive mixtures of hydrogen and oxygen. Because self-discharge action generates hydrogen gas even when the battery is not in op- eration. Make sure batteries ...

Page 57

Magnum service manual v1.0 11 11-2 battery system handling battery acid battery acid, or electrolyte, is a solution of sulfuric acid and water that can destroy clothing and burn the skin. Use extreme caution when handling electrolyte and keep an acid neu- tralizing solution - such as baking soda or ...

Page 58

Magnum service manual v1.0 11 11-3 battery system stud terminal the stud terminal is typically used on heavy duty batter- ies. The terminals have a stainless steel threaded stud embedded in them that the connections are made to. Combination terminal the combination terminals come in a few different ...

Page 59

Magnum service manual v1.0 11 11-4 battery system battery system the battery system for the magnum series consists of either 2 - 12 volt or 4 -6 volt deep cycle batteries. They are offered in 3 different sizes of lead acid and 2 sizes of mainte- nance free gel battery for each machine. The batteries...

Page 60

Magnum service manual v1.0 11 11-5 battery system battery cables & terminals the battery cable connections must remain tight and corrosion free. In the event that the battery cables or terminals become corroded follow accepted battery safety precautions, disassemble and clean the terminals with a ba...

Page 61: Open Circuit

Magnum service manual v1.0 11 11-6 battery system the state-of-charge of a lead acid battery can be determined by the specific gravity of the electrolyte (its weight compared to water). The specific gravity can be measured directly with a hydrometer or determined by the stabilizing voltage. A hydromet...

Page 62

Magnum service manual v1.0 11 11-7 battery system when testing with a load tester you are looking for a difference between cells of the batter- ies. All the battery cells should have similar readings. Any battery that contains a cell that has a value lower than .050 of the rest of the cells indicate...

Page 63

Magnum service manual v1.0 11 11-8 battery system battery replacement when replacing batteries in a machine it is important to replace them with quality batteries that are designed for high-output deep-cycle applications, such as the ones furnished by the factory when the machine was new. All batter...

Page 64

Magnum service manual v1.0 11 11-9 battery system on-board charger an on-board charger is offered as an option on the magnum series of machines. The charger is a waterproof charger that is mounted right to the chassis of the scrubber. It is operated by simply plugging the power cord into the wall. T...

Page 65

Magnum service manual v1.0 11 11-10 battery system 2 ...

Page 66

Magnum service manual v1.0 11 11-11 battery system see the following chart as to what the light mean. Important note! Do not unplug any charger’s dc plug from the machine while the charger is running. This can cause an electrical arc that can ignite any flammable gasses that are in the area from eith...

Page 67

Magnum service manual v1.0 11 11-12 battery system blank this page intentionally left blank.

Page 68

Magnum service manual v1.0 12 12-1 electrical system electrical system the electrical system on the magnum series is a 24 volt system. This is not a chassis ground system for safety reasons. Switches the switches we use all have a similar face but are configured differently internally. Major- ity of ...

Page 69

Magnum service manual v1.0 12 12-2 electrical system vacuum motor the vacuum motor is a very high speed motor that develops vacuum for the recovery sys- tem. The motors are designed to give a service life of 500 hours. See the “recovery sys- tem” chapter 5 for more information. Actuators the magnum ...

Page 70

Magnum service manual v1.0 12 12-3 electrical system controller high amp output terminals (brush, vacuum, traction) the controller high amp output connectors are crimped with a special crimping tool at the factory. The tool is not practical to use in the field so in the event that a new terminal is n...

Page 71

Magnum service manual v1.0 12 12-4 electrical system 5 5 4 4 3 3 2 2 1 1 d d c c b b a a yellow yellow yellow yellow yellow yellow yellow #254 yellow #254 yellow #254 green #295 red/wht #294 orange #242 orange #242 orange #242 black #29 black #29 black #31 black #31 red #27 red #27 red #27 red #27 r...

Page 72

Magnum service manual v1.0 12 12-5 electrical system 5 5 4 4 3 3 2 2 1 1 d d c c b b a a white #131 white #131 white #131 orange #71 black #72 pink #130 pink #130 pink #130 black #184 black #184 black #184 red #183 red #183 red #183 bla ck #7 2 to controller to controller to controller to controller...

Page 73

Magnum service manual v1.0 12 12-6 electrical system ...

Page 74

Magnum service manual v1.0 12 12-7 electrical system ...

Page 75

Magnum service manual v1.0 12 12-8 electrical system ...

Page 76

Magnum service manual v1.0 12 12-9 electrical system ...

Page 77

Magnum service manual v1.0 12 12-10 electrical system ...

Page 78

Magnum service manual v1.0 12 12-11 electrical system blank this page was intentionally left blank.

Page 79

Magnum service manual v1.0 13 13-1 computer control system computer control system the magnum series of machines is equipped with the central command ii control system. Central command ii is designed around a very powerful controller that is has a industrial computer integrated into it. The controll...

Page 80

Magnum service manual v1.0 13 13-2 computer control system soft start three of the outputs; traction, brush & vacuum, have a soft start function on them. This function provides the ability to start and stop a motor gradually over a measured period of time, 0-10 seconds. This aids in the longevity of...

Page 81

Magnum service manual v1.0 13 13-3 computer control system screen 1 screen 1 is the default screen that appears after the machine has powered up. 1: battery meter - this meter shows the charge level of the batteries in the machine. This gauge is designed to read properly while the machine is in use ...

Page 82

Magnum service manual v1.0 13 13-4 computer control system screen 3 to access this from screen 1 press the green page button twice. 9: battery meter - this meter shows the charge level of the batteries in the machine. This gauge is designed to read properly while the machine is in use and therefore ...

Page 83

Magnum service manual v1.0 13 13-5 computer control system diagnosing the control system the central command ii system with all its robust capabilities is also very easy to diagnose and repair. To diagnose the system a clamp type dc amp meter and high impedance dc volt meter are required. The machin...

Page 84

Magnum service manual v1.0 13 13-6 computer control system decide what device there is a request for and how it should operate the device. Tri-state logic the central command ii system uses very low voltage throughout it’s control system. This voltage is less than battery voltage and the controller ...

Page 85

Magnum service manual v1.0 13 13-7 computer control system programming we use the same controllers on nearly all of our machines. The controller’s embedded computer needs a set of instructions to operate the machine. The instructions are the program the computer runs and we can modify this program b...

Page 86

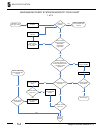

Magnum service manual v1.0 13 13-8 computer control system magnum battery diagnostic flow chart 1 of 1 batteries are not working properly / diminished run time. Operate machine and verify the customers complaint. Do the batteries work properly? Instruct owner on proper machine operation yes are the ...

Page 87

Magnum service manual v1.0 13 13-9 computer control system magnum brush deck actuator diagnostic flow chart 1 of 1 brush deck actuator does not operate properly. Operate machine and verify the customers complaint. Does the actuator work properly? Instruct owner on proper machine operation yes does t...

Page 88

Magnum service manual v1.0 13 13-10 computer control system “brush pressure” switch does not work. Operate machine and verify the customers complaint. Does the switch work properly? Instruct owner on proper machine operation yes using voltmeter set the meter to dc volts. Connect the ( -) probe of th...

Page 89

Magnum service manual v1.0 13 13-11 computer control system from page 1 “a” place the ( + ) probe back on the center terminal of the switch. (yellow wire) move the switch down and note your reading. Was the voltage between 0 and 0.3 volts? Call the factory yes place the ( + ) probe back on the botto...

Page 90

Magnum service manual v1.0 13 13-12 computer control system “brush switch” does not work. Operate machine and verify the customers complaint. Does the switch work properly? Instruct owner on proper machine operation yes is the one touch switch off? The one touch switch is the large green button righ...

Page 91

Magnum service manual v1.0 13 13-13 computer control system did the voltage of the terminal raise to between 4.8 and 5.2 volts when the switch was moved up? Replace the brush pressure switch yes with a voltmeter set to the dc volt scale measure from the negative buss bar to the rear terminal of the ...

Page 92

Magnum service manual v1.0 13 13-14 computer control system “( + ) buss bar” does not power up. Operate machine and verify the customers complaint. Is the (+) buss bar receiving battery voltage? Instruct owner on proper machine operation yes magnum buss relay diagnostic flow chart 1 of 2 does the ma...

Page 93

Magnum service manual v1.0 13 13-15 computer control system repair break in the wiring between terminal #86 (black wire) and the negative buss bar is there battery voltage across these terminals? Yes using a voltmeter set the meter to dc volts. Measure the voltage between terminals #85 (red wire) an...

Page 94

Magnum service manual v1.0 13 13-16 computer control system “drive motor” does not work. Operate machine and verify the customers complaint. Does the drive motor work properly? Instruct owner on proper machine operation yes magnum drive motor diagnostic flow chart 1 of 1 does anything else on the ma...

Page 95

Magnum service manual v1.0 13 13-17 computer control system magnum emergency stop diagnostic flow chart 1 of 1 “emergency stop switch” does not work. Operate machine and verify the customers complaint. Does the emergency stop work properly? Instruct owner on proper machine operation yes can you depr...

Page 96

Magnum service manual v1.0 13 13-18 computer control system “key switch” does not work. Operate machine and verify the customers complaint. Does the switch work properly? Instruct owner on proper machine operation yes magnum key switch diagnostic flow chart 1 of 1 using a voltmeter set to dc volts. ...

Page 97

Magnum service manual v1.0 13 13-19 computer control system lcd window does not operate properly. Operate machine and verify the customers complaint. Is there something wrong with the display? Instruct owner on proper machine operation replace the display and 6 wire harness with a known good or a ne...

Page 98

Magnum service manual v1.0 13 13-20 computer control system onboard charger does not work operate machine and verify the customers complaint. Does the charger work properly? Instruct owner on proper machine operation yes magnum onboard charger diagnostic flow chart 1 of 1 ask customer to plug the ma...

Page 99

Magnum service manual v1.0 13 13-21 computer control system onboard charger does not work operate machine and verify the customers complaint. Does the charger work properly? Instruct owner on proper machine operation yes magnum onboard charger diagnostic flow chart 1 of 1 ask customer to plug the ma...

Page 100

Magnum service manual v1.0 13 13-22 computer control system from page 1 -a- with a voltmeter set to the dc scale measure the voltage of the battery pack in the machine. Is the voltage above 4.0 volts? Does the green light turn on when the charger is plugged into the wall? No replace the charger. Yes...

Page 101

Magnum service manual v1.0 13 13-23 computer control system “page” switch is in operative. Operate machine and verify the customers complaint. Does the switch work properly? Instruct owner on proper machine operation unplug the 20 pin connector from the back of the lcd display using and ohm meter me...

Page 102

Magnum service manual v1.0 13 13-24 computer control system squeegee actuator does not operate properly. Operate machine and verify the customers complaint. Does the actuator work properly? Instruct owner on proper machine operation yes magnum squeegee actuator diagnostic flow chart 1 of 1 does the ...

Page 103

Magnum service manual v1.0 13 13-25 computer control system “vacuum motor” does not run. Operate machine and verify the customers complaint. Does the motor work properly? Instruct owner on proper machine operation yes magnum vacuum motor diagnostic flow chart 1 of 1 turn on the vac motor switch and ...

Page 104

Magnum service manual v1.0 13 13-26 computer control system magnum water potentiometer diagnostic flow chart 1 of 3 water potentiometer does not change water delivery. Operate machine and verify the customers complaint. Can you change water volume with the potentiometer? Instruct owner on proper mac...

Page 105

Magnum service manual v1.0 13 13-27 computer control system was there a smooth sweeping voltage from 0 to 5 volts? While it’s disconnected, measure the voltage at the orange wire that was connected to the center terminal of the potentiometer. Was there between 0.8 and 2.7 volts? Yes with a voltmeter...

Page 106

Magnum service manual v1.0 13 13-28 computer control system unscrew the solution screen and make sure that water flows freely out of the filter when the bowl and filter are off. Was there a good solid flow of water out of the filter bowl? The solution tank or the feed line to the filter bowl is clog...

Page 107

Magnum service manual v1.0 13 13-29 computer control system spray jet does not work properly operate machine and verify the customers complaint. Is there something wrong with the spray jet? Instruct owner on proper machine operation magnum spray jet diagnostic flow chart 1 of 2 does the spray jet pu...

Page 108

Magnum service manual v1.0 13 13-30 computer control system was there battery voltage? Yes with a voltmeter set to the dc scale measure from the negative lead to the positive battery terminal. Was there battery voltage? With a voltmeter set to the dc scale measure from both the leads at the spray je...

Page 109

Ri ri-1 repair instructions magnum service manual v1.0 2/23/2006 253-01 vacuum motor r&r page 1 of 5 help hotline: 800-634-4060 time required: 30 minutes number of techs: 1 person required parts 290-250 vacuum motor qty(1) 4’’ wire tie qty(2) 10-12 butt connectors required tools 7\16 12 poin...

Page 110

Ri ri-2 repair instructions magnum service manual v1.0 2/23/2006 253-01 vacuum motor r&r page 2 of 5 help hotline: 800-634-4060 2. Release the latch on the front of the jaws and open them. (see figure below) need pitcher when new parts are here 3. Carefully tip tank back. (see figure below) disconne...

Page 111

Ri ri-3 repair instructions magnum service manual v1.0 2/23/2006 253-01 vacuum motor r&r page 3 of 5 help hotline: 800-634-4060 3. Pull the red cable off and secure away from post .( see figure below) vacuum motor is located on the bottom side of recovery and soltion tank (see figure below) removing...

Page 112

Ri ri-4 repair instructions magnum service manual v1.0 2/23/2006 253-01 vacuum motor r&r page 4 of 5 help hotline: 800-634-4060 1. Using a side cutters remove the yellow 10-12 awg butt connectors. (see figure below) 2. Using 7\16”12 point deep well socket remove the (qty: 3) 1\4 -20 nylock nuts that...

Page 113

Ri ri-5 repair instructions magnum service manual v1.0 2/23/2006 253-01 vacuum motor r&r page 5 of 5 help hotline: 800-634-4060 2. Locate red and black wires from machine and the two black wires from new vacuum motor strip 5\16”off each end. (see figure below) 3. Using a crimper with insolated 10 &1...

Page 114

Ri ri-6 repair instructions magnum service manual v1.0 2/23/2006 253-02 draining tanks page 1 of 1 help hotline: 800-634-4060 number of techs: 1 person completely draining recovery and solution tanks. 1. Make sure machine is on level ground and by a floor drain. 2. Pull down on solution drain hose a...

Page 115

Ri ri-7 repair instructions magnum service manual v1.0 2/23/2006 253-03 handle bar button switch r&r page 1 of 2 help hotline: 800-634-4060 time required: 30 minutes per: switch number of techs: 1 person required parts qty(2) 1/2’’ long 16 awg shrink tubing qty(2) 7-229 push button switch requir...

Page 116

Ri ri-8 repair instructions magnum service manual v1.0 2/23/2006 253-03 handle bar button switch r&r page 2 of 2 help hotline: 800-634-4060 removing old push button switch plate 1. Using a 3” #2 phillips head screw driver remove the two 8\32x1\2” screws that hold the switch plate on handle bars. 2. ...

Page 117

Ri ri-9 repair instructions magnum service manual v1.0 2/23/2006 253-04 disconnecting batteris page 1 of 1 help hotline: 800-634-4060 number of techs: 1 person required parts none required tools 9\16 12- point box wrench place machine on level ground and chock wheels. Disconnecting batteries 1. ...

Page 118

Ri ri-10 repair instructions magnum service manual v1.0 2/23/2006 253-05 transaxle r&r page 1 of 4 help hotline: 800-634-4060 time required: 45 minutes number of techs: 1 person required parts 32- 3000 transaxle qty(1) 8” wire tie qty(2) 10-12 butt connectors required tools 9\16” 12 point so...

Page 119

Ri ri-11 repair instructions magnum service manual v1.0 2/23/2006 253-05 transaxle r&r page 2 of 4 help hotline: 800-634-4060 removing transaxle 1. Using a 1/2” socket remove the (qty 4) 5/16 nuts that hold each tire on axle.(remove tiers) 2. Cut the wire tie that is around the wires harness located...

Page 120

Ri ri-12 repair instructions magnum service manual v1.0 2/23/2006 253-05 transaxle r&r page 3 of 4 help hotline: 800-634-4060 4. Mark transaxle mounts and frame on both sides of machine before removing. (see figure below) 5. Using a 1\2” socket remove the (qty 2) 5\16-18 nuts that hold the each (qty...

Page 121

Ri ri-13 repair instructions magnum service manual v1.0 2/23/2006 253-05 transaxle r&r page 4 of 4 help hotline: 800-634-4060 reinstalling transaxle 1. Strip red and black transaxle wires 5\16”. 2. Strip red and black harness wires 5\16”. 3. Crimp butt connectors on to transaxle wires. 4. Carefully ...

Page 122

Ri ri-14 repair instructions magnum service manual v1.0 2/23/2006 253-06 jacking up disk machine page 1 of 1 help hotline: 800-634-4060 number of techs: 1 person required tools 3 ton jack (qty:2) wheel chocks completely drain recovery and solution tanks. (see repair instruction # 253-04) make su...

Page 123

Ri ri-15 repair instructions magnum service manual v1.0 2/23/2006 253-07 jacking up cylindrical machine page 1 of 1 help hotline: 800-634-4060 number of techs: 1 person required tools 3 ton jack (qty:2) wheel chocks completely drain recovery and solution tanks. (see repair instructoin # 253-04) ...

Page 124

Ri ri-16 repair instructions magnum service manual v1.0 2/23/2006 253-09 cylindrical belt r&r page 1 of 3 help hotline: 800-634-4060 time required: 15 minutes number of techs: 1 person required parts (qty: 1) 353-8230 cylindrical belt required tools 9/16’’ crows foot 3/8’’ drive 9/16’’ open en...

Page 125

Ri ri-17 repair instructions magnum service manual v1.0 2/23/2006 253-09 cylindrical belt r&r page 2 of 3 help hotline: 800-634-4060 2. Using a 9/16’’ open end wrench loosen the (qty: 1) 3/8-24 locking nut and (qty: 1) 3/8-24x1’’ belt tension bolt. (see figure below) belt tention bolt locking nut 3....

Page 126

Ri ri-18 repair instructions magnum service manual v1.0 2/23/2006 253-09 cylindrical belt r&r page 3 of 3 help hotline: 800-634-4060 installing new cylindical belt 1. Install belt on top sprocket then slip it onto bottom sprocket. 2. Using a 9/16’’ open end wrench slowly tighten the 3/8’’-24x1’’ bel...

Page 127

Ri ri-19 repair instructions magnum service manual v1.0

Page 128

Ri ri-20 repair instructions magnum service manual v1.0

Page 129: Index

Magnum service manual v1.0 index i index index s squeegee system 3-1 lift system 3-1 squeegee tool 3-1.

Page 130

Magnum service manual v1.0 index ii index.

Page 131

Magnum service manual v1.0 index iii index.

Page 132

Safety iv safety message your safety and the safety of others is very important and operating this unit safely is an important responsibility. To help you make informed decisions about safety, we have provided operation procedures and other safety information in this manual. This information informs...

Page 133

Safety v safety precautions • hazardous voltage. Shock, burns or electrocution can result. Always disconnect the batteries before servicing machine. • batteries emit hydrogen gases, explosion or fire can result. Keep sparks and open flame away.! • charge unit in a well ventilated area and keep battery...

Page 134

Magnum service manual v1.0 index vi index.