- DL manuals

- Raider

- Outboard Motor

- R50-001

- Owner's Manual

Raider R50-001 Owner's Manual

1

2015

Two stroke - Multi-Fuel - Submers

ible – Air Drop

Outboard Motor

Owner’s Manual R50-0

01

This manual has been prepared for the United Stat

es military for

Operator knowledge of the Multi-fuel, Submersible Outboard mot

or designed and manufactured

Under Contract No. N61331•11•C-0008, dated 3/4/11. The

data presented in this

Manual was revised as of January 2015 representing

the latest revision.

Raider Outboards are not sold to the pu

blic.

Raider 50 Owner’s Manual

Summary of R50-001

Page 1

1 2015 two stroke - multi-fuel - submers ible – air drop outboard motor owner’s manual r50-0 01 this manual has been prepared for the united stat es military for operator knowledge of the multi-fuel, submersible outboard mot or designed and manufactured under contract no. N61331•11•c-0008, dated 3/4...

Page 2

1 serial number location: found on top of block – three digits the raider r50-001 is a specially manufactured outboard motor for the military for use on rubber inflatable boats. This motor can be submerged for long periods of time and quickly restarted; operated on multiple fuels; contains electric ...

Page 3: Caution

2 the limited warranty does not cover maintenance items. The following items are some examples not covered by the limited warranty. Spark plugs, anode, trim-tub, propeller , fuel filter , oil filter . Carbon brush. Starter rope, shear-pin, split-pin, bolt/nut ·washer, wire cable. Rubber goods: pump ...

Page 4

3 servicing, replacement parts & lubricants only qualified personnel should perform maintenance on the raider. Training classes can be given or questions answered by contacting www.Raideroutboards.Com . Be sure to use genuine raider parts and genuine raider lubricants or recommended lubricants. 50:1...

Page 5

4 contents page 1. Specifications ................................................................................. 6 2. Names of parts ............................................................................. 7 3. Engine installation on rubber inflatable boat (rib) ...................... 8 3-1 ...

Page 6

5 10. Raider periodic inspection ……………………………....................... ....... . 30 10-1 periodic inspection checklist ……………………………………………. 31 10-2 periodic dewatering system maintenance …………………………. 31 10-3 battery maintenance ……………………………………………………….. 31 10-4 grab rail maintenance ……………………………………………………….. ...

Page 7

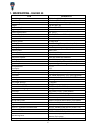

6 1. Specifications – raider 50 item raider 50 hp overall length 45.1 inches (1145 mm) overall width 13 inches (330.2 mm) overall height 55.6 inches (1413 mm) (long shaft) weight 178 lbs. (80.7 kg) transom length 550 mm (21.7 in.) engine type 2-stroke fuel induction system piston displacement 697 (4...

Page 8: 2. Names Of Parts

7 2. Names of parts – raider 50 raider 50 1. Tilt handle 2. Pull start (primary) 3. Tiller 4. Throttle grip speed control 5. Shifter 6. Upper motor cover 7. Rear cowling hook lever 8. Water check port 9. Tilt stopper 10. Water plug 11. Anti-ventilation plate 12. Trim tab 13. Propeller 14. Oil plug (...

Page 9

8 20. Dewatering 21. Emergency stop lanyard 22. Grab rail 23. Starter button (secondary start) 24. Anode 20 21 22 23 24 change from gasoline to heavy fuels turn six valves to open (turn counter clockwise until open) to return to gasoline; close valves..

Page 10: (Ribs)

9 3. Raider installation on rubber inflatable boats (ribs) 4.7 rib’s may have weight/horsepower limitations – raider 40 weight is 148 pounds for single outboard – without safety jet drive raider 50 weight is 178 pounds for single outboard – without safety jet drive check transom tag on rib prior to ...

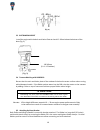

Page 11: Caution

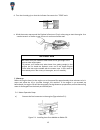

10 3-3 rib transom height install the engine with the anti-ventilation plate at a level l0 - 30mm below the bottom of the boat (fig. 3). 10-30mm (0 .4 -1.2 inches . ) (fig . 3) 3-4 transom matching with raider 50. Be sure that the anti-ventilation plate of the outboard is below the water surface whe...

Page 12

11 3.6 propeller selection the propeller supplied with the raider is an “all around” propeller. Whatever propeller you ultimately decide to use must be selected so that the engine rpm measured at wide open throttle while cruising is within the recommended range between 5000 to 5700 rpm. The raider 5...

Page 13: Caution

12 4. Fuel & engine oil - tc-w3 or raider oil must be added to bladder for operation of raider 50 on any fuels. 4-1 fuels: gasoline (primary) other fuels jp-5/8; kerosene; diesel danger a caution do not mix different brands of oil. Using different brands of oil, or different type of oil even if the ...

Page 14: Caution

13 4-2 raider 50 fuel mix ratio (50:1) add engine oil into fuel oil tank. The mixing ratio with gasoline is 50:1 (one part oil and 50 parts gasoline) . Mix well by hand. The mixing ratio during break-in running is i: 25. Mixing ratio engine oil gasoline during break-in 1 25 after break-in 1 50 4-3 h...

Page 15: Ution

14 5-2. Starting the raider 50 has three starting capabilities. A) primary is manual pull start. This method simply uses the pull start located at the top of the raider. B) secondary starting is the “push button” which engages the battery. If the battery is dead if you start the raider it will recha...

Page 16: Caution

15 d. Turn the throttle grip so that the indicator line meets the "start mark. E. Wind the starter rope around the flywheel a few turns . Give it a sharp tug to start the engine . Use a socket wrench or similar to get a firm grip on the end of the rope. F. Warm-up before driving the boat, let the en...

Page 17: Caution

16 b) feed fuel to the carburetor by squeezing the primer bulb until firm. A. Install the safety lock in the stop switch (lanyard). B. Set the shift lever to neutral caution motor will start in gear when electric start is used. Note: be sure that the shift is at neutral when starting the engine. The...

Page 18

17 c. Turn the throttle grip so that the indicator line meets the "start" mark. D. If not dewatering insure dewatering valve is pushed to in position. E. Pull the starter rope slowly until resistance is met. Give it a sharp tug to start the engine. F. Electric start button can be used to start engin...

Page 19

18 j. Release the starter button as soon as the engine starts. For dewatering you can pull dewatering valve: note: pull starter rope slowly eight (8) times; leave open valve; press starter button. This will eliminate any water left in cylinder. Close valve once engine begins to start. K. Pull back t...

Page 20

19 m. Engine speed - proper idle speed after warm-up operation clutch engaged clutch disengaged 750 rpm 900 rpm do not exceed the full-throttle engine speed full throttle engine speed 5150-5850 rpm.

Page 21: Caution

20 6. Operation 6-1. Forward/reverse running turn the throttle grip toward " slow" and move the shift lever quickly to forward or reverse when the engine speed has reached the lowest rpm. Set the reverse lock lever provided on the starboard side to "release" by turning it downward . A caution 1. The...

Page 22

21 tilt the engine up approximately to 45 ° and lower it. The engine will now be set to the shallow water setting. 6-3. Stopping the engine a. Reduce the engine speed to idling rpm. Keep pressing on the stop switch and the engine will then stop . Notes: 1. When the engine stopped, disconnect the bla...

Page 23

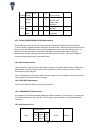

22 7.0 trim adjustment the following instructions explain how to set the best trim angle of the rib. The trim angle is adjusted by setting the thrust rod in the correct thrust rod hole. - proper trim angle the trim angle is optimum when the rib is parallel to the water surface while running. Imprope...

Page 24

23 in this case, the trim angle should be increased by setting the thrust rod in a higher hole. Select a higher hole the reverse lock lever is located on the starboard side - to "release" by turning it downward. Tilt the engine up entirely. The tilt will lock in the raised position. To tilt the engi...

Page 25: Caution

24 8. Removing and carrying the motor the raider 50 has a “grab” handle installed to help the operator install/remove the outboard. This also protects the raider when dropped. 8.1 removing the motor from the rib 1) stop the engine . 2) disconnect the fuel connector from the bladder 3) undo the clamp...

Page 26: A. Caution

25 8.3 storing the motor store the motor on the raider carts supplied if possible. For long periods of time unplug battery; insure motor has been washed and dried; spay corrosion zero on engine; run all fuels from engine; spray corrosion zero inside fuel induction system – all three carbs. 8.4 trail...

Page 27

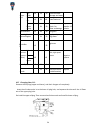

26 8.5 trim tab adjustment if straight-line cruising cannot be achieved, adjust the trim tab located under the anti- ventilation plate. If the boat veers toward the right, direct the trim tab towards a if the boat veers toward the left. Direct the trim tab towards r 8-6. Steering load adjustment ste...

Page 28: Caution

27 8-7. Throttle grip turning load adjustment turn the friction adjustment screw on the steering handle to adjust the turning load of the throttle grip. To decrease load i to increase load 9.0 inspection and maintenance care of your outboard motor to keep your motor in the best operating condition, ...

Page 29

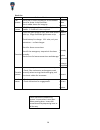

28 check list item points to check action fuel system check fuel/2-stroke oil/additive in the bladder. Check for water in the fuel filter. Check rubber hoses for integrity replenish clean rep l ace lubrication system if jp-5/8 is being used insure additive is placed in bladder. 2-stroke oil is also ...

Page 30

29 item points to check action clutch and propeller system check the propeller for bent or damaged blades . Check if the propeller nut is tightened and the split pin is present. Adjust replace dewater- ing check movement of valve; inspect back valves check the dewatering rod installation. Tighten st...

Page 31: Caution

30 remove cowling and wash motor with soap and water. Let dry. Spray corrosion zero on raider. Long-term storage. After mission run the engine at low speed with the fresh water/ear muffs; set shifter to neutral to flush out fresh water from the cooling system and in the process remove salt, mud and ...

Page 32: Caution

31 9.4 replacing the spark plugs - pulstar model sbe 1/10 spark plugs must be used i. Remove the upper engine cover (cowling) . 2. Remove the spark plugs by turning counter-clockwise with the socket wrench. Tap lightly on the spark plugs if they are hard to turn. The pulstar model sbe 1/10 spark plu...

Page 33

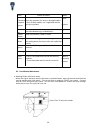

32 10. Periodic inspection it is important to inspect and maintain your outboard motor regularly. At each interval on the chart below, be sure to perform the indicated serv i cing . Maintenance intervals should be determined according to the number of hours or number of months, whichever comes first...

Page 34

33 ignition *ignition timing 0 0 adjust timing . Starting system * starter motor 0 check tor salt deposits and battery cable condition. Dewater ing 0 0 0 check for tightness starter rope 0 0 0 check for wear or damage 10-2 periodic dewatering system maintenance the dewatering system consists of valv...

Page 35

34 lower unit l pro- peller 0 0 0 bend of blades damage and wear gear oil 0 0 0 change of oil and water leak eval. Water pump 0 0 check for wear or damage replace impeller -12 months bolt and nuts 0 0 0 retighten rotating parts . Grease nipples 0 0 apply and pump in grease. Dgrab bar s 0 0 check for...

Page 36: Caution

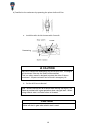

35 lower oil plug upper oil plug lower oil plug clean or change fuel filter on the engine after removing the fuel filter case. Tilt the engine up to check the oil level in the tank. Remove the oil plug by turning oil plug counter-clockwise, then check if the oil level reaches the bottom line of the ...

Page 37

36 10-8 engine long term storage wash the engine exterior and flush the cooling water system thoroughly with fresh water. Let the water drain completely. Wipe off any surface water with an oily rag. Drain all fuel from the fuel lines, fuel pump and carburetor by running the motor until it quits. Cle...

Page 38: Caution

37 10-10 electric starter motor coat the pinion gear and shaft of the electric starter motor with grease. Spray corrosion zero on all electrical parts and motor. Motor should be clean and dry before spraying. 11. Checking after striking underwater object striking sea bottom or underwater object may ...

Page 39

38 when operating raider 50 in cold weather at sub-zero temperatures the water in the cooling water pump may freeze and severely damage the pump, impeller, and associated parts. To avoid this, submerge the lower half of the engine into the water, or tilt the engine and operate the electric starter m...

Page 40

39 15. Emergency tool kit spark plug socket three (3) spark plugs pliers screwdriver socket for removal of pull starter pull rope slit pin 16. Epa emissions regulations epa (united states environmental protection agency) has emission regulations and is controlling air pollution from new outboard mot...