- DL manuals

- Raleigh

- Bicycle

- COMFORT BIKE

- Assembly Manual

Raleigh COMFORT BIKE Assembly Manual

Summary of COMFORT BIKE

Page 2

2 service call toll free 800-222-5527 monday - friday 8:00 a.M. To 5:00 p.M. Pacific standard time.

Page 3

3 congratulations on the purchase of your new raleigh bicycle! With proper assembly and maintenance it will offer you years of enjoyment. We at raleigh are concerned with your safety and well being. We ask you to carefully read and follow the owner's manual and the assembly guide before riding your ...

Page 4

4 parts identification graphics .................................. 04-07 before riding ......................................................... 08-21 assembly instructions ............................................ 22-56 table of contents warning / caution take notice of this symbol throughout th...

Page 5

5 mountain bicycles: mountain bicycles are designed to give maximum comfort over a wide variety of road surfaces. The wider handlebars and convenient shift lever position make them very easy to control. Wider rims and tires give them a softer ride with more traction on rough surfaces. The frame and ...

Page 6

6 youth bicycles: this style of bicycle is a popular general purpose type most suited for young riders. They are valued because of their sturdy, simple construction and low maintenance. Parts identification graphics.

Page 7

7 road bicycles: road bicycles are designed to be ridden on roads or paved paths. The drop handlebars, convenient shift lever position and narrow tires make them very easy to control at speed. Seat/saddle seat post seat post clamp rear reflector seat stay rear brake wheel reflector cassette stem hea...

Page 8

8 full suspension bicycles: full suspension bicycles are designed to be ridden over fairly to moderately aggressive terrain. Their combined suspension and wider rims and tires allow them to easily roll over obstacles. Parts identification graphics.

Page 9

9 #### serial number location bike shown upside down serial number tools included: * 4mm, 5mm & 6mm hex wrenches * 25 torx wrench * 13mm and 15mm open end wrench other tools required: * adjustable wrench * phillips head screwdriver * a pair of pliers with cable cutting ability before riding: your ne...

Page 10

10 about this guide it is important for you to understand your new bicycle. By reading this guide before you go out on your first ride, you’ll know how to get better performance, comfort, and enjoyment from your new bicycle. It is also important that your first ride on your new bicycle is taken in a...

Page 11

11 correct frame size when selecting a new bicycle, the correct choice of frame size is a very important safety consideration. Most full sized bicycles come in a range of frame sizes. These sizes usually refer to the distance between the center of the bottom bracket and the top of the frame seat tub...

Page 12

12 rider inseam bike bike height length frame size frame size (feet/inches) (inches) (inches) (name) 4 ft. 11 in. – 5 ft. 3 in. 25 in. – 27 in. 13 - 15 in. Xs 5 ft. 3 in. – 5 ft. 7 in. 27 in. – 29 in. 15 - 17 in. Sm 5 ft. 7 in. – 5 ft. 11 in. 29 in. – 31 in. 17 - 19 in. Md 5 ft. 11 in. – 6 ft. 2 in....

Page 13

13 riding position saddle height in order to obtain the most comfortable riding position and offer the best possible pedaling efficiency, the seat height should be set correctly in relation to the rider’s leg length. The correct saddle height should not allow leg strain from over-extension, and the ...

Page 14

14 threadless headsets and clamp-on stems are not adjustable. The stem’s “minimum insertion” mark must not be visible above the top of the headset. If the stem is extended beyond this mark, the stem may break or damage the fork’s steerer tube, which could cause you to lose control and fall. Failure ...

Page 15

15 safety checklist before every ride, it is important to carry out the following safety checks: 1. Brakes • ensure front and rear brakes work properly. • ensure brake shoe pads are not over worn and are correctly positioned in relation to the rims. • ensure brake control cables are lubricated, corr...

Page 16

16 9. Accessories • ensure that all reflectors are properly fitted and not obscured. • ensure all other fittings on the bike are properly and securely fastened, and functioning. • ensure the rider is wearing a helmet. Helmets it is strongly advised that a properly fitting, ansi approved, bicycle saf...

Page 17

17 reflectors your bicycle is supplied with one front (white), one rear (red), two wheel (white), and pedal (orange) reflectors. (please note: sidewalk bikes, 12˝ and under, may not have reflectors.) these are an important safety and legal requirement, and should remain securely fitted and in good, ...

Page 18

18 front reflector mount with caliper brake assembly first remove the hex nut from the back of the fork and pull the brake from the fork. Insert a spacer, washer and the reflector bracket on to the caliper bolt. Insert the caliper bolt back into the fork and secure firmly with a concave spacer, wash...

Page 19

19 gears - how to operate derailleur gears most multi-speed bicycles today are equipped with what are known as derailleur gears. They operate using a system of levers and mechanisms to move the drive chain between different sized driving gears or cogs. The purpose of gears is to let you maintain a c...

Page 20

20 6 5 4 3 2 1 3 2 1 high middle low these combinations are not recommended for optimal performance. 6 5 4 3 2 1 2 high 1 low these combinations are not recommended for optimal performance. Operating principles the front derailleur is operated by the left shift lever and the rear derailleur by the r...

Page 21

21 hand grip shifters some bicycles will have a shifting mechanism which is built into the handlebar grips and does not make use of separate levers. To select a lower gear, twist the right shifter toward you to engage a larger rear cog. You can shift one gear at a time or through multiple gears by c...

Page 22

22 left hand lever right hand lever levered shifters many mountain style bicycles now use a shift lever arrangement mounted on the underside of the handlebars, which use two levers operated by the thumb and index finger. To select a lower gear push the larger (lower) right shifter with your thumb to...

Page 23

23 we recommend that you consult a professional bicycle mechanic if you have doubts or concerns as to your experience or ability to properly assembly, repair, or maintain your bicycle. Getting started open the carton from the top and remove the bicycle. Remove the straps and protective wrapping from...

Page 24

24 installed by factory compression bolt top cap stem clamp bolts spacer headset wedge bearing race bearing dust cover bearing retainer star nut (inside steerer tube) upper headset cup headtube lower headset cup bearing retainer bearing dust cover headset crown race fork s te er er t ube handlebar s...

Page 25

25 seat and seat post attach the seat to the seat post if required by loosening the nuts on the seat clamp. Insert the tapered end of the seat post into the seat clamp until it is at the top of the clamp. Partially tighten the nuts on the seat clamp until the seat is snug, but can still be turned. I...

Page 26

26 attachment of an incorrect pedal into a crank arm can strip pedal threads and cause irreparable damage. Before your first ride, please check to insure your pedals are attached correctly. Pedals look for the letters “r” for right, and “l” for left, stamped on each pedal spindle. Start each pedal s...

Page 27

27 closed position open position hub hub axle axle adjusting nut cam lever spring if you can fully close the cam lever without wrapping your fingers around the fork blade for leverage, and the lever does not leave a clear imprint in the palm of you hand, the tension is insufficient. Open the lever, ...

Page 28

28 brakes v-style brakes if not already assembled, take the brake noodle from the parts box and slide the cable through the larger opening. The cable housing will then seat into the end of the noodle. Slide the cable through the cable lead on the end of the left brake arm, this will cause the noodle...

Page 29

29 v-style brake 1. If fitted with v-style brakes, insert the brake body into the center spring hole in the frame mounting boss, and then secure the brake body to the frame with the link fixing bolt. 5 mm hex key washer link fixing bolt stopper pin spring hole 2. While holding the shoe against the r...

Page 30

30 5 mm hex key 1mm shoe fixing nut 5 mm hex key 1mm 1mm 3. While holding the shoe against the rim, tighten the shoe fixing nut. 4. Pass the inner cable through the inner cable lead. Set the cable with a clearance of 1mm between each brake pad and the rim, tighten the cable fixing bolt. 5. Adjust th...

Page 31

31 do not ride the bicycle until the brakes are functioning properly. To test, apply the brakes while trying to push the bike forward to make sure they will stop the bicycle. Never ride a bicycle that is not functioning properly. Press each brake lever to make sure that there is no binding and that ...

Page 32

32 brake disc gets hot! Severe injury could result from contact with the hot disc! Mind your legs, as well as your hands. Disc brakes if fitted with a front disc brake, the components should already be attached. However, please check all connections before attempting to ride the bicycle. Secure tigh...

Page 33

33 fork leg brake cable housing rotating rod cable boot with spring inside cable anchor bolt caliper body actuating arm caliper mounting bolts with spacers cam lever fork drop out disc disc mounting bolts hub centering bolt centering bolt (inside) disc brakes require a break in period! Ride and use ...

Page 34

34 ensure all bolts are secured tightly and the chain does not fall off in either direction. Derailleur although the front and rear derailleurs are initially adjusted at the factory, you will need to inspect and readjust both before riding the bicycle. Rear derailleur begin by shifting the rear shif...

Page 35

35 low adjusting screw cable anchor bolt outer chainguide inner chainguard high adjusting screw chainguide clearance of 1-3mm front derailleur shift both shifters to the smallest number indicated and place the chain on the corresponding cog and chainwheel. Disconnect the front derailleur cable from ...

Page 36

36 there must be enough tension on the spring to hold the spring plate in place. Failure to do this may cause the mechanism to fail. Failure to maintain, check and properly adjust the suspension system may result in suspension malfunction, which can cause you to lose control and fall. Changing suspe...

Page 37

37 accessories if your bike is supplied with a water bottle and cage, attach the cage to the bicycle using the hex bolts provided. Some 20˝ and 24˝ model bicycles come with a rear derailleur guard to protect the rear derailleur from damage. To install, remove the rear wheel axle nut on the drive sid...

Page 38

38 figure 1 figure 2 fenders front fender the front fender is mounted at the fork crown. There are two ways in which to mount your front fender. The first is the caliper brake mounting system (see figure 1), and the second is the 10mm nut and bolt system (see figure 2). Identify the mounting system ...

Page 39

39 fenders rear fender the rear fender is mounted at the seatstay brace. There are two ways in which to mount your rear fender. The first is the screw mounting system (see figure 3), and the second is the 10mm bolt and screw system (see figure 4). Identify the mounting system used on your bicycle an...

Page 40

40 final check • after all adjustments have been made, shift through every gear several times at varying speeds. This will ensure all your adjustments are correct and will allow you to pinpoint any trouble areas. If you encounter any problems, refer to the appropriate section and make any necessary ...

Page 41

41 single-speed and bmx bicycles we recommend that you consult a professional bicycle mechanic if you have doubts or concerns as to your experience or ability to properly assembly, repair, or maintain your bicycle. The handlebar must be inserted so that the minimum insertion mark cannot be seen. War...

Page 42

42 seat and seat post attach the seat to the seat post if required by loosening the nuts on the seat clamp. Insert the tapered end of the seat post into the seat clamp until it is at the top of the clamp. Partially tighten the nuts on the seat clamp until the seat is snug, but can still be turned. I...

Page 43

43 attachment of an incorrect pedal into a crank arm can strip pedal threads and cause irreparable damage. Before your first ride, please check to insure your pedals are attached correctly. Dust cap pedals look for the letters “r” for right, and “l” for left, stamped on each pedal spindle. Start eac...

Page 44

44 it is very important to check the front wheel connection to the bicycle. Failure to properly tighten may cause the front wheel to dislodge. Front wheel 1. Make sure the brakes are loose enough to allow the wheel to pass through the brake pads easily. 2. Place wheel into fork drop outs. 3. Install...

Page 45

45 v-style brake 1. If fitted with v-style brakes, insert the brake body into the center spring hole in the frame mounting boss, and then secure the brake body to the frame with the link fixing bolt. 5 mm hex key washer link fixing bolt stopper pin spring hole 39 mm or more a 3 mm washer b 6 mm wash...

Page 46

46 5 mm hex key 1mm shoe fixing nut 5 mm hex key 1mm 1mm spring tension adjustment screw spring tension adjustment screw 1 mm 1 mm depress about 10 times 3. While holding the shoe against the rim, tighten the shoe fixing nut. 4. Pass the inner cable through the inner cable lead. Set the cable with a...

Page 47

47 u-brakes begin by adjusting the pads of the u-brakes using a 10mm wrench. Make sure the pad is hitting the rim and not the tire. Ideally the front of the pad should hit the rim approximately 1mm before the rear pad. Front u-brake slide the brake cable and housing through the housing barrel and th...

Page 48

48 rear u-brake option 1: next, tighten the cable carrier to the brake cable approximately 20mm from the brake arms when they are closed against the rim. Attach the straddle cable to the carrier. Hook cable end into the brake slot, pull excess straddle cable through the cable anchor and tighten the ...

Page 49

49 rotors some freestyle bmx bicycles come equipped with a detangler system that will allow the handlebar to spin 360-degrees without binding the cables. It is very important that this system is adjusted correctly. Installation should only be done by a qualified bicycle mechanic with the correct too...

Page 50

50 6. Check for bearing flop by placing the handlebars in the normal riding position, then quickly rotate the handlebars back and forth. Perform the following steps to eliminate bearing flop. Note: the bearing should never be allowed to rest on the lower plate or lower cable adjusting barrels. A) sc...

Page 51

51 accessories axle peg assembly instructions non-threaded first remove the axle nut from the wheel. There will be either a retaining washer or a step retaining washer included. Place this washer between the peg and the frame of the bicycle. Slide the peg onto the axle, followed by a flat washer and...

Page 52

52 training wheels there are two options when attaching the training wheels to the wheel brace. Determine which option is used on your bicycle and follow the given instructions for that option. Option 1 first attach the training wheels to the wheel brace. Position a washer on the shoulder bolt. Next...

Page 53

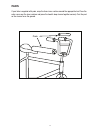

53 c-shape attaching training wheel brace to bicycle there are two different braces used to attach the training wheels to the bicycle: the c-shape brace and the flat brace. Determine which brace was included with your bicycle and follow the given instructions for that particular brace. C-shape brace...

Page 54

54 flat flat brace remove the axle nut and washer from the rear wheel axle. Place the flat wheel brace onto the axle. Next place the brace stabilizer washer onto the axle and align it so that the notch fits into the rear frame drop out. Replace the washer and axle nut. Tighten the axle nut securely,...

Page 55

55 training wheel stabilizer bracket your bicycle may include a stabilizer bracket to attach the training wheel to the bicycle. First remove the nut and washer from the rear wheel axle. Align the stabilizer bracket onto the brace. Align the brace and stabilizer bracket on the wheel axle. Replace the...

Page 56

56 pads if your bike is supplied with pads, wrap the foam inner cushion around the appropriate bar. Place the outer cover over the inner cushion and press the hook & loop closure together securely. Turn the pad so the closure faces the ground. Pads.

Page 57

57 before riding, ensure all nuts, bolts and fittings on the bicycle have been correctly tightened and all accessories are secured. Rear reflector (red) front reflector (white) chainguard final check install any additional parts that are supplied with your bike. Note: your bicycle may be equipped wi...

Page 58

Raleighusa.Com 6004 s 190th st, suite 101, kent, wa 98032.