Installation & operation manual rais gabo direct vent gas stove installer: leave this manual with the appliance. Consumer: retain this manual for future reference. This appliance may be installed in an aftermar- ket, permanently located manufactured home (usa only) or in a mobile home, where not pro...

2 avertissement : assurez-vous de bien suivre les instructions données dans cette notice pour réduire au minimum le risque d’incindie ou d’explosion ou pour éviter tout dommage matériel, toute blessure ou la mort. - ne pas entreposer ni utilizer d’essence ni d’autres vapeurs ou liquides inflammables...

3 important safety information 4 specifications 5 installation 6 massachusetts requirements 7 venting 8 electrical connections & wiring diagram 13 assembly 14 conversion to rear vent 17 gas connection 18 primary air adjuster 18 air inlet and exhaust outlet restrictors 19 fine-tuning 20 lighting and ...

4 important safety information the installation must conform with local codes or, in the absence of local codes, with the national fuel gas code, ansi z223.1 or the canadian installation code, can/cga b149. A manufactured home (usa only) or mobile home oem installation must conform with the manufact...

5 specifications input natural gas propane (lp) input rating-btu/hr 31,000 31,000 min. Input-btu/hr 21,000 22,800 orifice-dms 7/64” #52 input (rear vent, directly though wall to horizontal termination) input rating-btu/hr 25,000 28,000 min. Input-btu/hr 18,000 22,000 orifice-dms #39 #53 gas supply m...

6 installation minimum clearances to combustible construction stove to left side wall 6” (150mm) stove to corner wall 2” (51mm) stove to right side wall 6” (150mm) stove to ceiling 35” (890mm) stove to rear wall 2” (51mm) stove to 12” deep mantel 12” (305mm) max. Alcove depth 24” (610mm) stove to 1½...

7 installation the gas stove is shipped with a flexible connector that has a 1/2” npt female connection. The gas supply piping should have a separate gas shutoff valve and a 1/8” npt plugged tapping upstream of the valve. The stove and its main control valve must be disconnected from the gas supply ...

8 venting the gabo gas stove has been tested and listed for installation with 4” x 6 5/8” simpson duravent gs ® , amerivent direct ® and selkirk dt ® direct venting components. For specific installation requirements, fol- low the installation instructions included by the venting manufacturer with th...

9 venting example 1 fuel = propane (lp) vertical rise = 22 feet horizontal run = 3 feet elbows = 3 equivalent horizontal run = (3 + 4(elbow 2) + 4(elbow 3)) = 11 feet air restrictor setting = 3 ¾ exhaust baffle setting = f + example 2 fuel = natural gas vertical rise = 10 feet horizontal run = 5 fee...

10 venting vertic a l rise in feet horizontal run in feet natural gas venting venting not allowed 4 ½ - f ⅛ 4 - f ⅛ 3 ¾ - f ⅛ 3 ¾ - f ⅛ 3 ¾ - f + 4 - f + 3 ½ - f + 3 - f + 3 ½ - f + 3 ½ - f + 3 ½ - f 3 ½ - f 3 ½ - f 3 - f 3 - f 2 ½ - f 3 ½ - e ⅞ 3 - e ⅞ 3 ½ - e ¾ 2 ½ - e ⅞ venting not allowed 2 ½ - ...

11 venting vertic a l rise in feet horizontal run in feet propane (lp) gas venting venting not allowed venting not allowed 4 - f ⅛ 3 ¾ - f ⅛ 3 ½ - f ⅛ 3 ¾ - f + 3 ½ - f + 3 ¼ - f + 3 ¾ - f 3 ½ - f 3 ¼ - f 3 ½ - f 3 ¾ - f 3 ¾ - e ⅞ 3 ½ - e ⅞ 3 ½ - f 3½ - f 3 - e ⅞ 3 ½ - e ¾ 3 - e ¾ 3 ½ - e ⅞ 3 - e ⅞ ...

12 venting please note: if your specific venting configuration falls in a box in the venting charts (on pages 10 & 11) that is above the dotted line ( ), you must use one of the approved direct vent venting systems that utilizes a stainless steel inner liner. This requirement is part of the ansi sta...

13 venting vent terminal clearances (refer to illustration on page 12) venting terminals shall not be recessed into a wall or siding. Electrical connections the gabo gas stove may be connected to an optional mil- livolt thermostat or remote controller. Connect the two wires from the optional thermos...

14 assembly unpacking and placing the gabo by now, you will have removed the shipping carton from the base pallet. The gabo is shipped in a spe- cially designed shipping carton cut the strapping that secures the stove to the pallet and remove the wooden cribbing from the top of the stove. Remove the...

15 place the right cross log next. Use the recessed area at the front right corner of the burner top that corresponds to the shape of the base of the cross log. Place the charred end of the log in the recess and guide the alignment pin hole in the underside of the log onto the rear alignment pin in ...

16 assembly place the left cross log next. Use the raised platform at the left rear corner of the burner top to support the end of the cross log. The split charred end of the log faces toward the front. Place the pin socket over the front alignment pin hole in the arch log. You may have to wiggle th...

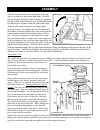

17 assembly after the logs and embers have been placed, the next step is to replace the glass panel and frame. Carefully pick up the glass and glass frame assembly by grasping the sides of the frame and using your thumbs and fingers to hold the glass in place within the gasket and frame. With the gl...

18 assembly install and tighten the four screws. Finally, install the vent starter section in the rear vent position. Again, make sure that the inner and outer gaskets are in their proper positions and in- stall and tighten the four screws. Replace the stove back plate by aligning the rear vent cut-...

19 air inlet and exhaust outlet restrictors the gabo is equipped with externally adjustable restrictors for both the inlet air and the exhaust outlet. This makes it possible to fine tune the direct vent system for the specific conditions of your installation. The recommended settings are keyed to th...

20 fine-tuning the recommended settings found in the vent charts on pages 10 & 11 and the default primary air settings have been optimized based on extensive testing, however, additional adjustments may be required to accommodate specific in- stallation circumstances. For example, a north wall insta...

21 lighting and operation lighting the fire for your safety read before lighting a. This appliance has a pilot which must be lighted by hand. When lighting the pilot, follow these instructions exactly. B. Before lighting smell all around the appliance area for gas. Be sure to smell next to the floor...

22 lighting and operation pilot and main burner operation follow the lighting instructions on page 21. When the pilot is lit and operating properly, it should look like the adjacent illus- tration. One flame will be directed at the pilot thermocouple, a second flame is directed at the pilot thermopi...

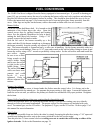

23 fuel conversion the gabo gas stove is shipped from the factory equipped to burn natural gas. If you will be burning pro- pane (lp) gas you must convert the stove by replacing the burner orifice and valve regulator and adjusting the pilot fuel selector plate and primary burner air setting. This sh...

24 pilot orifice (cont.) slide the orifice strip from the natural gas position to the lp gas position. Refer to the illustrations below. Once the pilot strip has been re-positioned, re-tighten the pilot burner barrel and the pilot conversion is complete note: the pilot burner should align with the t...

25 maintenance a qualified service agency should conduct an annual inspection and maintenance of your gabo including the overall installation and venting to keep it running safely. The following procedures should be per- formed only by a qualified service person. The gas supply should be turned off ...

26 maintenance inspecting the venting an inspection of both the inner and outer vent pipes and the vent terminal should be made as part of the an- nual service appointment. The venting must have no blockage and be in good repair. The vent manufac- turer’s instructions may provide specific details on...

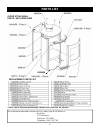

27 parts list *this is a quick response thermocouple. Replace it only with part no. 8303565 for replacement parts and customer service, contact your rais dealer or: rais inc. 133 elm street winooski, vt 05404 telephone: 888-724-7789 8303505 outer stove shell parts - exploded view replacement parts l...

28 manufactured by: rais a/s industrivej 20 dk-9900 frederikshavn denmark www.Rais.Com v05/06.07 installation record the installer should complete the form below that describes the details of the installation. Having this writ- ten record of installation information available will greatly expedite t...