Sedbuk band a installation, operating, commissioning and maintenance instructions . Ce 0694 ta05a140 .A0307 technical specification radiant bruciatori s.P.A. Montelabbate (pu) italy english instruction manual for model rk 25 premix condensing system boiler.

Contents 1. General information 1.1 general warnings pag. 1 1.2 product conformity 3 2. Technical characteristics 2.1 technical data 4 2.2 dimensions 5 2.3 internal parts of the boiler 6 2.4 water circuit 7 2.5 circulation pump head/flow graph 8 2.6 printed circuit board – technical characteristics ...

Contents 6. Maintenance (authorised personnel) 6.1 general warnings pag. 37 6.2 boiler inspection 37 6.3 accessing the boiler 38 6.4 flushing out the primary side 38 6.5 draining the central heating and domestic hot water system 39 6.6 maintenance operations 40 6.7 wiring diagrams 46 6.8 troubleshoo...

General information ta05a140.A0307 1 1. General information 1.1 general warnings professionally qualified personnel in accordance with current laws and standards and in line with the manufacturer’s instructions must install the appliance. In gb, the installation must be carried out by a corgi regist...

General information ta05a140.A0307 2 • only original accessories or optional extras (including electrical parts) must be used with the appliance. • should there be a smell of gas present in the room where the appliance is installed, do not attempt to activate any electric switches, telephones or any...

General information ta05a140.A0307 3 1.2 product conformity radiant bruciatori s.P.A. Declares that all its products are manufactured to a high specification and in compliance with the relevant standards. All radiant boilers are ce certified and possess technical and functional characteristics that ...

Technical characteristcs ta05a140.A0307 4 2. Technical characteristics 2.1 technical data models rk 25 ce certification n° 0694bn3485 appliance type c13, c33, c43, c53, c63, c83 appliance category ii2h3+ heat input max kw 25 heat input min kw 9 heat output max (50/30°) kw 26.67 efficiency 100% (full...

Technical characteristcs ta05a140.A0307 5 110 137 163 285 132 730 hf g hr 49 31 285 730 111.5 187 111.5 48.5 313 48.5 105 182 148 2.2 dimensions legend hr heating return Ø3/4” hf heating flow Ø3/4” g gas Ø1/2” sc condensate drain Ø25.

Technical characteristcs ta05a140.A0307 6 2.3 internal parts of the boiler legend 1. Primary condensing heat exchanger 2. Premix burner unit (gas manifold + burner) 3. Condensate drain pipe 4. Ionisation electrode 5. Ignition electrode 6. Fan 7. Venturi 8. Ignition transformer 9. Electronic gas valv...

Technical characteristcs ta05a140.A0307 7 2.4 water circuit legend 1. Primary condensing heat exchanger 2. Premix burner unit (gas manifold+burner) 3. Primary condensing heat exchanger condensate drain pipe 4. Ionisation electrode 5. Ignition electrode 6. Fan 7. Venturi 8. Ignition transformer 9. El...

Technical characteristcs ta05a140.A0307 8 2.5 circulation pump head/flow graph i ii i ii iii 1400 1200 1600 70 50 60 40 1000 800 400 600 30 10 20 0 0 200 iii appliance loss available head at minimum speed available head at second speed available head at maximum speed flow l/h he ad ( kpa ).

Technical characteristcs ta05a140.A0307 9 2.6 digitech ® printed circuit board – sm 20019 technical characteristics adjustments possible by service personnel only • standard (30/80°c) / reduced (25-40°c) central heating temperature • water hammer prevention function • central heating timer - (adjust...

Installation instructions ta05a140.A0307 10 3. Installation (authorised personnel) 3.1 reference standard in gb, the installation must be carried out by a corgi registered installer. To check for authorised qualified engineers please contact corgi 01256-372400. It must be carried out in accordance w...

Installation instructions ta05a140.A0307 11 b c a 3.2 boiler room – installation requirements please refer to local and national standards in force in the country of destination of the product. In particular the manufacturer recommends: the presence of threaded connections on the gas line, require t...

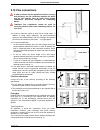

Installation instructions ta05a140.A0307 12 minimum distances in mm h a x l y model x y l h 1000 410 60 60 b a b 200 300 rk 25 3.4 installing the boiler ■ the appliance must be installed exclusively on a flat vertical solid wall capable of supporting its weight . ■ the boiler should be fitted within...

Installation instructions ta05a140.A0307 13 148 49 182 31 hr g hf 105 hf g hr Ø 22 mm Ø 15 mm Ø 22 mm 3.5 water connections in order to safeguard the heat exchanger and circulation pump, especially in case of boiler replacement, it is recommended that the system is hot-flushed to remove any impuriti...

Installation instructions ta05a140.A0307 14 3.6 central heating circuit the boiler is designed for use in a sealed central heating system in accordance with the requirements of bs 5449 and bs 6798. The system should be designed to operate with flow temperatures of up to 82°c. When designing the syst...

Installation instructions ta05a140.A0307 15 3.7 condensate drain failure to install the condensate discharge pipework correctly will affect the reliable operation of the boiler the condensate discharge pipe must not rise at any point along its length. There must be a fall of at least 2.5° (50mm per ...

Installation instructions ta05a140.A0307 16 3.8 gas connection the connection to the gas supply must be carried out by professionally qualified personnel in accordance with relevant standards: in gb this is bs 6891. When connecting the boiler to the gas supply pipe, only use appropriate washers and ...

Installation instructions ta05a140.A0307 17 3.9 electrical connections 3.9.1 general warnings the connection to the mains power supply must be carried out by professionally qualified personnel, registered in accordance with current legislation and authorised by radiant bruciatori s.P.A. Always check...

Installation instructions ta05a140.A0307 18 3.9.2 remote control connection connect the power supply to the terminal board inside the control panel as follows: a. Switch off the power supply at the main switch. B. Remove the front case panel of the boiler. C. Slacken the screws and remove plate a (s...

Installation instructions ta05a140.A0307 19 3.10 flue connections in order to ensure that the appliance functions correctly and efficiently, the flue connection between the boiler and the flue terminal must be made using original components specifically designed for condensing boilers. Traditional f...

Installation instructions ta05a140.A0307 20 3.10.1 flue position important: the flue system shall be installed in accordance with the recommendations contained in bs 5440:1. The boiler must be installed so that the terminal is exposed to the external air. It is important that the position of the ter...

Installation instructions ta05a140.A0307 21 3.10.2 flue type - kit k horizontal concentric flue kit Ø60/100 mm polypropylene inner pipe adjustable through 360 °. Discharges exhaust fumes and draws air from atmosphere. Suitable for condensing boilers only. Discharges exhaust gases and draws combustio...

Installation instructions ta05a140.A0307 22 3.10.3 flue type - kit h horizontal twin pipe flue kit Ø80/80 – Ø60/60 in polypropylene adjustable through 360°. The dual pipe system discharges exhaust fumes into a chimney and draws air from atmosphere. Suitable for condensing boilers only. Discharges ex...

Installation instructions ta05a140.A0307 23 3.10.4 flue type - kit v vertical concentric flue kit Ø60/100 polypropylene inner pipe . Discharges exhaust fumes and draws air directly from high level. Suitable for condensing boilers only. Discharges exhaust gases and draws combustion air at roof level ...

Installation instructions ta05a140.A0307 24 4. Commissioning the appliance 4.1 general warnings the following operations must be carried out by professionally qualified personnel, registered in accordance with current legislation. Reference should be made to bs 5449:5 “commissioning”. The boiler lea...

Installation instructions ta05a140.A0307 25 pump plug pump air vent valve plug air vent valve rs m 4.2 filling the system use only a wras approved filling loop for connection and filling of the primary system. This should be disconnected when not in use. Check the properties of the water supply and ...

Installation instructions ta05a140.A0307 26 t s 4.3 flushing the system failure to flush and add inhibitor to the system will invalidate the appliance working. All systems must be thoroughly drained and flushed out using additives – corrosion inhibitors and flushing agents/descalers that comply to b...

Installation instructions ta05a140.A0307 27 4.5 starting up the boiler once the system has been filled, proceed as follows: • check that the exhaust flue is free of obstructions and correctly connected to the boiler; • switch on the power supply to the boiler; • open the gas isolation valve; • place...

Regulation instructions ta05a140.A0307 28 5. Regulating the appliance 5.1 parameters table notes: 1 - activate only for “heating only” boilers; 2 - if the heating system has more than one zone, an additional interface board (optional extra) must be installed on the circuit board and parameter 15 set...

Regulation instructions ta05a140.A0307 29 5.2 setting the parameters to modify the preset values of the parameters reported in the previous table, open the parameter settings menu as follows: 1. Place the on/off switch in the off position. 2. Activate the on/off switch while keeping buttons ‘+’ and ...

Regulation instructions ta05a140.A0307 30 to enter the parameters menu, follow the previously described procedure (steps 1-5). P arameter 1 – t ype of boiler 6. Use buttons ‘+’ and ‘-‘ to modify the value of the parameter: 00 = instantaneous boiler 01 = storage boiler; 02 = storage boiler ‘comfort’ ...

Regulation instructions ta05a140.A0307 31 p arameter 4 – c entral heating pump 6. Use buttons ‘+’ and ‘-‘ to modify the value of the parameter: 00 = standard (3” overrun) 01 = permanent (always running) 7. Press and release button ‘s’ to confirm. The parameter number (4) will appear on the display. ...

Regulation instructions ta05a140.A0307 32 s s 7 360 s s 180 8 p arameter 7 – c entral heating pump overrun timer 6. Use buttons ‘+’ and ‘-‘ to modify the value of the parameter within the prescribed limits 00 = 0 x 5” = 0” 90 = 90 x 5” = 450” (7.5 min) the default value is 36 = 180” = 3 min 7. Press...

Regulation instructions ta05a140.A0307 33 p arameter 13 – d.H.W priority not applicable p arameter 14 – t ype of burner 6. Use buttons ‘+’ o ‘-’ to modify the value of the parameter: 00 = boiler with atmospheric burner; 01 = boiler with premix burner 25 kw; 02 = boiler with premix burner 29-34 kw ; ...

Regulation instructions ta05a140.A0307 34 p arameter 17 – m inimum f an s peed s etting not applicable p arameter 18 – m aximum f an s peed s etting not applicable p arameter 19 – m inimum f an s peed s etting c entral h eating m ode 6. Use buttons ‘+’ o ‘-’ to modify the value of the parameter betw...

Regulation instructions ta05a140.A0307 35 p arameter 21 – i gnition s equence s etting 6. Use buttons ‘+’ o ‘-’ to modify the value of the parameter between: min = value of parameter 17; max = value of parameter 18. The default value is: - 90 hz for natural gas; - 110 hz for l.P.G.; 7. Press and rel...

Regulation instructions ta05a140.A0307 36 5.3 gas data 5.3.1 technical data tables table no.3 - gas data table natural gas g20 liquid butane gas g30 liquid propane gas g31 indice di wobbe inferiore (15°c; 1013 mbar) mj/nm 3 45.67 80.58 70.69 pressione nominale di alimentazione mbar 20 30 37 consumi ...

Installation instructions ta05a140.A0307 37 6. Maintenance (authorised personnel) 6.1 general warnings all maintenance operations must be carried out by professionally qualified personnel, authorised by radiant bruciatori spa. The radiant helpline uk 0870 770 0414 the frequency of boiler maintenance...

Installation instructions ta05a140.A0307 38 6.3 accessing the boiler all maintenance operations require one or more of the boiler casing panels to be removed. The side panels can only be removed after the front panel has been removed. Front panel: remove the fixing screws at the lower edge of the fr...

Installation instructions ta05a140.A0307 39 6.5 draining the central heating system if the need arises to drain the system, this can be done as follows: • switch the system to “winter” mode and ignite the boiler. • switch off the power supply to the boiler. • wait for the boiler to cool down. • conn...

Installation instructions ta05a140.A0307 40 6.6 maintenance operations before carrying out any cleaning or part replacement operations, always turn off the electricity, water and gas supplies to the boiler. Radiant bruciatori s.P.A. Will not be held responsible for damage to any of the boiler’s comp...

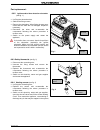

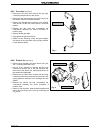

Installation instructions ta05a140.A0307 41 6.6.1 cleaning the main exchanger module and combustion unit (see fig. 1) • disconnect the electrical connections of the electric fan. • disconnect the joint and remove the pipe linking the gas valve to the injector unit (venturi). • disconnect the joint a...

Installation instructions ta05a140.A0307 42 heating sensor safety thermostat part replacement : 6.6.2 ignition and/or flame detection electrodes (see fig. 1) • un-plug the electrode wires; • slacken the fixing screws; • remove the electrodes. When fitting the new ones, check that the seals are not d...

Installation instructions ta05a140.A0307 43 6.6.5 gas valve (see fig. 2) • disconnect the joints and remove the gas pipe connecting the gas valve to the venturi. • disconnect the gas feed pipe and valve ring-nut at the bottom of the room-sealed chamber. • remove the flanged elbow coupling of the exi...

Installation instructions ta05a140.A0307 44 6.6.7 expansion vessel (see fig. 1) • close the shut-off valves and drain the central heating circuit of the boiler. • use a 19 mm spanner to unscrew the pipe coupling to the vessel. • unscrew the fixing screws and remove the upper mounting bracket. Remove...

Installation instructions ta05a140.A0307 45 6.6.9 modulation circuit board (see fig. 1-2) • open the control panel (see 6.3 “accessing the boiler”); • disconnect all the connectors, remove the regulating knobs, unscrew the four fixing screws and remove the modulation circuit board; • replace the cir...

Installation instructions ta05a140.A0307 46 6.6.11 primary heat exchanger (see fig. 1) • close the shut-off valves and drain the central heating circuit of the boiler; • switch off the power and gas supply to the boiler; • remove and dismantle the entire burner unit (see 6.6.1 “cleaning the condensa...

Installation instructions ta05a140.A0307 47 6.6 wiring diagrams 6.7.1 electrical connections m7 m5 m9 m4 m6 m2 1 2 3 4 5 66 7 8 m1 1 2 3 4 5 6 1 2 3 4 5 6 7 1 2 3 4 1 2 3 4 5 6 5 4 m10 3 2 1 zone valve management + option remote controller board zone valve contact closure remote controller zone valv...

Installation instructions ta05a140.A0307 48 6.7.2 connecting the room thermostat (option) connect the wires to the terminal board inside the instrument panel as follows: (example with week digital weekly chronostat): a. Switch off the power supply at the main switch. B. Remove the front case panel o...

Installation instructions ta05a140.A0307 49 remote "open therm" a se se ta n l b ta outside temperature sensor (option) ta b ln ta se se a remote "open therm" telephone control 6.7.4 connecting the remote controller the outside temperature sensor (option) connect the wires to the terminal board insi...

Installation instructions ta05a140.A0307 50 ou ts id e te mp er atu re se ns o r (o pt ion) t ermi na l bl ock re mo te "o p e n the r m" zone va lv e mana g em ent + o pti on r emote co nt ro ller boar d 6.7.6 remote control and zone valves wiring for the installation of a zone valve p.C.B, it is n...

Installation instructions ta05a140.A0307 51 re mo te "o p e n t h e r m" t e le ph on e c ont ro l termin a l blo ck o ut side te mp er at ure se ns or (o ption) zo ne valve m a nagem ent + optio n remo te control ler bo ar d 6.7.7 remote control, zone valves and telephone control wirings.

Installation instructions ta05a140.A0307 52 6.7.8 regulating the flow temperature in accordance with the outdoor temperature the outdoor sensor has to be connected directly to circuit board sm 20019. The sensor can thus be managed in one of two ways: • in case of remote controller + outdoor temperat...

Installation instructions ta05a140.A0307 53 6.8 troubleshooting error code problem possible cause remedy e01 no flame with no ignition a. No gas. B. Ignition electrode broken or earthed. C. Gas valve malfunction d. Mechanical minimum adjustment (on gas valve) set too low or slow ignition adjustment ...

Installation instructions ta05a140.A0307 54 6.9 diagnostics ■ error codes: e01 ionisation lock out e02 safety thermostat tripped e03 flue gas thermostat tripped h2o low water pressure alarm e05 heating sensor malfunction e06 d.H.W sensor malfunction (not applicable) e12 d.H.W storage cylinder sensor...

Installation instructions ta05a140.A0307 55 6.10 parts list 6.10.1 main components code description rk 25 20069la primary exchanger isotherm. 4+1 3+2 25kw 9 24052la pump ups 15-50 ciao 3v. 9 27044la condensate trap 99200229 9 36067la electronic gas valve vk4115v1006b 9 36068la venturi 45900444002b 9...

Radiant bruciatori s.P.A. Via pantanelli, 164/166 - 61025 loc. Montelabbate (pu) tel. +39 0721 9079.1 • fax. +39 0721 9079279 e-mail: tecnico@radiant • internet: http://www.Radiant.It radiant helpline uk technical helpline - 0870 770 0414 spares - 0870 770 0424 email - info@portsdean.Co.Uk the techn...