- DL manuals

- Radiant

- Boiler

- RCM

- Installation, Use And Maintenance Manual

Radiant RCM Installation, Use And Maintenance Manual

Summary of RCM

Page 1

Ce 0694 english technical specification radiant bruciatori s.P.A. Montelabbate (pu) italy by technical department installation, use, and maintenance manual for gas fired, wall-hung boilers model rcm type b open combustion chamber model rsf type c room sealed.

Page 3

Index user manual page i-ii installation instructions and warnings page 2 technical data page 3 overall dimensions - exhaust flue system page 4 general installation requirements page 6 boiler installation page 8 electrical connections page 10-11;20-23 boiler control panel page 12 starting up the boi...

Page 4

User manual wall hung boiler – cod. 99817na – july 2001 i boiler operation and adjustment procedures for user before turning on the boiler read the following warnings carefully . Make sure that the warranty booklet carries the stamp of the authorised technician responsible for installing the boiler....

Page 5

User manual wall hung boiler – cod. 99817na – july 2001 ii turning on procedure for electronic ignition (only for u.K. And ireland): # turn on the gas cock situated under the boiler grill; # turn selector switch 1 to the !Symbol denoting winter (see fig.1); # make sure that 6 light is on (see fig. 2...

Page 6

Installation manual wall hung boiler – cod. 99817na – july 2001 1 the friendly power of heat at your service for 40 years in the heating sector. Thank you for choosing radiant re: declaration for purposes of art. 7 of law 46 of 5 april 1990. Radiant bruciatori s.P.A. Hereby declares that all of its ...

Page 7

Installation manual wall hung boiler – cod. 99817na – july 2001 2 installation instructions warnings this installation, use, and maintenance manual is an essential and integral part of the product, and must always be kept near the device. The warnings contained in this section are addressed both to ...

Page 8

Installation manual wall hung boiler – cod. 99817na – july 2001 3 technical data type b unit type b boilers have open combustion chambers, and must be connected to a flue duct to convey combustion exhaust out of the room. Air for combustion is taken directly from the room in which the boilers are in...

Page 9

Installation manual wall hung boiler – cod. 99817na – july 2001 4 type b wall-mounted boilers open combustion circuit: type c wall-mounted boilers sealed combustion circuit: kit a horizontal coaxial exhaust flue system with 360° rotation. It allows the flue exhaust and the air intake directly to an ...

Page 10

Installation manual wall hung boiler – cod. 99817na – july 2001 5 flue exhaust directly into a duct (chimney) or collective branch- type flue vertical exhaust open chamber model a maximum of 3 changes of direction are allowed. Keep to the distances and angles shown in the diagram. Flue exhaust direc...

Page 11

Installation manual wall hung boiler – cod. 99817na – july 2001 6 general installation requirements gas safety it is the law that all gas appliances are installed by a corgi registered installer in accordance with the regulations listed below. Failure to install appliances correctly could lead to pr...

Page 12

Installation manual wall hung boiler – cod. 99817na – july 2001 7 where installation will be in an unusual location, special procedures may be necessary. Bs 6798 gives detailed guidance on this aspect. For clearances to be made available for installation and servicing, see sections 5.2.2. To 5.2.4. ...

Page 13

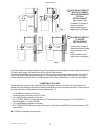

Installation manual wall hung boiler – cod. 99817na – july 2001 8 minimum distances for fixing to wall to allow access in the boiler for maintenance operations, the minimum distances shown below must be respected (fig. 1): to facilitate installation, the boiler is supplied with a template for advanc...

Page 14

Installation manual wall hung boiler – cod. 99817na – july 2001 9 gas connections the gas supply must be connected up by qualified person. The following standards must be complied with: unicig 7131/72 and unicig 7129/92 (of 21/04/93) before installing the boiler, make sure of the following: • the pi...

Page 15

Installation manual wall hung boiler – cod. 99817na – july 2001 10 electrical connections the boiler works with 230 v 50 hz ac current and has maximum input of 170 w. Connection to the electrical mains must be performed with a device having an omnipolar opening of at least 3 mm. Make sure the live a...

Page 16

Installation manual wall hung boiler – cod. 99817na – july 2001 11 connection of room thermostat note: use class ii room thermostats only. The thermostat wire must not be placed in the channel containing high tension wires, but must have its own line the room thermostat lead must not exceed 50m n le...

Page 17

Installation manual wall hung boiler – cod. 99817na – july 2001 12 control panel legend (see fig. 1) 1. Summer-winter on-off switch 2. Lock-out indicator 3. Heating temperature adjustment knob 4. Water temperature adjustment knob 5. Space for adding an optional timer self- diagnostic legend (see fig...

Page 18

Installation manual wall hung boiler – cod. 99817na – july 2001 13 • check the pressure in the system: if this has gone down and led 16 (see fig. 2) comes on (pressure gauge shows 1.5 bar) restore pressure; • close the filling tap once this operation is completed; filling the system (only for u.K. A...

Page 19

Installation manual wall hung boiler – cod. 99817na – july 2001 14 boiler adjustments selector gpl-met natural gas l.P.G. Selector m5 m11 d6 + c22 cm3 rs1 j16 r48 r2 3 r2 4 fa1 c2 0 c1 9 c7 c6 c2 1 r47 r17 r49 r1 5 r32 c13 41 r16 c14 r5 7 r6 1 r39 r62 m9 j20 c9 c5 + r38 42 r31 r37 r1 8 ic2 + r58 r42...

Page 20

Installation manual wall hung boiler – cod. 99817na – july 2001 15 conversion of gas type conversion of the boiler from natural gas to lpg and vice versa must be performed by qualified personnel only. Conversion is performed as follows: a) turn off the main power switch; b) close the gas cock; c) su...

Page 21

Installation manual wall hung boiler – cod. 99817na – july 2001 16 regulating the gas pressure maximum and minimum modulation pressures. N.B. The following operations must only be carried out by authorised personnel and are necessary when the boiler is converted to run on one type of gas or another ...

Page 22

Installation manual wall hung boiler – cod. 99817na – july 2001 17 technical data differential air pressure switch for fan control to guarantee maximum safety in flue exhaust, a differential pressure switch is installed on the room sealed combustion chamber model (wall- mounted, room-sealed boilers)...

Page 23

Installation manual wall hung boiler – cod. 99817na – july 2001 18 limiter the boiler is equipped with a variable flow limiter at the cold water inlet. The flow limiter can be adjusted by turning the screw (see fig.2 pos.C) in order to obtain the correct flow rate of domestic hot water for the speci...

Page 24

Installation manual wall hung boiler – cod. 99817na – july 2001 19 mod. Rcm 20 e mod. Rsf 20 e – rsf 24 e open combustion chamber model room sealed combustion chamber model key 1. Frame 2. Flue hood – open combustion chamber 3. Flue hood – room sealed combustion chamber 4. Combustion chamber 5. Room...

Page 25

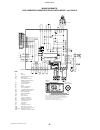

Installation manual wall hung boiler – cod. 99817na – july 2001 20 electrical connection for open combustion chamber electronic ignition boiler – mod. Rcm 20 e electronic ignition s4565a20 terminal block wiring of components by means of connectors 8 7 lb 9 10 11 12 13 blu e brown m2 ps r l cy n ts 1...

Page 26

Installation manual wall hung boiler – cod. 99817na – july 2001 21 wiring diagram for open combustion chamber electronic ignition boiler – mod. Rcm 20 e th e r m o s ta ts a n d m o dula ti o n b lo c k 49 rva-rvb rta - pump relay lb - thermostat relay - lock-out indicator - ionisation electrode - i...

Page 27

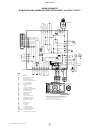

Installation manual wall hung boiler – cod. 99817na – july 2001 22 electrical connection for room sealed comb. Chamber electronic ignition boiler – mod. Rsf 20 e - rsf 24 e m4 m1 m5 m6 m1 rl1 gas valve pressure modulator 42 41 44 46 45 47 48 43 m10 bl ue br ow n bl ac k bl ac k bl ac k m.F. M9 water...

Page 28

Installation manual wall hung boiler – cod. 99817na – july 2001 23 wiring diagram for room sealed comb. Chamber electronic ignition boiler – mod. Rsf 20 e - rsf 24 e 11 or rva-rvb rta - ionisation electrode - ignition electrode rsa rpa rt - lock-out indicator - reset botton - thermostat relay rp rv ...

Page 29

Installation manual wall hung boiler – cod. 99817na – july 2001 24 maintenance to keep the boiler in efficient and safe operating condition, we recommend you perform the following checks at least once a year: • check all seals on the gas side and replace gaskets to restore perfect seal as required. ...

Page 30

Installation manual wall hung boiler – cod. 99817na – july 2001 25 malfunction possible cause solution 1) light 6 (fig.2) is on but nothing works. A. Water pressure switch b. Water pressure below 0.5 bar (light 14 fig. 2 flashing). C. Ramire circuit board damaged a. Replace it b. Load water c. Repla...

Page 31

Installation manual wall hung boiler – cod. 99817na – july 2001 26.

Page 32

Installation manual wall hung boiler – cod. 99817na – july 2001 27 spare parts short list n° code description rcm 20 e rsf 20 e rsf 24 e open chamber electronic ignition room sealed electronic ignition room sealed electronic ignition 1 58006lp main heat exchanger mod. 20.000 - 63 a % % 58007lp main ...

Page 33

Radiant bruciatori s.P.A. Gas oil, heavy-oil burners wall-hung boilers cast iron thermal unit storage cylinder boilers water heaters registered office: 61025 montelabbate (pu) italy • via pantanelli, 164 tel +39 0721 498822 • fax +39 0721 499815 email: italia@radiant.It • tecnico@radiant.It • export...