- DL manuals

- RADWAG

- Scales

- APP R

- User Manual

RADWAG APP R User Manual

Summary of APP R

Page 1

R series balances as r2 analytical balances ps r1 precision balances ps r2 precision balances ps r2.H precision balances app r precision balances user manual immu-03-24-06-16-en www.Radwag.Com.

Page 2

- 2 - if you are reading this, it means that you are bound to achieve success. You have purchased a device that was designed and manufactured to give you years of service. Congratulations and thank you for selecting radwag product. June 2016.

Page 3

- 3 - table of contents 1. General information .................................................................................... 6 1.1. Dimensions ........................................................................................... 6 1.2. Connectors ...........................................

Page 4

- 4 - 8.1. Adjustment report ............................................................................... 27 8.2. Header, footer, glp printouts ................................................................ 27 8.3. Non-standard printouts ............................................................

Page 5

- 5 - 11.11. Totalising ........................................................................................ 64 11.11.1. Additional settings ............................................................................... 64 11.11.2. Means of operation ...............................................

Page 6: 1. General Information

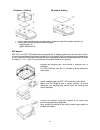

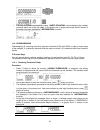

- 6 - 1. General information 1.1. Dimensions as series: ps series with pan 128 x 128 mm: ps series with pan 195 x 195 mm: app series:.

Page 7

- 7 - 1.2. Connectors 1 power supply socket 2 com 2 connector (additional display or external buttons) 3 com 1 connector (printer) 4 usb 2, type b (computer) 5 usb 1, type a (keyboard) 1.3. Connection cables - diagrams scale – computer cable (rs232) scale – printer cable (citizen, epson).

Page 8

- 8 - 1.4. Ps r2.H series ps r2.H series redefine the level of standard for precision balances. Not only do they share all the features of r series balances, but can also work in adverse operating conditions (condensed dust, drops of water falling down at different angles) typical for ip 54. Ps.R2.H...

Page 9

- 9 - caution! While cleaning it is advisable to follow below precautions. Additionally it is a must to disconnect the device from mains and unplug all the peripherals (printers, computer etc.) remembering at the same time to protect ports by means of stoppers. Only thus prepared device can be clean...

Page 10: 2. Transport And Storage

- 10 - 1.9. User manual significance it is very important to read the user manual carefully before switching on and starting up balance operation, even if the user is experienced and has worked with this type of balance before. 1.10. Balance user training the balance should be utilized and supervise...

Page 11

- 11 - 3.3. Standard delivery components list • balance • bottom insert (as balance exclusively) • centring ring (as balance exclusively) • weighing pan, open-work pan for as with d=0,01/0,1mg exclusively • draft shield (as and ps balances, d=0.001g, exclusively). • power supplier • user manual – cd...

Page 12

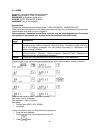

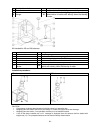

- 12 - ps balance, d=0.001g ps balance, d=0.01g • remove tape protecting the grounding spring, located on one of the rubber mandrels (1) • install components following the above diagram: • weighing pan (2), • glass draft shield (3). App balance app 10.R1 and app 10.R2 balances are equipped with 2 we...

Page 13

- 13 - 3.4. Settings it is necessary to level the balance prior connecting it to the mains. To level the balance turn its feet until an air bubble takes the central position. After adjusting the balance level, use a wrench (3) in order to screw a bolt (2) of foot (1), the bolt shall touch balance ho...

Page 14

- 14 - in case of heavy contamination use brush or detergent nevertheless avoid detergents containing large and hard molecules which could potentially scratch glass panes. Use soft brush with wooden or plastic handle exclusively to avaoid risk of scratches. Do not use wire brush. At the end of the c...

Page 15

- 15 - undo and remove top pane protection, next slide the pane out of a guide bar. Remove the back pane. Remove side panes. Side panes shall not be swapped therefore it is necessary to remember which one is right, and which one is left in order to install them back properly. Caution! Do not remove ...

Page 16

- 16 - 3.6. Powering the device balance can be connected to the mains only with a power adapter that comes standard with the particular model. Nominal power supply of the power adapter (specified on the power adapter data plate) should be compatible to the power from the mains. Plug the balance to t...

Page 17: 5. Start-Up

- 17 - press to select working mode. F5 button of the computer keyboard. Press to change measuring units. Print/enter button press to send measurement to a printer or a computer (print). Press to confirm selected parameter value or function (enter). Press to zero the balance press to tare the balanc...

Page 18

- 18 - the blinking thermometer pictogram means that temperature inside the balance is not stable, this may result in inaccurate mass measurement. For such a case it is recommended to wait until the temperature stabilizes or to perform balance adjustment (blanking of the blinking thermometer pictogr...

Page 20

- 20 - • home screen of the software is displayed again automatically. • when logged, add users and set the permissions levels (for the procedure of assigning permissions levels read section 9.1). On future logging in, select a user from the list and enter the password, the software initiates operat...

Page 21

- 21 - 5.8. Start unit selection upon selection of start unit, the balance activates with the specified unit for these modes where change of the unit is possible. Ability of selecting a given unit depends on the balance status, i.E. If the balance is verified or not. Procedure: 5.9. Custom unit you ...

Page 22

- 22 - available access levels: admin. / user. / adv. Depending on selected permissions level, you can enter balance parameters and modify the settings, as far as possible for a particular level (for permissions overview read point 9.1). „beep” sound – reaction to operation of pressing a key sound p...

Page 23

- 23 - date format date form. Parameter enables altering the date format on the printout [yyyy.Mm.Dd / yyyy.Dd.Mm / dd.Mm.Yyyy / mm.Dd.Yyyy], where: yyyy – year; mm – month; dd – day. Time format time form. Parameter enables specifying time format for a printout [12h / 24h]. For [12h] option selecte...

Page 24: 7. Adjustment

- 24 - procedure: to initiate parameter press button. The balance software launches the glp autotest procedure and it is carried out automatically from now on to the end. You can stop the procedure at any time by pressing button of the glp process window. Once the procedure is finished, the value of...

Page 25

- 25 - • balance user has 30 seconds to make a decision • in order to start adjustment, do not take any actions • in order to complete weighing procedure, press esc. When pressed, balance returns to weighing procedure and displays last weighing result. In about 5 minutes balance indicates cal_30 mes...

Page 26

- 26 - • p1.6 auto calib. C. - time of automatic adjustment determination of time interval for innitiation of automatic adjustment process (function unavailable for verified balances). 7.3. Manual adjustment 7.3.1. Internal adjustment the balance performs internal adjustment automatically. During ad...

Page 27

- 27 - 7.4. Adjustment report printout at the end of each adjustment process or adjustment test, an adjustment report is generated automatically and sent to a communication port com 1. The content of the report is declared in menu p5.1 cal report. The instruction on how to declare settings for this ...

Page 28

- 28 - footer group of parameters enabling to declare data that is to be printed on a footer printout.

Page 29

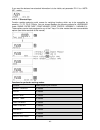

- 29 - printout variables list: variable overview active for working mode option enables printing out the name of a working mode. Header footer balance type option enables printing out the balance type. Header footer balance id option enables printing out the balance id number. Header footer user op...

Page 30

- 30 - header glp printout footer 8.3. Non-standard printouts the balance software enables entering 4 non-standard printouts. Each of them can consist of approximately 160 characters. Non-standard printout may include: • variables dependent on the working mode and other needs (mass, date etc.) • per...

Page 31

- 31 - variables depending on the currently used working mode variable description mode for which the variable is active %w standard mass 1 pcs parts counting %h high threshold checkweighing %l low threshold %a target mass dosing %b reference mass percent weighing non-standard characters used in des...

Page 33

- 33 - 9.1. Users each user is characterized by the following data: name (30 characters), code (6 characters), password (8 characters, digits only), access (user, advanced, admin), language (any of the available). Access levels the balance software has three access levels: user, advanced, administra...

Page 34

- 34 - • the software shows message in the bottom line • confirm by pressing button • when confirmed, the software removes the selected user from the list 9.2. Products products – 1000 different products. The following data can be inserted for each product: • name (30 characters), • code (6 characte...

Page 35

- 35 -.

Page 36

- 36 - the measurements saved in the balance’s memory cannot be deleted. It is possible for a user to view and print out the data saved in the memory. Procedure: each measurement is saved with its individual number. The format is: b4.4.N, where is the consecutive number of the saved measurement. In ...

Page 37

- 37 - ----------------------------------------------- signature ………….......................................... The data that is to be printed out, depends on the settings of parameter p5.3 glp printout. Parameters selected for the printout ( option), are printed out also on measurement result print...

Page 38

- 38 - 10. Export and import of databases this option allows the user to: • archive data relating to the carried out weighings – weighings database and alibi database. • copy the products, tares and users databases between balances of this series. This can be performed by using external usb flash dr...

Page 39

- 39 - 10.2. Database import function allows transfer of data, recorded in balance databases, from one balance to another. This is a quick and reliable way for entering the data without any mistakes. To import the database, plug a flash drive to usb port, next select import option and choose one of ...

Page 40: 11. Working Modes

- 40 - more data can be recorded in the same file. The balance software will add the data to the file that has already been created on a flash drive. Consequently, you can continue saving measurements in the same file once created. Caution: usb flash drive shall feature fat file system>. 11. Working...

Page 41

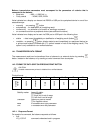

- 41 - - press to enter the selected working mode caution! Upon restart, the balance is launched with the most recently operated working mode!!! For settings of this function read later sections of this user manual. 11.1. Working modes accessibility group of parameters enabling the user to declare w...

Page 42

- 42 - yes no • avoid side loading, in particular side shocks: no no the balance requires adjusting before weighing process start or in case of drastic change of ambient conditions at a workstation. • before the start of weighing procedure, it is recommended to load the weighing pan a few times with...

Page 43

- 43 - caution! Taring negative values is impossible. On taring negative values the balance responds with an error message, err3. In such case, zero balance indication and repeat taring procedure. Manual tare determination procedure: • while in optional mode press quick access key f, to which option...

Page 44

- 44 - depending on the filter, the weighing time is shorter (v.Fast and fast) or longer (slow and v. Slow). Value release since ambient conditions at a workplace vary, it is necessary to determine the value release parameter in the most preferable way enabling balance adaptation, parameter options ...

Page 45

- 45 - balance ambient conditions parameter relating to ambient and environmental conditions in which the balance operates. There are two options: stable and unstable. Selecting stable mode makes the balance work much faster, i.E. Weighing takes much less time than for unsbable mode. If the ambient ...

Page 46

- 46 - • , for this option every single pressing of button results with sending the measurement indication to the printer port along with the settings for parameter. Every single indication is sent (stable and unstable). For unstable indication > character appears at the beginning of the printing fr...

Page 47

- 47 - 11.2.7. Information function enables displaying additional information in the bottom line. Depending on the needs, you can choose the following options, which are shown while working in weighing> mode: option presents amount of used weighing capacity in a graphic form, it covers 0 – max range...

Page 48

- 48 - if you want the declared non-standard information is to be visible, set parameter p2.1.2 to inf.> option. 11.2.9. F shortcut keys function enables assigning quick access for weighing functions which are to be accessible by pressing f1, f2, f3 or f4 keys. You can choose between the following o...

Page 49

- 49 - enter sample parts counting, dosing, percent weighing determine sample parts counting, percent weighing set hi_lo checkweighing exclusively start animal weighing, solids density, liquids density, pipettes calibration result statistics exclusively end statistics, totalizing delete last totaliz...

Page 50

- 50 - • upon completing under-pan weighing, put the plastic plug back onto its place. Caution! The suspension for hook must not be turned, twisted or manipulated in any direction. Such actions may cause damage to balance mechanism. Mass of all additional elements of under pan weighing kit, like the...

Page 51

- 51 - • use arrow buttons or to select the correct sample quantity. • for optional quantity variable (displayed value ) enter any number using arrow buttons • confirm selected sample quantity, confirmation message - placexx pcs> - shall be seen. • place the declared number of pieces in the containe...

Page 52

- 52 - • the balance software automatically enters parts counting> mode displaying the number of pieces which are on the pan (pcs). In the bottom line, a single piece mass value is shown (if the option has been selected for information> function) 11.4. Checkweighing checkweighing is a working mode t...

Page 53

- 53 - : mass contained within thresholds : mass higher than the value of the high threshold since lcd display capacity is limited, the threshold markers do not reflect threshold setups and target weight value precisely. They provide rough information and serve as user aid in course of the balance o...

Page 54

- 54 - • the sign is shown at the top of the display. It indicates the status of the mass on the pan with relations to the target mass. Bottom line of the display, if option is enabled, shall demonstrate weight indication, in a graphic form, in relation to target weight and set tolerance value : mas...

Page 55

- 55 - • 11.6.2. Setting the reference mass: entering mass value procedure: • press f button to which function enter sample> is assigned, enter sample> editing window is displayed. • use arrow buttons to enter the known reference mass value, press button to confirm. • the software automatically ente...

Page 56

- 56 - f shortcut keys you can declare which particular weighing function is to be launched using f1, f2, f3 or f4 keys. For procedure informing you how to declare the particular function, read f shortcut keys section. 11.7.2. Running the process manually – means of operation to start the process of...

Page 57

- 57 - 11.7.3. Running the process automatically – means of operation to start the process of weighing automatically, enter the mode settings, select an parameter and set value, follow description form the previous paragraph. Additionally set parameters and . In order to carry out the measurement in...

Page 58

- 58 - density determination 5 beaker 11 additional stand for a set of pans or a sinker 6 hanger 12 additional set of weighing pans for density determination of solids with density lower that density of water kit intended for as and xa balances. 1 beaker base 8 hanger 2 stand 9 top weighing pan for ...

Page 59

- 59 - f shortcut keys you can declare which particular weighing function is to be launched using f1, f2, f3 or f4 keys. For procedure informing you how to declare the particular function, read f shortcut keys section. 11.8.1. Density determination density determination of solids can be carried out ...

Page 60

- 60 - 13. Next, place a mass sample on the bottom pan of the kit (mass determination in the liquid), and confirm the indication when stable. 14. On the second confirmation of the indication, the program automatically calculates and displays the tested solid object density. At the same time, a repor...

Page 61

- 61 - settings for button shortcuts are the same as for function (see the previous point). 11.9.1. Density determination the basic element for measuring liquids density is the sinker (9). Its volume is precisely determined and given on a sinker’s hanger. Before starting liquid density determination...

Page 62

- 62 - an exemplary report: the report may be reprinted upon pressing button. In order to finish, press button. The software returns to the main window of the mode and a next measurement can be performed. The balance operates with previously set parameter values (liquid, temperature) thus shortening...

Page 63

- 63 - • when all the measurements are saved, it is possible to check the results of statistics by pressing button: • select an option by pressing button. • the information on number of saved measurements is displayed in a bottom line. On pressing or , the type of displayed information changes. • se...

Page 64

- 64 - activating option results in printing out the statistics data and moving to a window, using this window it is possible to check the data and print it out again, if necessary. To exit, press button. This leads to returning to the main window of mode and zeroing the data related to carried out ...

Page 65

- 65 - the software adds mass of the ingredient to the total mass, next automatic taring of the indication proceeds (zero indication is shown on the main display). In the bottom line modified data relating to the number of ingredients and total sum is presented. • next, place other ingredients in th...

Page 66

- 66 - it is possible to print out the report again by pressing button. To exit this window, press button. The main window for mode is displayed, data related to carried out measurements is automatically zeroed. 11.12. Peak hold this function enables snapping peak hold applied to the weighing pan du...

Page 67

- 67 - 11.13. Pipettes calibration caution! Function valid for as r series balances exclusively. Pipettes calibration function applies to fixed volume pipettes and adjustable volume pipettes. During volume testing procedure, the software determines accuracy and repeatability errors. In case of pipet...

Page 68

- 68 - f shortcut keys you can declare which particular weighing function is to be launched using f1, f2, f3 or f4 keys. For procedure informing you how to declare the particular function, read f shortcut keys section. 11.13.2. Means of operation • enter mode. • start the process. • follow the promp...

Page 69

- 69 - • upon entering the data the computer software proceeds to pipettes calibration. • follow the displayed description and complete the procedure. • by means of a pipette, dose the first portion of water, wait until the measurement is stable and press enter to confirm. • the computer software re...

Page 70

- 70 - an exemplary report: adjustable volume pipette, 3 volumes tested:.

Page 71: 12. Communication

- 71 - 12. Communication communication menu enables configuration of port settings. The settings are accessed upon pressing button. Communication with peripheral devices is established via the following ports: • com 1 (rs232), • com 2 (rs232), • usb type a • usb type b • wifi, parameters of usb port...

Page 72

- 72 - p3.3.3.3 – password (password – ‘stars’ are displayed) p3.3.3.4 – ip (balance id number, make sure that the number is not engaged by a different device using this network) p3.3.3.5 – mask (default 255.255.000.000) p3.3.3.6 – gate (default 10.10.8.244) p3.3.3.7 – mac adres (0008dc…) after ente...

Page 73

- 73 - flash drive may be used for export/import of data stored in balances, or for carrying out measurement data printout (set parameter p4.2.1 to value). Measurement data printout operation is described in section 10.3 of this manual. Please remember that for pcl printer the drivers print complete...

Page 74

- 74 - “ready to install” window: in order to run installation process, press „install” key and clicking respective keys, follow the install wizard. 2. Having completed driver installation, connect balance to a computer, use 1,8-meter long usb a/b cable maximally (in case of already connected balanc...

Page 75: 13. Peripheral Devices

- 75 - 4. Go to device manager and check number assigned to virtual com port. For this very case it is stmicroelectronics virtual com port (com8). 5. Set balance parameters: select usb value for parameter computer/port. 6. Run software for measurement readout. 7. Use the program to set parameters fo...

Page 76

- 76 - - enter menu - enter menu group: - select port to which a computer is to be connected, com 1 or com 2 – rs 232 port, to which the computer is connected usb 2 type b – usb port, to which the computer is connected usb free link – usb type b port, to which the computer is connected. The tool, ac...

Page 77

- 77 - the setting is valid for continuous transmission in calibration unit and in current unit activated by means of the balance (see parameter p4.2.1.2), it is also valid for continuous transmission activated by command sent from a computer (see point 15 communication protocol). 13.1.4. Cooperatio...

Page 78

- 78 - press and configure port settings to enable balance correct cooperation with computer programs: spread sheet– value yes - cooperation with excel type program, - value no – cooperation with other programs, delay – if any ‘looses’ of transferred information occur (caused by data auto-entering o...

Page 79

- 79 - example balance settings for correct cooperation (printout of polish signs) with tm-t20 epson thermal printer connected to rs232 port; if the printer is connected to usb port than the baud rate settings and parity do not matter. Communication parameters of port to which the printer is connect...

Page 80

- 80 - 13.5. External buttons submenu comprises settings that enable the balance to cooperate with external buttons: tare and print. Procedure: • press • enter menu • enter menu group • run the buttons set to value set to value • exit the balance menu caution: the balance program enables coopera...

Page 81

- 81 - balance transmission parameters must correspond to the parameters of a device that is connected to the balance. • baud rate - 4800 ÷ 115200 bit / s • parity control - none, odd, even value indicated on a display can be sent via rs232 or usb port to a peripheral device in one of four accessibl...

Page 82

- 82 - xx_i cr lf command understood but not accessible at this moment xx _ ^ cr lf command understood but max threshold is exceeded xx _ v cr lf command understood but min threshold is exceeded xx _ e cr lf time limit exceeded while waiting for stable measurement result (time limit is balance chara...

Page 83

- 83 - cu1 switch on continuous transmission in current measuring unit cu0 switch off continuous transmission in current measuring unit dh set min checkweighing threshold uh set max checkweighing threshold odh give value of min checkweighing threshold ouh give value of max checkweighing threshold sm...

Page 84

- 84 - commands overview zero balance format: z cr lf response options: z_a cr lf - command understood and in progress z_d cr lf - command carried out z_a cr lf - command understood and in progress z_^ cr lf - command understood but zeroing range is exceeded z_a cr lf - command understood and in pro...

Page 85

- 85 - send stable measurement result in a basic measuring unit format: s cr lf response options: s_a cr lf - command understood and in progress s_e cr lf - time limit exceeded while waiting for stable measurement result s_i cr lf - command understood but not accessible at this moment mass frame - r...

Page 86

- 86 - immediately send measurement result in a current measuring unit format: sui cr lf response options: sui_i cr lf - command understood but not accessible at this moment mass frame - immediate response: mass value in a current measuring unit response format: 1 2 3 4 5 6 7-15 16 17 18 19 20 21 s ...

Page 87

- 87 - set max checkweighing threshold format: uh_xxxxx cr lf, where: _ - space, xxxxx - mass format response options: uh_ok cr lf - command carried out es cr lf - command not recognised (mass format incorrect) give value of min checkweighing threshold format: odh cr lf response: dh_masa cr lf - com...

Page 88

- 88 - internal adjustment format: ic cr lf response options: ic_a cr lf - command understood and in progress ic_d cr lf - calibration completed ic_a cr lf - command understood and in progress ic_e cr lf - time limit exceeded while waiting for a stable measurement result ic_i cr lf - command underst...

Page 89

- 89 - mode name – parameter, working mode name, inserted in between inverted comas. The name takes form given on a particular balance display, it is provided in a currently selected language. N – parameter, decimal value determining working mode number. N → 1 – weighing 2 – parts counting 3 – devia...

Page 90

- 90 - working mode. Format: ui cr lf response options: ui_”x 1 ,x 2 , … x n ”_ok cr lf – command carried out, returns accessible units ui_i cr lf – command understood but not accessible at this moment x – unit symbols, separated by means of comas x → g, mg, ct, lb, oz, ozt, dwt, tlh, tls, tlt, tlc,...

Page 91

- 91 - send all implemented commands format: pc cr lf command: pc cr lf - send all implemented commands response: pc_a_”z,t,s,si…” - command carried out, the terminal displays all implemented commands. Give balance type format: bn cr lf response options: bn_a_”x” cr lf - command understood, response...

Page 92

- 92 - set ambient conditions state format: ev_n cr lf response options: ev_ok cr lf – command carried out ev_e cr lf – error in-course of command execution, no parameter or incorrect format ev_i cr lf – command understood but not accessible at this moment n – parameter, decimal value determining am...

Page 93

- 93 - set last digit format: lds_n cr lf response options: lds_ok cr lf – command carried out lds_e cr lf – error in-course of command execution, no parameter or incorrect format lds_i cr lf – command understood but not accessible at this moment n – parameter, decimal value determining last digit s...

Page 94: 16. Error Messages

- 94 - 16. Error messages -err2- value beyond zero range -err3- value beyond tare range -err8- taring / zeroing operation time exceeded -null- zero value from converter -full- measurement range exceeded -lh- start mass error 17. Additional ecquipment anti-vibration table it is a very stable basis wh...

Page 95

- 95 -.

Page 96

- 96 -.