- DL manuals

- Radiant

- Heating System

- BH15ST

- Installation, operation & service manual

Radiant BH15ST Installation, operation & service manual

WARNING

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Extinguish any open flame.

6. Leave the building.

7. Immediately call your local gas

supplier after leaving the building.

Follow the gas supplier’s

instructions.

8. If you cannot reach your gas

supplier, call the Fire Department.

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clear-

ances to combustibles away from

heater.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

WARNING

Installation must be done by a registered installer/

contractor qualified in the installation and service

of gas-fired heating equipment or your gas supplier.

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or

property damage. Read the installation, operation

and service manual thoroughly before installing or

servicing this equipment.

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your serviceman with necessary information.

© 2009 Radiant Services Ltd.

Radiant Services Limited

Unit A, Kings Hill Business Park

Darlaston Road, Wednesbury

West Midlands WS10 7SH UK

Telephone: +44 (0)121 556 4495

Fax: +44 (0)121 556 8142

www.radiantservices.co.uk

Radiant Services

™

BH

Vacuum Assisted

Linear, Double Linear,

U-Tube, and Multi-Burner

Gas Fired Heating Systems

Installation, Operation &

Service Manual

BH15UT

BH20UT

BH25UT/EF

BH30UT/EF

BH35UT/EF

BH40UT/EF

BH45UT/EF

BH50UT/EF

BH15ST

BH20ST

BH25ST/EF

BH30ST/EF

BH35ST/EF

BH40ST/EF

BH45ST/EF

BH50ST/EF

BH55ST

BH30DL

BH40DL

BH50DL/EF

BH60DL/EF

RS170101UK Rev. A 11/09

Summary of BH15ST

Page 1

Warning for your safety if you smell gas: 1. Open windows. 2. Do not try to light any appliance. 3. Do not use electrical switches. 4. Do not use any telephone in your building. 5. Extinguish any open flame. 6. Leave the building. 7. Immediately call your local gas supplier after leaving the buildin...

Page 3

Table of contents section 1: heater safety ............................................2 1.1 manpower requirements ....................................2 1.2 safety labels and their placement ....................2 section 2: installer responsibility............................4 2.1 low level user ins...

Page 5

Table of figures figure 1: side and back panel label placement ............2 figure 2: top panel label placement .............................3 figure 3: linear & double linear, horizontal mounts......6 figure 4: linear & double linear, one side reflector ....6 figure 5: linear & double linear, two ...

Page 7

1 product approval radiant services™ appliances have been tested and ce certified as complying with the essential requirements of the gas appliance directive, the low voltage directive, the electromagnetic compatibility directive and the machinery directive for use on natural gas and lpg when instal...

Page 8

Radiant services™ i nstallation o peration and s ervice m anual 2 section 1: heater safety your safety is important to us! This symbol is used throughout the manual to notify you of possible fire, electrical or burn hazards. Please pay special attention when reading and following the warnings in the...

Page 9

Section 1: h eater s afety 3 figure 2: top panel label placement internal wiring label gas connection label top panel - inside door top panel description part number gas connection label 91018126 internal wiring label 91031401.

Page 10: Caution

Radiant services™ i nstallation o peration and s ervice m anual 4 section 2: installer responsibility • to install the heater, as well as the gas and electrical supplies, in accordance with applicable specifications and codes. Radiant services ltd. Recommends the installer contact a local building i...

Page 11: Warning

Section 3: c learances to c ombustibles 5 section 3: clearances to combustibles 3.1 required clearances to combustibles clearances are the required distances that combustible objects must be away from the heater to prevent fire hazards. Caution should be used when running the system near combustible...

Page 12

Radiant services™ i nstallation o peration and s ervice m anual 6 3.2 clearance data - linear and double linear note: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses. 2. Clearances b, c and d can be reduced by 50% after 7500 mm of tubing downstream from the ...

Page 13

Section 3: c learances to c ombustibles 7 note: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses. 2. Clearances b, c and d can be reduced by 50% after 7500 mm of tubing downstream from the burner. 3. All measurements are in millimeters. ** when installed in t...

Page 14

Radiant services™ i nstallation o peration and s ervice m anual 8 3.3 clearance data -u tube note: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses. 2. Clearances b, c and d can be reduced by 50% after 7500 mm of tubing downstream from the burner. 3. All meas...

Page 15

Section 3: c learances to c ombustibles 9 note: 1. All dimensions are from the surfaces of all tubes, couplings, tees, elbows and crosses. 2. Clearances b, c and d can be reduced by 50% after 7500 mm of tubing downstream from the burner. 3. All measurements are in millimeters. 4. Add 60 mm clearance...

Page 16

Radiant services™ i nstallation o peration and s ervice m anual 10 section 4: major component descriptions burner (shown with tube gasket) must be installed with the flame observation window facing down. Reflector (aluminium or stainless steel) alternate overlap as shown on overview. Minimum overlap...

Page 17: Warning

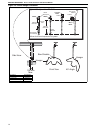

Section 5: g eneral s uspension d etails 11 section 5: general suspension details to ensure your safety, and comply with the terms of the warranty, all units must be installed in accordance with these instructions. The gas or the electrical supply lines must not be used to support the heater. Do not...

Page 18

Radiant services™ i nstallation o peration and s ervice m anual 12 figure 18: critical hanger placement * allows for thermal expansion of system. Hanger side view front view hanger bow shackle i-beam i-beam beam clamp bow shackle anchor concrete beam locknut washer screw hook min. 10 mm washer wood ...

Page 19: Warning

Section 6: l inear & d ouble l inear h eater i nstallation 13 section 6: linear & double linear heater installation the figures in this section provide a general overview of component placement in a radiant services™ linear and double linear system. The location of some components such as supports a...

Page 20

Radiant services™ i nstallation o peration and s ervice m anual 14 figure 19: linear general assembly overview fan tube r ef lect or r ef lect or end c ap r ef lect or suppor t bur ner c oupling u-clips bur ner tube tube and r ef lect or hanger tube clamp p ac kage int er nal s w irler fan assemb ly...

Page 21

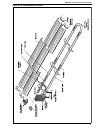

Section 6: l inear & d ouble l inear h eater i nstallation 15 figure 20: linear layout overview model bh15st bh20st bh25st/ef bh30st/ef bh35st/ef bh40st/ef bh45st/ef bh50st/ef bh55st reflector overlap (approx.) 700 mm 250 mm 250 mm 530 mm 530 mm 530 mm 330 mm 330 mm 200 mm a = reflector width (not s...

Page 22

Radiant services™ i nstallation o peration and s ervice m anual 16 6.2 double linear standard parts list * pvc coating must be removed prior to installation. **some models may receive s-hooks (p/n 91907302) or spring hooks (p/n 91903300), rather than bow shackles part no. Description bh 3 0 d l bh 4...

Page 23

Section 6: l inear & d ouble l inear h eater i nstallation 17 figure 21: double linear general assembly overview 1200 mm appr ox . Fan tube bur ner tube clamp p ac kage r ef lect or r ef lect or end c ap r ef lect or suppor t c oupling fan assemb ly bur ner tube tube and r ef lect or hanger tube cla...

Page 24

Radiant services™ i nstallation o peration and s ervice m anual 18 figure 22: double linear layout overview model bh30dl bh40dl bh50dl/ef bh60dl/ef bh70dl/ef reflector overlap (approx.) 700 mm 250 mm 250 mm 530 mm 530 mm tee assembly burner reflector tube tube/reflector hanger coupling assembly fan ...

Page 25

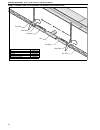

Section 6: l inear & d ouble l inear h eater i nstallation 19 step 6.3 burner tube installation step 6.4 coupling and tube assembly bow shackle burner tube hanger 2290 mm ± 250 mm note: tubing requires a downward slope of 13 mm per 6000 mm away from burner. Weld seam must be to the bottom of the tub...

Page 26

Radiant services™ i nstallation o peration and s ervice m anual 20 step 6.4.1 coupling and tube assembly (continued) step 6.4.2 coupling and tube assembly (continued) incorrect slide bar position correct slide bar dimensions ± 50 mm drive slide bar until tight. End of slide bar should be within tole...

Page 27

Section 6: l inear & d ouble l inear h eater i nstallation 21 step 6.5 tube clamp package installation description part number tube clamp package 01318901 tube clamp 01396801 bolt 97113940 flat washer 95211600 nut 92113900

Page 28: Warning

Radiant services™ i nstallation o peration and s ervice m anual 22 step 6.6 reflector installation warning fire hazard support reflector with reflector hanger and support strap. Reflector must not touch tube. Failure to follow these instructions can result in death, injury or property damage. Hanger...

Page 29

Section 6: l inear & d ouble l inear h eater i nstallation 23 step 6.6.1 reflector, u-clip and reflector support installation the pictorial drawings of the heater construction in section 6 are schematic only and provide a general guideline of where hangers, reflector supports and u-clips are to be i...

Page 30

Radiant services™ i nstallation o peration and s ervice m anual 24 step 6.7 double linear tee installation (for double linear heaters only) tee coupling coupling fan tube fan tube weld spot weld spot description part number tee e0009170 fan tube s51xxw coupling 01329600 slide bar/coupling lock 01329...

Page 31: Warning

Section 7: u-t ube h eater i nstallation 25 section 7: u-tube heater installation the figures in this section provide a general overview of component placement in a radiant services™ u- tube system. The location of some components such as supports and couplings is crucial for proper installation. As...

Page 32

Radiant services™ i nstallation o peration and s ervice m anual 26 *pvc coating must be removed prior to installation. **some models may receive s-hooks (p/n 91907302) or spring hooks (p/n 91903300), rather than bow shackles part no. Description bh 15 ut bh 20 ut bh 25 ut bh 25 ut /e f bh 30 ut bh 3...

Page 33

Section 7: u-t ube h eater i nstallation 27 figure 23: u-tube assembly overview mm 200

Page 34

Radiant services™ i nstallation o peration and s ervice m anual 28 figure 24: u-tube layout overview model bh15ut bh20ut bh25ut/ef bh30ut/ef bh35ut/ef bh40ut/ef bh45ut/ef bh50ut/ef reflector overlap (approx.) 1780 mm 250 mm 250 mm 580 mm 580 mm 580 mm 690 mm 690 mm bh20ut bh25ut/ef bh15ut bh30ut/ef ...

Page 35

Section 7: u-t ube h eater i nstallation 29 step 7.2 u-tube hanger placement step 7.3 burner tube and fan tube installation 2290 mm ± 250 mm see assembly drawing first tube and reflector hanger bow shackle tube and reflector hanger suspension chain optional hanging configuration washers bolt (torque...

Page 36

Radiant services™ i nstallation o peration and s ervice m anual 30 step 7.3.1 tube clamp package installation step 7.4 u-tube support bracket assembly installation tube clamp bolt lock washer nut (torque: 13.56 nm 120 in lb) weld spot description part number tube clamp package 01318901 tube clamp 01...

Page 37

Section 7: u-t ube h eater i nstallation 31 step 7.5 coupling and tube assembly step 7.5.1 coupling and tube assembly (continued) tube tube orient coupling so that the impact block is in the 2:00 or 10:00 oclock positions closed open tab 76 mm to 101 mm slide bar coupling wide end coupling tube sli...

Page 38

Radiant services™ i nstallation o peration and s ervice m anual 32 step 7.6 tube installation step 7.7 u-tube installation tube coupling weld spot coupling u-tube u-tube support bracket assembly weld spot description part number coupling 01329600 slide bar/coupling lock 01329700 u-tube 01335901.

Page 39: Warning

Section 7: u-t ube h eater i nstallation 33 step 7.8 reflector installation warning fire hazard support reflector with reflector hanger and support strap. Reflector must not touch tube. Failure to follow these instructions can result in death, injury or property damage. Reflector weld spot descripti...

Page 40

Radiant services™ i nstallation o peration and s ervice m anual 34 step 7.8.1 reflector, u-clip and reflector support installation the pictorial drawings of the heater construction in section 6 are schematic only and provide a general guideline of where hangers, reflector supports and u-clips are to...

Page 41: Warning

Section 8: m ultiburner c onfiguration & i nstallation 35 section 8: multiburner configuration & installation 8.1 initial assembly see page 13, section 6 for linear heater assembly instructions. See page 25, section 7 for u-tube heater assembly instructions. Check layout drawings for location of man...

Page 42

Radiant services™ i nstallation o peration and s ervice m anual 36 figure 26: typical manifold layout (linear and u-tube configuration) typical fan arrangement 150 mm hanger 150 mm manifold damper (typical) cross (100 x 150 x 100 x 150) 100 mm manifold 100 mm hanger id/id sleeve tee (100 x 100 x 100...

Page 43

Section 9: b urner & f an i nstallation 37 section 9: burner & fan installation step 9.1 burner installation step 9.2 fan assembly lock washer gasket bolt (torque: 13.5 nm 120 in lb) burner description part number bolt 94273914 lock washer 96411600 gasket 02568200 burner r0720xxxx note: tube clamp p...

Page 44

Radiant services™ i nstallation o peration and s ervice m anual 38 9.3 linear & u-tube fan installation step 9.4 double linear fan installation fan tube fan assembly tighten securely until tube cannot be removed. Weld spot tee fan assembly tighten securely until tube cannot be removed..

Page 45

Section 9: b urner & f an i nstallation 39 step 9.4.1 double linear fan installation (continued) step 9.5 multiburner 83/90 bwlg fan assembly (horizontal and vertical outlets) fan assembly height adjuster bow shackle suspension chain tee weld spot tee condensate cap non-return valve 83/90 bwlg fan i...

Page 46

Radiant services™ i nstallation o peration and s ervice m anual 40 step 9.6 condensate drain assembly tee condensate cap wall 1" bsp threaded hole. Use 1" x ¾" reducer. (not supplied) must be connected to a drain system in accordance with local codes. 3/4" cpvc pipe flow non-return valve 3/4" cpvc p...

Page 47: Warning

Section 10: o ptional h eater a ccessories 41 section 10: optional heater accessories warning cut/pinch hazard wear protective gear during installation, operation and service. Edges are sharp. Failure to follow these instructions can result in injury..

Page 48

Radiant services™ i nstallation o peration and s ervice m anual 42 10.1 reflector side extension installation step 10.1.1 bracket installation step 10.1.2 side reflector installation reflector side extension bracket (2 per reflector) use additional supports in high air movement applications. Tube an...

Page 49

Section 10: o ptional h eater a ccessories 43 10.2 u-tube cover installation the package contains two reflector joint pieces (p/n 02750901), one 8’ reflector and 18 x #8 sheet metal screws. Install the u-tube cover using the following procedure. Step 10.2.1 cut the 8’ reflector in half to be used on...

Page 50

Radiant services™ i nstallation o peration and s ervice m anual 44 10.3 decorative grille installation step 10.3.1 grille installation step 10.3.2 frame shield installation step 10.3.3 reflector side extension installation for decorative grilles description part number aluminium grille 610 mm x1220 ...

Page 51

Section 10: o ptional h eater a ccessories 45 10.4 protective grille installation step 10.4.1 silicone cap installation step 10.4.2 grille end cap installation step 10.4.3 grille installation silicone cap grille finger description part number grille section 08050001 grille end cap 08050002 silicone ...

Page 52

Radiant services™ i nstallation o peration and s ervice m anual 46 10.5 sports hall guard installation step 10.5.1 grille installation step 10.5.2 fastener installation step 10.5.3 mesh guard connection tube and reflector hanger reflector tube reflector support strap - stainless steel mesh guard des...

Page 53

Section 10: o ptional h eater a ccessories 47 10.6 undershield installation 10.6.1 hanger installation 10.6.2 undershield installation 10.6.3 adjust undershield height reflector tube assembly hanging bracket stud hex nut description part number undershield reflector package 101 cm s7399k assembly ha...

Page 54

Radiant services™ i nstallation o peration and s ervice m anual 48 10.7 wall mounting install wall mounting brackets at the height shown in the layout drawing provided by the estimator. Space wall mounting brackets and hangers as indicated by dimensions d, e and f (u-tube) in the relevant layout ove...

Page 55

Section 10: o ptional h eater a ccessories 49 figure 28: u-tube (angle mounted) figure 29: linear.

Page 56: Warning

Radiant services™ i nstallation o peration and s ervice m anual 50 section 11: venting 11.1 general venting requirements 11.1.1 type c 12 , c 32 & c 62 appliance room sealed the heaters are designed to be installed as room sealed appliances. The flue and air intake are run as separate pipes to the s...

Page 57

Section 11: v enting 51 figure 30: individual flue connection detail figure 31: flue connection dimensions 11.3 outside combustion air supply where necessary, clean air may be ducted into the burner box through an added spigot on the back of the burner box replacing the existing dust arrest baffle p...

Page 58

Radiant services™ i nstallation o peration and s ervice m anual 52 figure 32: fresh air intake spigot figure 33: air supply with flue configurations 11.4 common duct when using a common air inlet duct, always ensure that the area of the common air inlet duct represents the area of all air ducts. Bur...

Page 59: Warning

Section 12: g as p iping 53 section 12: gas piping it is important that the gas supply pipe and electrical connections do not support any of the heater’s weight. Installation pipes should be fitted in accordance with national standards. Pipe work from the meter to the heater(s) must be of adequate s...

Page 60: Caution

Radiant services™ i nstallation o peration and s ervice m anual 54 figure 34: gas connection with stainless steel flex connector incorrect positions (wrong installation) heater movement heater movement heater movement heater movement correct positions correct position with flex connector not supplie...

Page 61: Danger

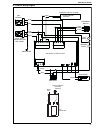

Section 13: w iring 55 section 13: wiring connect to the electrical supply using a 3 pin plug via a locally mounted double pole fused switch having a minimum disconnection of 3 mm on each pole. This switch should be fused to 3 amps. The burner is fused at 2 amps. There are no control connections in ...

Page 62

Radiant services™ i nstallation o peration and s ervice m anual 56 13.3 typical external wiring diagram (double linear option 2) 13.4 typical external wiring diagram (multiburner) controller or thermostat burner 1 burner 2 l n earth fan earth n l 230 v 1 Ø 50 hz 83/90 btlw fan 230 v 1 Ø 50 hz burner...

Page 63

Section 13: w iring 57 13.5 internal wiring diagram switch pressure white yellow black neon burner neon fan l n e l n e blue blue black black socket fan emc filter mains in socket 230 v, 50 hz blue brown brown earth stud gas valve green/yellow sense electrode brown blue purple 1 2 lockout indicator ...

Page 64: Warning

Radiant services™ i nstallation o peration and s ervice m anual 58 section 14: operation figure 35: sequence of operation chart 14.1 heater lockout indication (optional) in case of flame loss during operation of the heater, the burner control unit goes to lockout mode after three ignition trials. At...

Page 65

Section 14: o peration 59 14.2 testing establish that a satisfactory purged gas supply and an electrical supply is available to the heater. Ensure that all time clocks and thermostats are set to call for heat. With the gas supply cut off at the appliance isolating cock and the electrical supply isol...

Page 66: Warning

Radiant services™ i nstallation o peration and s ervice m anual 60 section 15: servicing instructions important: never use the heater as a support for ladders or other access equipment. Always test for gas soundness with a suitable detection fluid after completing any servicing or exchange of gas ca...

Page 67

Section 15: s ervicing i nstructions 61 15.2.4 automatic flame control unit remove black ignition lead. Withdraw the connectors. Remove two screws from the cover. Replace if faulty. Refit in reverse sequence. 15.2.5 pressure switch disconnect the two silicone tubes. Remove wires from the three blade...

Page 68

Radiant services™ i nstallation o peration and s ervice m anual 62 tubes make sure there are no cracks. Make sure tubes are connected and suspended securely. See page 11, section 5. Make sure there is no sagging, bending or distortion. Gas line check for gas leaks. See page 53, section 12. Burner ob...

Page 69: Danger

Section 16: t roubleshooting 63 section 16: troubleshooting danger electrical shock hazard disconnect electric before service. Heater must be properly grounded. Failure to follow these instructions can result in death or electrical shock. Fire hazard keep all flammable objects, liquids and vapors th...

Page 70

Radiant services™ i nstallation o peration and s ervice m anual 64 16.1 troubleshooting flow chart (linear, double linear and u-tube) no no no no ye s no ye s ye s no no no no no ye s no no ye s ye s ye s ye s no ye s ye s ye s ye s replace ignition module. Is there power out from pin 10 on ignition...

Page 71

Section 16: t roubleshooting 65 troubleshooting flow chart (linear, double linear and u-tube).

Page 72

Radiant services™ i nstallation o peration and s ervice m anual 66 16.2 troubleshooting flow chart (multiburner) refer to control panel ios manual for troubleshooting. Fan motor may have to be replaced. Remove obstruction. No no ye s ye s no no no ye s no no ye s ye s ye s ye s no no ye s no ye s ye...

Page 73

Section 16: t roubleshooting 67 troubleshooting flow chart (multiburner).

Page 74

Radiant services™ i nstallation o peration and s ervice m anual 68 16.3 manifold gas pressure setting 0 1 2 3 4 5 6 1 2 3 4 5 6 0 1 2 3 4 5 6 1 2 3 4 5 6 manometer governor adjustment screw (behind cover) governor (orifice) pressure while burner is running. See page 73, section 18.9.1 or see page 74...

Page 75: Warning

Section 17: r eplacement p arts 69 section 17: replacement parts carbon monoxide hazard warning use only genuine radiant services™ replacement parts per this installation, operation and service manual. Failure to follow these instructions can result in death, electric shock, injury or property damag...

Page 76

Radiant services™ i nstallation o peration and s ervice m anual 70 notes: a c d e f g h i j k l m n o q item description part number item description part number a automatic control unit 90438702 o dust arrest baffle plate 07230000 c flex line adapter 91220700 q mains in socket with emc filter 90438...

Page 77

Section 18: s pecifications 71 section 18: specifications 18.1 material specifications 18.1.1 combustion and tubes 100 mm dia. 16 gauge heat treated aluminised mild steel. 18.1.2 reflectors ns3 h14 aluminium or 1.4016 2r stainless steel (option). 18.2 heater specifications 18.2.1 sequence controller...

Page 78

Radiant services™ i nstallation o peration and s ervice m anual 72 * only available in multiburner. 18.6 linear heater b h 15s t b h 20s t b h 25s t b h 25s t/ e f b h 30s t b h 30s t/ e f b h 35s t b h 35s t/ e f b h 40s t b h 40s t/ e f b h 45s t b h 45s t/ e f b h 50s t b h 50s t/ e f b h 55s t* ...

Page 79

Section 18: s pecifications 73 18.9 burner specifications figure 37: linear and u-tube specifications *only available in multiburner. **based on gross caloric value. Natural g20: 8.7 mbar 3.5 in wg natural g25: 11.1 mbar 4.5 in wg natural g25 bh 55*: 9.5 mbar 3.8 in wg 18.9.1 standard burner specifi...

Page 80

Radiant services™ i nstallation o peration and s ervice m anual 74 **based on gross caloric value. 18.9.2 ef burner specifications bh25/ef bh30/ef bh35/ef bh40/ef bh45/ef bh50/ef burner airplate id number 14 5 6 5 6 10 jet numbers - natural g20 #20 #16 #9 #5 #2 b gas consumption** - natural g20 (m 3...

Page 82

Radiant services ™ radiant services limited unit a, kings hill business park darlaston road, wednesbury west midlands ws10 7sh uk telephone: +44 (0) 121 556 4495 fax: +44 (0) 121 556 8142 installation code and annual inspections: all installation and service of radiant services™ equipment must be pe...