- DL manuals

- Radiant

- Boiler

- RS 20 E

- Installation And Maintenance Manual

Radiant RS 20 E Installation And Maintenance Manual

Summary of RS 20 E

Page 1

Ta02a101.B1203 technical specification radiant bruciatori s.P.A. Montelabbate (pu) italy english installation, and maintenance manual for gas fired, only heating wall-hung boilers (system boilers) model rs 20 e / 40 - 60 type c room sealed model rs 24 e / 70 - 90 type c room sealed sedbuk band d.

Page 3

Index installation instructions and warnings page 1 technical data page 2 overall dimensions - exhaust flue system page 3 general installation requirements page 5 boiler installation page 7 boiler control panel page 9 starting up the boiler for the first time page 9 main components page 10 open (ven...

Page 4

Installation manual system boiler – ta02a009a0703 1 the friendly power of heat thank you for choosing radiant declaration for purposes of art. 7 of law 46 of 5 april 1990. Radiant bruciatori s.P.A. Hereby declares that all of its products are constructed to industry standards as required by the arti...

Page 5

Installation manual system boiler – ta02a009a0703 2 model rs technical data type c devices are devices in which the combustion circuit (air intake, combustion chamber, exchanger, combustion exhaust) is sealed off from the place where they are installed. Central heating only sealed combustion circuit...

Page 6

Installation manual system boiler – ta02a009a0703 3 overall dimensions type c wall-mounted boilers sealed combustion circuit: kit a horizontal coaxial exhaust flue system with 360° rotation. Allows fumes exhaust and air intake from external wall. N.B.: to insert a bend in the flue, reduce total flue...

Page 7

Installation manual system boiler – ta02a101.B1203 4 kit b. Double exhaust/intake flue system with 360° rotation. The twin tube system allows fumes exhaust into a flue duct and air intake from outside. N.B.: to insert a 90° bend in the flue, reduce total flue length by 1.5 m. To insert a 45° bend in...

Page 8

Installation manual system boiler – ta02a101.B1203 5 general installation requirements gas safety it is the law that all gas appliances are installed by a corgi registered installer (you can check this by contacting corgi on 01256.372200) in accordance with the regulations listed below. Failure to i...

Page 9

Installation manual system boiler – ta02a101.B1203 6 flue position important: the flue system shall be installed in accordance with the recommendations contained in bs 5440:1. The boiler must be installed so that the terminal is exposed to the external air. It is important that the position of the t...

Page 10

Installation manual system boiler – ta02a101.B1203 7 minimum distances for fixing to wall to allow access in the boiler for maintenance operations, the minimum distances shown below must be respected (fig. 1): installation instruction 1. With a spirit level, draw a line on the wall on which the boil...

Page 11

Installation manual system boiler – ta02a101.B1203 8 gas connections the gas supply must be connected up by qualified person. The following standards must be complied with: unicig 7131/72 and unicig 7129/92 (of 21/04/93) before installing the boiler, make sure of the following: the pipeline must be ...

Page 12

Installation manual system boiler – ta02a101.B1203 9 starting up the boiler before turning on the boiler read the following warnings carefully . Make sure that the warranty booklet carries the stamp of the authorised technician responsible for installing the boiler. Installation, starting up for the...

Page 13

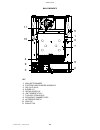

Installation manual system boiler – ta02a101.B1203 10 main components 4 1 3 2 5 6 7 8 9 10 11 key 1. Main heat exchanger 2. Electronic ignition board s4565qm1012 3. Gas valve vk4105 4. Burner 13 r. 5. Heating sensor 1/8” 6. Limit thermostat 90°c 7. Flue hood room sealed 8. Room-sealed chamber cover ...

Page 14

Installation manual system boiler – ta02a101.B1203 11 22 mm (min.) drain cock lockshield bypass with return valve flow 22 mm vent (min.) cold feed 15 mm (minimun) feed and expansion circulating pump cistern point air release heigh t 450 mm mi n. Valve ser vice cold main 115 0 mm mi n. 600 mm. M in ....

Page 15

Installation manual system boiler – ta02a101.B1203 12 sealed water system safety valve: a safety valve complying with bs 6750 part 1 must be fitted close to the boiler on the flow pipe by means of a horizontal or vertically upward connection with no intervening valve or restrictions and should be po...

Page 16

Installation manual system boiler – ta02a101.B1203 13 supply terminal block l n electrical connections the boiler works with 230 v 50 hz ac current and has maximum input of 70 w. Connection to the electrical mains must be performed with a switch having an dual polar opening of at least 3 mm. Make su...

Page 17

Installation manual system boiler – ta02a101.B1203 14 electrical connections 32 - air pressure swtich - io nisatio n electrode - ignitio n electrode - sammer-winter switch - heating sensor - safety thermo stat - fan - neutral - main switch - line important: rispect live neutral-polarity 30 b la ck 3...

Page 18

Installation manual system boiler – ta02a101.B1203 15 regulating the max. And min. Modulation gas pressure to regulate the maximum gas pressure to the burner proceed as follows: insert a gauge into the pressure socket b (fig.1). Remove the aluminium protective cap from screw a (fig.1) counter-clockw...

Page 19

Installation manual system boiler – ta02a101.B1203 16 tr1 f u s e 2 a tr2 cm1 p2 min.Gas cm1 cm1 selector selector link disabled on cm1 selector. Timing 3 min. Timing 0 min. Link inserted on cm1 selector. Gas type conversion conversion of the boiler from natural gas to lpg and vice versa must be per...

Page 20

Installation manual system boiler – ta02a101.B1203 17 gas burner pressure g 20 15°c 1013 mbar 0 2.5 5.0 7.6 10.1 12.6 15.1 0 1 2 3 4 5 6 7 8 t h e rm a l c a p a c it y kw gas burner pressure in mbar 0 10000 20000 30000 40000 50000 60000 90000 100000 btu/h g 20 15°c 1013 mbar 5 6 7 8 9 10 11 12 gas ...

Page 21

Installation manual system boiler – ta02a101.B1203 18 gas burner pressure g 30-31 15°c 1013 mbar rs 20 e 0 10000 20000 30000 40000 50000 60000 70000 80000 90000 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 gas pressure mbar t h e rm a l c a p a c it y b tu /h g 30-31 15°c 1013 mbar rs 24 e 0 10000 20...

Page 22

Installation manual system boiler – ta02a101.B1203 19 short list n° code description rs 20 e / 40-60 rs 24 e / 70-90 electronic ignition electronic ignition 1 58006la main heat exchanger 20.000 kcal/h 58007la main heat exchanger 24.000 kcal/h 2 36066la electronic gas valve vk4105 g1112 3 76631la ele...

Page 23

Installation manual system boiler – ta02a101.B1203 20 fault finding chart maintenance to keep the boiler in efficient and safe operating condition, we recommend you perform the following checks at least once a year: check all seals on the gas side and replace gaskets to restore perfect seal as requi...

Page 24

Radiant bruciatori s.P.A. Via pantanelli, 164/166 - 61025 loc. Montelabbate (pu) tel. +39 0721 9079.1 • fax. +39 0721 9079279 e- mail: tecnico@radiant • internet: http://www.Radiant.It uk – radiant helpline – 01329.828555 all descriptions and illustrations contained in this leaflet have been careful...