- DL manuals

- Railway Equipment

- Blower

- 934

- Operating Manual

Railway Equipment 934 Operating Manual

P/N R9340-0104 1 © 2010 RAILWAY EQUIPMENT CO.

REV B

5/11

OPERATING MANUAL

MODEL NO. 934

ELECTRIC HOT AIR BLOWER

TRACK SWITCH SNOW MELTER

480 / 230 VAC 1 & 3 PHASE

50KW AND 60 KW LOAD CAPACITY

MANUFACTURED

BY

RAILWAY EQUIPMENT COMPANY

15400 MEDINA ROAD

PLYMOUTH, MINNESOTA 55447

TEL. 763-972-2200

FAX. 763-972-2900

E-Mail:

Support: Techsupport@rwy.com

Sales: Order@rwy.com

Summary of 934

Page 1

P/n r9340-0104 1 © 2010 railway equipment co. Rev b 5/11 operating manual model no. 934 electric hot air blower track switch snow melter 480 / 230 vac 1 & 3 phase 50kw and 60 kw load capacity manufactured by railway equipment company 15400 medina road plymouth, minnesota 55447 tel. 763-972-2200 fax....

Page 2

P/n r9340-0104 2 © 2010 railway equipment co. Rev b 5/11 caution general hazard warning failure to comply with the precautions and instructions provided with this heater, can result in death, serious injury and property loss or damage from hazards of fire, explosion, burn, asphyxiation, carbon monox...

Page 3

P/n r9340-0104 3 © 2010 railway equipment co. Rev b 5/11 please read this instruction manual entirely before handling this material or attempting to install, operate or service this hot air blower system. Please read the warnings and cautions listed below. Caution caution caution caution two (2) com...

Page 4

P/n r9340-0104 4 © 2010 railway equipment co. Rev b 5/11 table of contents i. General information 6 a. Model number description 6 b. Standard features 7 ii. Component description 8 a. Main hab unit 8 b. Standard ductwork 8 c. Optional ductwork 9 iii. Installation 12 a. Tie duct 12 b. Main hab unit 1...

Page 5: Electric Hot Air Blowers

P/n r9340-0104 5 © 2010 railway equipment co. Rev b 5/11 i. General information a. Model number description options 0 = standard 1 = ge in tie switch 2 = ge snf in tie switch 3 = track duct nozzles for snf duct 4 = 3/5 panel configured 10x10 adaptor flange and nozzle (no tie duct) 5 = 2hp panel conf...

Page 6

P/n r9340-0104 6 © 2010 railway equipment co. Rev b 5/11 b. Standard features of track switch hot air blower 1. Direct drive motor, totally enclosed fan cooled. 2. High efficiency, quiet operation blower. 3. Voltage sensor to prevent low or high voltage damage. 4. Current coils for open heater detec...

Page 7

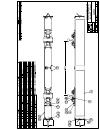

P/n r9340-0104 7 © 2010 railway equipment co. Rev b 5/11 ii. Component description a. Main hot air blower (hab) unit 1. Main circuit breaker: provides main over-current protection and manual on-off control of electrical power. 2. Motor contactor: provides automatic blower motor control, with high cu...

Page 8

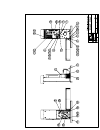

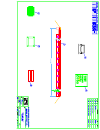

P/n r9340-0104 8 © 2010 railway equipment co. Rev b 5/11 b. Standard ductwork 1. Heat duct: the first section of ductwork attached to the main hab unit. This duct contains the heaters, fuses, air flow switch and overtemp. 2. Flex duct: connects the heat duct to the offset duct. It is a section of fl...

Page 9

P/n r9340-0104 9 © 2010 railway equipment co. Rev b 5/11 c. Optional ductwork 1. Extension ducts: extension ducts of various lengths are available to meet specific requirements. These are insulated and enclosed in a metal wrapper. Make sure the duct is mounted in the correct orientation, as there is...

Page 10

P/n r9340-0104 10 © 2010 railway equipment co. Rev b 5/11 (intentionally left blank).

Page 11

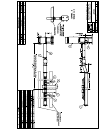

P/n r9340-0104 11 © 2010 railway equipment co. Rev b 5/11 iii. Installation installation should be done in this order: a. Tie duct outlet duct/offset duct b. Main hab unit/flex duct c. Point nozzles and track ducts d. Electrical a. Tie duct 1. Remove the appropriate tie. Choose the tie that will res...

Page 12

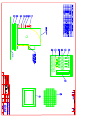

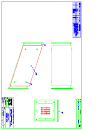

P/n r9340-0104 12 © 2010 railway equipment co. Rev b 5/11 b. Main hab unit 1. The main hab unit has four slotted mounting holes on 15-1/2” x 34-1/2” centers. 2. Refer to foundation assembly drawing for the assembly of the optional mounting foundation. 3. Use the provided ehab positioning drawings to...

Page 13

P/n r9340-0104 13 © 2010 railway equipment co. Rev b 5/11 13. Adjustable air intake screens. To start the ghab in a new location, set the intake screens in the closed position. If there proves to be a moisture problem where frost builds up on the intake screens, the intake screens can be set in the ...

Page 14

P/n r9340-0104 14 © 2010 railway equipment co. Rev b 5/11 4. Lay the track ducts on the rail ties alongside where they will be installed. 5. Refer to the drawing 92774. Place the track duct support brackets in position on the ties so that one is near the heel end and one near each joint. Use the lag...

Page 15

P/n r9340-0104 15 © 2010 railway equipment co. Rev b 5/11 (intentionally left blank).

Page 16

P/n r9340-0104 16 © 2010 railway equipment co. Rev b 5/11 f. Electrical connection 1. There are knockouts on the side and bottom of the control enclosure for incoming electrical wires. Caution 2. Incoming power: the incoming power should be connected directly to the main circuit breaker. The neutral...

Page 17

P/n r9340-0104 17 © 2010 railway equipment co. Rev b 5/11 iv. Control module a. Description the hot air blower control module contains all of the elements and functions necessary for advanced snow melter operation. The unique single-chip microcomputer has been programmed with logic and timing sequen...

Page 18

P/n r9340-0104 18 © 2010 railway equipment co. Rev b 5/11 c) force: placing ss1 in the force position enables the snow melter dependant on outside air temperature. The snow melter will remain on until force is turned off. This is useful for on site testing. To use the force position to operate the e...

Page 19

P/n r9340-0104 19 © 2010 railway equipment co. Rev b 5/11 1. Delay start delay start displays the time remaining until the buzzer delay will start. 2. Buzzer delay buzzer delay displays the time remaining until the motor will start. 3. Start motor start motor displays the time remaining until the he...

Page 20

P/n r9340-0104 20 © 2010 railway equipment co. Rev b 5/11 c. Fault conditions 1. Major voltage fault major voltage fault is caused by a mismatch in control modules. If a module set up for 230 volts is used in a 460 volt ehab, this fault is set. To correct this, chance the unit type screen (found on ...

Page 21

P/n r9340-0104 21 © 2010 railway equipment co. Rev b 5/11 6. Ac frequency fault: ac frequency fault is set when ac frequency is either above or below frequency setpoints. This fault is generally caused by a backup power source not being able to handle the load. 7. Check fuse # 2 5vdc: fuse # 2 is tr...

Page 22

P/n r9340-0104 22 © 2010 railway equipment co. Rev b 5/11 13. Voltage fault phase 2: voltage fault phase 2 is set when phase 2 line voltage is either above or below voltage setpoints. 14. Voltage fault phase 3: voltage fault phase 3 is set when phase 3 line voltage is either above or below voltage s...

Page 23

P/n r9340-0104 23 © 2010 railway equipment co. Rev b 5/11 reset. To reset, turn knob. 2. Kwh total display of accumulated kwh. G. 1. Rail temp __ f requires an optional rail temp sensor for display. 2. Cabinet temp __ f h. 1. Hour meter 2. Reset hour 2. Fault history: the following fault counters wi...

Page 24

P/n r9340-0104 24 © 2010 railway equipment co. Rev b 5/11 g. Motor overload fault counter: overloads counter is total motor overloads faults. To reset above faults, rotate selector dial. H. Sail on fault counter: sail on counter is total count of sail on faults. To reset above faults, rotate selecto...

Page 25

P/n r9340-0104 25 © 2010 railway equipment co. Rev b 5/11 3. Set point: the set point menu has two selectable levels: basic or advanced. If the advanced level is selected, the next screen is password. To adjust items on the advanced menu, enter password: 5 by rotating re1. The advanced menu includes...

Page 26

P/n r9340-0104 26 © 2010 railway equipment co. Rev b 5/11 displays the program revision level and the date of the last program revision. B. Line voltage high setpoint: the ac line voltage high setpoint can be set from 0 to 700. If the measured line voltage rises above the selected value, the high li...

Page 27

P/n r9340-0104 27 © 2010 railway equipment co. Rev b 5/11 j. Select run timer pulse mode: the choices are on or off, factory default is off. When on is selected a pulse will start run time sequence and continue until run timer has timed out. When off is selected run timer will time as long as remote...

Page 28

P/n r9340-0104 28 © 2010 railway equipment co. Rev b 5/11 . ..

Page 29

P/n r9340-0104 29 © 2010 railway equipment co. Rev b 5/11 d. Operation with switch ss1 in the “auto” position, the unit can be activated by applying a circuit closure between terminals ts1-1 and 2. If the outside temperature is above set point, the unit will not start a snow melt sequence but will t...

Page 30

P/n r9340-0104 30 © 2010 railway equipment co. Rev b 5/11 b. Fall 1. Check all ductwork for clear airflow. Ensure that the point and track duct nozzle screens are not damaged and are completely covering the openings. Make sure that no debris or rodents have obstructed any area of the ductwork. 2. In...

Page 31

P/n r9340-0104 31 © 2010 railway equipment co. Rev b 5/11 c. Low airflow 1. Check for obstructions in all ductwork and the air intake. 2. If there is frost buildup on the air intake screens, move the screens to the “open” position. 3. Check the voltage and current levels on the blower motor. 4. Make...

Page 32

P/n r9340-0104 32 © 2010 railway equipment co. Rev b 5/11 viii. Snow detector a. Snow detector installation 1. The snow detector sensing circuitry is contained within the control module. All that is required for snow detector operation is to connect the sensing head(s). 2. Either one or two sensing ...

Page 33

P/n r9340-0104 33 © 2010 railway equipment co. Rev b 5/11 b. Snow detector operation note: a snow detector sensing head only detects moisture. With temperature sensing capability, the hab unit assumes moisture is due to snow when the air temperature is below set point. All operating functions are si...

Page 34

P/n r9340-0104 34 © 2010 railway equipment co. Rev b 5/11 d. Snow detector troubleshooting note: a newly-installed snow detector sensing head should operate 15-20 minutes to allow the internal heater to reach normal operating temperature. 1. No heat on the sensing head a. Check for voltage between t...

Page 35

P/n r9340-0104 35 © 2010 railway equipment co. Rev b 5/11 ix. Specifications: 480v single phase voltage: 480vac, 1ph 60 hz, 150 amp motor: 2 hp, 3450rpm, tefc 39 amp starting current 6 amp running current airflow: 2000 cfm kw output: 50 – 60 kw indication contacts: 30vdc 1a or 125vac 300ma specifica...

Page 36

P/n r9340-0104 36 © 2010 railway equipment co. Rev b 5/11 x. Drawings ehab 480v 60kw/3ph 934n4603 ehab main unit 9348-1360 tie duct assembly 136lb e-clip 9278-4805 tie duct assembly 115lb e-clip 9278-4605 point / track assembly rh 9508-4000 point / track assembly lh 9508-4001 nozzle track duct assem...

Page 60

Menu select main menu l1 l2 l3 volts 460 450 453 displays line volts for each phase l1 l2 l3 amps 60 50 53 displays line amps for each phase outside temp 22 f run timer 45 min displays outside temp and current mode of operation. All faults and other messages will be displayed menu select fault histo...

Page 61

P/n r9340-0104 37 © 2010 railway equipment co. Rev b 5/11 xi. Limited warranty railway equipment co., inc. (“railway”) warrants all of its products to be free from defects in material and workmanship when used under specified operating conditions and within specified limits. Railway’s warranty shall...

Page 62

P/n r9340-0104 38 © 2010 railway equipment co. Rev b 5/11 (intentionally left blank).