- DL manuals

- RADWAG

- Accessories

- PUE C32

- User Manual

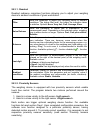

RADWAG PUE C32 User Manual - 3. Maintenance Activities

7

A worn out battery can be replaced only by the

manufacturer or by the authorized service.

The equipment including accumulators does not belong to

regular household waste. The European legislation requires

electric and electronic equipment to be collected and

disposed separately from other communal waste with the

aim of being recycled. Dear user, you are obliged to

dispose of the worn out battery as regulated.

Notice:

Symbols on butteries identify harmful compounds: Pb = lead, Cd = cadmium,

Hg = mercury.

3. MAINTENANCE ACTIVITIES

In order to ensure safety in the course of cleaning, it is necessary to disconnect

the device from the mains. With this condition met, uninstall the weighing pan

and other detachable balance components.

Caution:

Cleaning the weighing pan while still installed may cause damage of the

measuring system.

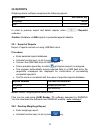

3.1. Cleaning ABS Components

To clean dry surfaces and avoid smudging, use clean non-colouring cloths

made of cellulose or cotton. You can use a solution of water and detergent

(soap, dishwashing detergent, glass cleaner). Gently rub the cleaned surface

and let it dry. Repeat cleaning process if needed.

In the case of hard to remove contamination, e.g: residues of adhesive, rubber,

resin, polyurethane foam etc., you can use a special cleaning agents based on

a mixture of aliphatic hydrocarbons that do not dissolve plastics. Before using

the cleanser for all surfaces we recommend carrying out tests. Do not use

products containing abrasive substances.

3.2. Cleaning Stainless Steel Components

Avoid using cleansers containing any corrosive chemicals, e.g. bleach

(including chlorine). Do not use products containing abrasive substances.

Always remove the dirt using microfiber cloth to avoid damage of protective

coating. In case of a daily maintenance:

1. Remove the dirt using cloth dipped in warm water.

2. For best results, add a little dishwashing detergent.

Summary of PUE C32

Page 1

Pue c32 weighing indicator user manual itku-97-07-10-17-en www.Radwag.Pl.

Page 2

2 october 2017.

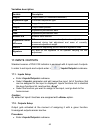

Page 3: Contents

3 contents 1. Intended use............................................................................................................................................. 6 2. Precautions ......................................................................................................................

Page 4

4 15.1.3. Printout template for weighing ................................................................................................ 34 15.1.4. Continuous transmission ......................................................................................................... 34 15.1.5. Printout i...

Page 5

5 24.3.1. Readout.................................................................................................................................... 62 24.3.2. Proximity sensors..................................................................................................................... 62 2...

Page 6: 1. Intended Use

6 1. Intended use pue c32 weighing indicator is a device intended to design industrial scales operating on the basis of load cells. The indicator features abs plastic housing and 5'' colour graphic display ensuring perfect readability. It is operated using 22-key membrane keypad equipped with progra...

Page 7: 3. Maintenance Activities

7 a worn out battery can be replaced only by the manufacturer or by the authorized service. The equipment including accumulators does not belong to regular household waste. The european legislation requires electric and electronic equipment to be collected and disposed separately from other communal...

Page 8: 4. Warranty Conditions

8 4. Warranty conditions a. Radwag feels obliged to repair or exchange all elements that appear to be faulty by production or by construction. B. Defining defects of unclear origin and means of their elimination can only be realized with assistance of manufacturer and user representatives. C. Radwag...

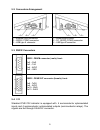

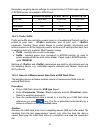

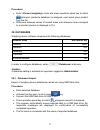

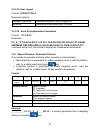

Page 9

9 5.2. Connectors arrangement 1 – ethernet rj45 connector 2 – rs232 (com1) connector 3 – usb type a connector 1 – power supply socket 2 – i/o, rs232 (com2) connector 3 – usb type b connector 5.3. Rs232 connectors rs232 - db9/m connector (male), front: pin2 – rxd pin3 – txd pin4 - 5vdc pin5 – gnd rs2...

Page 10

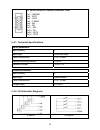

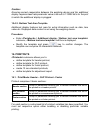

10 i/o, rs232 dsub15/f (female) connector, front: pin1 – gndwe pin2 - out1 pin3 - out2 pin4 – comm pin6 - in4 pin7 - in3 pin11 - in2 pin12 - in1 pin14 - out4 pin15 - out3 5.4.1. Technical specifications inputs parameters inputs quantity 4 inputs type solid-state relay cable cross-section 0.14 - 0.5m...

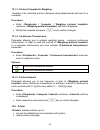

Page 11: 7. Start-Up and Operation

11 6. Unpacking and installation a. Take the indicator out of the packaging. B. Connect the indicator to a weighing platform, next place the weighing device on a flat and even surface. Keep it far away from any sources of heat. 7. Start-up and operation 7.1. Levelling to level the weighing instrumen...

Page 12: 8. Operation Panel

12 • pictogram displayed continuously: battery charged within 25% - 50% range of permissible voltage. • pictogram displayed continuously: battery discharged (charge status below 25% of the permissible voltage), connect the balance/scale to the mains in order to charge it. • blinking pictogram: damag...

Page 13: 9. Home Screen

13 press to zero the balance/scale. Press to tare the balance/scale. Press to change the weighing unit. Press to confirm the message. Press to confirm the weighing result (print). Press to confirm the messages (enter). Press to cancel the messages. Press to change the working mode. Programmable key ...

Page 14

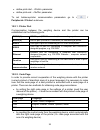

14 9.1. Top bar the top bar displays the following information: working mode name and symbol. Weighing device name. Symbol informing that wireless communication is on. Symbol informing that communication with a usb flash drive is on. Symbol informing that pc keyboard is connected. Symbol informing t...

Page 15: 10. Operating The Menu

15 you can define screen pictograms individually for each working mode. For detailed procedure informing you how to define screen pictograms read section 'display'. 10. Operating the menu in order to navigate the program menu use the operation panel. 10.1. Entering the menu in order to enter the men...

Page 16

16 press to move one menu level up. Press to delete a character when editing numeric and text values . Press to change keyboard mode when editing numeric and text values. Press to select/change working mode. Press to confirm/accept modifications. Press to move one menu level up, or to discard enteri...

Page 17

17 where: digits mode. To change keyboard working mode press key. Keyboard working mode options: - digits mode, - arrow keys operation, - bottom line operation. Press to clear box content. Keys: press to enter digit 1. Press to enter digit 2. Press to enter digit 3. Press to enter digit 4. Press to ...

Page 18

18 10.3.2. Text box where: capital letters mode. To change keyboard working mode press key. Keyboard working mode options: - upper-case characters mode, - lower-case characters mode, - digits mode, - arrow keys operation, - bottom line operation. Press to save project to *.Lb file on usb flash drive...

Page 19

19 keys: press to enter . , { } : ° - . Press to enter a b c. Press to move the cursor to the left, hold the key for a few seconds. Press to enter d e f. Press to move the cursor up, hold the key for a few seconds. Press to enter g h i. Press to move the cursor to the right, hold the key for a few s...

Page 20

20 diacritical signs table: polish. Diacritical signs table: english, german, french, spanish. Where: press to activate „caps lock” function. !$& press to switch to special signs keyboard. 10.3.4. Special signs table in order to activate special signs table while editing text box it is necessary to ...

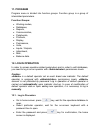

Page 21: 11. Program

21 11. Program program menu is divided into function groups. Function group is a group of interrelated parameters. Function groups: • working modes, • databases, • reports, • communication, • peripherals, • printouts, • display, • permissions, • units, • inputs / outputs, • adjustment, • misc, • bal...

Page 22: 13. Weighing Operation

22 12.2. Log out procedure • go to home screen, press key, wait for the operators database to open. • select option, the home screen is displayed. 12.3. Permissions levels there are 4 permissions levels: administrator, advanced operator, operator, none. Access to operator-related parameters and prog...

Page 23

23 13.1. Good weighing practice in order to assure a long-term device operation, wherein correct measurements are provided, the following principles must be adhered to: avoid applying mechanical shocks to the weighing pan. Place the loads centrally on the weighing pan (refer to section 3.6.2 of pn-e...

Page 24

24 caution: indication can be zeroed only within ±2% range of maximum capacity. If the zeroed value is greater than ±2% of the maximum capacity, then the software displays a respective error message: 13.3. Taring operation to determine net weight value, load the weighing pan with a packaging, wait f...

Page 25

25 in case of dual range balances and scales: • upon switching to weighing with the accuracy of the i weighing range, pictogram/marker is displayed on the left. • upon switching to weighing with the accuracy of the ii weighing range, pictogram/marker is displayed on the left. Switching from weighing...

Page 26

26 13.6. Setting min, max thresholds min, max thresholds are used: • to control mass of the weighed loads (read section 24.3.5 of this user manual), • for graphic visualization informing you how much of the weighing device capacity is used (read section 18.1.3 of this user manual), • to control the ...

Page 27: 14. Communication

27 13.6.3. Setting min, max threshold using proximity sensor • enter menu and select respective working mode. • edit a given proximity sensor (left or right). • select parameter from the list. • exit to home screen. • move your hand near the previously programmed proximity sensor, numerical box is o...

Page 28

28 14.2. Ethernet • select port. • set transmission parameters: dhcp yes, no ip address 0.0.0.0 subnet mask 0.0.0.0 default gateway 0.0.0.0 mac address --- caution: 1. Set the transmission parameters in accordance with your local network. 2. Parameter is automatically assigned to the weighing device...

Page 29

29 procedure: • enter parameter and activate wireless communication. • enter submenu and set respective values: scan available networks enter this parameter to trigger automatic search for available networks. Dhcp - select this option to make the program automatically read and display data assigned ...

Page 30

30 - operator's parameters export/import, - alibi and weighing reports export. • connecting balance to pcl printer. • connecting epson tm-t20 printer (featuring usb port). Caution: the usb flash drive must support fat files system. 14.5. Usb b port usb port of type b is intended for connecting the b...

Page 31

31 select directory and press „next” button. In order to start installation process, press „next” button. Connect the balance/scale to a computer, use 1.8-meter long usb a/b cable maximum (in case of already connected balance/scale, it is necessary to disconnect it and reconnect using usb cable). Re...

Page 32

32 press „finish” button. Connect the balance/scale to a computer again, use 1.8-meter long usb a/b cable maximum. Respective message box is displayed, press ok button for confirmation. Respective message box is displayed, press ok button for confirmation. „com ports screen” automatically displays n...

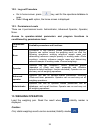

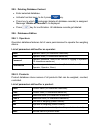

Page 33: 15. Peripheral Devices

33 15. Peripheral devices 15.1. Computer the weighing device can cooperate with a computer. Active weighing device – computer connection is signalled by pictogram (top bar of the home screen). To configure balance-computer cooperation settings go to / peripherals / computer> submenu. 15.1.1. Compute...

Page 34

34 15.1.3. Printout template for weighing template of an individual printout designed using balance/scale and sent to a computer. Procedure: • enter submenu, edit box is displayed. • modify the template and press key to confirm changes. 15.1.4. Continuous transmission parameter allowing you to activ...

Page 35

35 • define print start - parameter, • define print end - parameter. To set balance-printer communication parameters go to / peripherals / printer> submenu. 15.2.1. Printer port communication between the weighing device and the printer can be established via the following ports: rs232 (1) rs232 port...

Page 36

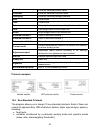

36 exemplary weighing device settings for correct printout of polish signs with use of epson printer connected to rs232 port: epson tm-u220d epson tm-t20 epson tm-t20 baud rate 9600 bit/s 38400 bit/s 38400 bit/s parity none none none code page 852 1250 852 prefix - 1b742d 1b7412 15.2.3. Prefix, suff...

Page 37

37 the data may be printed using any printer connected to a computer. New data can be recorded to an existing file therefore it is possible to continue recording measurement data using the file once created. Caution: usb flash drive must comprise . 15.3. Barcode scanner the balance allows for cooper...

Page 38

38 15.3.4. Prefix, suffix parameter allowing you to edit and in order to provide synchronization of the balance program with a barcode scanner. Caution: in radwag-adopted standard, the prefix is 01 sign (byte) hexadecimal format, the suffix is 0d sign (byte) hexadecimal format. For detailed descript...

Page 39

39 customer name, code. Packaging name, code. Lot number ** batch number ** *) - submenu hidden. Function inactive. *) - submenu hidden. Function active. 15.3.7. Test parameter allowing you to verify if operation of a barcode scanner connected to a balance/scale is correct. Procedure: • enter submen...

Page 40: 16. Printouts

40 caution: ensuring correct cooperation between the weighing device and the additional display requires baud rate parameter value to be set to 115200 bit/s for the port to which the additional display is plugged. 15.4.2. Bottom text area template additional display features text area for extra info...

Page 41

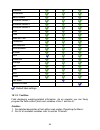

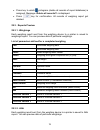

41 variables list header glp printout section footer dashes * working mode * date * time * balance type balance s/n operator * product * customer universal variable 1 universal variable 2 universal variable 3 empty line * adjustment report non-standard printout date time operator product customer pa...

Page 42

42 product currently selected product name. Customer currently selected customer name. Packaging currently selected packaging names. Date current date. Time current time. Net net weight value in a basic unit (calibration unit). Tare tare weight value in the current unit. Gross gross weight value in ...

Page 43

43 16.2.1. Adding non-standard printout • enter submenu. • press button (add record) assigned to panel key, a new record is created, it is defined by the following data: name non-standard printout name (43 characters maximum). Code non-standard printout code (15 characters maximum). Project text edi...

Page 44

44 {18} statistics: min {19} statistics: max {35} parts counting: reference sample mass {36} percent weighing: reference sample mass {37} statistics: standard deviation {39} 1) universal variable: value {41} batch number: value {45} parts counting: reference sample quantity {49} 1) universal variabl...

Page 45: 17. Inputs / Outputs

45 variables description variable description project project name (31 characters maximum). Adjustment type performed adjustment type. Operator logged-in operator name. Project project name printout. Date adjustment performance date. Time adjustment performance time. Balance s/n balance serial numbe...

Page 46: 18. Display

46 • select parameter and edit respective output, list of functions that can be assigned to the output is displayed. None output inactive. Stable stable weighing result over lo threshold value. Min stable stable weighing result below the min threshold. Min unstable unstable weighing result below the...

Page 47

47 18.1. Workspace workspace of your weighing device can comprise the following widgets: label, text box, bar graph. Each working mode features default home screen widgets set. Available fields (widgets) dimensions (width x height): • label – 1x1; 2x1. • text box - 1x1; 2x1. • bar graph – 1x1; 2x1. ...

Page 48

48 customer lot number batch number universal variable 1 universal variable 2 universal variable 3 date time date and time thresholds min threshold max threshold number sum gross sum average min max sdv gross part mass reference mass - default label settings. 18.1.2. Text box field displaying weighi...

Page 49

49 submenu for a field comprising widget features the following parameters: information enter this parameter to read info on selected widget type and dimensions. Settings enter this parameter to specify which widget-assigned data is to be displayed. Upon entering this parameter line 1 and line 2 set...

Page 50

50 additionally it shows where min and max thresholds are (providing that they were declared). • visualisation of mass value lower than min value: • visualisation of mass value higher than min value and lower than max value: • visualisation of mass value higher than min value and lower than max valu...

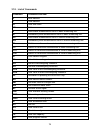

Page 51

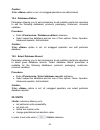

51 keys functions list (function accessibility is conditioned by a working mode). Working mode pictogram function working mode parameters select product select packaging select customer set tare set min and max print header print footer c statistics: zero edit lot number edit batch number edit unive...

Page 52

52 change working mode change unit last digit set date set time set part mass determine part mass assign reference sample reference sample quantity - 5 pcs. Reference sample quantity – 10 pcs. Reference sample quantity – 20 pcs. Reference sample quantity – 50 pcs. Reference sample quantity – 100 pcs...

Page 53: 19. Permissions Levels

53 19. Permissions levels submenu is available for operators logged as administrator. This group of parameters allows you to determine access rights for particular operators. In order to set permissions levels enter / permissions> submenu. 19.1. Anonymous operator parameter allowing you to assign un...

Page 54: 20. Units

54 caution: when option is set, all unlogged operators can edit printouts. 19.4. Databases edition parameter allowing you to set permissions levels enabling particular operators to edit the following databases: products, packaging, customers, universal variables. Procedure: • enter submenu. • select...

Page 55

55 caution: accessibility of particular units is conditioned by weighing device status; i.E. On the fact whether the given balance is verified or not. 20.1. Units availability parameter allowing you to declare which units are to be accessible upon pressing key. Procedure: • enter submenu. • units li...

Page 56

56 20.4. Custom units option available for non-verified weighing devices exclusively parameter allowing you to declare two custom units. Displayed custom unit value is a result of calculation, where obtained in the course of measurement weight value is multiplied by a multiplier determined for this ...

Page 57

57 where: sound signal enabled. Sound signal disabled. 21.3. Display brightness parameter allowing you to change display brightness, the brightness can be changed within 0% - 100% range. Procedure: • enter submenu and set respective value. Available values: 0%, 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%...

Page 58

58 date format * enter this parameter to set date format. Options: yyyy.Mm.Dd (set by default), yyyy.Dd.Mm, dd.Mm.Yyyy, mm.Dd.Yyy. Time format enter this parameter to set time format. Options: 24h (set by default), 12h. *) date format symbols: y – year, m – month, d – day. 21.6. Backlight standby ti...

Page 59: 22. Adjustment

59 22. Adjustment option available for non-verified weighing devices exclusively in order to ensure the highest weighing accuracy, it is recommended to periodically introduce a corrective factor of indications to weighing device memory, the said factor must be referred to the reference mass. Adjustm...

Page 60: 23. Balance Data

60 procedure: • enter submenu. Message is displayed. • unload the weighing pan and press key, message determination; please wait...> is displayed. • upon completion of start mass determination procedure, the weighing device displays the submenu. 22.4. Adjustment report adjustment report is automatic...

Page 61

61 • select the working mode you need to operate, the home screen is displayed automatically, wherein the top bar of the screen features pictogram of the selected mode. 24.2. Working mode accessibility you can declare which working modes are to be accessible for an operator upon pressing key. Proced...

Page 62

62 24.3.1. Readout readout submenu comprises functions allowing you to adjust your weighing device to ambient conditions of given workstation. Filter enter this parameter to adjust your weighing device to ambient conditions. The higher filter level, the longer the indication takes to stabilise. Opti...

Page 63

63 24.3.3. Save mode parameter allowing you to set mode of sending data from the weighing device to a peripheral device. Procedure: • enter menu and select respective working mode. • enter submenu and select respective save mode. Save mode options list: manual each stable manual printout of each sta...

Page 64

64 24.3.5. Result control when your weighing device operates with 'result control' mode on, the printout is carried out only when mass of load placed on the weighing pan is comprised within min, max thresholds. If the 'result control' mode is on, respective pictograms are displayed on the right of t...

Page 65

65 25. Working mode – weighing is a standard working mode enabling you to carry out the weighing operation along with record of the result to the database. 25.1. Home screen 25.2. Local settings in order to access local settings, press operation panel key to which working mode parameters> pictogram ...

Page 66

66 26.1. Home screen 26.2. Local settings in order to access local settings, press operation panel key to which working mode parameters> pictogram is assigned: readout for detailed description read section 24.3.1 proximity sensors for detailed description read section 24.3.2 save mode for detailed d...

Page 67

67 function of automatic correction of reference sample mass enabled. Function gets activated for mode at the moment of determination of reference sample quantity, it is signalled by display of pictogram at the home screen top bar. There are four conditions of acai function operation implemented int...

Page 68

68 caution: 1. If the value of entered single part mass is greater than max capacity value, then the following message is displayed: , 2. If the value of entered single part mass is lower than 0.1 of the reading unit, then the following message is displayed: . 26.4. Setting reference sample mass by ...

Page 69

69 procedure: • enter mode and press operation panel key to which pictogram (product database) is assigned, next select given product from the list. Caution: weight value of a single part must be declared for the selected product. To declare weight value of a single part, enter products database and...

Page 70

70 27.2. Local settings in order to access local settings, press operation panel key to which working mode parameters> pictogram is assigned: readout for detailed description read section 24.3.1 proximity sensors for detailed description read section 24.3.2 save mode for detailed description read se...

Page 71: 28. Databases

71 procedure: • enter mode and press operation panel key to which pictogram (products database) is assigned, next select given product from the list. • difference between values of loaded mass and reference mass assigned to a selected product is displayed in [%]. 28. Databases weighing device softwa...

Page 72

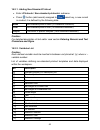

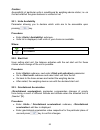

72 databases file name and extension operators users.Idb32 products products.Idb32 packaging packages.Idb32 customers customers.Idb32 universal variables universal variables.Idb32 non-standard printouts non standard printouts.Idb32 28.2. Databases import import of weighing device databases carried o...

Page 73

73 28.5. Deleting database content • enter selected database. • activate function keys, to do it press key. • press key to which pictogram (delete all database records) is assigned. Message is displayed. • press key for confirmation. All database records get deleted. 28.6. Databases edition 28.6.1. ...

Page 74

74 28.6.3. Packaging packaging database features list of product containers. When carrying out weighing process, upon selection of particular packaging, a respective tare value is triggered automatically. The tare value is displayed with minus sign. List of parameters defined for a packaging: name p...

Page 75: 29. Reports

75 29. Reports weighing device software comprises the following reports: report name max records qty weighings 50000 alibi 500000 in order to preview, export and delete reports, enter / reports> submenu. Caution: database of alibi reports is protected against deletion. 29.1. Export of reports export...

Page 76

76 • press key to which pictogram (delete all records of report database) is assigned. Message is displayed. • press key for confirmation. All records of weighing report get deleted. 29.3. Reports preview 29.3.1. Weighings each weighing result sent from the weighing device to a printer is saved to w...

Page 77: 30. Import / Export

77 list of parameters defined for a completed weighing date performed weighing date. Time performed weighing time. Result weighing result given in specific unit (%, pcs). Mass net weight. Tare tare value. 30. Import / export import/export option facilitates the following: • archiving alibi and weigh...

Page 78: 31. Communication Protocol

78 the files extensions are specific (read section 'databases export', 28.1), file- stored data is encoded therefore the files content is not readable for standard computer programs. Data stored in weighings and alibi reports files can be read using special radwag-designed pc software. 30.2. Data im...

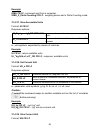

Page 79

79 31.2. List of commands command command overview z zero balance. T tare balance. Ot give tare value. Ut set tare. S send stable measurement result in basic measuring unit. Si immediately send measurement result in basic measuring unit. Su send stable measurement result in current measuring unit. S...

Page 80

80 a set autozero function. Login user logging. Logout user logout. Pc send all implemented commands. Caution: each command must end with cr lf characters. 31.3. Response format on receipt of a command, the indicator responds as follows: xx_a cr lf command understood and in progress. Xx_d cr lf comm...

Page 81

81 31.4.2. Tare balance format: t cr lf response options: t_a cr lf t_d cr lf - command understood and in progress. - command carried out. T_a cr lf t_v cr lf - command understood and in progress. - command understood but taring range is exceeded. T_a cr lf t_e cr lf - command understood and in prog...

Page 82

82 s_a cr lf s_e cr lf - command understood and in progress. - time limit exceeded while waiting for stable measurement result. S_i cr lf - command understood but not accessible at this moment. S_a cr lf mass frame - command understood and in progress. - response: mass value in basic measuring unit....

Page 83

83 su_a cr lf su_e cr lf - command understood and in progress. - time limit exceeded while waiting for stable measurement result. Su_i cr lf - command understood but not accessible at this moment. Su_a cr lf mass frame - command understood and in progress. - response: mass value in current measuring...

Page 84

84 c1_i cr lf - command understood but not accessible at this moment. C1_a cr lf mass frame - command understood and in progress. - response: mass value in basic measuring unit. Response format: 1 2 3 4 5 6 7-15 16 17 18 19 20 21 s i space stability marker space character mass space unit cr lf 31.4....

Page 85

85 31.4.13. Lock balance keypad format: k1 cr lf response options: k1_i cr lf - command understood but not accessible at this moment. K1_ok cr lf - command carried out. Caution: command is not stored in memory upon weighing device restart. 31.4.14. Unlock balance keypad format: k0 cr lf response: k0...

Page 86

86 mass - 9 characters, right justification. Unit - 3 characters, left justification. 31.4.18. Give value of max checkweighing threshold format: ouh cr lf response: uh_mass cr lf - command carried out. Response format: 1 2 3 4-12 13 14 15 16 17 18 19 u h space mass space unit space cr lf mass - 9 ch...

Page 87

87 31.4.21. Set mass value of a single item format: sm_xxxxx cr lf, where: _ - space, xxxxx - mass format. Response options: sm_ok cr lf - command carried out. Sm_i cr lf - command understood but not accessible at this moment. Es cr lf - command not recognised (mass format incorrect). Caution: comma...

Page 88

88 2. Beep sound activated via bp command is inhibited if in-course of its activation the sound is activated by means of other device: keypad, proximity sensors. 31.4.24. Give available working modes format: omi cr lf response options: omi cr lf n_mode name cr lf ok cr lf - command carried out, resp...

Page 89

89 caution: working modes numbering is identical for each kind of balance or scale. The numbers are assigned to working modes names. Example: omi cr lf - command sent from a computer omi cr lf - return accessible working modes 1_weighing cr lf 2_parts counting cr lf 3_percent weighing cr lf ok cr lf...

Page 90

90 example: omg cr lf - command sent from a computer. Omg_2_parts counting cr lf - weighing device set to parts counting mode. 31.4.27. Give accessible units format: ui cr lf response options: ui_”x 1 ,x 2 , … x n ”_ok - command carried out, response: accessible units. Ui_i - command understood but ...

Page 91

91 response options: ug_x_ok - command carried out, response: set unit. Ug_i - command understood but not accessible at this moment. X - parameter, unit symbol. Example: ug cr lf - return current unit. Ug_kg_ok cr lf – currently set unit is „kg”. 31.4.30. Give balance type format: bn cr lf response ...

Page 92

92 response options: rv_a_”x” cr lf - command understood, response: program version. Rv_i cr lf - command understood but not accessible at this moment. X – program version (in between inverted commas). Example: rv cr lf - return program version. Rv_a_”1.0.0” cr lf – response: program version „1.0.0”...

Page 93

93 31.4.35. User logout format: logout cr lf response options: logout_ok cr lf - command understood, user is logged out. Es cr lf - command not recognized (error in format). 31.4.36. Send all implemented commands format: pc cr lf response: pc_a_"z,t,s,si,su,sui,c1,c0,cu1,cu0,dh,odh,uh,ouh,ot,ut,ss,n...

Page 94

94 32. Diagrams of connection cables balance - computer cable (rs23) balance - printer cable (zebra) balance - printer cable (epson, citizen).

Page 95

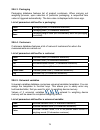

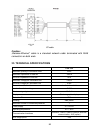

95 i/o cable caution: „balance-ethernet” cable is a standard network cable terminated with rj45 connectors on both ends. 33. Technical specifications pue c32 maximum quantity of verification units 6000 maximum impedance of load cell 1200 Ω minimum impedance of load cell 50 Ω maximum voltage per veri...

Page 96: 34. Error Messages

96 34. Error messages 35. Additional equipment accessories: • p0108 - computer cable. • p0151 - epson printer cable. • k0047 - 12v dc cigarette lighter cable. • epson - thermal printer. • epson - dot matrix printer. • ap2-1 - power loop output. • kr-01 - rs232/rs485 converter..

Page 97

97 • kr-04-1 - rs232/ethernet converter. • wd-6 - additional display. • mouse, pc keyboard. Computer software: • pw-win, • rad-key. 36. Appendix 01 - communication with barcode scanner 1. For communication with barcode scanners, radwag scales use rs232 interfaces and simplex transmission (one-way di...

Page 98

98.