- DL manuals

- Raider

- Outboard Motor

- Outboard Motor

- Owner's manual

Raider Outboard Motor Owner's manual

Confidential

Page 1

8/23/20132--

O

O

w

w

n

n

e

e

r

r

’

’

s

s

M

M

a

a

n

n

u

u

a

a

l

l

40 and 50 Horsepower

Two stroke Low pressure Direct

Injection (TLDI)

Multi-Fuel SubmersibleOutboard Motor

This manual has been prepared for the United States Guardian Angels for

service of the Multi-fuel, Submersible Outboard motor designed and manufactured

under Contract No. N61331•11•C-0008, dated 3/4/11. The data presented in this

manual was revised as of August 2013 representing the latest revision.

2013

Summary of Outboard Motor

Page 1

Confidential page 1 8/23/20132-- o o w w n n e e r r ’ ’ s s m m a a n n u u a a l l 40 and 50 horsepower two stroke low pressure direct injection (tldi) multi-fuel submersibleoutboard motor this manual has been prepared for the united states guardian angels for service of the multi-fuel, submersibl...

Page 2: Contents

2 contents 1. Your raider outboard motor____________________________________ 1 a. Limited warranty ............................................................................................................. 1 b. Serial number ...........................................................................

Page 3

1 1. Your raider outboard motor____________________________________ a. Limited warranty this raider product is fully guaranteed against defective materials and workmanship for the period on one year. The limited warranty will not apply to normal wear and tear of parts, adjustments, tune-ups, or to a...

Page 4

2 there is an air compressor, an air/fuel rail, and six injectors. Three fuel injectors introduce fuel into the air/fuel rail. 80 psi fuel and air are mixed and then injected into the combustion chamber through three air injectors after the exhaust port is closed. The result is complete atomizing wi...

Page 5

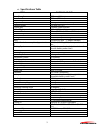

3 e. Specifications table item raider 50 hp tldi overall length 1120 mm (44.1 in.) overall width 384 mm (15.1 in.) overall height 1514 mm (59.6 in.) weight 92.0 kg (202 lbs.) – w/o composites transom length 530 mm (20.9 in.) engine type 2-stroke direct injection piston displacement 697 ml (42.5 cu. ...

Page 6

4 f. Tldi verses carburetor tldi is an abbreviation that stands for two-stroke low-pressure direct injection. The air assisted, low-pressure direct injection system has been combined with the in- ducted ignition system and the engine control unit, which performs control or fuel mix- ture, injection ...

Page 7

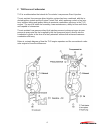

5 g. Tldi raider parts identification 2. Raider a b c a rear dewatering valve b front dewatering valve c mid dewatering valve.

Page 8

6 raider installation____________________________________________________ a. Handling engine the raider was designed to be carried by the two side rails installed to allow the outboard to be moved through submarine hatches and small areas. The handle/shifter should be upright into the hollow area to...

Page 9

7 c. Installation of twin engines when installing two outboard engines, be sure to keep an interval of 470 to 600 mm (18 to 26 inches) between the two engines. Both outboard engines should be at the exact center of the stern and mount it against the rubber inflatable boat pad or plate. It is importa...

Page 10

8 f. Propeller a propeller must be selected so that the engine rpm measured at wide open throttle while cruising is within the maximum operating range. In the raider that range is between 5150 and 5850 rpm. To ensure optimum performance, the propeller should match the boat type and its load. Replaci...

Page 11

9 raider running _____________________________________________________ a. Fuels (multi-fuel) the raider can run on jet fuels (jp-5/8), diesel fuel, kerosene, gasoline or gasohol/ethanol. There is no knob or valves to turn. If you switch from one fuel to another fuel the raider en- gine will operate ...

Page 12

10 pull starter handle slowly until starter engages, then pull forcibly for a full rope pull (short or slow pulls will not provide enough current to the ecu to start). Maintain fuel pressure by squeezing primer bulb until engine is running. Raider comes with an electric start option. Flip on switch;...

Page 13

11 g. Throttle friction to increase throttle friction, turn the throttle friction screw clock- wise. To decrease friction, turn the throttle friction screw counter- clockwise. Do not over tighten. H. Shifting to avoid gear case damage: do not attempt to shift engine from neutral to forward or revers...

Page 14

12 i. Stopping raider 1. Slow engine to idle speed. 2. Move shift lever to neutral position. 3. Press and hold stop button until the engine stops running. J. Trim angle engine should be perpendicular to water when boat is underway. This ad- justment can only be determined by water testing the boat. ...

Page 15

13 m. Trim tab adjustment n. Shallow water drive the engines shallow water tilt is controlled by the gas assist tilt cylinder engage shallow water drive 1. Move red button tilt/run lever to tilt position 2. Raise the engine to the desired shallow drive position. 3. When drive angle is reached, lock ...

Page 16

14 p. Impact damage your boat and engine can be seriously damaged by a collision at high or low speeds, while trailering, or in the water. If you hit an object, stop immediately and examine the engine for loose mounting hardware or clamp screws. Inspect for damage to stern and swivel brackets, and c...

Page 17

15 if you suspect the engine is overheating or has overheated, stop the engine only when it is safe. When operating the engine, the water intakes must be completely submerged. Make sure the water intake screens are not in- stalled upside down (ramps must be forward). If upside down, the engine will ...

Page 18

16 if starter cord is missing or gets broken, it might not be long enough to use as an emergency starter cord. If in you need an additional rope cut cord from starter assembly. Tie a knot to one end of cord. Place knot in the notch on top of flywheel. Wrap cord around flywheel clockwise as shown. Fo...

Page 19

17 starting after submersion 1. Move all 3 drain valves to the run position. 2. Pump primer bulb until firm resistance is felt. 3. Pull starter handle slowly until starter engages, then pull forcibly to start. 4. Run engine at part throttle for 10-15 seconds. You must run the engine after performing...

Page 20

18 4. General maintenance_______________________________________________ general safety warnings when replacement parts are required, use genuine raider parts or parts with equivalent characteristics including type, strength, and materi- al. Failure to do so may result in product malfunction and pos...

Page 21

19 b. Removing and carrying the raider a.

Page 22

20 c. Tool kit and spare parts d. Corrosion protection whenever possible after use in sea water or submersion in sea water, wash entire engine with fresh water to remove salt deposits and wipe down with a dry cloth. Spray entire powerhead with a liberal coat of anti-corrosion spray penetrant/lubrica...

Page 23

21 f. Trouble shooting g. Storage use the following procedure to properly prepare the engine for extended periods of nonuse. These steps are intended to protect the engine during storage and simplify the out of stor- age servicing procedure. Use a flushing attachment to prevent engine or water pump ...

Page 24

22 5. Inspect the engine's steering, throttle, de-watering and shift systems for damage due to corrosion, aging, lack of maintenance, or abuse. Follow the maintenance and lubrication recommendations when servicing these systems. 6. Replace the engine's fuel filter. 7. Clean and inspect oil reservoir...

Page 25

23 i. After submersion after submersion or after a mission, the raider must be prepared to be returned to nonuse or prepared for your next mission. If the raider is re-submersed after your mission and it cannot be serviced, keep it sub- mersed until it can be serviced to avoid prolonged exposure to ...

Page 26

24 motor on stand back of raider front of raider top view of rear dewatering valve.

Page 27: Raider Advantages

25 raider advantages best power to weight ratio long history of bullet proof reliability and maintenance most compact in horsepower class extensive modifications to commercial off the shelf outboard solely for the warfighters needs no bells and whistles o rugged o durable originally designed for jap...

Page 28

26 robotics and conceptual engineering, inc. 2702 lake dauterive rd. Loreauville, la 70552 (337) 577-6810 7887 bryan dairy rd largo, fl 33777 (321) 403-3585 august 2013.