- DL manuals

- Rally

- Tiller

- FN620K

- Owner's Manual

Rally FN620K Owner's Manual

•

Assembly

•

Operation

•

Maintenance

•

Service and Adjustments

•

Storage

•

Troubleshooting

•

Repair Parts

OWNER'S MANUAL

184873 11.27.02 TR

PRINTED IN U.S.A.

MODEL NO. FN620K

3.5 HP 17 Inch

Tiller

00137

For Parts and Service, contact our authorized distributor: call 1-800-849-1297

For Technical Assistance: call 1-800-829-5886

For Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

Summary of FN620K

Page 1

• assembly • operation • maintenance • service and adjustments • storage • troubleshooting • repair parts owner's manual 184873 11.27.02 tr printed in u.S.A. Model no. Fn620k 3.5 hp 17 inch tiller 00137 for parts and service, contact our authorized distributor: call 1-800-849-1297 for technical assi...

Page 2: Safety Rules

2 • never operate the tiller without proper guards, plates, or other safety protective devices in place. • keep children and pets away. • do not overload the machine capacity by attempting to till too deep at too fast a rate. • never operate the machine at high speeds on slippery surfaces. Look behi...

Page 3: Table of Contents

3 congratulations on your purchase of a new tiller. It has been designed, en gi neered and manu fac tured to give you the best pos sible de penda bil ity and per form ance. Should you experience any prob lems you can not easily remedy, please contact your nearest authorized service center. We have c...

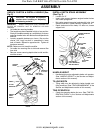

Page 4: Assembly

4 assembly operator’s position (see fig. 1) when right or left hand is mentioned in this manual, it means when you are in the operating position (standing behind tiller handles). Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes. T...

Page 5: Assembly

5 assembly tiller handles cable handle panel bolts fig. 2 han dle panel hex bolt 5/16-18x3/4" tiller handle hex bolt 5/16-18x1" flat washer lock wash er nut depth stake support bolt hex bolts, lock wash ers, and hex nuts depth stake support nut “a” engine brack et halves fig. 3 stake spring install ...

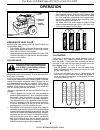

Page 6: Operation

6 know your tiller read this owner's manual and safety rules before operating your tiller. Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference. Recoil starter handle depth stake tine shield ch...

Page 7: Operation

7 operation the operation of any tiller can result in foreign objects thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields before starting your tiller and while tilling. We recommend a wide vision safety mask over spectacles or standard safety glasse...

Page 8: Operation

8 operation fig. 7 oil filler plug oil level to start engine (see fig. 8) caution: keep drive control bar in “disengaged” position when start- ing en gine. When starting engine for the fi rst time or if engine has run out of fuel, it will take extra pulls of the recoil starter to move fuel from the ...

Page 9: Operation

9 operation • you will fi nd tilling much easier if you leave a row un- tilled between passes. Then go back between tilled rows. (see fig. 9) there are two reasons for doing this. First, wide turns are much easier to negotiate than about-faces. Sec ond, the tiller won’t be pulling itself, and you, t...

Page 10: Maintenance

10 general recommendations the warranty on this tiller does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, operator must main tain tiller as instructed in this manual. Some adjustments will need to be made periodically to properly m...

Page 11: Maintenance

11 maintenance fig. 12 air cleaner (see fig. 13) service air cleaner cartridge every twenty-fi ve hours, more often if engine is used in very dusty conditions. • loosen air cleaner screws, one on each side of cover. • remove air cleaner cover. • carefully remove air cleaner cartridge. Be care ful. D...

Page 12: Maintenance

12 muffler do not operate tiller without muffl er. Do not tamper with exhaust system. Damaged muffl ers or spark arresters could create a fi re hazard. Inspect pe ri odi cally and re place if nec es sary. If your engine is equipped with a spark arrester screen assembly, re move every 50 hours for cl...

Page 13: Service and Adjustments

13 tiller to adjust handle height (see fig. 15) factory assembly has provided lowest handle height. Se lect handle height best suited for your tilling conditions. Handle height will be different when tiller digs into soil. • if a higher handle height is desired, loosen the four nuts securing handle ...

Page 14: Service and Adjustments

14 service and adjustments tine operation check (see fig. 21) be sure tines do not rotate when engine is running and tine control is in the “off” position. Warning: disconnect spark plug wire from spark plug to prevent starting while checking tine operation. Final check “off” position • with tine co...

Page 15: Service and Adjustments

15 service and adjustments v-belt idler pul ley trans mis sion pul ley belt guide engine pulley belt guide to replace v-belt (see fig. 23) replace v-belt if it has stretched considerably or if it has cracks or frayed edges. Belt guard must be removed to service belt. See “to re- move belt guard” in ...

Page 16: Storage

16 storage engine oil drain oil (with engine warm) and replace with clean oil. (see “engine” in the maintenance section of this man ual). Cylinder(s) • remove spark plug. • pour 1 ounce (29 ml) of oil through spark plug hole into cylinder. • pull starter handle slowly several times to distribute oil...

Page 17: Troubleshooting Points

17 will not start 1. Out of fuel. 1. Fill fuel tank. 2. Engine not “choked” properly. 2. See “to start engine” in the operation section. 3. Engine fl ooded. 3. Wait several minutes before attempting to start. 4. Dirty air cleaner. 4. Clean or replace air cleaner cartridge. 5. Water in fuel. 5. Drain...

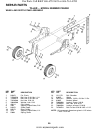

Page 18: Repair Parts

18 repair parts tiller - - model number fn620k handle assembly 1 137176x505 bracket, handle 2 72140512 bolt, carriage 5/16-18 unc x 1-1¦2 3 9266r grip, handle 4 151473 handle, l.H. 5 73680500 locknut, crown 5/16-18 6 19111116 washer 11/32 x 11/16 x 16 ga. 7 19121414 washer 3/8 x 7/8 x 14 ga. 8 74760...

Page 19: Repair Parts

19 repair parts tiller - - model number fn620k belt guard and pulley assembly key part no. No. Description 16 12000035 ring, klip 17 73350600 nut, hex, jam 3/8-16 18 161806 pulley, idler 19 175377 arm, idler 20 74760620 bolt, hex 3/8-16 x 1-1/4 21 106968x shaft, idler arm 25 73350500 nut, hex, jam 5...

Page 20: Repair Parts

20 repair parts tiller - - model number fn620k wheel and depth stake assembly 1 9194r pin, clevis 2 74760520 bolt, hex 5/16-18 x 1-1/4 3 74760512 bolt, hex 5/16-18 x 3/4 4 73220500 nut, hex 5/16-18 5 10040500 washer, lock 5/16 7 4921h clip, hairpin 8 318j support, depth stake, r.H. 9 9193r stake, de...

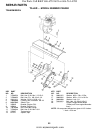

Page 21: Repair Parts

21 key part no. No. Description 1 165774 tine, outer, r.H. 2 4921h retainer, spring 3 165772 tine, inner, r.H. 4 165771 tine, inner, l.H. 5 165773 tine, outer, l.H. 6 9194r pin, clevis key part no. No. Description repair parts tiller - - model number fn620k tine assembly for parts call k&t 606-678-9...

Page 22: Repair Parts

22 repair parts tiller - - model number fn620k transmission key part no. No. Description 16 19091412 washer 9/32 x 7/8 x 12 ga. 17 19092016 washer 9/32 x 1-1/4 x 16 ga. 18 10040400 washer, lock 1/4 19 74610412 bolt, hex 1/4-28 x 3/4 gr. 5 20 - - - - - - - engine, briggs model 94202 (order parts from...

Page 23: Repair Parts

23 key part no. No. Description 1 132629 decal, logo 2 163989 decal, logo 4 127185x decal, description 5 110613x decal, tine control 6 110614x decal, hand placement 8 120076x decal, warning, rotating tines 9 171803 decal, briggs & stratton 10 171806 decal, 3.5 hp 11 162384 decal, warning 12 165327 d...

Page 24: Limited Warranty

00137 limited warranty the manufacturer warrants to the original consumer purchaser that this product as manufactured is free from de- fects in materials and work man ship. For a period of two (2) years from date of purchase by the original consumer purchaser, we will repair or replace, at our optio...