- DL manuals

- R-Tech

- Welding System

- TIG200PDC

- Operation Instructions Manual

R-Tech TIG200PDC Operation Instructions Manual

Summary of TIG200PDC

Page 1

Www.R-techwelding.Co.Uk tig200pdc dc tig welder operation instructions www.R-techwelding.Co.Uk tel: 01452 733933.

Page 2

2.

Page 3

3 thank you for selecting the r-tech tig200pdc inverter dc tig welder. The tig200pdc has many benefits over traditional tig welders, including pulse welding, slope up/down and an industrial 60% duty cycle. We want you to take pride in operating our tig200pdc as much pride as we have taken in making ...

Page 4: Technical

Introduction the r-tech tig200pdc is a member of our field acclaimed family of welding products. Premium features include:- 1 inverter power source - more efficient to operate, provides smoother weld characteristics. 2 pulse welding in dc tig welding mode 3 hf arc start - easy arc striking and prolo...

Page 5: Safety Precautions

Safety precautions read entire section before starting installation warning! Electric shock can kill - only qualified personnel should perform this installation. Turn off input power at the fuse box before working on this equipment. Do not touch electrically live parts. Always connect the machine to...

Page 6: Electrical Installation

Electrical installation warning! Electric shock can kill machine grounding and high frequency interference protection this welder must be grounded to earth. See national electrical codes fro proper grounding methods. The high frequency generator being similar to a radio transmitter may cause interfe...

Page 7

Make sure fuse or circuit breaker is correct rating for machine. Using fuses or circuit breakers smaller than recommended will result in 'nuisance' shut off from welder inrush currents even if welding at low amperages. Failure to follow these instructions can cause immediate failure within the welde...

Page 8

Connections for tig200pdc rear machine connections fig 1 1 mains input cable fit required plug as per your electrical installation 2 on/off switch 3 gas input connector connect input gas hose ensuring connection is tight 4 earth for chassis if experiencing localized interference when using machine, ...

Page 9

Connections for tig (gtaw) welding fig 2 1 negative power connector connect tig torch dinze to power connector by inserting and twisting until tight 2 gas outlet connect the torch gas hose 3 positive power connector + connect the earth lead to by inserting and twisting until tight and the earth clam...

Page 10

Connections for stick mma (smaw) welding fig 3 1. Negative power connector connect the earth lead to by inserting and twisting until tight and the earth clamp to work/bench. 2. Gas outlet - not used in mma mode 3. Positive power connector + connect the electrode holder by inserting and twisting unti...

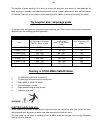

Page 11: Controls And Settings

Controls and settings fig 4 1. Up slope adjustment 0-5 seconds. The main welding current raises from minimum amperage to main current selected in time selected when weld started 2. Down slope down-slope adjustment 0-5 seconds. The main welding current decreases from main amperage to minimum amperage...

Page 12

Press and hold the tig torch switch to start sequence. The machine will open gas valve to start flow of shield gas, after a 0.5 seconds pre-flow time to purge air from torch hose the welding output of machine will be turned on and the arc will be started. After the arc is started the output current ...

Page 13: Operating Machine

This condition can be maintained as long as required. Release the tig torch switch to go to step 2 the machine will now increase output to base (main) current in time set by slope-up. Press and hold the tig torch switch when main weld is complete the machine will now decrease the welding output curr...

Page 14

Warning! Welding sparks can cause fire or explosion keep flammable material away from work area. Do not weld on containers that have held combustibles warning! Arc rays can burn wear eye, ear and body protection - make sure work area is protected by proper shielding to avoid injury to passers by. We...

Page 15

The benefits of pulse welding is the ability to control the weld pool and amount of heat absorbed by work resulting in a smaller heat affected zone which results in fewer deformations and reduced chance of cracking. There are no set rules for pulse welding as this is down to personal choice by the w...

Page 16: Maintenance

Maintenance routine and periodic maintenance warning! Electric shock can kill turn the input power off at the mains switch & fuse box before working on this equipment. Have a qualified electrician install & service this equipment. Allow machine to sit for 5 minutes minimum to allow the power capacit...

Page 17

Tig welding problems ●no output - power light is not lit check machine on/off switch is in the 'on' position check input power to machine check plug wiring check mains trip / fuses ● no output - fan runs - power light is lit check torch connections are secure and torch switch operation, try replacin...

Page 18: Mma Stick Welding Problems

● weak hf - poor arc striking - welding output normal 1 check torch and earth connections - is torch cable insulation in good condition. 2 check for leaks or contamination on gas hoses & connections. 3 gas flow may be insufficient, increase gas flow, reduce tungsten stick out from ceramic 4 keep out...

Page 19: Wiring Diagram

Wiring diagram 19.

Page 20: Warning

Warning aviso de precaucion attention warnung atenÇÃo spanish french german portuguese japanese chinese korean arabic read and understand the manufacturer’s instruction for this equipment and the consumables to be used and follow your employer’s safety practices. Se recomienda leer y entender las in...

Page 21: Warning

Warning aviso de precaucion attention warnung atenÇÃo spanish french german portuguese japanese chinese korean arabic leia e compreenda as instruÇÕes do fabricante para este equipamento e as partes de uso, e siga as prÁticas de seguranÇa do empregador. ● keep your head out of fumes. ● use ventilatio...