- DL manuals

- Radiant

- Boiler

- RHR 25

- Instruction Manual

Radiant RHR 25 Instruction Manual

Installation, operating, commissioning and maintenance instructions.

CE

0694

RHR 25-RAD- ING-MAN.INST-1411.1-DIGITECH_TR-MIAH6-DIMA-E04

Technical specification RADIANT BRUCIATORI S.p.A. Montelabbate (PU) ITALY

ENGLISH

Instruction Manual

for model

RHR 25

Wall mounted instantaneous combi boiler

room sealed chamber

b-condense

Summary of RHR 25

Page 1

Installation, operating, commissioning and maintenance instructions. Ce 0694 rhr 25-rad- ing-man.Inst-1411.1-digitech_tr-miah6-dima-e04 technical specification radiant bruciatori s.P.A. Montelabbate (pu) italy english instruction manual for model rhr 25 wall mounted instantaneous combi boiler room s...

Page 3

Contents 1. General information 1.1 general warnings pag. 1 1.2 product conformity pag. 3 2. Technical characteristics 2.1 technical data pag. 4 2.2 dimensions pag. 5 2.3 internal parts of the boiler pag. 6 2.4 circulation pump head/flow graph pag. 7 2.5 water circuit pag. 8 2.6 printed circuit boar...

Page 4

Contents 6. Maintenance (authorised personnel) 6.1 general warnings pag. 44 6.2 boiler inspection pag. 44 6.3 accessing the boiler pag. 45 6.4 draining the central heating system pag. 46 6.5 flue safety thermostat pag. 46 6.6 wiring diagrams pag. 47 6.7 electrical connections (option) pag. 48 6.8 tr...

Page 5: 1. General Information

General information 1 1. General information 1.1 general warnings professionally qualified personnel in accordance with current laws and standards and in line with the manufacturer’s instructions must install the appliance. With ‘professionally qualified personnel’ is intended a personnel with techn...

Page 6

General information 2 • as dictated by current legislation, this appliance must be installed exclusively by qualified personnel. Before starting the boiler for the first time, make sure that it is connected to a water supply and central heating system compatible with its performance characteristics....

Page 7

General information 3 1.2 product conformity radiant bruciatori s.P.A. Declares that all its products are manufactured to a high specification and in compliance with the relevant standards. All radiant boilers are ce certified and possess technical and functional characteristics that comply with the...

Page 8

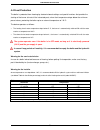

Installation instructions 4 2. Technical characteristics 2.1 technical data model rhr 25 ce certification n° 0694co7385 appliance type ii2h3+ appliance category c12 - c32 - c42 - c52 - c62 - c82 heat input max kw 26 heat input min (central heating circuit) kw 18 heat input min (domestic hot water ci...

Page 9

Installation instructions 5 78 5 330 115 150 185 13 5 21 0 64.5 78 70 80 102 55.5 hf cwi g hwo hr 450 125 hf cwi g hwo hr 2.2 dimensions hr heating return Ø3/4” hf heating flow Ø3/4” g gas Ø3/4” cwi cold water inlet Ø1/2” hwo hot water outlet Ø1/2”.

Page 10

Installation instructions 6 2.3 internal parts of the boiler legend 1. Flue safety thermostat 2. Fan 3. Heat exchanger 4. Combustion chamber 5. Ignition electrocode 6. Burner 7. 3 bar pressure relief valve 8. Pump 9. D.H.W. Sensor 10. Sistem drain valve 11. Flow limiter 12. Electronic gas valve 13. ...

Page 11

Installation instructions 7 2.4 circulation pump head/flow graph pump head at minimum speed i ii pump head at second speed pump head at maximum speed iii appliance loss flow m3/h h e a d ( m ) i ii iii.

Page 12

Installation instructions 8 1 2 3 4 5 6 14 7 8 10 9 11 12 13 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 2.5 water circuit legend 1. Flue safety thermostat 2. Fan 3. Expansion vessel 4. Heat exchanger 5. Ignition electrocode 6. Burner 7. Electronic gas valve 8. 3 bar pressure relief valve 9. Air...

Page 13

Installation instructions 9 2.6 digitech ® tr printed circuit board (miah6) technical characteristics adjustments possible by service personnel only • standard (30/80°c) / reduced (25-45°c) central heating temperature • water hammer prevention function • central heating timer - (adjustable from 0 to...

Page 14

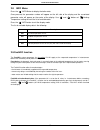

Installation instructions 10 2.8 info menu press the ‘ ’ info button to display the boiler data. Once pressed, the parameter number will appear on the left side of the display and the associated parameter value will appear on the centre of the display. Use ‘ ’ and ‘ ’ buttons of heating temperature ...

Page 15: 3. Installation

Installation instructions 11 3. Installation 3.1 reference standard failure to install a gas appliance correctly and in accordance with the above norms could lead to prosecution. It is in the interest of the installer and safety that the law is complied with. The manufacturers instructions form an i...

Page 16

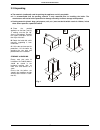

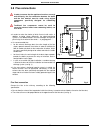

Installation instructions 12 b c a 3.3 unpacking ■ the materials (cardboard) used for packing the appliance are fully recyclable. ■ it is recommended that the packing material is only removed prior to installing the boiler. The manufacturer will not be held responsible for damage caused by incorrect...

Page 17

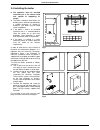

Installation instructions 13 3.4 installing the boiler ■ the appliance must be installed exclusively on a flat vertical solid wall capable of supporting its weight. ■ the boiler should be fitted within the building unless otherwise protected by a suitable enclosure i.E. Garage or outhouse. (the boil...

Page 18

Installation instructions 14 3.5 water connections in order to safeguard the heat exchanger and circulation pump, especially in case of boiler replacement, it is recommended that the system is hot-flushed to remove any impurities (especially oil and grease) from the pipes and radiators. Make sure th...

Page 19

Installation instructions 15 3.6 gas connection the connection to the gas supply must be carried out by professionally qualified personnel in accordance with relevant standards: when connecting the boiler to the gas supply pipe, only use appropriate washers and gas fittings. The use of hemp, teflon ...

Page 20

Installation instructions 16 3.7 electrical connections general warnings the connection to the mains power supply must be carried out by professionally qualified personnel, registered in accordance with current legislation and authorised by radiant bruciatori s.P.A. Always check to make sure that th...

Page 21

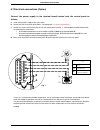

Regulation instructions 17 remote control connection connect the power supply to the terminal board inside the control panel as follows: a. Switch off the power supply at the main switch. B. Remove the front case panel of the boiler. C. Slacken the screws and remove plate a (see fig. 1). D. With the...

Page 22: 3.8 Flue Connections

Regulation instructions 18 3.8 flue connections in order to ensure that the appliance functions correctly and efficiently, the flue connection between the boiler and the flue terminal must be made using original components specifically designed for condensing boilers. Traditional flue components can...

Page 23: Flue Type - Kit K

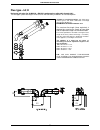

Regulation instructions 19 flue type - kit k horizontal concentric flue kit Ø60/100 mm polypropylene inner pipe adjustable through 360°. Discharges exhaust fumes and draws air from atmosphere. Suitable for condensing boilers only. Discharges exhaust gases and draws combustion air by means of two con...

Page 24: Flue Type - Kit H

Maintenance instructions 20 flue type - kit h horizontal twin pipe flue kit Ø80/80 – Ø60/60 in polypropylene adjustable through 360°. The dual pipe system discharges exhaust fumes into a chimney and draws air from atmosphere. Suitable for condensing boilers only. Discharges exhaust gases and draws c...

Page 25: Flue Type - Kit V

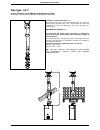

Maintenance instructions 21 flue type - kit v vertical concentric flue kit Ø60/100 polypropylene inner pipe. Discharges exhaust fumes and draws air directly from high level. Suitable for condensing boilers only. Discharges exhaust gases and draws combustion air at roof level by means of two concentr...

Page 26

Maintenance instructions 22 adjustable flue diaphragms • coaxial flue kit system (horizontal-coaxial or vertical-coaxial) adjustable flue diaphragms have to be installed on the top of boiler. Installation instructions: (see fig. 1): − clean the inspection collar surface; − stick the neoprene washer ...

Page 27

Maintenance instructions 23 twin pipe flue kit system adjustable flue diaphragms have to be installed on the air intake hole on the top of the boiler. Installation instructions: (see fig. 1): − install the Ø60mm. Aluminium collar onto the flue exhaust vertical connector and fit it on the top of boil...

Page 28

Maintenance instructions 24 diaphragms system setting • kit k - horizontal-coaxial flue kit system with intake / exhaust pipes Ø100/60 • kit v - vertical-coaxial flue kit system with intake / exhaust pipes Ø100/60 • kit h - separate air intake/exhaust fumes discharge system through 360° linear lengt...

Page 29

Maintenance instructions 25 4. Commissioning the appliance 4.1 general warnings the following operations must be carried out by professionally qualified personnel, registered in accordance with current legislation. The boiler leaves the factory pre-set and tested for burning either natural gas or lp...

Page 30

Maintenance instructions 26 4 air vent valve plug pump plug air vent valve 3 2 1 3 bar 1.5 bar 0.5 bar 1.2 bar green area m r 4.2 filling the system check the properties of the water supply and install the appropriate treatment devices if the mains water has a hardness rating more than 25 °f i n ord...

Page 31

Maintenance instructions 27 4.3 filling the condensate trap the condensation trap must be pre-filled when starting the boiler for the first time in order to prevent flue gases from flowing back through the trap. The filling operation is carried out as follows (see fig. 1): • remove plug t and fill t...

Page 32

Maintenance instructions 28 4.4 frost protection the boiler is protected from freezing by electronic board settings and special functions that provide the starting of the burner to heat all the interested parts, when their temperature drops below the minimum preset values, protecting the boiler up t...

Page 33

Maintenance instructions 29 t a l n t a s e s e 220 v - 50 hz terminal board heating elements fig. 1 brown white wh ite blue thermostat fixing clip heating elements kit installation and wiring please proceed as follows: a. Switch off the power supply at the main switch; b. Position the 4 resistances...

Page 34

Maintenance instructions 30 4.5 starting up the boiler once the system has been filled, proceed as follows: • check that the exhaust duct is free from obstructions and correctly connected to the flue exhaust system. • remove the front panel (see 6.3 ‘accessing the boiler’); • unscrew the screw of th...

Page 35: 5. Regulating The Boiler

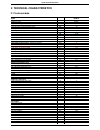

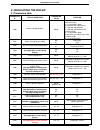

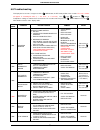

Maintenance instructions 31 5. Regulating the boiler 5.1 parameters table parameter n° type of operation parameter value function p00 selects the type of boiler 00-05 00 = instantaneous boiler (w/dual circuit exchanger) 01 = instantaneous boiler (w/secondary d.H.W plate exch.) 02 = storage cylinder ...

Page 36

Maintenance instructions 32 5.2 accessing the parameters menu to modify the preset values of the parameters reported in the previous table, open the parameter settings menu as follows: 1. Place mode selection button ‘ ’ in off position; 2. Keep pressed ‘ ’ and ‘ ’ buttons simultaneously and wait for...

Page 37

Maintenance instructions 33 5.3 setting the parameters p arameter p00 – selects the type of boiler to enter the parameters menu, follow the previously described procedure (see paragraph 5.2 ‘accessing the parameters menu’ - steps 1-5). 6. Use ‘ ’ and ‘ ’ buttons (d.H.W temperature setting) to modify...

Page 38

Maintenance instructions 34 p arameter p03 - w ater hammer prevention function activating this function, the d.H.W contact is delayed for 2 seconds. To enter the parameters menu, follow the previously described procedure (see paragraph 5.2 ‘accessing the parameters menu’ - steps 1-5). 6. Use ‘ ’ and...

Page 39

Maintenance instructions 35 p arameter p05 - c entral heating pump overrun timer this parameter is used to set the pump functioning time, in heating mode, after switching off the main burner for the intervention of the room thermostat. To enter the parameters menu, follow the previously described pr...

Page 40: 5.4

Maintenance instructions 36 5.4 gas valve adjustment p arameter p08 - m aximum domestic hot water output before switching on the boiler to adjust the setting, insert a pressure gauge in the pressure take-off point b on the gas valve (fig. 1); to enter the parameters menu, follow the previously descr...

Page 41

Maintenance instructions 37 p arameter p07 - m inimum central heating output 12. Enter the parameters menu and select parameter p07. The pressure gauge will indicate the gas pressure. If this pressure value is different to that on the rating plate of the boiler (see paragraph 5.4 ‘gas data’), use ‘ ...

Page 42

Maintenance instructions 38 p arameter p09 – s ets the ignition sequence this parameter is used to set the gas pressure during the starting up of the boiler.. To enter the parameters menu, follow the previously described procedure (see paragraph 5.2 ‘accessing the parameters menu’ - steps 1-5). 6. U...

Page 43

Maintenance instructions 39 te (°c) 35 30 25 20 15 10 75 80 45 max tm (°c) 5 0 -5 -10 65 55 60 50 40 45 35 30 30 -15 -20 25 min 35 70 kd = 0 kd = 5 kd = 10 kd = 15 kd = 20 kd = 25 kd = 30 p arameter p12 – sets the climatic compensation curve (w/outdoor temperature sensor only installation) the insta...

Page 44

Maintenance instructions 40 p arameter p13 – c entral heating m inimum s et point this parameter is used to set the central heating minimum user set point. To enter the parameters menu, follow the previously described procedure (see paragraph 5.2 ‘accessing the parameters menu’ - steps 1-5). 6. Use ...

Page 45

Maintenance instructions 41 p arameter p15 – d. H . W . Maximum set point this parameter is used to set the d.H.W maximum user set point. To enter the parameters menu, follow the previously described procedure (see paragraph 5.2 ‘accessing the parameters menu’ - steps 1-5). 6. Use ‘ ’ and ‘ ’ button...

Page 46

Maintenance instructions 42 5.5 gas data technical data tables natural gas g20 liquid butane gas g30 liquid propane gas g31 lower wobbe index (15°c; 1013 mbar) mj/nm 3 45.67 80.58 70.69 nominal supply pressure mbar 20 30 37 main burner jets: n° x Ø (mm) 13 x 1.25 13 x 0.77 13 x 0.77 consumption (15°...

Page 47

Maintenance instructions 43 5.7 converting the boiler to a different gas type the conversion of a boiler from burning natural gas to lpg, or vice versa, must be carried out exclusively by professionally qualified personnel, registered in accordance with current legislation. Check that the gas supply...

Page 48: 6. Maintenance

Maintenance instructions 44 6. Maintenance (authorised personnel) 6.1 general warnings all maintenance operations must be carried out by professionally qualified personnel, authorised by radiant bruciatori spa. The frequency of boiler maintenance must comply with current law and, nevertheless, shoul...

Page 49

Maintenance instructions 45 6.3 accessing the boiler all maintenance operations require one or more of the boiler casing panels to be removed. The side panels can only be removed after the front panel has been removed. Front panel: remove the fixing screws at the lower edge of the front panel. Grasp...

Page 50

Maintenance instructions 46 6.4 draining the central heating system if the need arises to drain the system, this can be done as follows: • switch the system to “winter” mode and ignite the boiler. • switch off the power supply to the boiler. • wait for the boiler to cool down. • connect a hosepipe t...

Page 51

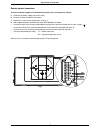

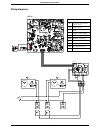

Maintenance instructions 47 sr ts pacq ma ce tra ea m9 m7 m4 m8 m6 m13 m11 m12 m15 m3 m10 er 4 3 2 1 1 2 3 4 5 8 1 2 3 4 5 6 7 1 2 3 4 5 6 7 2 1 1 2 3 4 5 6 1 2 c e m a ne ne ce ma ev vg md mf ar ar ce ma ma ce ne ne ne ne ne ce ma ne 1 2 3 pa mp s e s e t a t a n l vd ne ce ma sf tf ss c 6.6 wiring...

Page 52

Maintenance instructions 48 t a b l n t a s e s e a ta cr se fig. 1 6.7 electrical connections (option) connect the power supply to the terminal board located onto the control panel as follows: a. Switch off the power supply at the main switch; b. Remove the front case panel of the boiler. (see para...

Page 53

Maintenance instructions 49 svz srb miah6 n l tp ct wiring diagrams: key tp storage cylinder pre-heating timer option (only if parameter p00 = 2, 3 or 4) ct telephone control srb remote boiler lock-out indicator option svz zone valves management pcb (if remote control is installed) taz 1 zone 1 room...

Page 54

Maintenance instructions 50 6.8 troubleshooting to display the last 5 errors, keep pressed the ‘ ’ info button, in off mode position, for 5 seconds. The errors number will appear in chronological order (-1- = first fault… -5- = last fault) . Use ‘ ’ and ‘ ’ buttons of heating temperature setting, to...

Page 55

Maintenance instructions 51 6.9 function codes code function description f07 flue test function enabled (chimney- sweeper) pressing ‘ ’ button for 7 seconds the flue test function is enabled. Pressing the boiler off button the function is disabled. The flue test function operates the boiler at the m...

Page 56

Maintenance instructions 52 6.10 parts list main components code description 20047la 20-plate d.H.W heat exchanger 21001la burner 13 r- 1.25 nat.Gas 25-00131 3 bar pressure relief valve -htg circ. 25-00196 water pressure gauge 25-00261 pump upso 15-50 aokr 27044la condensate trap 30-00024 air pressu...

Page 58

Radiant bruciatori s.P.A. Via pantanelli, 164/166 - 61025 loc. Montelabbate (pu) tel. +39 0721 9079.1 • fax. +39 0721 9079279 e-mail: info@radiant • internet: http://www.Radiant.It the technical data and measurements are provided for information purposes only and are not binding. The company reserve...