- DL manuals

- R.P.S. Corporation

- Scrubber

- XR 34'' CYLINDRICAL

- Operating Instructions Manual

R.P.S. Corporation XR 34'' CYLINDRICAL Operating Instructions Manual

XR

Operating Instructions (EN)

MODELS:

34'' DISK

40'' DISK

46'' DISK

34'' CYLINDRICAL

40'' CYLINDRICAL

46'' CYLINDRICAL

www.rpscorporation.com

www.factorycat.com

VERSION 14.0117

www.tomcatequip.com

XR-OP-EN

© 2014 RPS Corporation

Read these Instructions before

using the machine.

Read these Safety Messages

before using the machine.

Summary of XR 34'' CYLINDRICAL

Page 1

Xr operating instructions (en) models: 34'' disk 40'' disk 46'' disk 34'' cylindrical 40'' cylindrical 46'' cylindrical www.Rpscorporation.Com www.Factorycat.Com version 14.0117 www.Tomcatequip.Com xr-op-en © 2014 rps corporation read these instructions before using the machine. Read these safety me...

Page 2

- 2 - xr-op-en introduction this manual is furnished with each new machine. This manual will allow the operator to get the best performance out of your rps manufactured scrubber-drier, sweeper, burnisher, or orbital scrubber. Read this manual thoroughly before operating or servicing the machine. Thi...

Page 3

Xr-op-en - 3 - table of contents introduction 2 about this manual 2 table of contents 3 safety messages 4 safety label locations 6 operation controls 7 operation controls 8 machine components 9 machine components 10 lcd screen menu displays: 11 machine setup 12 un-crating machine: 12 connecting batt...

Page 4: Danger

- 4 - xr-op-en safety messages you will see four kinds of safety reminders in this manual: danger danger indicates a hazardous situation which, if not avoided, will result in death or serious injury. Warning warning indicates a potentially hazardous situation which, if not avoided, could result in d...

Page 5: Warning

Xr-op-en - 5 - warning the batteries in this machine produce hazardous voltage which can cause electrical shock, burns and/ or electrocution. Always disconnect batteries before servicing this machine. Warning when climbing or descending ramps, always drive machine forward. To avoid overturning the m...

Page 6: Danger

- 6 - xr-op-en safety label locations read and obey all safety labels on your xr floor scrubber. If you have questions about these labels, ask your supervi- sor. These images indicate where on the xr safety labels are located. If ever the labels become illegible, worn off, or torn, promptly report i...

Page 7

Xr-op-en - 7 - operation controls 1. Lcd screen: lists functions and settings of the machine 2. High water recovery light [red]: indicates when the recovery tank is nearly full 3. Menu control: scrolls through different options on the lcd display - there are 3 different screens it will scroll throug...

Page 8

- 8 - xr-op-en operation controls 1. Headlight switch: turns power of the headlight on and off 2. Horn: sounds the horn for warning oncoming traffi c 3. Adjustable steering: four settings for operator comfort and easy of entry 4. Hour meter: hour meter to indicate complete time machine has been on 5...

Page 9

Xr-op-en - 9 - machine components 1. Strobe light (optional): optional strobe light silently alerts others nearby of the machines presence 2. Recovery tank lid: latch must be secured for recovery tank to seal properly 3. Adjustable seat with arm rests: the machine is equipped with an ergonomic seat ...

Page 10

- 10 - xr-op-en machine components 1. Recovery tank: holds approximately 68 gallons of dirty “recovered” water 2. Solution fill port: holds approximately 68 gallons of clean water 3. Drain saver: prevents debris from clogging drain 4. Foam protection screen: used to protect the vacuum motor from deb...

Page 11

Xr-op-en - 11 - lcd screen menu displays: ** use green menu selection button on control panel to change screens ** 1. Battery level indicator - indicates the energy level remaining in the batteries (shown on all menu displays) 2. Scrubdeck down pressure gauge - sets the down pressure on the brushes ...

Page 12: Notice

- 12 - xr-op-en machine setup un-crating machine: carefully check the crate for any signs of damage and that the batteries are in the unit. To un-crate the machine, remove banding strips from around the crate. Take off the top and sides and dispose properly. Remove brackets from machine wheels. Remo...

Page 13: Notice

Xr-op-en - 13 - adjusting squeegee: 1. Turning adjustment knob (a) clockwise (tightening) will lower tips and raise the center of the squeegee (see below). 2. This squeegee is adjusted too far back and will not pick up on the corners (see below). Note: tips off of the fl oor. 3. This squeegee is adj...

Page 14

- 14 - xr-op-en installing disk pad driver or brush: 1. Turn on machine power. 2. Raise the scrubdeck by depressing the brush switch to the up and off position and turn the machine power back off. Remove key. 3. Loosen star knobs (a) and remove shrouds to access the scrubdeck (see below). 4. If the ...

Page 15: Caution

Xr-op-en - 15 - installing cylindrical brush: 1. Turn on machine power. 2. Raise the scrubdeck by depressing the brush switch to the up and off position and turn machine power back off. Remove key. Caution disconnect the batteries. 3. Remove side wiper pin (a) and open the wipers out- ward to allow ...

Page 16: Notice

- 16 - xr-op-en leveling disk decks: notice all scrubdeck’s should be level at time of machine delivery. If machine scrubdeck is not level - contact your servicing dealer. 1. Drive machine to a fl at level surface and turn machine off. 2. Ensure that scrubdeck is in full upright position. Remove shr...

Page 17: Notice

Xr-op-en - 17 - machine operation pre-cleaning checklist: read and understand the safety messages section on pages 3 and 4 before operating the machine. 1. Check battery condition gauge on the control panel. Make sure batteries are fully charged before using. 2. Check the condition of the pads or br...

Page 18

- 18 - xr-op-en one pass scrubbing: 1. Turn on machine key switch (a). 2. Lower the squeegee by depressing the squeegee switch (g) (vacuum motor will turn on automatically). 3. Lower scrubdeck head to the fl oor by pressing the scrubdeck switch on the control panel (d). 4. Press up or down on the so...

Page 19

Xr-op-en - 19 - adjust shrouds blades: 1. For shroud rubber adjustments, loosen the nylok nuts (a) on the back of the shrouds (see below). 2. To adjust rubber to the desired height, just slide the curtain up or down in the slits and tighten screws. 3. Reattach the shroud to the scrubdeck by sliding ...

Page 20: Notice

- 20 - xr-op-en open recovery lid: 1. Release both latches (a) on recovery tank lid (see below). 2. Rotate lid fully open. Flush recovery tank: 1. Rinse the recovery tank after every use. This will prevent heavy build-up on the bottom of the tank, foul odors as well as clogging of the drain hose. 2....

Page 21

Xr-op-en - 21 - solution filter: the solution system has an “inline filter” (a) to fi lter out cleaning solution prior to scrubbing (see below). Cleaning solution filter: 1. To clean the solution filter, tip tank and then close gate valve (b) (see below). 2. Unscrew the clear cap (c) from house (d) ...

Page 22: Notice

- 22 - xr-op-en draining solution tank: to drain unwanted cleaning solution from the solution tank, perform the following steps: (see below) 1. Tip machine tank back and pull the clear sight tube/drain hose (c) off barbed fi tting. 2. Rinse out tank and solution fl ow system with clean water. Draini...

Page 23: Danger

Xr-op-en - 23 - battery charging charger specifi cations • output voltage of 36 volts • output current of 36 amps max (optional) • input voltage of 110 volts/ 60 hz (220v/50 hz available) • automatic shut off circuit • made for deep cycle batteries danger explosive hydrogen gas forms when batteries ...

Page 24: Danger

- 24 - xr-op-en on-board charger charger specifi cations • output voltage of 36 volts • output current of 36 amps max • input voltage of 110 volts/ 60 hz (220v/50 hz available) • automatic shut off circuit • made for deep cycle batteries danger explosive hydrogen gas forms when batteries are chargin...

Page 25: Danger

Xr-op-en - 25 - battery maintenance guide safety: danger explosive hydrogen gas forms when batteries are charging. An open fl ame or spark can cause this gas to explode. Serious personal injury or property damage could occur. Only charge the batteries in this machine in a well ventilated area. Warni...

Page 26: Notice

- 26 - xr-op-en maintenance daily maintenance: 1. Remove the clean pads or brushes. Never use soiled pads when cleaning. Replace pads when they become packed with residue. 2. Remove and clean debris from the fl oat shut-off screen and drain saver located inside the recovery tank. 3. Drain and rinse ...

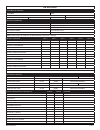

Page 27

Xr-op-en - 27 - pm records customer information customer email address phone city state zip contact machine information model #: serial #: work order#: hour meter (key): chassis hour meter: hour meter (traction): recharge number: hour meter (scrub): isolator hour meter: re-charge counter: note: isol...

Page 28

- 28 - xr-op-en vacuum switch vacuum motor performance off-board vac switch squeegee lift system squeegee adjustment pitch and height squeegee blades drain hose and plug side broom operation spray jet pump, hose & nozzle battery charger connection & function pitch of scrubdeck (must be level) pitch ...

Page 29

Xr-op-en - 29 - trouble-shooting problem cause solution no power - nothing operates faulty power switch contact local servicing dealer batteries need charging see charging batteries faulty batteries replace battery loose battery cable tighten loose cable main circuit breaker tripped wait 5 minutes f...

Page 30

- 30 - xr-op-en problem cause solution poor water recovery on turns wipers worn replace wiper material wipers chatter tighten pivot points squeegee swing is binding contact local servicing dealer incorrect squeegee size contact local servicing dealer tires noisy bearing dry grease bearings faulty hu...

Page 31

Xr-op-en - 31 - trouble-shooting central command note: this machine is operated by a sophisticated electronic “controller” that has many fail safes within it. It self-analyzes problems and fl ashes a four-digit alpha-numeric code of what is wrong in the lcd window. Most of these codes require a tech...

Page 32

- 32 - xr-op-en 5. 7700: vacuum motor circuit is open. 6. Throttle error: you pressed the foot pedal before turning on the key. Turn off the key and try again, leaving foot off of the pedal. 7. 2c00 and 2c01 error: low voltage warning. Voltage has dropped down below the minimum required to operate t...

Page 33

Xr-op-en - 33 - machine specs body construction/dimensions xr tank material: poly ( 3 ⁄ 8 '') (0.9525 cm) chassis construction: 3 ⁄ 16 '' steel (.2 cm) rear wheels: (2×) 14'' × 5'' [(2×) 35.5 × 12.7 cm] size (l × w × h): 69'' × 36'' × 56'' (175 × 91 × 142 cm) weight (without batteries): 1,230 lb wei...

Page 34: Notice

- 34 - xr-op-en common wear parts round disk brushes: brushes model 34'' disk model 40'' disk model 46'' disk super grit 17-421ss 20-421ss 23-421ss tough grit 17-421s 20-421s 23-421s midi grit 17-421c 20-421c 23-421c light grit 17-421ps 20-421ps 23-421ps poly (.028) 17-421p 20-421p 23-421p nylon (.0...

Page 35: Notice

Xr-op-en - 35 - new style cylindrical brushes: for machine serial #50000 & greater brushes model 34'' cylindrical model 40'' cylindrical model 46'' cylindrical super grit n / a n / a n / a tough grit 327-821s 387-821s 447-821s midi grit 327-821c 387-821c 447-821c light grit 327-821ps 387-821ps 447-8...

Page 36

- 36 - xr-op-en soap choices traditional drums / totes wall-mounted supercon demo / rental quarts onboard auto dispensing industrial • commercial • environmentally safe.

Page 37

Xr-op-en - 37 - powercat p.O. Box 503 racine, wi 53404-0503 phone: 414-745-9337 fax: 262-632-1630 www.Powercatsolutions.Com distributed by: powercat, llc, 2008. An environmentally cleaner that works! It is a solvent free degreaser that works on oil, carbon, even rubber marks. Incorporates the latest...

Page 38

- 38 - xr-op-en standard warranty policy rps corporation warrants its machines, parts and accessories to be free of manufacturer’s defects for the periods specifi ed below. Warranty will be granted at the sole discretion of rps corporation and is subject to fi nal claim and parts review by r.P.S. Co...

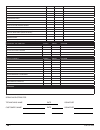

Page 39

Xr-op-en - 39 - machine install / warranty registration installing dealer: installed by: location: (city, state): install date: end-user company name: end-user contact: address: city/state: zip: phone: fax: email: model: serial #: hour meter: buyer’s representative has received instruction in proper...

Page 42

? rps corporation 2014 1711 south street racine, wi 53404 www.Rpscorporation.Com www.Factorycat.Com www.Tomcatequip.Com tel. Us: 800-634-4060 tel. Int: (011) 262-681-3583 fax: 866-901-3335.