R-Tech I-CUT100P Operation Instructions Manual - Controls And Settings

Controls and Settings

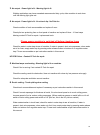

Fig 1

1. Air pressure gauge

This shows the air pressure as set by regulator at rear of machine. This should be set to 70PSI when

the test gas button is activated.

2. Amperage control knob

This adjusts the amperage (cutting power) from 20 to 100 amps

3. L.E.D amperage display

When cutting this shows the actual cutting amperage

4. Test Gas / Cutting selector switch & Post flow air timer

When in the down position this is test gas mode, when setting air pressure switch to test gas so you

obtain actual air flow cutting pressure. When in the up position this is cutting mode, you can now

start cutting, the knob controls post flow air from 3 - 15 seconds and cools the torch head after

cutting. We recommend a minimum of 10 seconds (12 o'clock position) to pro-long torch tip life and if

cutting at 100amps to turn to maximum - 15 seconds.

5. Auto / Standard switch

When in the down position this is in standard cutting mode, this is the normal operating position for

plasma cutting with a hand held and machine type torch, When in the up position this is in auto mode

(4T) this is for special applications when using automated machinery.

6. Indication of too low air pressure

The led will be shown when the air pressure is less than 26psi and the machine will not work. Adjust

pressure to correct 70psi, led will go out and you can resume cutting.

7. Indication of too low air pressure

9