- DL manuals

- RADWAG

- Scales

- MYA 4Y

- User Manual

RADWAG MYA 4Y User Manual

Summary of MYA 4Y

Page 1

4y series uya 4y ultra-microbalances mya 4y microbalances myb 4y microbalances mya 4y.P microbalances mya 4y.F microbalances xa 4y analytical balances xa 4y.A analytical balances xa 4y.F analytical balances user manual immu-01-15-06-17-en www.Radwag.Com.

Page 2

- 2 - if you are reading this, it means that you are bound to achieve success. You have purchased a device that was designed and manufactured to give you years of service. Congratulations and thank you for selecting radwag product. June 2017.

Page 3

- 3 - contents 1. General information .................................................................................... 9 1.1. Dimensions ........................................................................................... 9 1.2. Connectors ....................................................

Page 4

- 4 - 12. Permissions levels ..................................................................................... 32 13. Profiles ...................................................................................................... 34 13.1. Creating a profile .........................................

Page 5

- 5 - 19.4. Supplementary settings for percent weighing mode ................................. 66 20. Density ...................................................................................................... 66 20.1. Density determination kit .......................................................

Page 6

- 6 - 27.2. Means of operation .............................................................................104 28. Prepackaged goods controls ................................................................... 105 28.1. Prepacked goods control mode start-up ............................................

Page 7

- 7 - 31.4. Tcp settings .......................................................................................144 32. Peripherals .............................................................................................. 144 32.1. Computer .........................................................

Page 8

- 8 -.

Page 9: 1. General Information

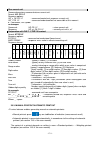

- 9 - 1. General information 1.1. Dimensions ultra-microbalances and microbalances.

Page 10

- 10 - myb 4y microbalances indicator xa 4y series balances.

Page 11

- 11 - xa 4y.F series balances.

Page 12

- 12 - 1.2. Connectors 1 –ethernet rj45 connector 2 – rs232 connector (com1) 3 – usb connector 4 – in/out, rs232 connector (com2) caution! “balance-ethernet” cable is a standard cable terminated with rj45 connector on both ends. Balance – computer cable (rs232) balance – printer cable (citizen, epso...

Page 13

- 13 - • while loading the balance make sure that loads are placed in the very center of the weighing pan. • load the weighing pan with loads, gross weight of which does not exceed instrument’s measuring range (maximum capacity). • do not leave heavy loads on the weighing pan for a longer period of ...

Page 14: 2. Transport And Storage

- 14 - 2. Transport and storage 2.1. Delivery checklist upon delivery it is necessary to check the package and the device, make sure that your package bears no signs of damage. If it does contact the manufacturer’s representative. 2.2. Package keep all package elements should your balance be transpo...

Page 15

- 15 - caution: make sure there is no protective sticker 1 while carrying measurement (see the above diagram). Install components following the above diagram depending on balance’s type. A – standard (uya and mya) 2. Anti-draft chamber 3. Weighing pan 4. Glass lid for the weighing pan b – mya 0.8/3....

Page 16

- 16 - myb 4y microbalances take all the components from the packaging. Install the anti-draft chamber (1) and screw it to the base using bolt (2). Install: - draft shield (3) - weighing pan (4) - glass lid (5) a – balance with d=0.01mg interval b – balance with d=0.1mg interval remove a transport l...

Page 17

- 17 - xa 4y.F install all standard components: • bottom insert (4) • bottom ring (3) • standard weighing pan (1) • anti-draft chamber (2) install supplementary equipment. Connect the balance to the mains (use the power adapter provided by the manufacturer) before weighing filters remove the anti-dr...

Page 18

- 18 - rinsing is a necessary cleaning process stage allowing to remove remaining soap, detergents and other cleansers from the panes prior their reinstallation. Avoid drying the panes either using paper towel or forced air circulation since some fibres, grains or contamination of other type could p...

Page 19

- 19 - xa 4y.A series – order of actions: undo and remove top pane protection, next slide the pane out of a guide bar. Remove the left and the right side pane. Before removing the panes completely pull protection, see the picture on the left. The side panes are not interchangeable therefore it must ...

Page 20

- 20 - xa 4y series – order of actions: undo and remove top pane protection, next slide the pane out of a guide bar. Remove the back pane. Remove side panes. Side panes shall not be swapped therefore it is necessary to remember which one is right, and which one is left in order to install them back ...

Page 21

- 21 - thus prepared anti-draft chamber and panes can be properly cleaned. All the operations have to be done carefully. Pay special attention to the spot where the weighing pan is installed: dirt and other small elements might enter the balance construction through this opening, which might negativ...

Page 22

- 22 - wireless connection between a terminal and a weighing module positively influences weighing process making it more comfortable and safer. 3. Elimination of unfavourable influence factors due to wireless connection the weighing module may be completely separated from the operator by being plac...

Page 23: 4. Start-Up

- 23 - wireless connection pictogram: no. Pictogram description 1 correct connection of wireless modules – correct cooperation 2 connection interrupted – loss of connection 3.8.3. Settings in order to provide long enough operation while powering the device by means of battery, the correct parameters...

Page 24: 6. Software Structure

- 24 - 6. Software structure the main menu has been divided into function groups. Each group comprises parameters grouped by their reference. For detailed description of each menu group read later sections of this user manual. List of groups - parameters balance’s main menu is accessed by pressing s...

Page 25

- 25 - 7. Weighing mode home screen the main window of balance software can be divided into 4 sections: • top section displaying data on active working mode, logged operator, date, time, active connection to a computer and current level status of a balance. • section presenting the weighing result a...

Page 26: 8. Logging

- 26 - 8. Logging full access to user parameters and to editing databases requires logging as an operator with permissions level. Carry out logging procedure on each switching on of the balance. First log in operation - procedure: 1. Run home screen and press button, operators database window opens ...

Page 27: 10. Adjustment

- 27 - press to search for a particular record in a database by name. Press to search for a particular record in a database by code. Press to print out a particular record from a database. Press to clear the editing field. Press to enable / disable an on-screen keyboard. Press to read printout templ...

Page 28

- 28 - procedure: 1. Enter submenu, next select “ external adjustment” parameter. 2. “remove weight” prompt is displayed. 3. Take the weight off the weighing pan and press button. Whereas balance determines start mass, “start mass determination” message is displayed. 4. Upon completed start mass det...

Page 29

- 29 - • using displayed menu, select appropriate time interval (given in hours) which is a time gap elapsing from the last carried out internal automatic adjustment until activation of the following automatic internal adjustment. Caution! Parameter settings can be modified only for balances that ar...

Page 30

- 30 - in order to add a new position, click button, wait for a window with data on planned balance adjustment to open. Select task: automatic adjustment (internal) or external calibration. For automatic adjustment option, enter data on the adjustment and its schedule. For external calibration optio...

Page 31

- 31 - 10.8. Report printout parameter report printout > determines whether or not a report on automatic internal adjustment is to be automatically printed on its completion. In order to set automatic report printout on adjustment completion go to parameter: report printout > and select value . 10.9...

Page 32: 11. Users

- 32 - extension *.Tdb is saved on a usb flash drive connected to the usb port. The file can be edited using excel spreadsheet or a text editor. 11. Users “users” menu contains list of operators, who are authorized to operate the instrument. The following data can be defined for each balance user: ...

Page 33

- 33 - 2. Select anonymous user> parameter. 3. Set appropriate access level for the anonymous user. Available access levels for an anonymous user: guest, user, advanced user, administrator. Caution! Selecting access level for not logged in user prevents him/her from modifying any balance settings. D...

Page 34: 13. Profiles

- 34 - 1. Enter access level> menu. 2. Select movies> parameter, select one of available parameters: guest, user, advanced user, administrator. Caution! Selecting access level provides free access to movies settings (no need to log in). Auto logout auto logout parameter has been designed to trigger ...

Page 35

- 35 - 1. Enter main menu, to do it press setup key. 2. Enter submenu. 3. Press and hold profile that is to be copied. 4. Menu referring to a profile record is displayed. 5. Select parameter. 6. A new name> profile is created, all new profile setting and base profile settings are likewise. 7. Modify...

Page 36

- 36 - 13.2.1. Settings name on entering this option, the display opens a message box with keyboard. Insert name of a profile and press key to confirm. The name is assigned to the profile. Default working mode on entering this option you can select a specific working mode, which is set as default in...

Page 37

- 37 - value release the parameter has been designed to determine when the stability marker is to be displayed. There are three different settings for value release parameter: • fast • fast + reliable /recommended/ • reliable caution! Both parameters, filter and value release, determine how long it ...

Page 38: 14. Working Modes

- 38 - a custom measuring unit features: • a multiplier • a name (3 characters) upon completed operation of designing a custom unit its name is added to the list of accessible measuring units. Units menu additionally enables entering the value of gravitational acceleration force for balance’s place ...

Page 39

- 39 - differential weighing statistical quality control means of operation: analysis of mass sample change over time. Working mode is intended to carrying out different types of product packing processes and aimed at monitoring and / or controlling the packing process. It enables detecting excess o...

Page 40

- 40 - 14.2. Parameters related to a working mode each working mode has programmable parameters determining its functioning. Procedure for entering the parameters: 1. Press grey workspace area 2. Wait to see the following menu: − - additional options − - defining quick access keys − - selecting info...

Page 41

- 41 - caution! Using left motion or right motion, it is necessary to remember that parameter must be set to value 500 ms! To each of the motions you can assign one of the available options: [none; profile; adjustment; zeroing; taring; tare setting; tare switch off; reset tare; packaging; print; hea...

Page 42

- 42 - 14.5. Printouts printouts menu comprises two separate sections: • standard printouts, • non-standard printouts. Standard printout standard printout comprises three internal sections featuring different variables. For each variable set option yes to include it in a standard printout. If option...

Page 43: 15. Weighing Operation

- 43 - • current result – currently displayed measuring unit • supplementary unit – supplementary measuring unit • mass – main measuring unit (adjustment unit) non-standard printout non-standard printout may contain: texts and variables (which are acquired from the software). Each non-standard print...

Page 44

- 44 - 15.2. Good weighing practice in order to ensure long lasting use of a balance plus correct and reliable measurement of weighed loads, follow below procedures: • start the balance with no load on the weighing pan (permissible value of load on the weighing pan on balance start is ±10% of its ma...

Page 45

- 45 - 3. Level the balance, to do it turn the feet in a way indicated by blinking pictograms on the display > – the level point moves towards the center of the level circle. 4. As the level point is in the center point, its colour changes from red to green – which is a confirmation for correct leve...

Page 46

- 46 - 4. The balance returns to the weighing mode, and the display indicates entered tare value with minus ‘–‘ sign. Deleting tare the tare value indicated on a balance display can be deleted by pressing key on a balance overlay, or by using programmable function key . Procedure 1 – on taking the t...

Page 47

- 47 - considerably the final result, wherein the density is influenced by changes of pressure, temperature and humidity. In order to carry out a reliable measurement it is necessary to know the measuring methods, features of tested sample, air density in the laboratory room and density of weighed s...

Page 48

- 48 - for correct balance cooperation with the thb module it is necessary to set port’s transmission parameters, they must be compatible with those of the thb module. The thb module transmission parameters are detailed on its data plate. On returning to the weighing mode, the display indicates an a...

Page 49

- 49 - as the indication returns to autozero zone, the software automatically deletes tare value. Automatic footer printout options: • mode – no – manual footer printout, sum of measurements – footer is printed when mass value entered in parameter is out of range measurements quantity – footer is pr...

Page 50

- 50 - caution: for information on how to design printouts go to section 14.5. Air buoyancy compensation parameters allowing you to switch on the compensation and to enter weighed sample density data and air density data. Caution! The function is valid for weighing mode exclusively. For information ...

Page 51

- 51 - 3. Select menu - additional weighing process options. 4. Press field. 5. Wait for minimum sample weight window to open. 6. Press field, window with a list of database-stored methods opens. 7. Select the method you need. 8. Previous screen is displayed. 9. Press field, window with the followin...

Page 52

- 52 - caution! If more than one reference tare value is programmed (with corresponding minimum sample weight mass) then the indicated value automatically moves to a range corresponding to the weight of the tared container. At the same time the required minimum mass is changed. 15.9. Cooperation wit...

Page 53

- 53 - radwag has designed analysis method and selected permissible vibrations thresholds respectively to make signalling device operation both effective and convenient (not troublesome). Balance screen displays balance-registered vibrations level in percent. Vibrations threshold cannot be changed, ...

Page 54

- 54 - upon pressing vibrations pictogram, window with current values measured by sensors is displayed. Displayed vibrations value (is v) is the effective value registered within the most recent 2 seconds. This value id refreshed every 2 seconds. If the screen displays 100% value, this means that vi...

Page 55

- 55 - by default the interval is set to 10 min, this value may range between 1 min - 60 min. Record analysis allow the user to select the most optimal time of the day for the measurements performance, i.E. Time when the environmental conditions influence the vibrations the least. Mind that there ar...

Page 56: 16. Parts Counting

- 56 - 16. Parts counting parts counting> is a working mode enabling determination of quantity of small parts with equal weight. Determined mass of a single part is used for the counting procedure. The single part mass may be: • determined from a reference quantity of parts subjected to weighing, • ...

Page 57

- 57 - • yes, print and save only those measurements which are included within the lo and hi thresholds. • no, all measurements are printed and saved. • other functions in parameter. For means of operation of acai function read below, to find out more about the remaining functions go to section 15.7...

Page 58

- 58 - 16.3. Setting reference mass by entering determined part mass procedure: 1. Press determine part mass> key or the label , editing window featuring an on-screen keyboard is displayed. 2. Enter the requested value and confirm by pressing key, parts counting> mode is run with automatically speci...

Page 59

- 59 - 1. Press button, next press button. 2. Go to products database and press add> button. 3. Fill in product related fields, weight value (field [5]) among many. 4. Return to mode. 16.6. Updating part mass in a database determined single part mass can be assigned to a product in the database of p...

Page 60

- 60 - in order to define low and high thresholds’ values open products database and edit the product record, or use a quick access key, defining thresholds>. Procedure: 1. Press grey workspace, next select parameter. 2. Set bar graph to yes value, return to parts counting mode. 3. Press grey worksp...

Page 61: 17. Checkweighing

- 61 - caution! The checkweighing and dosing functions can operate simultaneously in the parts counting mode. In such case the dosing tolerance is controlled by lo and hi thresholds of the checkweighing function. 17. Checkweighing checkweighing> is a working mode using two thresholds (min and max) f...

Page 62: 18. Dosing

- 62 - procedure 2 – entering checkweighing thresholds manually 1. Press checkweighing thresholds> button. 2. Select min threshold button and enter low limit value. 3. Press > button for confirmation. 4. Select max threshold button and enter high limit value. 5. Press > button for confirmation. Caut...

Page 63: 19. Percent Weighing

- 63 - 5. Bar graph is displayed, its colour corresponds to the current status of weight. yellow: weight value below target value - tolerance green: weight value within tolerance, target value +/- tolerance red: weight value above target value + tolerance procedure 2 – target value entered man...

Page 64

- 64 - 1. Setup – press to access balance menu 2. Print header – press to print data declared in the header 3. Print footer – press to print data declared in the footer 4. Products database – press to select products from a corresponding database 5. Percent weighing – press to set reference mass 6. ...

Page 65

- 65 - 5. All samples weighed afterwards are compared with the reference mass, and the display indicates the difference, expressed in [%], for each weighed sample in relation to the reference mass 19.2. Checkweighing and dosing for percent weighing mode percent weighing function can be aided by dosi...

Page 66: 20. Density

- 66 - 19.3. Bargraph - a tool for function interpretation the dosing and checkweighing functions are aided by a graphic indication, i.E. Bar graph. Example of simultaneous operation of dosing and checkweighing functions. • checkweighing thresholds low limit = 90%, high limit = 110%. • target value ...

Page 67

- 67 - 20.1. Density determination kit kit intended for xa and as balances. 1 beaker base 2 stand 3 sinker 4 beaker 5 thermometer holder 6 thermometer 7 flexible connector for sinker 8 hanger 9 top weighing pan for solids density determination 10 flexible connector for weighing pans 11 bottom weighi...

Page 68

- 68 - 20.3. Solids density determination prior the procedure start it is necessary to determine the following process related data: • liquid type (distilled water, ethanol, other liquid with determined density), • liquid temperature (required in case of water or ethanol), • liquid density (set auto...

Page 69

- 69 - v - sinker’s volume d - air density (max 0,001 g/cm 3 ) install the density determination kit, and enter sinker’s volume to balance’s memory. • press liquid density> button, a respective menu is displayed, using it press sinker’s volume> button and enter sinker’s volume value, take it from th...

Page 70

- 70 - 3. Press field for entering steel mass standard weight and enter the mass standard value as provided in its calibration certificate. 4. Press field for entering aluminium mass standard weight and enter the mass standard value as provided in its calibration certificate. 5. Press field for ente...

Page 71

- 71 - 3. Press start> button, density determining begins. 4. Fill in the pycnometer with tested substance, follow the pycnometer guidelines. 5. Load the pan with a pycnometer, wait for a stable measurement result and press > button. 6. Density result is displayed. 7. Press > button to finish the pr...

Page 72

- 72 - 20.8. Printouts printouts option has been designed to enable you to determine content of particular standard printout and to define non-standard printout. Standard printout standard printout comprises four internal blocks, each featuring different variables. Each variable can be attributed wi...

Page 73

- 73 - 20.9. Report on completed density determination process on completing any type of density determining processes, i.E. Solid, liquid or air, a report is generated. The report is saved to the density reports> database. The files are named by date and time (hour) of density determining process. ...

Page 74: 21. Animal Weighing

- 74 - 21. Animal weighing animal weighing> is a working mode enabling reliable determination of mass of weighed objects in motion. In principle, this type of objects generate unstable measurement, thus it requires using a different filtering method of measurement signal. Animal weighing mode screen...

Page 75: 22. Formulations

- 75 - 21.2. Supplementary settings for animal weighing mode the supplementary settings enable adjusting the working mode to your needs and requirements. For information on how to access the settings read section 15.7. 22. Formulations formulations> is a working mode enabling you to prepare multi-in...

Page 76

- 76 - means of ingredient verification: use this function to specify how to determine ingredient mass during formulation making process, by tolerance or by thresholds. • tolerance: the software accepts mass of an ingredient as correct if it is within set percent tolerance of total ingredient’s mass...

Page 77

- 77 - • press add> button, • select one of the following options: - select to add a new product, first enter name, next specify mass to be weighed during formulation making process. The software automatically adds the products to the products database. Caution! In order to enter remaining product d...

Page 78

- 78 - 10. With all the ingredients weighed, select one of the following options: - select to save the process to formulations database, the process is finished automatically, the final report is recorded in formulation database. - select to complete without saving the process to formulations databa...

Page 79

- 79 - 1. Press formulation> button. 2. List of formulations is displayed, select the formulation that is to be carried out. 3. Press formulation with target mass> button. 4. Window with an on-screen keyboard for entering target mass of a mixture is displayed. 5. Enter the target mass value and pres...

Page 80: 23. Statistics

- 80 - • user • customer • warehouse • formulation • formulation code • start date • end date • ingredients quantity • measurements quantity • measurements • target value • sum • formulation difference • status • empty line • dashes • signature • non-standard printout user john smith formulation nam...

Page 81

- 81 - 23.1. Buttons and information setup buttons crucial for series of measurement: • print> button – press to trigger printout and to add measurement to statistics, • add to statistics> - press to add measurement to statistics, printout is not triggered. Each working mode features automatically d...

Page 82: 24. Pipettes Calibration

- 82 - delete last – to cancel the last measurement delete – to remove all statistics data measurements chart – to make the software generate and display a chart with distribution of measurements in the coordinates mass/measurement for completed measurement series. Probability distribution chart – t...

Page 83

- 83 - mya 4y balance with a set for pipettes calibration: installation procedure: 1. Dismantle the weighing pan and the anti-draft chamber 2. Place the following elements inside: • anti-anti-draft chamber (1) • bottom ring (2) • weighing pan (3) • glass vessel (5) • evaporation ring (6) • glass cov...

Page 84

- 84 - evaporation ring minimizes measurement errors being a result of liquid evaporation occurring in the course of the weighing process. Prior pipettes calibration distilled water must be poured into the evaporation ring, the amount of water cannot exceed 2/3 of the ring height. The set may be ope...

Page 85

- 85 - with thus prepared balance you can start pipettes calibration procedure. Pipette calibration> is a working mode allowing you to determine measurement errors of piston pipettes volume, the errors can be determined either with reference to iso 8655 standard or your requirements. In case of cali...

Page 86

- 86 - 24.1. Supplementary settings for pipettes calibration mode the supplementary settings enable adjusting the working mode to your needs and requirements. For information on how to access the settings read below: procedure: 1. Press grey workspace. 2. Settings, keys, information, printouts and p...

Page 87

- 87 - list of pipette parameters: • name: press “name” field, a window for entering pipette’s name opens. • code: enter pipette’s code; • model: enter pipette’s type; • tip: enter tip’s name; • type of volume: adjustable / fixed; • nominal volume: nominal volume value; • minimum volume: minimum vol...

Page 88

- 88 - • pipette • serial no. • channels quantity • channel no. • measurements quantity • operation with adherance to iso 8655 • start date • end date • water temperature • z coefficient • measurements and statistics • statistics • status • empty line • dashes • signature • non-standard printout 24....

Page 89

- 89 - thb module, water temperature must be entered manually, enter it and press > button for confirmation. 7. Pipettes calibration home screen is displayed, tested volume and process status are visible in info field. The task bar displays prompts guiding you through the process - , where: c1 – cha...

Page 90: 25. Differential Weighing

- 90 - average volume 1000.82389 µl average [%] 100.08 % systematic error 0.82389 µl systematic error [5] 0.08239 % permissible error ± 16 µl random error 0 µl random error [%] 0 % permissible error ± 6 µl status positive ------------------------------------------------------ signature 25. Different...

Page 91

- 91 - procedure: 1. Press grey workspace. 2. Settings, keys, information, printouts, series and profiles submenus are displayed. 3. Press key. 4. The display indicates functions related to differential weighing process. Differential weighing process functions: threshold: mass value (maximum mass of...

Page 92

- 92 - 25.3. Adding series to series database series database comprises series and series samples. While creating a series, first set its name, next add samples. The software is intuitive and you are guided by means of respective prompts. Provide a name for each sample. To add a series go either to ...

Page 93

- 93 - upon selecting a series, press one of the following buttons determining how the differential weighing is to be carried out: weighing a press to start weighing initial mass. Weighing (t+a) press to start sample container taring which is next followed automatically by sample weighing (non-separ...

Page 94

- 94 - caution: if parameter for the differential weighing mode is set to parameter the software skips this part of the process. • press > button to confirm ambient conditions values, differential weighing home screen is displayed, you are prompted to unload the weighing pan. • unload the weighing p...

Page 95

- 95 - caution: if parameter for the differential weighing mode is set to parameter the software skips this part of the process. • press > button to confirm ambient conditions values, differential weighing home screen is displayed, you are prompted to unload the weighing pan. • unload the weighing p...

Page 96

- 96 - • weighing t procedure only – weighing a value is , • weighing t+a procedure – tare and weighing a values is mass. You can print weighed sample data, to do it press a printer pictogram located in the top bar. In order to preview data on weighing a, press field: if a given series already conta...

Page 97

- 97 - particular weighing preview mode provides you with values. Numbers referring to weighing inform on the measuring cycle. Data on a specific series can be printed or exported to a file. 25.5. Copy tare copy tare option enables copying once selected tare value (in a series) to all samples which ...

Page 98

- 98 - the previous step of the procedure. The process can be carried out once only, otherwise respective message informing on error is displayed, deleting a record is aborted. 25.8. Printouts printouts option has been designed to enable you to determine content of particular standard printouts and ...

Page 99

- 99 - • universal variable 1…5 • net • tare • interval • difference • difference % • residue % • non-standard printout 26. Statistical quality control - sqc statistical quality control> is a working mode enabling support control of product packing process. It enables detecting surplus or shortfall ...

Page 100

- 100 - 2. Set sqc> mode parameters, for detailed information read section 26.2. 3. Select a product that is to be controlled (press > button located in the bottom bar or on the overlay), mind to select a product with correctly entered control data. List of data to be entered prior control start: ma...

Page 101

- 101 - quantity of disqualifying samples [qn + t1] max permissible quantity of t1 high limit errors with nominal weight as point of reference quantity of disqualifying samples [qn + t2] max permissible quantity of t2 high limit errors with nominal weight as point of reference quantity of disqualify...

Page 102

- 102 - 1. Press product> button to select product to be controlled. 2. Press button located in the bottom bar to initiate the control; an editing window with an on-screen keyboard opens. 3. Enter the batch number and press button for confirmation, the software proceeds to the next process steps. In...

Page 103

- 103 - 26.4. Sqc control report an exemplary sqc control report: ---------------------------- sqc -------------------------- balance type as 3y range 220 g reading unit 0.0001 g balance id 442566 start date 2012.10.19 12:27:09 end date 2012.10.19 12:37:20 operator kowalski product test 01 batch num...

Page 104: 27. Peak Hold

- 104 - 27. Peak hold peak hold> is a working mode enabling you to snap value of maximum force applied to the weighing pan during one loading. Apart from standard settings for this mode (described in the weighing mode), additional parameter has been introduced, it sets threshold value determining fu...

Page 105

- 105 - 28. Prepackaged goods controls (disabled for standard balance versions) prepacked goods controls> is a working mode enabling realizing prepackaged goods controls (single stand control or multi-stand control) supported by a database containing products and users. A control initiated from a ba...

Page 106

- 106 - 28.2. Control settings caution! Before entering control settings it is necessary to log in. Press button located in a prepacked goods controls> mode window to open control settings window: where: press to select a product from a database press to edit batch number press to start control 28.3...

Page 107

- 107 - 28.4. Editing product for control in order to edit a product go to „ / database” submenu. Caution! For cooperation with e2r system> software database editing is blocked on a balance. Products editing and export is carried out by means of the software. Procedure: 1. Enter „ / database” submen...

Page 108

- 108 - error value [- t] max permissible low limit error t (-t), given in unit set for a product. Measurements lower than value of qn-t are regarded as invalid. Error value [+ t] max permissible high limit error t (+t), given in unit set for a product. Measurements higher than value of qn+t are reg...

Page 109

- 109 - where: batch number – identification of controlled products batch bach quantity – software controls specified number of samples average tare determining quantity of packages – more than 10 4. Remove load from the weighing pan. 5. Press start soft key located in a bottom of the parameters set...

Page 110

- 110 - for power loss case the software allows to complete an aborted control upon reconnection to the mains. Caution: remember to restart the balance when unloaded. During balance restart the software searches for any in course control procedure. If there is one, the following message is displayed...

Page 111

- 111 - - characteristics of sample’s negative errors 2t1 - net mass of a controlled packaging - tare of a packaging - control status of a packaging load empty - command for process in progress with specified number of all packagings to be weighed - work pane in a form of graph. Graph applies to con...

Page 112

- 112 - where: bar graph information on product net mass in a form of graph: green bar graph – mass within tolerance range: [-t], and [+t] of net mass. Yellow bar graph – mass within tolerance range: [-t], and [-2t] of net mass. Red bar graph – mass below net mass [netto – 2t]. Product controlled pr...

Page 113

- 113 - control status is presented by the following pictograms: - positive, - negative (control of sample 2 permitted) - negative for status respective field of a work pane turns to yellow: - yellow warns that occurrence of another t error will end with negative result of control. For status respec...

Page 114

- 114 - window for control in progress: press button to see a window with measurements performed for actual control: upon control completion, summary of the process is generated, control is automatically saved to database:.

Page 115

- 115 - • press button to print report on a printer connected to the balance. • press to get back to setting window of prepacked goods controls> mode without printing the report. Caution: for cooperation with e2r system> summary process message shall not contain a query for report printout. All data...

Page 116

- 116 - the software, accordingly to the pre-set batch portion, displays a message asking you to weigh empty packagings first, full next in the same order: where: product - controlled product name code - controlled product code - controlled product nominal value - controlled product average mass - d...

Page 117

- 117 - 1. Select a product using the list; set its parameters for destructive control and determine a measuring batch portion. 2. Start destructive control; prompts helping you to go through control process are displayed (as in case of the controls described above). Depending on enabled control mod...

Page 118

- 118 - - characteristics of sample's positive errors t: 4,5g – value of positive error t, t max – permissible number of positive errors t, n – actual number of positive errors t - characteristics of sample's positive errors 2t 9g - value of positive error 2t, 2t max - permissible number of positive...

Page 119: 29. Mass Control

- 119 - . 28. 100.013 g 29. 100.012 g 30. 100.012 g ---------------------------------------- signature ........................................ Report template: you can edit a template of a report on product control. To do it enter printouts/ printout template of a report on average tare > submenu. ...

Page 120

- 120 - 3. Press button to confirm. Set low limit> parameter. Provide value lower than weight value of the lightest controlled part. While setting the low limit value make sure that the set value prevents improper record of mass on a final report. Improper record may happen when the mass of a part i...

Page 121

- 121 - 29.3. Printouts printouts option has been designed to enable you to determine content of particular standard printouts and to define non-standard printout. Standard printout: standard printout comprises four internal blocks, each featuring different variables. Each variable can be attributed...

Page 122: 30. Databases

- 122 - 30. Databases software of 4y series balances features the following databases >: products weighing data/alibi customers formulations formulations reports density reports prepacked goods controls average tares pipettes pipette calibration reports series sqc reports minimum sample weight mass ...

Page 123

- 123 - 1. Press and hold for a moment a button with a respective database icon. 2. Wait to see a database menu. 3. Select one of available options (options depend on a database type). Options overview: • open – option allows to enter a chosen database (result is similar to the one obtained by a sin...

Page 124

- 124 - the above processes are carried out by pressing dedicated soft keys located in the upper right corner of the display. Follow the prompts displayed by the balance’s software. 30.2. Products database of products contains names of all products that are weighed, counted or controlled. Procedure:...

Page 125

- 125 - number of packagings needed for estimation of average tare] internal control [option available only for mode, allows for specification of internal control criteria accordant with company standards for a given product] sqc [option available only for mode, allows for specification of internal ...

Page 126

- 126 - 14. Ambient conditions alerts, demonstrates if temperature and humidity were stable during measurement. 30.4. Customers customers database contains name of customers for whom the measurements are carried out. Procedure: 1. Enter submenu databases>, and press field. 2. Press add > button. 3. ...

Page 127

- 127 - list of parameters on a report on formulation: 1. Start date 2. End date 3. Formulation 4. Sum 5. Target value 6. User 7. Customer 8. Warehouse 9. Measurements quantity 10. Status 30.7. Density reports density reports contain data on carried out density determination processes of solids, liq...

Page 128

- 128 - 30.8. Prepacked goods controls each product control carried out in sqc or pgc mode is sent to a connected printer and saved to the prepacked goods controls> database. Each control saved to the database features its specific number set at the moment of its completion. Control number format: x...

Page 129

- 129 - x - control type which takes the following values: u – control regulated by the act, z – control completed by a user, w - control regulated by an internal criteria. Yy – year of control end, mm – month of control end, dd – day of control end, hh – hour of control end, mm – minute of control ...

Page 130

- 130 - 30.11. Pipette calibration reports reports contain data on completed pipette calibration processes. In case of multichannel pipettes, the reports are generated for each channel separately. Each report can be previewed, searched by date, exported or printed. Procedure: 1. Enter submenu databa...

Page 131

- 131 - 30.13. Sqc reports each report on completed product control is sent to a printer and saved to the database. Each record features its individual number assigned on its completion. Control number format: y y / m m / d d / h h / m m / s s, where: yy – year of control end, mm – month of control ...

Page 132

- 132 - distribution probability chart: 30.14. Minimum sample weight minimum sample weight database contains data on declared methods and minimum sample weights. Caution: only authorized radwag personnel can enter new minimum sample weight records or make changes in those stored in the database. Pro...

Page 133

- 133 - sample weight settings. Thresholds – option that enables entering data on minimum sample weight mass and range of packaging mass (tare) with applicable criteria: tare – maximum value of tare for which the minimum sample weight is valid. The software enables entering three characteristic quan...

Page 134

- 134 - 30.15. Mass controls (mode not available in standard version of the balance) each product control carried out on a balance is sent to a connected printer and saved to the controls> database. Each control saved to the database features its specific number set at the moment of its completion. ...

Page 135

- 135 - procedure: 1. Select the report and display its details. 2. Press print> key locater on the upper bar. 3. The printer connected to balance’s terminal prints the report. Additionally, the complete database can be exported to an external file by pressing a export to file> button located in the...

Page 136

- 136 - it is possible to use an option for searching a record by name or code. 30.19. Printouts printouts database contains all non-standard printouts. Each printout features a name, code and a template. Procedure: 1. Enter submenu databases> and press printouts> key. 2. Press add > key to add new ...

Page 137

- 137 - 6 – delete all printout content 7 – printout editing field 6. Save designed printout. Caution: to erase characters in a printout press back key. To move cursor press navigating arrows. Example of printout no. 1 – using large editing field balance no. 400015 balance parameters: max = 220 g d=...

Page 138

- 138 - it is possible to use an option for searching a record by name or code. 30.21. Databases management function allows to manage database data. It comprises three options: export weighing database, delete databases and delete weighments and reports. 30.21.1. Export weighing database all carried...

Page 139

- 139 - 4. Set option and click , software automatically exports weighing database. 5. Upon completion a respective message, information on number of exported data and the file name (with file extension *.Txt) is displayed, next the software returns to the previous window. 6. You may return to a wei...

Page 140

- 140 - 3. Upon confirmation the software deletes data and displays a message: 4. Upon confirmation the software returns to a previous window; you may continue a weighing procedure or proceed to other operations. 30.21.3. Delete weighings and reports function allows to delete weighments and reports ...

Page 141: 31. Communication

- 141 - 5. Number of removed weighments and reports is displayed. 31. Communication communication menu is located in a parameters menu group. It is accessed by pressing setup key or setup > quick access key. The balance enables communicating with peripheral devices through the following ports: • com...

Page 142

- 142 - • subnet mask - 255.255.255.0 • default gate - 192.168.0.1 caution: above settings are for information purpose only. Transmission parameters have to be selected in accordance with the settings of customer’s local network. 3. On carrying out changes, press key; the following message is displa...

Page 143

- 143 - icon with a padlock means that the password is required. Press icon to search for available networks. Press field to check selected network parameters. The following message is displayed: selected network and parameters for connection are stored in the balance’s memory. The software connects...

Page 144: 32. Peripherals

- 144 - 31.4. Tcp settings tcp (transmission control protocol) operating in customer-server mode enables communicating two computers. Customer establishes connection on port specified by server. Follow procedure below to set port for tcp. Procedure: 1. Enter communication> parameters. 2. Select: „ t...

Page 145

- 145 - 32.2. Printer submenu enables: • setting communication port with a printer. • defining printer’s code page (default 1250). • defining controlling codes for pcl printer or epson label printer. Caution: codes must be entered in a hexadecimal form! • defining printout standards. Speed of transm...

Page 146

- 146 - a printout standard describes how to print information from databases. Printout standard can be modified if insufficient. In order to check format of printout standard, print data related to e.G. Product parameters – function activated on moving to database and pressing printer icon. Default...

Page 147

- 147 - to configure barcode scanner follow instruction below: „ / peripherals / barcode scanner”. Caution: communication> submenu requires setting baud rate to compatible with the one used by barcode scanner (default 9600b/s). For detailed description of communicating the balance with a barcode sca...

Page 148

- 148 - customer universal variable 2 packaging universal variable 3 warehouse universal variable 4 formulation universal variable 5 pipette 4. Select one item from the list. The following parameters may be edited: filtering selecting object for which the searching is carried out (see table below) o...

Page 149

- 149 - 1. Open barcode scanner> submenu. 2. Press test> parameter; window opens with ascii and hex fields in it. 3. Scanned barcode is entered into ascii or hex field; result of test is displayed in the bottom part of the window. When: • and are identical for both – balance settings and scanned bar...

Page 150: 33. Inputs/outputs

- 150 - 2. Press “ additional display / project” field, a editing window with an on- screen keyboard is displayed. 3. Use on-screen keyboard to insert desired value of a standard, or 4. Press > key and select desired value of a standard using a list. 5. Press to confirm. Caution: balance 3y series c...

Page 151

- 151 - • print • percent weighing: set 100% • header printout • solid density • footer printout • liquid density • universal variable 1 ÷ 5 • air density • accept • automatic weight crane control • abort • task • user • standard • left door on changing the logic status of the input system, e.G. Fro...

Page 152: 34. Miscellaneous

- 152 - procedure: 1. Press and next press: “ inputs / outputs” key. 2. Enter inputs / outputs> submenu, select and press outputs> key. 3. Enter editing mode of a selected output; list of available functions is displayed. 4. Select a function from displayed list and return to weighing with saving ca...

Page 153

- 153 - icon name value description time zone (utc+01:00) sarajevo, skopje, warsaw, zagreb parameter’s setting is: name of time zone/country, which informs of summer/winter time change. The information comes from microsoft website. Automatically adjust clock for daylight saving yes no function enabl...

Page 154

- 154 - 34.3. ‘beep’ sound procedure: 1. Enter miscellaneous> submenu. 2. Select beep> parameter. 3. Set appropriate option. None - beep sound inactive for keys and proximity sensors keys/buttons - beep sound active for keys/buttons sensors - beep sound active for proximity sensors all - beep sound ...

Page 155

- 155 - 3. Use finger or a thin (but not sharp edged) and soft stylus to press and hold a display area occupied by a cross. After pressing the fifth cross in order, accept the changes by pressing key. Caution: the process can be aborted by pressing esc key on an external keyboard connected to the ba...

Page 156

- 156 - 34.11. Autotest function is designed to aid you in both assessing balance’s operation and diagnosing the reasons for occurrence of errors in weighing which exceed the maximum permissible values for a given balance model. By means of a simple, repeatable and fully documented way the function ...

Page 157

- 157 - settings providing optimal measurement (the lowest value of time and deviation product) current settings for filters measurement results: • filter type • setting of parameter • repeatability of indications expressed as standard deviation • average time of measurement stabilization example: y...

Page 158

- 158 - temperature: start 25.26 °c temperature: stop 25.66 °c ---------------------------------------- filter very fast value release fast repeatability 0.0042 g stabilization time . . 4.505 s filter very slow value release reliable repeatability 0.0207 g stabilization time 5.015 s signature .........

Page 159

- 159 - report template: ---------- autotest glp: report -------- balance type ps 3y/2 balance id 400010 user admin software rev. L0.0.21 s date 2012.01.16 time 09:17:16 ---------------------------------------- measurements quantity 10 reading unit 0.001/0.01 g internal weight mass 1402.094 g filter...

Page 160: 35. Update

- 160 - procedure: 1. Plug a usb flash drive to balance’s usb port. 2. Enter submenu miscellaneous>. 3. Select parameter. 4. The software generates a file and automatically saves it on the usb flash drive. 5. The generated file has to be sent to radwag. 35. Update the function contains modules which...

Page 161: 37. Movies

- 161 - on selecting parameter the balance sends all settings to a printer. 37. Movies option activating instructional movie explaining how to operate balance functions. Procedure: 1. Open parameter group. 2. Select the demanded file and press to watch the movie stored in the balance memory. 3. The ...

Page 162

- 162 - play/ pause playing stop playing increase/decrease the volume (volume power adjusted, for settings go to parameters group). Enabling/disabling the volume restart video 38. Communication protocol general information a. A character based communication protocol balance-terminal is designed for ...

Page 163

- 163 - ouh give value of max checkweighing threshold sm set mass value of a single item tv set target mass value rm set reference mass value nb give balance serial number profile select balance profile login operator logging logout operator logout ss value release ic internal adjustment performance...

Page 164

- 164 - xx_i cr lf command understood but not accessible at this moment xx _ ^ cr lf command understood but max threshold is exceeded xx _ v cr lf command understood but min threshold is exceeded xx _ ok cr lf command carried out es_cr lf command not recognised xx _ e cr lf time limit exceeded while...

Page 165

- 165 - set tare format: ut_tare cr lf, where tare – tare value response options: ut_ok cr lf - command carried out ut_i cr lf - command understood but not accessible at this moment es cr lf - command not recognised (tare format incorrect) caution! Use dot in tare format as decimal point. Send stabl...

Page 166

- 166 - 1 2 3 4 5 6 7-15 16 1 7 1 8 1 9 20 2 1 p n space stability marker space characte r mas s space unit c r l f where: n weighing platform number mass 9 characters with right justification unit 3 characters with left justification an example: in case there are two weighing platforms. S i a cr lf...

Page 167

- 167 - c1_i cr lf - command understood but not accessible at this moment c1_a cr lf - command understood and in progress mass frame - response: mass value in a basic measuring unit response format: 1 2 3 4 5 6 7-15 16 17 18 19 20 21 s i space stability marker space character mass space unit cr lf s...

Page 168

- 168 - u h space mass space unit space cr lf mass - 9 characters with right justification unit - 3 characters with left justification set mass value of a single item (only for parts counting) format: sm_xxxxx cr lf, where: _ - space, xxxxx – mass format response options: sm_ok cr lf - command carri...

Page 169

- 169 - format: logout cr lf response options: logout ok cr lf - command understood, user is logged out es cr lf - command not recognized (error in format) value release format: ss cr lf response options: ss_ok cr lf - command understood and in progress command’s function is similar to function of p...

Page 170

- 170 - parameter given in [ms]. Recommended range . If value greater than the permissible high limit is given, than beep sound is operated for the maximum permissible amount of time. An example: command: bp_350 cr lf – activate beep for 350 ms response: bp_ok cr lf – beep activated caution! Beep so...

Page 171

- 171 - n – parameter, decimal value determining working mode number. To see detailed description go to omi command an example: command: oms_13 cr lf – set statistics mode response: oms_ok cr lf – statistics mode set give current working mode command overview: command returns currently set working m...

Page 172

- 172 - a_i cr lf – command understood but not accessible at this moment n – parameter, decimal value determining autozero settings n → 0 – autozero off 1 – autozero on caution! Command changes settings for a current working mode. An example: command: a_1 cr lf – turn autozero function on response: ...

Page 173

- 173 - 2 – fast+reliable 3 – reliable caution! The numbering is assigned to a particular value release option and it is identical for all balance types. The command changes settings for a current working mode if, for a particular balance type, value release settings are assigned to the working mode...

Page 174

- 174 - give current unit command overview: command returns current unit. Format: ug cr lf response options: ug_x_ok cr lf – command carried out, response: current unit ug_i cr lf – command understood but not accessible at this moment x – parameter, unit symbol an example: command: ug cr lf – return...

Page 175: 40. Error Messages

- 175 - format of mass printout: 1 2 3 4 -12 13 14 15 16 17 18 stability marker space character mass space unit cr lf stability marker [space] if stable [?] if unstable [!] if air buoyancy compensation mode is enabled [^] if error of exceeding range to + occurs [v] if error of exceeding range to – o...

Page 176: 41. Additional Ecquipment

- 176 - -no level- not levelled balance -err 100- weighing module restart in process in-course process resulting in unstable measurement (automatic feeder – pills feeding process or comparator – load change process) 41. Additional ecquipment type name p0136 rs232 cable for kafka printer p0151 rs232 ...

Page 177

- 177 - {4} date and time {5} working modes {6} net mass in current measuring unit {7} net mass is adjustment unit {8} gross mass {9} tare {10} current measuring unit {11} adjustment unit {12} low threshold {13} high threshold {15} statistics: number {16} statistics: sum {17} statistics: mean {18} s...

Page 178

- 178 - {45} target value {46} tolerance {47} difference {48} balance type {50} product: name {51} product: code {52} product: ean code {53} product: mass {54} product: tare {55} product: price {56} product: minimum {57} product: maximum {58} 2) product: pgc mode {59} product: shelf-life time in day...

Page 179

- 179 - {91} customer: discount {100} 2) pgc report: batch number {101} 2) pgc report: start date {102} 2) pgc report: end date {103} 2) pgc report: result {104} 2) pgc report: batch quantity {105} 2) pgc report: measurements quantity {106} 2) pgc report: value of t1 error {107} 2) pgc report: value...

Page 180

- 180 - {144} hex utf-8 {146} gross mass in current measuring unit {147} tare in current measuring unit {150} epson printer: paper cut {151} pcl printer: page offset {155} cooperation with radwag connect software {165} formulation: name {166} formulation: code {167} formulation: number of ingredient...

Page 181

- 181 - {198} 2) comparator: standard deviation {199} 2) comparator: number of cycles {200} 2) comparator: method {201} 2) comparator: min temperature {202} 2) comparator: max temperature {203} 2) comparator: min humidity {204} 2) comparator: max humidity {205} 2) comparator: min pressure {206} 2) c...

Page 182

- 182 - {234} 2) mass control: t1+ threshold {235} 2) mass control: t2+ threshold {236} 2) mass control: t2- threshold value {237} 2) mass control: t1- threshold value {238} 2) mass control: t1+ threshold value {239} 2) mass control: t2+ threshold value {240} 2) mass control: average in percent (dx)...

Page 183

- 183 - {285} 2) mass comparator: (reference) standards: name {286} 2) mass comparator: (reference) standards: code {287} 2) mass comparator: (reference) standards: class {288} 2) mass comparator: (reference) standards: factory no. {289} 2) mass comparator: (reference) standards: mass {290} 2) mass ...

Page 184

- 184 - {333} pipette calibration report: pressure {334} pipette calibration report: water temperature {335} pipette calibration report: z coefficient {336} pipette calibration report: statistics {337} pipette calibration report: measurements and statistics {338} pipette calibration report: number o...

Page 185

- 185 - 1) format of variables {0} and {1} is finished with characters cr lf, (i.E. Switching to a next line is carried out automatically), 2) variables are not operated by software version: “standard”. 42.2. Variables formatting you can randomly format numerical variables, text variables and date w...

Page 186

- 186 - • determining number of characters for printing / displaying, • determining number of decimal places for numerical variables, • converting the format of date and hour, • converting numerical variables into a code type ean13, • converting numerical variables and date into a code type ean128. ...

Page 187

- 187 - {27:v7.3} net value in ean 13 code (7-character code) {7:t6.3} net mass in ean 128 code {8:t6.3} gross mass in ean 128 code {55:t6.2} product price in ean 128 code {2:yymmdd} data in ean 128 code {61:yymmdd} product data in ean 128 code {62:yymmdd} product’s shelf-life time in ean 128 code 4...

Page 188

- 188 - universal variable 1 parts counting: determine mass using 50 parts universal variable 2 parts counting: determine mass using 100 parts universal variable 3 parts counting: assign standard to product universal variable 4 pipettes universal variable 5 differential weighing: series checkweighin...

Page 189

- 189 - formulation with target mass prepacked goods controls: measurements chart formulation without database default working mode skip ingredient user accept left door opening/closing abort 44. Appendix c – settings of citizen printer baud rate 9600b/sec parity control none bits 8bit stop bits 1 b...

Page 190

- 190 - 46. Appendix e – communication with barcode scanner 1. For communication with barcode scanners radwag balances 4y series use rs232 interfaces and simplex transmission (one direction) without handshaking. Only two wires are required for assuring such a transmission. Therefore, used scanners h...

Page 191

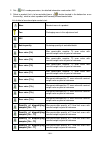

- 191 - report printout no / yes glp project . . Name setting » adjustment no / yes » working mode no / yes » date no / yes » time no / yes » user no / yes » balance type no / yes » balance id no / yes » level status no / yes » nominal mass no / yes » difference no / yes » temperature no / yes » cur...

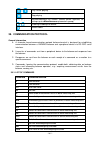

Page 192

- 192 - description value com 1 - » baud rate 9600 » data bits 8 » stop bits 1 » parity no com 2 - » baud rate 9600 » data bits 8 » stop bits 1 » parity no ethernet - » dhcp no » ip address 192.168.0.2 » subnet mask 255.255.255.0 » default gate 192.168.0.1 tcp - port 4001 peripherals description val...

Page 193

- 193 - » code length 0 transponder card scanner port none / com 1/ com 2 additional display port none / com 1-2 / tcp project settings ambient conditions module port none / com 1-2 / com internal address 3 inputs / outputs description value inputs » input 1 selection » input 2 selection » input 3 s...

Page 194

- 194 - printouts » guest selection » user selection » advanced user selection » administrator selection databases products customers selection: formulation - guest packages - user warehouses - advanced user printouts - administrator delete data older than miscellaneous description value language se...

Page 195

- 195 -.

Page 196

- 196 -.