- DL manuals

- Rain Bird

- Weather Station

- WS-PRO

- Installation, Maintenance And Troubleshooting Manual

Rain Bird WS-PRO Installation, Maintenance And Troubleshooting Manual

Summary of WS-PRO

Page 1

Ws-pro weather station installation, maintenance and troubleshooting manual november 2004 gt27145d.

Page 3: Ws-Pro Weather Station

Page i ws-pro weather station table of contents description page 1.0 general . . . . . . . . 1 2.0 tools & supplies . . . . . . . 2 tools required . . . . . . 2 supplies required . . . . . . 2 3.0 weather station site selection . . . . . 3 temperature/relative humidity . . . . 4 solar radiation . . ...

Page 4

Page ii table of contents - cont’d. Description page installation of lightning rod . . . . 19 power supply rechargeable battery . . . . 19 ac external power wiring . . . . . 21 power supply option solar panel . . . . 22 8.0 installation of instrumentation . . . . . 24 general . . . . . . . 24 suppli...

Page 5

Page iii table of contents - cont’d. Description page 1 week . . . . . . 40 1 month . . . . . . 41 6 months . . . . . . 41 1 year . . . . . . . 41 2 years . . . . . . 41 3 years . . . . . . 41 4-5 years . . . . . . 41 general maintenance . . . . . 41 sensor maintenance . . . . . . 42 rain gage . . ....

Page 6

Page iv table of contents - cont’d. Description page no response from datalogger through sc32a or modem peripheral. . . . . 50 at the datalogger . . . 50 at the computer . . . 50 -99999 displayed in an input location . . 51 unreasonable results displayed in an input location . . . . . 51 6999 or 999...

Page 7: Appendix

Page v appendix description page upgrading the model jr weather station to a model pro weather station . . . . 59 typical 3-rod grounding grid . . . . . 59 ground resistance . . . . . . 59 bentonite contact . . . . . . 60 rocky conditions . . . . . . 60 rock layer . . . . . . . 60 improving earth gr...

Page 8: Table Of Figures

Page vi table of figures figure # description page #1 effect of structure on wind flow . . . 4 #2 magnetic declination for the contiguous united states . . . . . . 6 #3 declination angles . . . . . 8 #4 concrete base detail . . . . . 11 #5 anchor bolt/template detail. . . 11 #6 external wiring detai...

Page 9

Page vii table of figures cont’d. Figure # description page #20 desiccant pack installation . . . . 34 #21 installation at central computer for direct connected weather station . . . . 37 #22 installation at central computer for telephone connected weather station . . 39 #23 using the ml 10-kd keybo...

Page 10

Page viii.

Page 11: Ws-Pro Weather Station

Page 1 ws-pro weather station 1.0 general: the rain bird “model pro” weather station, when used in conjunction with the rain bird maxi 5, maxi “nimbus” or maxi “cirrus” central control system, provides the irrigation manager with a powerful tool to aid in the growing of lush, healthy, green turfgras...

Page 12

Page 2 2.0 tools & supplies: (installer supplied) the installer needs access to the following tools and supplies for installation of the weather station. Tools req’d. Shovel rake wire strippers screw driver, regular blade flat metal file screw driver, thin regular blade wheelbarrow screw driver, phi...

Page 13

Page 3 weather station site selection: site selection for the weather station is one of the most crucial steps in a successful installation and an efficiently operating irrigation system. The site selection will greatly impact the accuracy of the meteorological data collected by the station. The sit...

Page 14

Page 4 (a) temperature and relative humidity: sensors should be located over an open level turf area at least 30 feet in diameter. The surface should be the typical turfgrass of the area in interest. Sensors should be located a distance away of at least four (4) times the height of any nearby obstru...

Page 15

Page 5 (c ) precipitation a rain gage should be located over level ground that is covered with short grass or gravel. In open areas, the distance to obstructions should be two to four times the height of the obstruction. The height of the opening should be as low as possible, but should be high enou...

Page 16

Page 6 figure 2 - magnetic declination for the contiguous united state.

Page 17

Page 7 prompts from geomag geomag is accessed by phone with a pc and telephone modem and a communications program such as pro comm or windows 95 hyperterminal. Geomag prompts the caller for site latitude, longitude and elevation, which it uses to determine the magnetic declination and annual change....

Page 18

Page 8 example of report generated by geomag: model: uscon90 latitude: 42/2 n date: 7/27/93 longitude: 111/51/2w elevation: 4454.0 ft declination is: deg min 15 59.6 annual change: deg min 0 -6.1 exiting: press “cntrl-z” to exit geomag when the main menu reappears either select another option or typ...

Page 19

Page 9 4.0 weather station concrete base: supplied components (3) ½” x 12” long “l” anchor bolts (9) ½” nuts (3) flat steel washers (1) stainless steel template (1) 1 ½” dia. Long sweep elbow installer supplied (1) 2” x 4” x 10’-0” piece of forming lumber (4) 16p double headed nails 10’-0 “ length o...

Page 20

Page 10 6.0 insert the other end of the long sweep elbow into the center hole in the stainless steel template. Tape the end of the elbow with duct tape. 7.0 take the three ½” x 12” long “l” anchor bolts and install two (2) hex huts on to each bolt. Insert one in each of the holes in the template and...

Page 21

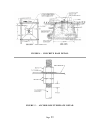

Page 11 figure 4 - concrete base detail figure 5 - anchor bolt/template detail.

Page 22

Page 12 5.0 external wiring to weather station: ( refer to figs. 6 & 7) wiring valve access box at the base of the weather station and as near to the base as feasibly possible, dig a hole large enough to install a standard 18” x 24” rectangular valve box and cover. The valve box shall accommodate al...

Page 23

Page 13 the weather station, and marked “p/n 9922”. This cable shall be routed through the 1 ½” dia. Long sweep elbow to the base of the weather station. All wire connections and splices in the power wiring shall be made using 3-m dby direct burial connectors. Do not apply power to transformer at th...

Page 24

Page 14 figure 6 - external wiring detail at the pro - sh weather station.

Page 25

Page 15 weather station communication wiring telephone connected - using telephone company lines: (model pro-ph - only) the telephone company needs to run a direct burial telephone cable to the weather station and terminate it near the base of the weather station. This needs to be a modem quality ty...

Page 26

Page 16 remove the three (3) “top” nuts and flat washers from the anchor bolts at the weather station template. Next remove the metal template - slipping it up over the cables that are extending from the 1 ½’ long sweep elbow. Be careful not to damage the cables or the connectors on the cables. Take...

Page 27

Page 17 figure 7 - external wiring detail at the pro - ph weather station.

Page 28

Page 18 7.0 instrumentation enclosure installation: general: the model pro weather station datalogger, power supply, sensor connection panel, communications devices and data retrieval peripherals are mounted in the et enclosure with the sensors themselves mounted on a cross- arm, which mounts to the...

Page 29

Page 19 installation of lightning rod refer to figure 8 above: carefully mount the lightning rod bracket, furnished with the weather station, to the top of the weather station tower. Locate it above the enclosure top bracket and near the top of the tower. Clearance between the clamp and the enclosur...

Page 30

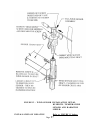

Page 20 figure 9 - 16vac connection and recharageable battery installation loosen the four (4) screws located on the back panel of the enclosure. Slip the end of the battery bracket, that has the two (2) keyhole slots in it over the upper two (2) screws. Line up the battery bracket slotted holes, in...

Page 31

Page 21 ac external power wiring refer to figure 8 & 9 above: the 16vac power wiring, that you have fed up through the weather station tower, shall be routed down the back side of the enclosure and into the enclosure through the heyco fitting, marked “power”. Unscrew the cap of the heyco fitting (on...

Page 32

Page 22 option solar panel refer to figure 10 below: model numbers shall be as; pro-sh-sp or pro-ph-sp. (sp designating the solar panel option). An option is for use of a solar panel, for the power supply, rather than the standard 120vac/16vac transformer. Mount the solar panel to the weather statio...

Page 33

Page 23 figure 10 - solar panel installation detail.

Page 34

Page 24 8.0 installation of instrumentation general: the model pro weather station comes with the some of the sensing instruments, and sensor wiring to datalogger completely assembled as a unit on a cross-arm. The solar radiation pyranometer - along with the leveling device are mounted on a bracket,...

Page 35

Page 25 figure 11 - cross-arm mounting installation of 034a wind sensor:.

Page 36

Page 26 refer to figure 12 below: with the sensor cross-arm securely installed to the enclosure you are ready to install the 034a wind sensor instrument. The wind vane is oriented after the datalogger has been programmed and the location of true north has been determined. Orientation is most easily ...

Page 37

Page 27 figure 12 - wind sensor installation detail installation of relative humidity / temperature sensor and radiation shield: refer to figure 13 below:.

Page 38

Page 28 on the bottom of the cross-arm, on the end where the wind sensor has been installed, remove the two screws for the relative humidity/temperature sensor radiation shield. Un-tape the rh/temperature sensor from the bottom of the cross-arm. Remove the “yellow” protective plastic cap from the en...

Page 39

Page 29 the solar radiation pyranometer, (with the leveling device) is mounted, at the factory, on a mounting bracket at the opposite end of the cross-arm near the tipping rain bucket gage. By using the three (3) leveling screws - level the pyranometer. After leveling - remove the “red” protective c...

Page 40

Page 30 enclosure and plugged into the connectors on the back panel of the enclosure as follows: solar radiation #10105 cable - connect to #3 connector [labeled “solar radiation”] rain #10094 cable - connect to #5 connector [labeled “rain (precip)”] temp/rh #10090 cable - connect to #1 connector [la...

Page 41

Page 31 configure sensor switch settings: refer to figure 16 below: the sensor switches are located on the et enclosure panel just below the modem and to the right of the the “heat sink” located to the right of the battery connectors. These switches or pots need to be set as indicated in figure 16 b...

Page 42

Page 32 thread the velcro mounting strap through the two outer slots of the lower set of slots in the modem mounting bracket. Thread from the top down on the far left slot first. The side of the strap with velcro should be facing “down” toward the datalogger housing. Then carry the strap across the ...

Page 43

Page 33 figure 18 - sh modem installation in et enclosure telephone modem installation refer to figure 19 below: (pro-ph) the telephone modem, at the weather station, is normally installed at the factory in the enclosure. The telephone modems enable communication between the datalogger and a hayes c...

Page 44

Page 34 central computer over a dedicated telephone line. Phone line surge protection is built into the enclosure. Installation for installation of the phone modem inside the enclosure, the following components are provided in the modem kit: com200 or com 300 modem 12 inch rj-11 patch cord modem mou...

Page 45

Page 35 figure 19 - telephone modem installation in et enclosure 9.0 sealing & desiccating the enclosure: the enclosure is supplied with a desiccant pack. The desiccant maintains a low humidity in the enclosure to minimize the chance of condensation on the instrumentation desiccant should be changed...

Page 46

Page 36 10.0 installation at central computer model pro - sh ~ direct connected: refer to figure 22 below: supplied components (1) smr-5a rad modem (1) 5 foot 4-wire patch cord (1) 25 foot #10 awg ground wire (1) surge protection box installation attach the 5 foot 4-wire patch cord to the srm-5a rad...

Page 47

Page 37 the copper drain wire shall also be left disconnected. Route the belden cable, out of the building, under ground and out to the valve box. Taking the green and black twisted pair of wires, connect the green (xmt+) wire to the red wire, on the end marked “equip”, to one of the msp-1 pipe surg...

Page 48

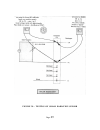

Page 38 figure 21 - installation at central computer for direct connected weather station.

Page 49

Page 39 model pro - ph phone connected: refer to figure 22 below: supplied components (1) telephone patch cable (2) 25 foot #10 gauge ground wire (1) surge arrestor box installation furnish and install a hayes compatible - 9600 baud modem. Using the ribbon cable that comes with the modem connect one...

Page 50

Page 40 figure 22 - installation at central computer for telephone connected weather station.

Page 51

Page 41 11.0 maintenance & troubleshooting general maintenance: proper maintenance of weather station components is essential to obtain accurate data. Equipment must be in good operating condition, which requires a program of regular inspection and maintenance. Routine and simple maintenance can be ...

Page 52

Page 42 1 month - • check the temperature/relative humidity sensor for contamination. 6 months - • clean the temperature/relative humidity sensor. • check battery by disconnecting the ac power and allow it to stabilize for at least 2 hours. Then check the voltage. Reconnect battery to ac power. 1 ye...

Page 53

Page 43 sensor maintenance rain gauge inspect and clean every two to three months - removing leaves, debris, etc. In extreme environmental conditions it may be necessary to do this on a monthly basis. • check that the tipping mechanism moves freely and that it registers 0.01 inches per tip. • check ...

Page 54

Page 44 solar sensor • inspect and clean the solar sensor (pyranometer) every two (2) to three (3)months. It is best cleaned with a blast of clean, dry air or with a soft bristle, camel hair brush. Be careful not to scratch the surface of the sensor. Do not use windex, soap or any other cleaning age...

Page 55

Page 45 time for watering (spring and fall in the desert areas). • clean the screen, on the tip of the rh chip enclosure, every six (6) months more often, if required. If the screen gets dirty quickly, this will reflect how often the chip will need to be replaced. Temperature sensor • inspect and cl...

Page 56

Page 46 the top of the enclosure and be sure the cover is properly engaging in the tabs at the top of the enclosure. Gently close the cover and secure it with the latch at the bottom. Be sure the latch hasp is securely latched, as keeping out moisture, is dependent upon a tight seal between the encl...

Page 57

Page 47 wind speed sensor refer to schematic wiring diagram - located in the appendix - figure 29 • measure the resistance from p1 to g (pins 3 to 5) of the wind speed sensor. Slowly turn the wind speed cup. The resistance should vary from infinite to less than 1 ohm as the reed switch closes in the...

Page 58

Page 48 continuous low voltage going through this reed switch, except as it “tips” at which time the +5 volts dc is shorted, and thus there is a possibility of corrosion build up on the switch over time. • the reed switch is easily replaced and the parts are available from your local rain bird distr...

Page 59

Page 49 troubleshooting: the following information is for trouble- shooting the weather station only. Isolating the problem the recommended approach to trouble- shooting the weather station is to divide the system into three (3) sections, the weather station itself, the commun- ication path or netwo...

Page 60

Page 50 logger in a low energy mode to conserve battery charge. Datalogger location table location reading normal range 1 = battery voltage ~ 12.9 to 14.2 volts 2 = air temp. C ~ close to air temp 3 = relative humidity ~ 0 to 100% 4 = wind run ~ total wind 5 = solar radation ~ 0 to 1.2 kw m-2 6 = ra...

Page 61

Page 51 troubleshooting problems no display on the ml-10-kd keyboard. (if there is display but no response to input on the keyboard - continue with the next diagnostic problem below.) if you see no display on the keyboard then there is no power output from the datalogger of the weather station. Pins...

Page 62

Page 52 at the computer: • make sure the station file is configured correctly. • check the cable(s) between the serial port and the modem. If cables are not those furnished with the weather station, then check for the following configuration using an ohm meter: 25-pin serial port: computer endmodem ...

Page 63

Page 53 using a laptop computer when a laptop computer is being used to check the weather station it is necessary to use a serial cable between the computer and the weather station, as configured in figure 24 shown below. Caution ! Before “plugging” the serial cable and computer into the serial i/o ...

Page 64

Page 54 checking the communications wire path: before initially connecting a direct connect or phone line weather station, or when troubleshooting the weather station and the communication wiring is suspect, check the communication wires for their integrity. Loop resistance connect the pair of wires...

Page 65

Page 55 type, on the screen then the short haul modem has a problem or the com port and needs to be replaced. Figure 25 - test of short haul modem second: after having determined, with the test above that the rad modem at the computer is “good” - you can then check to see if the communication path, ...

Page 66

Page 56 note ! Remember that you have a “spare” pair of communication wires in the belden #9883 cable. Using this spare pair substitute it for one of the other pairs and test again. If it is not this pair that are “bad” then substitute the “spare” pair for the other pair and test again. In this way ...

Page 67

Page 57 caution ! Connect a volt/ohm meter to the phone line only in extreme cases. It is recommended to use fcc approved equipment only - while measuring current on a telephone line. Use no msp-1, pipe surge arrestor on the telephone communication wires. If an msp-1 pipe surge arrestor is used in t...

Page 68

Page 58 • with the modem connected to the computer, jumper the output terminals of the rad modem as shown in figure 25. • with the rain bird weather software, go to the main menu and set the “capital lock” on the keyboard of the computer. • be sure to configure a direct connect weather station. • pr...

Page 69

Page 59 testing the phone modem if a hayes model 1200 or 2400 smart modem is being used to communicate with the weather station - be sure the switch settings are as follows: sw # setting function 1 down ignores dtr 2 up english word result codes sw # setting function 3 down result codes sent to comp...

Page 70: Appendix

Page 60 appendix typical 3-rod grounding grid: grounding grids are required at the central equipment location, for the weather station (grounding grid for the central equipment may also be used for the weather station if accessible) and at the weather station itself. A typical 3-rod grounding grid s...

Page 71

Page 61 ground rather than go to the electronic components. From this you can see that it is also important to maintain a “good ground” at all times. Bentonite contact: in using grounding rods we are depending upon the “contact” of the surface of the rod to the soil. The greater the contact the bett...

Page 72

Page 62 valve box cover over the end of the pipe and cover it with soil to finish grade. Msp-1 pipe surge arrestors: each of the pairs of wires in the communication path, between the central computer and the weather station, shall be wired through an msp- 1 pipe surge arrestor, at both the computer ...

Page 73

Page 63 figure 28 - typical 3-rod grounding grid detail.

Page 74

Page 64 figure 29 - testing of wind sensor.

Page 75

Page 65 figure 30 - testing of solar radiation sensor.

Page 76

Page 66 figure 31 - testing of rain gage.

Page 77

Page 67 figure 32 - testing of temperature/relative humidity sensor.

Page 78

Page 68 figure 33 - testing of air temperature probe.