- DL manuals

- Radiant

- Boiler

- RH 28

- Installation And Maintenance Manual

Radiant RH 28 Installation And Maintenance Manual

Summary of RH 28

Page 1

Ce 0694 ta01a011.B1003 technical specification radiant bruciatori s.P.A. Montelabbate (pu) italy english installation, and maintenance manual for gas fired, wall-hung boilers model rsf 30 e type c room sealed sedbuk band d.

Page 3

Index installation instructions and warnings page 1 technical data page 2 overall dimensions - exhaust flue system page 3 general installation requirements page 4 boiler installation page 6 electrical connections page 8;13 boiler control panel page 9 starting up the boiler for the first time page 9 ...

Page 4

Installation manual combi - ta01a011.B1003 1 the friendly power of heat thank you for choosing radiant declaration for purposes of art. 7 of law 46 of 5 april 1990. Radiant bruciatori s.P.A. Hereby declares that all of its products are constructed to industry standards as required by the article in ...

Page 5

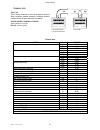

Installation manual combi - ta01a011.B1003 2 technical data type c unit type c devices are devices in which the combustion circuit (air intake, combustion chamber, exchanger, combustion exhaust) is sealed off from the place where they are installed. Central heating - domestic hot water sealed combus...

Page 6

Installation manual combi - ta01a011.B1003 3 overall dimensions - exhaust flue system type c wall-mounted boilers sealed combustion circuit: kit g horizontal coaxial exhaust flue system with 360° rotation. Kit b double exhaust/emission twin flue system with 360° rotation. R return ¾” g gas ½” c hot ...

Page 7

Installation manual combi - ta01a011.B1003 4 general installation requirements gas safety it is the law that all gas appliances are installed by a corgi registered installer (you can check this by contacting corgi on 01256.372200) in accordance with the regulations listed below. Failure to install a...

Page 8

Installation manual combi - ta01a011.B1003 5 flue position important: the flue system shall be installed in accordance with the recommendations contained in bs 5440:1. The boiler must be installed so that the terminal is exposed to the external air. It is important that the position of the terminal ...

Page 9

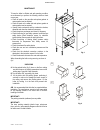

Installation manual combi - ta01a011.B1003 6 400 m m a a 400 m m minimum distance mm. Section a-a 1200 min. Balcony minimum distance mm. 45 0 60 450 60 minimum distances for fixing to wall to allow access in the boiler for maintenance operations, the minimum distances shown below must be respected (...

Page 10

Installation manual combi - ta01a011.B1003 7 available head with by-pass partially (50%) on. 2 available head at top speed. Available head at second speed. Ii 0 iii 0 1 200 400 800 600 1000 3 4 5 6 head m c.W. 6 1800 flowrate litres/h 1400 1200 ii 1600 iii gas connections the gas supply must be conn...

Page 11

Installation manual combi - ta01a011.B1003 8 electrical connections for qualified personell only: the boiler works with 230 v 50 hz ac current and has maximum input of 170 w. Connection to the electrical mains must be performed with a device having an omnipolar opening of at least 3 mm. Make sure th...

Page 12

Installation manual combi - ta01a011.B1003 9 control panel legend (see fig. 1) 1. On / off power switch 2. Heating temperature adjustment knob 3. Domestic hot water temperature adjustment knob 4. Outside temperature display pad (only with optional outside temperature sensor fitted) 5. Chimney-sweepe...

Page 13

Installation manual combi - ta01a011.B1003 10 rs air vent valve cap circulating pump air vent valve pump cap • set on/off switch in on position (see fig.1), after a few seconds the pump will come into operation; • once the boiler is working, if any noises are heard in the system, repeat the above ai...

Page 14

Installation manual combi - ta01a011.B1003 11 conversion of gas type conversion of the boiler from natural gas to lpg and viceversa must be performed by qualified personnel only. Conversion is performed as follows: a. Turn off the main power switch; b. Close the gas cock; c. Substitute the jets on t...

Page 15

Installation manual combi - ta01a011.B1003 12 main components 1. Flue hood – room sealed combustion chamber 2. Combustion chamber 3. Room sealed chamber cover 4. Room sealed chamber back 5. Heat exchanger mod. 30.000 6. Flat plate type exchanger 7. Multigas burner with 17 ramps 8. Heating safety the...

Page 16

Installation manual combi - ta01a011.B1003 13 electrical connection printed circuit board cvi-m sm20015 (cod. 76655la) r 22 m4 m4 19 18 21 20 c br ow n light- blue light- blue bl ac k s c br ow n vd re d electric connection with mater xp300 water pressure switch 50 bl ac k bl ac k bl ac k bl ac k wh...

Page 17

Installation manual combi - ta01a011.B1003 14 wiring diagram for remote control installation (no zone valves) fit the interface (fig. 2) on the circuit board (fig. 1) into the holes a and b provided (see fig. 1). Connect plug m1 on the interface circuit board (fig. 2) to plug m11 on the modulation c...

Page 18

Installation manual combi - ta01a011.B1003 15 maintenance to keep the boiler in efficient and safe operating condition, we recommend you perform the following checks at least once a year: • check all seals on the gas side and replace gaskets to restore perfect seal as required. • check all seals on ...

Page 19

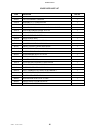

Installation manual combi - ta01a011.B1003 16 spare parts short list code description rsf 30 e 20046la 24 plate exchanger 17b1902406 9 21032la gas burner 17 r. 1,20 natural gas 9 21033la gas burner 17 r. 0,75 l.P.G. 9 24040la circulating pump gold 50v1 shul clf6 15/6 w/ air vent 9 24041la circulatin...

Page 20

Radiant bruciatori s.P.A. Via pantanelli, 164/166 - 61025 loc. Montelabbate (pu) tel. +39 0721 9079.1 • fax. +39 0721 9079279 e-mail: tecnico@radiant • internet: http://www.Radiant.It uk – radiant helpline – 01329.828555 all descriptions and illustrations contained in this leaflet have been carefull...